IEC 60350-2:2011

(Main)Household electric cooking appliances - Part 2: Hobs - Methods for measuring performance

Household electric cooking appliances - Part 2: Hobs - Methods for measuring performance

IEC 60350-2:2011 defines methods for measuring the performance of electric hobs for household use. Appliances covered by this standard may be built-in or for placing on a working surface or the floor. The hob can also be a part of a cooking range. This standard defines the main performance characteristics of these appliances which are of interest to the user and specifies methods for measuring these characteristics. This standard does not specify requirements for performance. This first edition of IEC 60350-2 is related to IEC 60350:1999 which shall be separated in two parts: one part for cooking ranges, ovens and steam ovens and the other part for hobs. This part 2 of IEC 60350 covers hobs, and IEC 60350-1 covers ovens.

Appareils de cuisson électrodomestiques - Partie 2: Tables de cuisson - Méthodes de mesure de l'aptitude à la fonction

la CEI 60350-2:2011 définit des méthodes de mesure de l'aptitude à la fonction des tables de cuisson électriques à usage domestique. Les appareils couverts par la présente norme peuvent être encastrés, ou prévus pour être placés sur un plan de travail ou posés sur le sol. La table de cuisson peut également faire partie d'une cuisinière. La présente norme a pour objet de définir les principales caractéristiques d'aptitude à la fonction de ces appareils, qui intéressent l'utilisateur, et de spécifier des méthodes pour la mesure de ces caractéristiques. La présente norme ne spécifie pas les exigences d'aptitude à la fonction. La première édition de la CEI 60350-2 est liée à la CEI 60350:1999, qui doit être séparée en deux parties: une partie consacrée aux cuisinières, aux fours et aux fours à vapeur, et l'autre partie aux tables de cuisson. La présente partie 2 de la CEI 60350 traite des tables de cuisson, et la CEI 60350-1 traite des fours.

General Information

- Status

- Published

- Publication Date

- 15-Dec-2011

- Technical Committee

- SC 59K - Performance of household and similar electrical cooking appliances

- Drafting Committee

- MT 1 - TC 59/SC 59K/MT 1

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 30-Aug-2017

- Completion Date

- 13-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 60350-2:2011 is an international standard published by the International Electrotechnical Commission (IEC) that specifies methods for measuring the performance of household electric hobs. This standard applies to built-in or freestanding electric hobs, including those integrated into cooking ranges. It focuses on defining key performance characteristics important to users and outlines standardized test methods for evaluating these parameters.

As part 2 of the IEC 60350 series, IEC 60350-2 complements IEC 60350-1, which covers ovens. Notably, this standard does not set performance requirements or safety guidelines; rather, it provides consistent ways to measure and compare performance metrics among different hob models. It excludes portable cooking appliances and concentrates on laboratory test procedures that manufacturers, testers, and regulatory bodies can implement for objective evaluations.

Key Topics

- Scope and appliance types: Includes household electric hobs on work surfaces, floors, built-in units, and cooking ranges. Excludes portable appliances covered by IEC 61817.

- Performance measurements: Defines principal characteristics to measure, such as:

- Dimensions and mass of the appliance and cooking zones

- Heating performance including time to heat water and temperature control accuracy

- Heat distribution uniformity using test recipes like pancake cooking tests

- Smallest detected diameter for induction hobs, indicating pan size compatibility

- Standby power consumption to assess energy efficiency

- Spillage capacity and ease of cleaning

- Test environment and instrumentation: Specifies general test conditions such as ambient room temperature, power supply specifications, instrumentation calibration, and appliance positioning for reproducibility.

- Measurement procedures: Detailed steps for conducting tests, including water heating tests with specific quantities and pots, temperature overshoot evaluations, heat distribution assessments, and power measurement protocols.

- Comparative testing: Many tests are intended for comparative purposes rather than absolute certification because of variability across laboratories, assisting consumers and manufacturers in assessing relative product performance.

Applications

IEC 60350-2:2011 is highly valuable for:

- Manufacturers designing household electric hobs who want to benchmark and optimize performance characteristics.

- Testing laboratories performing standardized evaluations of hob performance per internationally recognized methods.

- Regulatory bodies and certification organizations that wish to reference standardized measurement procedures to verify supplier claims.

- Retailers and consumers seeking comparative data on hob performance, efficiency, and usability.

- Product developers focused on innovation in cooking technology, especially induction hobs that require precise measurement of pan compatibility and heat distribution.

The standard serves as a foundation to increase transparency and reliability in how performance claims for household electric hobs are validated and communicated worldwide.

Related Standards

- IEC 60350-1: Household electric cooking appliances – Part 1: Ovens – Methods for measuring performance. Complements Part 2 by focusing on ovens instead of hobs.

- IEC 60335-2-6 and IEC 60335-2-9: Cover safety requirements for household electrical cooking appliances and ovens respectively, ensuring safe operation separate from performance metrics.

- IEC 61817: Standard for portable electric cooking appliances which are excluded from IEC 60350-2.

- IEC 62301:2005: Specifies measurement of standby power, referenced within IEC 60350-2 for evaluating energy consumption related to hobs in standby mode.

By following IEC 60350-2:2011, stakeholders across the industry can apply harmonized, precise methods to evaluate household electric hobs, leading to improved product quality, consumer confidence, and market transparency. The standard’s focus on practical performance measurement makes it an essential reference for the electric cooking appliance sector.

Frequently Asked Questions

IEC 60350-2:2011 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Household electric cooking appliances - Part 2: Hobs - Methods for measuring performance". This standard covers: IEC 60350-2:2011 defines methods for measuring the performance of electric hobs for household use. Appliances covered by this standard may be built-in or for placing on a working surface or the floor. The hob can also be a part of a cooking range. This standard defines the main performance characteristics of these appliances which are of interest to the user and specifies methods for measuring these characteristics. This standard does not specify requirements for performance. This first edition of IEC 60350-2 is related to IEC 60350:1999 which shall be separated in two parts: one part for cooking ranges, ovens and steam ovens and the other part for hobs. This part 2 of IEC 60350 covers hobs, and IEC 60350-1 covers ovens.

IEC 60350-2:2011 defines methods for measuring the performance of electric hobs for household use. Appliances covered by this standard may be built-in or for placing on a working surface or the floor. The hob can also be a part of a cooking range. This standard defines the main performance characteristics of these appliances which are of interest to the user and specifies methods for measuring these characteristics. This standard does not specify requirements for performance. This first edition of IEC 60350-2 is related to IEC 60350:1999 which shall be separated in two parts: one part for cooking ranges, ovens and steam ovens and the other part for hobs. This part 2 of IEC 60350 covers hobs, and IEC 60350-1 covers ovens.

IEC 60350-2:2011 is classified under the following ICS (International Classification for Standards) categories: 31.100 - Electronic tubes; 97.040.20 - Cooking ranges, working tables, ovens and similar appliances. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60350-2:2011 has the following relationships with other standards: It is inter standard links to IEC 60350:1999/AMD1:2005, IEC 60350:1999/AMD2:2008, IEC 60350:1999, IEC 60350-2:2017. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60350-2:2011 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60350-2 ®

Edition 1.0 2011-12

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Household electric cooking appliances –

Part 2: Hobs – Methods for measuring performance

Appareils de cuisson électrodomestiques –

Partie 2: Tables de cuisson – Méthodes de mesure de l'aptitude à la fonction

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 60350-2 ®

Edition 1.0 2011-12

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Household electric cooking appliances –

Part 2: Hobs – Methods for measuring performance

Appareils de cuisson électrodomestiques –

Partie 2: Tables de cuisson – Méthodes de mesure de l'aptitude à la fonction

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX S

ICS 97.040.20 ISBN 978-2-88912-843-3

– 2 – 60350-2 © IEC:2011

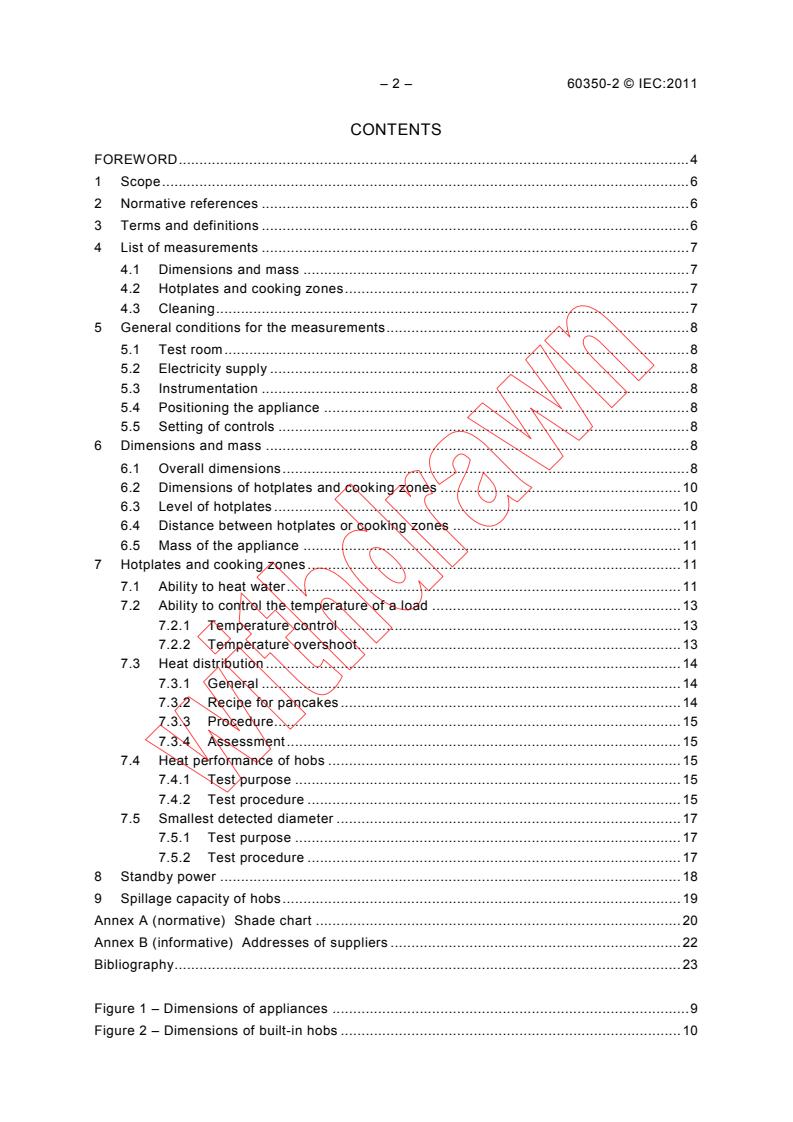

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 List of measurements . 7

4.1 Dimensions and mass . 7

4.2 Hotplates and cooking zones . 7

4.3 Cleaning . 7

5 General conditions for the measurements . 8

5.1 Test room . 8

5.2 Electricity supply . 8

5.3 Instrumentation . 8

5.4 Positioning the appliance . 8

5.5 Setting of controls . 8

6 Dimensions and mass . 8

6.1 Overall dimensions . 8

6.2 Dimensions of hotplates and cooking zones . 10

6.3 Level of hotplates . 10

6.4 Distance between hotplates or cooking zones . 11

6.5 Mass of the appliance . 11

7 Hotplates and cooking zones . 11

7.1 Ability to heat water . 11

7.2 Ability to control the temperature of a load . 13

7.2.1 Temperature control . 13

7.2.2 Temperature overshoot. 13

7.3 Heat distribution . 14

7.3.1 General . 14

7.3.2 Recipe for pancakes . 14

7.3.3 Procedure . 15

7.3.4 Assessment . 15

7.4 Heat performance of hobs . 15

7.4.1 Test purpose . 15

7.4.2 Test procedure . 15

7.5 Smallest detected diameter . 17

7.5.1 Test purpose . 17

7.5.2 Test procedure . 17

8 Standby power . 18

9 Spillage capacity of hobs . 19

Annex A (normative) Shade chart . 20

Annex B (informative) Addresses of suppliers . 22

Bibliography . 23

Figure 1 – Dimensions of appliances . 9

Figure 2 – Dimensions of built-in hobs . 10

60350-2 © IEC:2011 – 3 –

Figure 3 – Device for checking the level of hotplates . 11

Figure 4 – Saucepan . 12

Figure 5 – Frying pan . 14

Figure 6 – Disc to determine the smallest detected diameter . 18

Table 1 – Quantity of water in the saucepan . 13

Table 2 – Ingredients and cooking durations . 14

Table 3 – Quantities. 16

Table 4 – Frying times . 16

Table A.1 – Classification of shade numbers . 20

Table A.2 – Examples for the shade charts . 20

– 4 – 60350-2 © IEC:2011

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

HOUSEHOLD ELECTRIC COOKING APPLIANCES –

Part 2: Hobs – Methods for measuring performance

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60350-2 has been prepared by subcommittee 59K: Ovens and

microwave ovens, cooking ranges and similar appliances, of IEC technical committee 59:

Performance of household and similar electrical appliances.

This first edition of IEC 60350-2 is related to IEC 60350:1999 which shall be separated in two

parts: one part for cooking ranges, ovens and steam ovens and the other part for hobs. This

part 2 of IEC 60350 covers hobs, and IEC 60350-1 covers ovens.

This edition includes the following significant technical changes with respect to

IEC 60350:1999:

– A measurement procedure for measuring the smallest detected diameter for induction

hobs (see 7.5).

IEC 60350:1999 will be withdrawn after the publication of IEC 60350-1 and IEC 60350-2.

In this standard, terms in bold characters are defined in Clause 3.

60350-2 © IEC:2011 – 5 –

The text of this standard is based on the following documents:

FDIS Report on voting

59K/233/FDIS 59K/236/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all the parts in the IEC 60350 series, under the general title Household electric

cooking appliances, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – 60350-2 © IEC:2011

HOUSEHOLD ELECTRIC COOKING APPLIANCES –

Part 2: Hobs – Methods for measuring performance

1 Scope

This part of IEC 60350 defines methods for measuring the performance of electric hobs for

household use.

NOTE 1 Appliances covered by this standard may be built-in or for placing on a working surface or the floor. The

hob can also be a part of a cooking range.

NOTE 2 This standard does not apply to

– portable appliances for cooking, grilling and similar functions (IEC 61817).

This standard defines the main performance characteristics of these appliances which are of

interest to the user and specifies methods for measuring these characteristics.

NOTE 3 Some of the tests which are specified in this standard are not considered to be reproducible since the

results may vary between laboratories. They are therefore intended for comparative testing purposes only.

This standard does not specify requirements for performance.

NOTE 4 This standard does not deal with safety requirements (IEC 60335-2-6 and IEC 60335-2-9).

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 62301:2005 , Household electrical appliances – Measurement of standby power

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

cooking range

appliance having a hob and at least one oven. It may incorporate a grill

NOTE Methods for measuring performance of ovens are described in IEC 60350-1.

3.2

hob

appliance or part of an appliance which incorporates one or more cooking zones

NOTE A hob is also known as a cooktop.

3.3

cooking zone

part of the hob or area marked on the surface of a hob on which pans are placed for heating

___________

This document has been replaced by a new edition (2011), but for the purposes of this standard, the 2005 edition is cited.

60350-2 © IEC:2011 – 7 –

3.4

hotplate

part attached to the surface of a hob which forms a cooking zone

3.5

solid hotplate

hotplate having a closed surface which is usually constructed from cast iron with an

integrated heating element

3.6

tubular hotplate

hotplate having a surface which is formed by the configuration of a tubular sheathed heating

element in a substantially flat plane

3.7

glass ceramic hob

hob in which the heating elements are located beneath a glass ceramic surface

3.8

induction cooking zone

cooking zone on which the pan is heated by means of eddy currents

NOTE 1 The eddy currents are induced in the bottom of the pan by the electromagnetic field of a coil.

NOTE 2 The hob surface may be of glass ceramic.

4 List of measurements

4.1 Dimensions and mass

The following measurements are carried out:

– overall dimensions (see 6.1);

– dimensions of hotplates and cooking zones (see 6.2);

– level of hotplates (see 6.3);

– distance between the hotplates or cooking zones (see 6.4);

– mass of the appliance (see 6.5).

4.2 Hotplates and cooking zones

The following tests are carried out:

– ability to heat water (see 7.1);

– ability to control the temperature of a load (see 7.2);

– heat distribution (see 7.3);

– heat performance of hobs (see 7.4);

– smallest detected diameter for induction hobs (see 7.5).

4.3 Cleaning

– Spillage capacity of hobs (see Clause 9).

– 8 – 60350-2 © IEC:2011

5 General conditions for the measurements

5.1 Test room

The tests are carried out in a substantially draught-free room in which the ambient

temperature is maintained at 20 °C ± 5 °C.

The measurement of the ambient temperature shall not be influenced by the appliance itself

or by any other appliance.

5.2 Electricity supply

The appliance is supplied at rated voltage, ± 1 %.

If the appliance has a rated voltage range, the tests are carried out at the nominal voltage of

the country where the appliance is intended to be used.

NOTE In case of a fixed cable, the plug (or the end of the cable) is the reference point to maintain the voltage.

5.3 Instrumentation

The temperature measuring instrument including thermocouples shall have an accuracy of

0,5 K within the temperature range of 0 °C to 100 °C and an accuracy of 2 K within the

temperature range 100 °C to 300 °C.

The energy measuring meter shall have an accuracy of 1 %.

5.4 Positioning the appliance

Built-in appliances are installed in accordance with the instructions for installation. Other

appliances are placed with their back against a wall, unless otherwise specified in the

instructions.

Floor-standing appliances are positioned between kitchen cabinets. Table-top appliances are

positioned away from side walls.

5.5 Setting of controls

The control is set to give the temperature specified for the test. However, if the temperature

cannot be attained due to the construction of the control, the nearest setting related to the

specified temperature is chosen.

6 Dimensions and mass

6.1 Overall dimensions

The overall dimensions of the appliance are measured and stated in millimetres as follows:

– cooking ranges and other appliances placed on a surface are measured as shown in

Figure 1;

– built-in hobs are measured as shown in Figure 2.

60350-2 © IEC:2011 – 9 –

c

a

b

a

c

IEC 2754/11

Key

a

height from the supporting surface to the hob surface

NOTE If adjustable feet are provided, the height is measured with the feet in both extreme positions.

b overall width of the appliance

a maximum height from the supporting surface to the uppermost part of the appliance, with any lid in the open

position

c

depth of the appliance, ignoring any knobs, etc.

c maximum depth of the appliance, with any doors and drawers fully open

Figure 1 – Dimensions of appliances

– 10 – 60350-2 © IEC:2011

b

a

c

c

a

b

IEC 2755/11

Key

a depth of the hob

b width of the hob

c height of the hob on the outside of the kitchen furniture

c height of the hob on the inside of the kitchen furniture

a depth of the hob on the inside of the kitchen furniture

b width of the hob on the inside of the kitchen furniture

Figure 2 – Dimensions of built-in hobs

6.2 Dimensions of hotplates and cooking zones

The main dimensions of hotplates and cooking zones are determined as follows:

– for solid hotplates, the diameter of the surface intended to come into direct contact with

the bottom of saucepans is measured;

– for tubular hotplates, the diameter of the periphery excluding any lead-in section is

measured;

– for glass ceramic hobs, the diameters of the cooking zones are measured.

The dimensions are indicated in millimetres rounded to the nearest 5 mm.

If the hotplates or cooking zones are not circular the dimensions are determined as follows:

– for rectangular shapes, the lengths of the sides are measured;

– for elliptical and similar shapes, the major and minor dimensions are measured.

NOTE If the markings identifying cooking zones are not clear, this is stated.

6.3 Level of hotplates

Cooking ranges with adjustable feet and hobs are installed with the perimeter of the hob

surface horizontal.

A device consisting of a disc and an annular ring is placed centrally on the hotplate. A spirit

level is placed centrally on the ring, as shown in Figure 3.

60350-2 © IEC:2011 – 11 –

∅100

∅225

IEC 2756/11

Dimensions in millimetres

Figure 3 – Device for checking the level of hotplates

A mass of 3 kg is placed on each of the remaining hotplates.

The spirit level is rotated to the position where it shows the maximum inclination from the

horizontal. Its lower side is then lifted to the horizontal by inserting a feeler gauge between

the level and the ring.

The measurement is carried out on each hotplate.

The deviation from the horizontal is given by the thickness of the gauge, in millimetres, to two

decimal places. It is expressed as a percentage, rounded to the nearest 0,1 %.

NOTE The direct conversion from millimetres to percentage is possible due to the ring having a diameter of

100 mm.

6.4 Distance between hotplates or cooking zones

The shortest distance between the edges of adjacent hotplates or cooking zones is

measured and indicated in millimetres, rounded to the nearest millimetre. If the hob has more

than two hotplates or cooking zones, the distance between each pair is determined.

NOTE The result may be shown by means of a sketch.

6.5 Mass of the appliance

The mass of the appliance, including accessories, is determined and expressed in kilograms,

rounded to the nearest kilogram.

7 Hotplates and cooking zones

7.1 Ability to heat water

The purpose of this test is to assess the heat transfer from the cooking zone to water in a

pan.

– 12 – 60350-2 © IEC:2011

NOTE 1 This test is applicable for comparative testing only.

A steel saucepan which completely covers the cooking zone is used for the test, as specified

in Figure 4.

b

c

-0,5

∅a

IEC 2757/11

Dimensions in millimetres

Specification of the saucepan

Diameter of cooking zone Dimensions of the saucepan

mm

a b c

145 140 3

≤ 145

180 140

> 145 ≤ 180 ≥ 3 ≤ 5

220 140

> 180 ≤ 220 ≥ 3 ≤ 5

The saucepan is made of low carbon steel having a maximum carbon content of 0,08 %. It is

cylindrical without metallic handles or protrusions. The diameter of the flat area at the base of

the saucepan is to be at least the diameter of the cooking zone. The maximum concavity of

the base of the saucepan is to be not more than 0,006 a, where a is the diameter of the flat

area at the base of the saucepan. The base of the saucepan shall not be convex.

NOTE The lid is adapted to accommodate a stirrer.

Figure 4 – Saucepan

NOTE 2 In order to prevent distortion of the base, a pan with sidewalls glued to the base by silicon-rubber may be

used for heating water.

NOTE 3 Commercially available pans which have equivalent thermal and mechanical properties may be used.

The saucepan is filled with the quantity of potable water specified in Table 1. The water has a

temperature of 15 °C ± 1 °C. The saucepan covered with the lid is positioned centrally on the

cooking zone.

NOTE 4 For non-circular cooking zones, an appropriately shaped saucepan may be used.

60350-2 © IEC:2011 – 13 –

Table 1 – Quantity of water in the saucepan

Diameter of cooking zone Quantity of water

mm

≤ 145

1,5

> 145 and ≤ 180

> 180 and ≤ 220

The cooking zone is heated with the control set at maximum. During the test the water is

stirred continuously with the aid of a non-metallic stirrer. The time taken for the water

temperature to rise by 75 K and the corresponding energy consumption are measured. The

test is repeated with the pan turned through 90 °.

The average value of the two results is determined.

The time is stated in minutes and seconds. The energy consumption is expressed in watt-

hours.

7.2 Ability to control the temperature of a load

7.2.1 Temperature control

The purpose of this test is to check the function of a control.

NOTE 1 This test is applicable for comparative testing only.

NOTE 2 Controls may be automatic, step-by-step, energy-regulated or temperature-regulated.

A saucepan as shown in Figure 4 but without a lid is filled to a height of 30 mm with fresh

sunflower oil at room temperature and placed on the cooking zone.

NOTE 3 Sunflower oil is considered to be fresh if it has not been used more than three times.

The cooking zone is heated with the control set at the minimum marked position. The

temperature at the centre of the oil is recorded continuously by means of a thermocouple.

The oil is not stirred. The time taken for the oil to reach a steady temperature is measured.

The test is repeated with the control set at the maximum position and also at an intermediate

position.

NOTE 4 If a steady temperature is not reached within 30 min or when the oil temperature reaches 250 °C, the test

is interrupted and the result noted.

The heating-up time and the temperature obtained for each setting are stated.

7.2.2 Temperature overshoot

The purpose of this test is to assess the heat retention of the hotplate.

NOTE This test is applicable for comparative testing only.

A saucepan, as shown in Figure 4 but without a lid, is filled to a height of 30 mm with fresh

sunflower oil at room temperature and placed on the cooking zone.

The cooking zone is heated with the control set at the maximum position. The temperature at

the centre of the oil is recorded. When the oil temperature reaches 80 °C ± 0,5 °C, the supply

– 14 – 60350-2 © IEC:2011

is switched off. The temperature in the oil is recorded continuously until the temperature starts

declining.

The temperature overshoot is the difference between the highest recorded temperature and

the temperature of the oil when the supply is switched off.

The temperature overshoot is stated in kelvins.

7.3 Heat distribution

7.3.1 General

The purpose of this test is to determine whether the cooking zone can steadily maintain a

medium-high temperature and an even heat distribution when frying continuously.

NOTE This test is applicable for comparative testing only.

The assessment is made by frying a batch of pancakes in a frying pan, as shown in Figure 5.

Min. 3 mm

IEC 2758/11

D

Specification of the frying pan

The frying pan is made of aluminium or stainless steel with an additional bottom layer of

aluminium, at least 3 mm thick. The inner surface of the pan has a non-stick surface coating

of polytetrafluoroethylene (PTFE). The diameter D of the flat part of the bottom is to be not

less than the diameter of the hotplate or cooking zone and is not to exceed this diameter by

more than 20 mm. The concavity of the bottom of the pan at ambient temperature is not to

exceed 0,003 D and is not to be convex. For cooking zones of induction hobs the bottom

surface of the pan has a thin layer of magnetic low carbon steel, for the absorption of

magnetic energy from the induction hob.

Figure 5 – Frying pan

7.3.2 Recipe for pancakes

The quantities of ingredients and approximate cooking durations corresponding to the

diameter of the cooking zone are given in Table 2.

Table 2 – Ingredients and cooking durations

Ingredients Diameter of the cooking zone

mm

≤ 145 > 145 and ≤ 180 > 180 and ≤ 220

White wheat flour, without raising agent 140 g 140 g 200 g

Fresh milk, fat content 3 % to 4 % 270 g 270 g 400 g

Egg (without shell) 110 g 110 g 160 g

Salt 3 g 3 g 4 g

Batter quantity for each pancake 45 ml 55 ml 85 ml

Cooking duration for the first side 40 s to 60 s 50 s to 70 s 60 s to 80 s

60350-2 © IEC:2011 – 15 –

7.3.3 Procedure

Whisk the milk and egg together, sieve the flour and salt together and add to the milk and egg

mixture.

Leave the batter to rest for one hour at room temperature before baking the pancakes.

Grease the frying pan with approximately 5 g of vegetable oil. Heat the pan until the centre of

the base has reached a temperature of 230 °C ± 5 °C. Pour the relevant quantity of batter into

the pan.

Fry the pancake until bubbles appear in the upper surface and the batter has set

(approximate times are shown in Table 2). Turn the pancake and fry until the second side is

golden brown. Fry a total of eight pancakes, maintaining the same orientation between the

frying pan and the cooking zone.

NOTE 1 A preliminary test may be necessary to determine the control setting in order to achieve the specified

temperature.

NOTE 2 The frying pan is only greased for the first pancake.

NOTE 3 A contact probe can be used to measure the temperature of the pan.

7.3.4 Assessment

The evenness of browning of the side which is fried first is evaluated for each pancake by

using the shade chart of Annex A.

The browning of each quadrant is determined. The difference between the lightest and the

darkest shade of each pancake is stated.

The average browning of each pancake is determined. The maximum difference between

these average values is stated.

7.4 Heat performance of hobs

7.4.1 Test purpose

Ceramic and induction hobs utilise electronic components for thermal protection. Temperature

sensors are integrated into the hob or range, which reduce or cut off the power to the cooking

zones when temperatures reach critical limits. Also, the electronic control system itself may

require thermal protection. This design characteristic may alter the hobs’ ability to heat food.

The purpose of the test method is to determine the heating performance of hobs that have

thermal protection.

7.4.2 Test procedure

Select saucepans according to Figure 4. Use the saucepan with oil on the cooking zone that

has the maximum diameter according to Table 3. On the other cooking zones, fill the

saucepans with water as indicated in Table 3. The water and the oil shall be at ambient

temperature. The chips shall be frozen at −18 °C ± 2 °C.

– 16 – 60350-2 © IEC:2011

Table 3 – Quantities

Quantity of fresh sunflower oil in the saucepan

Diameter of cooking zone Quantity of oil Quantity of potato chips

mm l g

1 200

≤ 145

> 145 and ≤ 180 2 350

3 500

≥ 180 and ≤ 220

Quantity of potable water in the saucepan

Diameter of cooking zone Quantity of water

mm l

≤ 145

1,5

> 145 and ≤ 180

≥ 180 and ≤ 220 2

The vessels filled with water are covered with glass lids. The temperature of the oil is

recorded continuously by means of a suitable temperature sensor. The position of the sensors

shall be 10 mm above the bottom of the saucepan and at a distance of 10 mm from the side of

the saucepan. The vessels shall be centred over the cooking zones.

NOTE 1 Thermocouples are suitable solutions for sensors.

Set the power level for the saucepan selected for frying to maximum power.

Set the power level for the remaining saucepans to maximum power.

For a hob range equipped with an oven, the oven is to be operated. Set the thermostat so that

the mean oven temperature is 180 °C ± 5 °C for ovens with forced air circulation and

200 °C ± 5 °C for ovens with natural convection. Operate the oven and be sure it is empty.

When the oven reaches the temperature or after a maximum time of 20 min, set all cooking

zone controls to maximum.

NOTE 2 An oven with a “cooling” fan can have a favourable influence on the thermal characteristics of the hob; in

this case, the oven is not operated. A cooling fan is not the same as a convection fan. A convection fan is visible in

the rear of the oven cavity.

After the water starts to boil, adjust the controls so that the water boils gently during the

relevant test time.

When the temperature of the oil reaches 180 °C ± 5 °C, remove one portion of chips from the

freezer and transfer it to the oil immediately. Fry for the time specified in Table 4.

Table 4 – Frying times

Diameter of cooking zone Time

mm min

≤ 145 4

> 145 and ≤ 180

≥ 180 and ≤ 220

If the temperature of the oil has dropped below 180 °C ± 5 °C during frying, wait after the

chips are taken out until the oil is heated up again at maximum setting to 180 °C ± 5 °C before

60350-2 © IEC:2011 – 17 –

putting the next portion of chips into the oil. This is to prevent the oil from cooling down

gradually during the test.

If the oil temperature rises over 180 °C ± 5 °C, reduce the power level.

This procedure is continued for 45 min after the cooking zones are switched on.

The following values should be recorded:

− the heat-up time for the oil to reach 180 °C;

− the heat-up time for the oil to reach 180 °C again, after taking out a portion of chips;

− the number of chip portions fried during the test.

7.5 Smallest detected diameter

7.5.1 Test purpose

Induction hobs may incorporate an electronic cookware detection means which automatically

cuts off the power to the induction cooking zone concerned when no cookware or a

cookware with a too small diameter is placed on the induction cooking zone, or a detected

cookware is removed from the induction cooking zone.

The purpose of the test method is to determine the smallest diameter which is detected on the

induction cooking zone under test.

NOTE 1 The detected diameter – measured with a disc – may not be identical to a base diameter of a cookware.

This depends from the design and material of cookware.

NOTE 2 The purpose of this test is not to grant a specific power to this smallest diameter.

7.5.2 Test procedure

Discs as defined in Figure 6 are used, each being at ambient temperature at the beginning of

the test. The test is started with a disc with a diameter which definitely will not be detected by

the induction cooking zone to be tested.

The disc is made from steel with the chemical composition in weight %: 0,42-0,50 % C,

< 0,40 % Si, 0,50-0,80 % Mn, < 0,045 % S, < 0,045 % P, 0,40 % Ni, < 0,40 % Cr, < 0,10 %

Mo, Cr+Mo+N I < = 0,63 %

NOTE This steel is for example equivalent to EN C45 (defined in EN 10277-2) and SAE 1045. A possible supplier

is mentioned in Clause B.2.

Place the disc in the centre of the cooking zone marked on the appliance. Set the control to

the lowest power level. If the disc is not detected by the cookware detection means, the test is

to be done with a disc having a 5 mm larger diameter. This procedure is to be repeated until a

disc is detected and is working continuously for at least 1 min.

The found detected diameter shall be verified in the hot condition. To do this: bring up the

amount of water according to Table 1 to the boiling point at maximum possible power level

simultaneously on all induction cooking zones available on the hob. For that test any

suitable cookware which covers the size of the induction cooking zone should be used. For

cooking zones with a diameter larger than 220 mm, use 3,5 l of water. Remove the cookware

after the water on one induction cooking zone has started boiling. Check detection with the

discs separately on each induction cooking zone over the whole voltage range of 230 V

(+ 10 % – 6 %) within 2 min.

If verifying fails, the test is to be repeated with the next larger diameter of the disc.

– 18 – 60350-2 © IEC:2011

The smallest detected diameter is defined as the smallest diameter of the disc which was

detected under all conditions mentioned above.

The test is repeated for all cooking zones in a hob.

0,5 × 45°

(Ra 0,4 - 0,1)

Table

∅D

(Ra 0,4 - 0,1)

See Table

0,1

D < 120

∅D

120 ≤ D < 150

0,15

150 ≤ D 0,2 max.

Material: C45 (Material number 1.0503 EN 10277-2)

IEC 2759/11

Dimensions in millimetres

Figure 6 – Disc to determine the smallest detected diameter

8 Standby power

The standby power shall be determined in accordance to IEC 62301:2005 with the following

modifications.

For multifunctional appliances which may consist of a variety of different hobs and ovens

which are designed to be combined in a single range, the recommended combination as

declared in the manufacturer’s instruction are used for the test.

For the determination of standby power, the appliance shall be in the state recommended in

the manufacturer’s instructions, if any, when the (product) intended function is not in use.

NOTE 1 Appropriate advice in the manufacturer’s instructions how to reduce standby energy has to be taken into

account when preparing the appliance for the test.

When testing appliances that are fitted with a clock, the clock shall be adjusted to the correct

time and date as specified in the instructions. If an option is provided to switch off the display

it is tested in this mode.

NOTE 2 If the brightness of the display can be altered by the user, the brightest illumination should be selected

for the measurement. If the brightness of the display is affected by the ambient light conditions, a steady state

condition should be used during the measurement and the ambient illumination level recorded in the test report.

The appliance shall be at ambient temperature before the power is monitored.

The appliance shall be connected to the power source and allowed to stabilize before the

measurements are made.

If the power reading is not stable the power consumption in each relevant mode shall be

determined as an average power measurement over a period of not less than 30 min.

When preparing the test report for multifunction appliances the combination of types of main

powered parts (hobs, ovens, grills, warming plates, griddles etc.) used for the measurement

shall be recorded in addition to the brand, model, type, and serial number of each part.

60350-2 © IEC:2011 – 19 –

9 Spillage capacity of hobs

The purpose of this test is to evaluate the capability of the hob to retain spillage.

NOTE This test is considered to give reproducible results.

The appliance is positioned so that the perimeter of the hob surface is horizontal. A saucepan

which has the smallest diameter required to cover the cooking zone is placed on one of the

cooking zones and completely filled with water. An additional quantity of 0,5 l of water is

poured steadily into it within 1 min. The effect of this spillage is determined and stated. If the

hob does not hold the excess quantity, it is stated which way the water runs.

The quantity of water that the hob will retain before it overflows is measured and stated in

millilitres.

– 20 – 60350-2 © IEC:2011

Annex A

(normative)

Shade chart

Tables A.1 and A.2 specify the relation between reflection value Ry and shade numbers

corresponding to NCS shade charts.

Table A.1 – Classification of shade numbers

Measured reflection value R Shade number

y

≥ <

7,2 17

7,2 9,3 16

9,3 12,2 15

12,2 16,4 14

16,4 20,1 13

20,1 22,9 12

22,9 26,5 11

26,5 31,7 10

31,7 38,5 9

38,5 46,9 8

46,9 54,2 7

54,2 64,3 6

64,3 75,2 5

75,2 4

Table A.2 – Examples for the shade charts

NCS

Shade chart L* R

y

S 8502-Y 30,3 6,4

S 7020-Y50R 34,4 8,2

S 6030-Y50R 38,6 10,4

S 5040-Y40R 44,5 14,2

S 4050-Y30R 50,4 18,8

S 4040-Y30R 53,4 21,4

S 4030-Y30R 56,6 24,5

S 3040-Y30R 60,5 28,7

S 2060-Y20R 65,7 34,9

S 2040-Y20R 71,1 42,3

S 1050-Y20R 77,1 51,7

S 1040-Y20R 80,1 56,9

S 0530-Y10R 88,1 72,3

S 0520-Y10R 90,9 78,3

60350-2 © IEC:2011 – 21 –

NOTE 1 The measured reflection value R does not correlate linearly to the visual perception. Although the widths

y

of the intervals given above increase with increasing reflection value R , visually the s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...