IEC TS 60825-13:2026

(Main)Safety of laser products - Part 13: Measurements for classification of laser products

Safety of laser products - Part 13: Measurements for classification of laser products

IEC TS 60825-13:2026 provides manufacturers, test houses, safety personnel, and others with practical guidance on methods to perform radiometric measurements or analyses to establish the emission level of laser energy or power in accordance with IEC 60825-1:2014. The measurement procedures described in this document are guidance for classification of laser products in accordance with IEC 60825‑1:2014. It is possible that other procedures are better or more appropriate.

Information is provided for calculating accessible emission limits (AELs) and maximum permissible exposures (MPEs), since some parameters used in calculating the limits are dependent upon other measured quantities.

This document applies to lasers, including extended sources and laser arrays. The procedures described in this document for extended source viewing conditions can yield more conservative results than when using more rigorous methods.

NOTE Work continues on more complex source evaluations and will be provided as international agreement on the methods is reached.

This first edition cancels and replaces the second edition of IEC TR 60825-13 published in 2011. This edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to IEC TR 60825-13:2011:

a) minor changes and additions have been made in the definitions;

b) classification flow has been updated;

c) apparent source sections have been clarified;

d) scanning has been updated;

e) more examples and useful conversions have been added to the annexes.

General Information

- Status

- Published

- Publication Date

- 02-Feb-2026

- Technical Committee

- TC 76 - Optical radiation safety and laser equipment

- Drafting Committee

- WG 3 - TC 76/WG 3

- Current Stage

- PPUB - Publication issued

- Start Date

- 03-Feb-2026

- Completion Date

- 30-Jan-2026

Relations

- Effective Date

- 06-Feb-2026

- Effective Date

- 06-Feb-2026

Overview

IEC TS 60825-13:2026 - Safety of laser products - Part 13: Measurements for classification of laser products, is a technical specification published by the International Electrotechnical Commission (IEC). This document delivers practical guidance to manufacturers, test laboratories, and safety personnel on radiometric measurement methods crucial for classifying laser products in compliance with IEC 60825-1:2014. It also provides detailed procedures for establishing emission levels of laser energy or power, supporting the accurate assignment of appropriate laser equipment classes.

Key Topics

Radiometric Measurement Guidance

IEC TS 60825-13:2026 outlines measurement and evaluation procedures to ensure reliable classification of laser products. It covers:- Methods for determining emission wavelengths, temporal characteristics, and angular subtense

- Steps to evaluate maximum permissible exposures (MPEs) and accessible emission limits (AELs)

- Procedures for dealing with extended sources and laser arrays

Foundation for Laser Product Classification

The technical specification serves as a reference for classifying lasers based on measured emissions and calculated exposure limits, as defined in IEC 60825-1:2014.Uncertainty Management

Instrument requirements and methods for evaluating measurement uncertainties are described, with an emphasis on calibration traceability and comprehensive consideration of error sources.Product Testing Considerations

Guidance is given on:- Configuring laser products and accessories for testing

- Assessing reasonably foreseeable single fault conditions

- Accounting for collateral radiation and all possible accessible configurations

Updated Content

The 2026 edition introduces updated terminology, improved classification flow, clarifications on apparent sources, revised scanning sections, and expanded practical examples.

Applications

IEC TS 60825-13:2026 is vital across various industries where laser safety and compliance are paramount. Typical applications include:

Laser Product Design and Compliance

- Supports manufacturers in validating that their products conform to international safety requirements for laser emissions.

- Enables accurate laser classification to determine appropriate labeling, user information, and protective measures.

Testing and Certification

- Serves as a reference for test laboratories to perform consistent, repeatable measurements according to internationally accepted procedures.

- Assists safety personnel in verifying that laser devices remain within specified emission limits during operation and under possible fault conditions.

Industrial and Medical Use

- Provides safety frameworks for organizations using lasers in manufacturing, healthcare, communications, and research by guiding hazard assessments and risk management.

Regulatory and Safety Audits

- Facilitates conformity assessment and regulatory checks by providing a clear methodology for emission measurement and classification.

Related Standards

IEC 60825-1:2014

The fundamental standard for laser product safety covering the classification system, requirements for labeling, and user precautions.IEC TR 60825-14

Offers guidance on the safe use of lasers and laser equipment in the workplace.ISO 11146 Series

Details measurement methods for laser beam width, divergence, and beam profile, complementing measurement practices in IEC TS 60825-13.JCGM 100 / ISO/IEC Guide 98-3

Provides general guidance on the evaluation and control of measurement uncertainty, referenced in determining the overall reliability of emission data.

Practical Value

Adhering to IEC TS 60825-13:2026 ensures precision and consistency in the classification of laser products, which is critical for user safety, regulatory compliance, and product acceptance in global markets. This standard supports safe laser development and use, minimizes liability risks, and aligns assessment practices with up-to-date international requirements for laser safety. By following the procedures and recommendations in this document, organizations can ensure their laser devices are tested accurately and classified appropriately, protecting users and facilitating international trade.

Frequently Asked Questions

IEC TS 60825-13:2026 is a technical specification published by the International Electrotechnical Commission (IEC). Its full title is "Safety of laser products - Part 13: Measurements for classification of laser products". This standard covers: IEC TS 60825-13:2026 provides manufacturers, test houses, safety personnel, and others with practical guidance on methods to perform radiometric measurements or analyses to establish the emission level of laser energy or power in accordance with IEC 60825-1:2014. The measurement procedures described in this document are guidance for classification of laser products in accordance with IEC 60825‑1:2014. It is possible that other procedures are better or more appropriate. Information is provided for calculating accessible emission limits (AELs) and maximum permissible exposures (MPEs), since some parameters used in calculating the limits are dependent upon other measured quantities. This document applies to lasers, including extended sources and laser arrays. The procedures described in this document for extended source viewing conditions can yield more conservative results than when using more rigorous methods. NOTE Work continues on more complex source evaluations and will be provided as international agreement on the methods is reached. This first edition cancels and replaces the second edition of IEC TR 60825-13 published in 2011. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to IEC TR 60825-13:2011: a) minor changes and additions have been made in the definitions; b) classification flow has been updated; c) apparent source sections have been clarified; d) scanning has been updated; e) more examples and useful conversions have been added to the annexes.

IEC TS 60825-13:2026 provides manufacturers, test houses, safety personnel, and others with practical guidance on methods to perform radiometric measurements or analyses to establish the emission level of laser energy or power in accordance with IEC 60825-1:2014. The measurement procedures described in this document are guidance for classification of laser products in accordance with IEC 60825‑1:2014. It is possible that other procedures are better or more appropriate. Information is provided for calculating accessible emission limits (AELs) and maximum permissible exposures (MPEs), since some parameters used in calculating the limits are dependent upon other measured quantities. This document applies to lasers, including extended sources and laser arrays. The procedures described in this document for extended source viewing conditions can yield more conservative results than when using more rigorous methods. NOTE Work continues on more complex source evaluations and will be provided as international agreement on the methods is reached. This first edition cancels and replaces the second edition of IEC TR 60825-13 published in 2011. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to IEC TR 60825-13:2011: a) minor changes and additions have been made in the definitions; b) classification flow has been updated; c) apparent source sections have been clarified; d) scanning has been updated; e) more examples and useful conversions have been added to the annexes.

IEC TS 60825-13:2026 is classified under the following ICS (International Classification for Standards) categories: 31.260 - Optoelectronics. Laser equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TS 60825-13:2026 has the following relationships with other standards: It is inter standard links to IEC TR 60825-13:2011, IEC TR 60825-13:2006. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC TS 60825-13:2026 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC TS 60825-13 ®

Edition 1.0 2026-02

TECHNICAL

SPECIFICATION

Safety of laser products -

Part 13: Measurements for classification of laser products

ICS 31.260 ISBN 978-2-8327-1003-6

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or

by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either

IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC copyright

or have an enquiry about obtaining additional rights to this publication, please contact the address below or your local

IEC member National Committee for further information.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - IEC Products & Services Portal - products.iec.ch

webstore.iec.ch/advsearchform Discover our powerful search engine and read freely all the

The advanced search enables to find IEC publications by a publications previews, graphical symbols and the glossary.

variety of criteria (reference number, text, technical With a subscription you will always have access to up to date

committee, …). It also gives information on projects, content tailored to your needs.

replaced and withdrawn publications.

Electropedia - www.electropedia.org

The world's leading online dictionary on electrotechnology,

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published containing more than 22 500 terminological entries in English

details all new publications released. Available online and and French, with equivalent terms in 25 additional languages.

once a month by email. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer

Service Centre: sales@iec.ch.

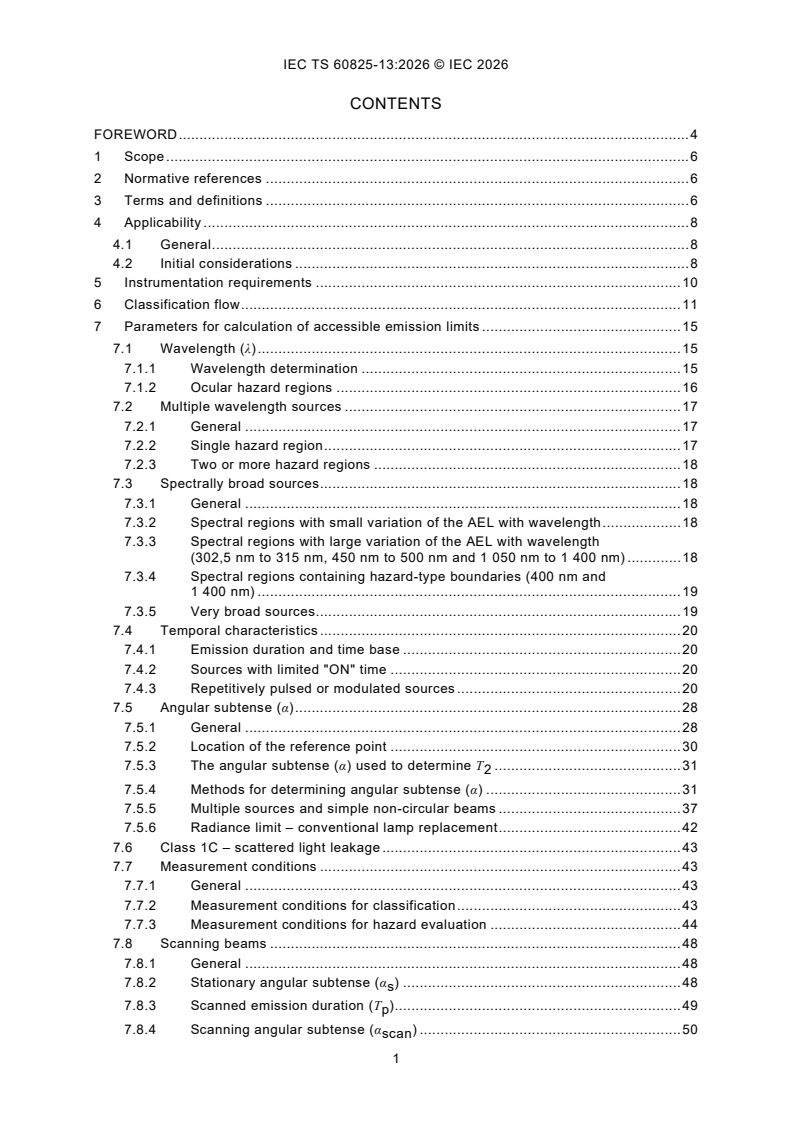

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Applicability . 8

4.1 General . 8

4.2 Initial considerations . 8

5 Instrumentation requirements . 10

6 Classification flow . 11

7 Parameters for calculation of accessible emission limits . 15

7.1 Wavelength (λ) . 15

7.1.1 Wavelength determination . 15

7.1.2 Ocular hazard regions . 16

7.2 Multiple wavelength sources . 17

7.2.1 General . 17

7.2.2 Single hazard region . 17

7.2.3 Two or more hazard regions . 18

7.3 Spectrally broad sources . 18

7.3.1 General . 18

7.3.2 Spectral regions with small variation of the AEL with wavelength . 18

7.3.3 Spectral regions with large variation of the AEL with wavelength

(302,5 nm to 315 nm, 450 nm to 500 nm and 1 050 nm to 1 400 nm) . 18

7.3.4 Spectral regions containing hazard-type boundaries (400 nm and

1 400 nm) . 19

7.3.5 Very broad sources. 19

7.4 Temporal characteristics . 20

7.4.1 Emission duration and time base . 20

7.4.2 Sources with limited "ON" time . 20

7.4.3 Repetitively pulsed or modulated sources . 20

7.5 Angular subtense (α) . 28

7.5.1 General . 28

7.5.2 Location of the reference point . 30

7.5.3 The angular subtense (α) used to determine T . 31

7.5.4 Methods for determining angular subtense (α) . 31

7.5.5 Multiple sources and simple non-circular beams . 37

7.5.6 Radiance limit – conventional lamp replacement . 42

7.6 Class 1C – scattered light leakage . 43

7.7 Measurement conditions . 43

7.7.1 General . 43

7.7.2 Measurement conditions for classification . 43

7.7.3 Measurement conditions for hazard evaluation . 44

7.8 Scanning beams . 48

7.8.1 General . 48

7.8.2 Stationary angular subtense (α ) . 48

s

7.8.3 Scanned emission duration (T ) . 49

p

7.8.4 Scanning angular subtense (α ) . 50

scan

7.8.5 Bi-directional scanning . 51

7.8.6 Number of scan lines in aperture (n) . 52

7.8.7 Most restrictive position . 53

7.8.8 Gaussian beam coupling parameter (η) . 54

7.8.9 Scan angle multiplication factor . 54

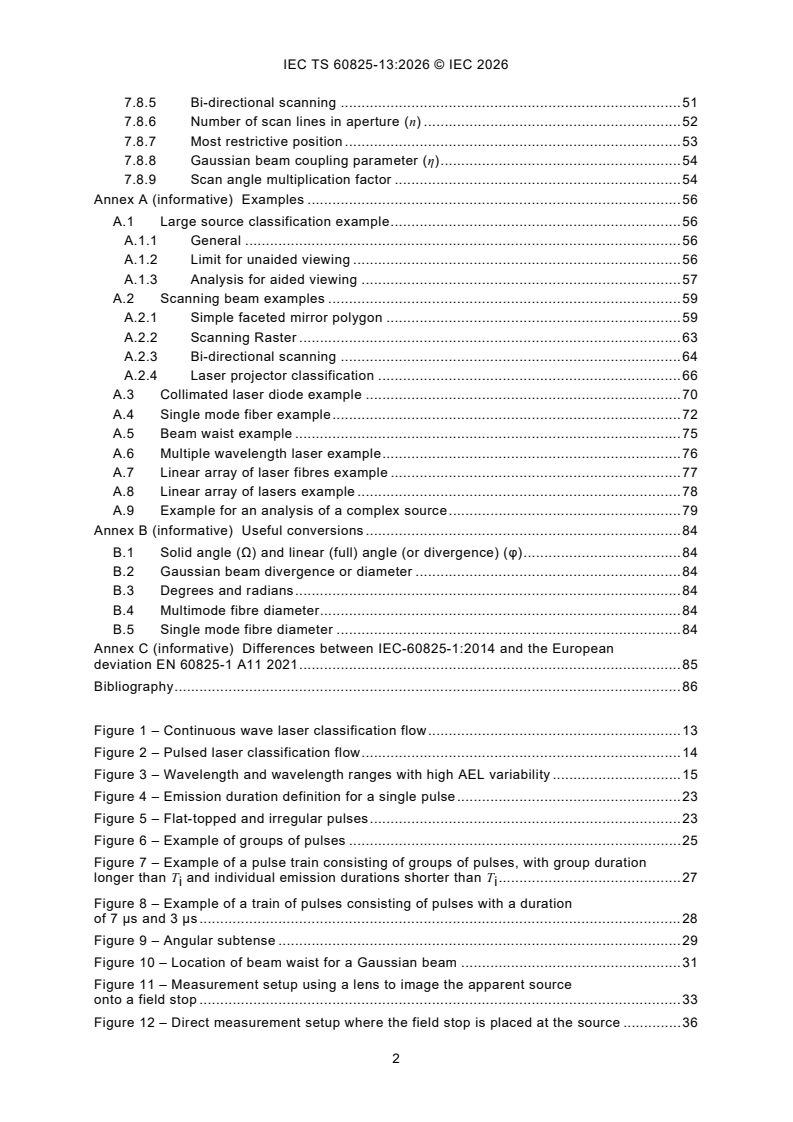

Annex A (informative) Examples . 56

A.1 Large source classification example . 56

A.1.1 General . 56

A.1.2 Limit for unaided viewing . 56

A.1.3 Analysis for aided viewing . 57

A.2 Scanning beam examples . 59

A.2.1 Simple faceted mirror polygon . 59

A.2.2 Scanning Raster . 63

A.2.3 Bi-directional scanning . 64

A.2.4 Laser projector classification . 66

A.3 Collimated laser diode example . 70

A.4 Single mode fiber example . 72

A.5 Beam waist example . 75

A.6 Multiple wavelength laser example . 76

A.7 Linear array of laser fibres example . 77

A.8 Linear array of lasers example . 78

A.9 Example for an analysis of a complex source . 79

Annex B (informative) Useful conversions . 84

B.1 Solid angle (Ω) and linear (full) angle (or divergence) (φ) . 84

B.2 Gaussian beam divergence or diameter . 84

B.3 Degrees and radians . 84

B.4 Multimode fibre diameter . 84

B.5 Single mode fibre diameter . 84

Annex C (informative) Differences between IEC-60825-1:2014 and the European

deviation EN 60825-1 A11 2021 . 85

Bibliography . 86

Figure 1 – Continuous wave laser classification flow . 13

Figure 2 – Pulsed laser classification flow . 14

Figure 3 – Wavelength and wavelength ranges with high AEL variability . 15

Figure 4 – Emission duration definition for a single pulse . 23

Figure 5 – Flat-topped and irregular pulses . 23

Figure 6 – Example of groups of pulses . 25

Figure 7 – Example of a pulse train consisting of groups of pulses, with group duration

longer than T and individual emission durations shorter than T . 27

i i

Figure 8 – Example of a train of pulses consisting of pulses with a duration

of 7 µs and 3 µs . 28

Figure 9 – Angular subtense . 29

Figure 10 – Location of beam waist for a Gaussian beam . 31

Figure 11 – Measurement setup using a lens to image the apparent source

onto a field stop . 33

Figure 12 – Direct measurement setup where the field stop is placed at the source . 36

Figure 13 – Linear array apparent source size . 38

Figure 14 – Measurement geometries . 40

Figure 15 – Long and short angular subtense of a non-circular source . 41

Figure 16 – Imaging a stationary apparent source located beyond the scanning beam

vertex . 49

Figure 17 – Imaging a scanning apparent source located beyond the scanning beam

vertex . 50

Figure 18 – Scanning mirror with an arbitrary scan angle multiplication factor . 55

Figure A.1 – Multiple raster lines crossing the aperture stop at distance from scanning

vertex where C = 1 . 64

Figure A.2 – Source pattern for the example of 20 diode emitters . 80

Figure A.3 – Example of two cases of subgroups . 81

Table 1 – Reference points . 30

Table 2 – Four source array . 39

Table A.1 – Number of source cases . 78

Table A.2 – Number of source cases . 79

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

Safety of laser products -

Part 13: Measurements for classification of laser products

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC Publication(s)"). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) IEC draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). IEC takes no position concerning the evidence, validity or applicability of any claimed patent rights in

respect thereof. As of the date of publication of this document, IEC had not received notice of (a) patent(s), which

may be required to implement this document. However, implementers are cautioned that this may not represent

the latest information, which may be obtained from the patent database available at https://patents.iec.ch. IEC

shall not be held responsible for identifying any or all such patent rights.

IEC TS 60825-13 has been prepared by IEC technical committee 76: Optical radiation safety

and laser equipment. It is a Technical Specification.

This first edition cancels and replaces the second edition of IEC TR 60825-13 published in

2011. This edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to IEC TR 60825-

13:2011:

a) minor changes and additions have been made in the definitions;

b) classification flow has been updated;

c) apparent source sections have been clarified;

d) scanning has been updated;

e) more examples and useful conversions have been added to the annexes.

The text of this Technical Specification is based on the following documents:

Draft Report on voting

76/786/DTS 76/791/RVDTS

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this Technical Specification is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/publications.

This document is to be used in conjunction with IEC 60825-1:2014.

A list of all parts of the IEC 60825 series, published under the general title Safety of laser

products, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

– reconfirmed,

– withdrawn, or

– revised.

1 Scope

This part of IEC 60825, which is a Technical Specification, provides manufacturers, test houses,

safety personnel, and others with practical guidance on methods to perform radiometric

measurements or analyses to establish the emission level of laser energy or power in

accordance with IEC 60825-1:2014. The measurement procedures described in this document

are guidance for classification of laser products in accordance with IEC 60825-1:2014. It is

possible that other procedures are better or more appropriate.

Information is provided for calculating accessible emission limits (AELs) and maximum

permissible exposures (MPEs), since some parameters used in calculating the limits are

dependent upon other measured quantities.

This document applies to lasers, including extended sources and laser arrays. The procedures

described in this document for extended source viewing conditions can yield more conservative

results than when using more rigorous methods.

NOTE Work continues on more complex source evaluations and will be provided as international agreement on the

methods is reached.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60825-1:2014, Safety of laser products – Part 1: Equipment classification and

requirements

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60825-1:2014 and

the following apply.

ISO and IEC maintain terminology databases for use in standardization at the following

addresses:

– IEC Electropedia: available at https://www.electropedia.org/

– ISO Online browsing platform: available at https://www.iso.org/obp

NOTE Some of the definitions differ from those given in regional standards, e.g. for Europe

EN 60825-1:2014/A11:2021.

3.1

angular velocity

speed of a scanning beam

Note 1 to entry: Angular velocity is measured in radians per second.

___________

Two interpretation sheets were issued by IEC TC 76 for IEC 60825-1:2014 in December 2017.

3.2

aperture stop

area over which the level of radiation is determined

Note 1 to entry: For extended sources, only the power or energy within α needs to be compared to the AEL

(sometimes this area is referred to as field stop, which can be varied in different dimensions). In this case, the energy

within α is not equal to the power or energy measured through the aperture stop.

3.3

beam profile

irradiance distribution of a beam cross-section

3.4

beam waist

minimum diameter of an axis-symmetric beam, or portion of a beam where the beam diameter

or beam width has a local minimum

Note 1 to entry: For non-symmetric beams, there can be a beam waist along each major axis, each located at a

different distance from the source.

3.5

beam diameter

beam width

d

u

diameter of the smallest circle which contains u % of the total laser power (or energy)

Note 1 to entry: For the purpose of this document, d is used.

Note 2 to entry: The beam waist is the position in the beam where the beam diameter is minimum.

Note 3 to entry: SI unit: metre.

Note 4 to entry: This definition of the beam diameter should not be used generally for the determination of the

angular subtense of the apparent source α since the definitions are different. However, for the case of a Gaussian

irradiance profile of the image of the apparent source, d can be applied for the determination of the angular

subtense of the apparent source α. For non-Gaussian irradiance profiles of the image of the angular subtense of the

apparent source, the method described in IEC 60825-1:2014, 4.3 d) is used.

Note 5 to entry: In the case of a Gaussian beam, d corresponds to the point where the irradiance (radiant

exposure) falls to 1/e of its central peak value.

Note 6 to entry: The second moment diameter definition (as defined in ISO 11146-1) is not appropriate to be used

for beam profiles with central high irradiance peaks and a low level background, such as produced by unstable

resonators in the far field: the power that passes through an aperture can be significantly underestimated when using

the second moment and calculating the power with the assumption of a Gaussian beam profile.

3.6

beam divergence

far field plane angle of the cone defined by the beam diameter

Note 1 to entry: If the beam diameters (3.5) at two points separated by a distance r are d and d′ the divergence

63 63

is given by:

'

d − d

63 63

φ = 2arctan

2r

Note 2 to entry: SI unit: radian.

Note 3 to entry: The second moment divergence definition (ISO 11146-1) is not appropriate to be used for beam

profiles with central high irradiance peaks and a low level background, such as produced by unstable resonators in

the far field or beam profiles that show diffraction patterns caused by apertures.

3.7

Gaussian beam profile

profile of a laser beam which is operated in the lowest transverse mode, TEM

Note 1 to entry: A Gaussian beam profile can also be produced by passing non-TEM laser beams through beam

shaping optical elements.

3.8

pulse repetition frequency

PRF

number of pulses occurring per second

Note 1 to entry: Pulse repetition frequency is expressed in hertz (Hz).

3.9

Q-switch

device for producing very short, high peak power laser pulses by enhancing the storage and

dumping of energy in and out of the lasing medium, respectively

3.10

responsivity

R

ratio of the output of a detector to the corresponding input expressed as R = O/I, where O is the

detector's electrical output and I is the optical power or energy input

3.11

ultrashort pulse laser

laser that emits pulses shorter than 1 ns and can contain a relatively broadband spectral content

Note 1 to entry: Pulse durations less than 1 ns are where biological effects begin to become nonlinear.

3.12

emission duration

temporal duration t of a pulse, of a train or series of pulses emitted within T , or groups of pulses

i

with the time base or of continuous operation, during which human access to laser radiation

could occur as a result of operation, maintenance or servicing of a laser product

Note 1 to entry: T is the time below which pulse groups are summed (see Table 2 of IEC 60825-1:2014).

i

Note 2 to entry: For a single pulse, emission duration is the duration between the half-peak power point of the

leading edge and the corresponding point on the trailing edge. For a train of pulses (or subsections of a train of

pulses), emission duration is the duration between the first half-peak power point of the leading pulse and the last

half-peak power point of the trailing pulse.

4 Applicability

4.1 General

This document is intended to be used as a reference guide by (but not limited to) manufacturers,

testing laboratories, safety officers, and officials of industrial or governmental authorities. This

document also contains interpretations of IEC 60825-1:2014 pertaining to measurements and

provides supplemental explanatory material.

4.2 Initial considerations

Before any radiometric measurement is started, a review of the general safety shall be done for

handling of the laser, lamp or LED product or component during test, measurements and during

the dismantling stage or maintenance. See IEC TR 60825-14 for further information.

Several parameters shall be determined before any radiometric measurements can be done for

the purpose of product classification or conformance with the other applicable requirements of

IEC 60825-1:2014. These parameters include the following.

a) Emission wavelength(s)

Lasers emit radiation at one or more distinct wavelengths.

The emission wavelength(s) or spectral wavelength distribution can typically be obtained

from the manufacturer of the laser. Depending on the type of laser, the manufacturer can

specify a wavelength range rather than a single value. Otherwise, the emission

wavelength(s) or spectral distribution can be determined by measurement, which is beyond

the scope of this document. See 7.1 for assessing the accessible emission limit (AEL) for

multiple wavelengths.

b) Time mode of operation

The time mode of operation refers to the rate at which the energy is emitted. Some lasers

emit continuous wave (CW) radiation; other lasers emit energy as pulses of radiation. Pulsed

lasers can be single pulsed, Q-switched, repetitively pulsed, or mode locked. Scanned or

modulated CW radiation at a fixed location also results in a train of pulses.

In addition, the pulse train can be encoded, but have an average duty factor (emission time

as a fraction of elapsed time, expressed as a decimal fraction or percentage).

c) Reasonably foreseeable single fault conditions

In accordance with IEC 60825-1:2014, the laser radiation emitted by the laser product shall

be evaluated under normal conditions and reasonably foreseeable single fault conditions. If

the single fault condition results in a more hazardous output than what is emitted under

normal conditions, that single fault value should be used to determine the laser class.

When performing single fault testing and analysis, the laser product should first be

configured to emit the maximum intended level of radiation as in normal operation (normal

condition). After normal condition measurements are made, single faults can be introduced

to the laser product while monitoring the impact on the measured laser power or energy.

Single faults can include shorting or opening components in the drive circuit of the laser in

an attempt to increase the electrical input to the laser itself. When the single fault involves

shorting pins of a component such as a transistor or voltage regulator, one method is to

solder wire leads onto these pins and extend them outside the product to a knife switch –

the single fault can be introduced via the knife switch. Other single faults that can be relevant

include checking the reliability of components that can lower the laser class such as

diffractive optical elements, diffusers, window materials, etc. When assessing which single

fault to impose, it can be necessary to check the impact of more than one single fault, one

at a time, to determine conformance.

If the single fault causes the laser to emit higher levels of laser power or energy, but only

for a short period of time, additional considerations can be made as to whether the single

fault needs to be used for classification. For example, if the laser emission is reduced to a

level below the normal condition level before human access is reasonably foreseeable, such

faults need not be considered (as described in IEC 60825-1:2014). For these limited

increases in power or energy levels, an assessment of whether human access is reasonably

foreseeable can be made considering the specifics and configuration of the product and the

intended use. Also, it can be possible to classify the brief higher power or energy levels only

over the time these levels are maintained.

For laser emissions that result in a higher laser class under single fault conditions,

conformance with the protective housing requirements should be maintained for the higher

laser class, i.e. exposure to radiation over Class 1 is only allowed when access to that level

of radiation is necessary for the performance of the functions of the product. If a single fault

equates to a laser class that does not maintain conformity with this protective housing

requirement, additional safeguards should be considered (example: revised laser drive

circuit, modification of protective housing, etc.).

d) Measurement uncertainties

It is important to consider potential sources of error in measurement of laser radiation.

Clause 5 addresses measurement uncertainties.

e) Collateral radiation (see IEC 60825-1:2014 for definition of collateral radiation)

Collateral radiation entering the aperture stop can affect measured values of power or

energy and emission duration. Test personnel should ensure that the measurement setup

blocks or accounts for collateral radiation that would otherwise reach the detector.

f) Product configuration

If measurements are being made for the purpose of classification, then all controls and

settings listed in the operation, maintenance and service instructions shall be adjusted in

combination to result in the maximum accessible level of radiation. Measurements are also

required with the use of accessories that can increase the radiation hazard (for example,

collimating optics) which are supplied or offered by the manufacturer of the laser product

for use with the product.

NOTE This includes any configuration of the product that it is possible to attain without using tools or defeating

an interlock, including configurations and settings against which the operation and maintenance instructions

contain warnings. For example, when optical elements such as filters, diffusers or lenses in the optical path of

the laser beam can be removed without tools, the product is tested in the configuration which results in the

highest hazard level. The instruction by the manufacturer not to remove the optical elements cannot justify

classification as a lower class. Classification is based on the engineering design of the product and cannot be

based on appropriate behaviour of the user.

If measurements are being made to determine the requirements for safety interlocks, labels

and information for the user, then the product shall be evaluated under the configurations

applicable for each of the defined categories of use (operation, maintenance, and service)

in accordance with IEC 60825-1:2014.

Equivalent measurement procedures exist, which can yield results that are as valid as the

procedures described in this document. This document describes measurement procedures that

are adequate to meet the measurement requirements of IEC 60825-1:2014 when

measurements are needed. In many cases, it is possible that actual radiometric measurements

are not necessary, and conformance with the requirements of IEC 60825-1:2014 can be

determined from an analysis of a well-characterized source and the design of the actual product.

Measurements of accessible emission (AE) shall be made at points in space to which human

access is possible during operation and maintenance, as applicable. (For example, if operation

requires removal of portions of the protective housing and defeat of safety interlocks,

measurements shall be made at points accessible in that product configuration.) Therefore,

under some circumstances it can be necessary to partially disassemble a product to undertake

measurements at the required measurement location, particularly when considering reasonably

foreseeable single fault conditions. Where a final laser product contains other laser products or

systems, it is the final product that is subject to the provisions of IEC 60825-1:2014.

Measurements shall be made with the measuring instrument detector so positioned and so

oriented with respect to the laser product as to result in the maximum detection of radiation by

the instrument. That is, the detector shall be moved or the angle changed to obtain a maximum

reading on the meter. Appropriate provision shall be made to avoid or to eliminate the

contribution of collateral radiation to the measurement. For example, it can be necessary to

take measurements some distance away from a laser system's output to avoid corrupting the

data with radiation from flash lamps or pump diodes or diode lasers. As another example, it can

be necessary to filter collateral radiation out with a line filter.

5 Instrumentation requirements

Measurement instruments used for classification shall be traceable to an independent verified

measurement standard to determine the measurement uncertainty.

The individual contributions of different parameters to the total measurement uncertainty shall

be evaluated separately and the combined individual uncertainties have an upper boundary on

overall uncertainty of 20 %. The main points to be considered for the evaluation are:

– change of responsivity with time;

– non-uniformity of responsivity over the detector surface;

– change of responsivity during irradiation;

– temperature dependence of responsivity;

– dependence of responsivity on the angle of incidence;

– non-linearity;

– wavelength dependence of responsivity;

– polarization dependence of responsivity;

– errors in averaging of repetitively pulsed radiation over time;

– zero drift;

– calibration uncertainty.

NOTE Further information about measurement uncertainty can be found from the Joint Committee for Guides in

Metrology (JCGM) Publications, for example the latest version of JCGM 100 or ISO/IEC Guide 98-3.

The calibrations should be traceable to a measurement standard and be documented.

Tests for the determination of measurement uncertainties of the instrument should be done

according to the measurement standard.

For measurement uncertainties of CCD arrays and cameras see ISO 11146-3.

6 Classification flow

Known or measured parameters of the product enable calculation of AELs and measurement

conditions. In addition, fault conditions that increase the hazard shall be analysed. Then, a

product emission measurement (or several different measurements) will determine if the

emission is within the AEL of the class under consideration.

Tables 3 to 8 of IEC 60825-1:2014 provide the accessible emission limits. These tables have

rows for the wavelength ranges and columns for the emission durations. Within each row and

column entry, there exist numerical values or one or more formulas containing parameters that

are defined in Table 9 of IEC 60825-1:2014.

The classification flow is illustrated in Figure 1 and Figure 2. The initial approach is to use the

default simplified evaluation from 5.4.2 of IEC 60825-1:2014. It considers the beam to be

emitted from a small (point) source with C = 1, a conservative approach if the apparent source

size is not known. If the product output appears to be generated by an extended source and is

in the 400 nm to 1 400 nm range, and if the class determined by the simplified evaluation is not

acceptable, then one can alternatively determine the class using the more complex evaluation.

This involves using additional parameters, including the angular subtense α. The paired

parameters angular subtense and accessible emission is a function of the distance to the laser

system, the accommodation state of the eye and the time which determines α . This is also

max

dependent on the pulse pattern, i.e. the maximal number of pulses or pulse groups, which can

give a larger time-average source size for a moving or a sweeping laser source. Another

additional parameter for using the complex evaluation is the measurement acceptance angle γ

p

for the visible photochemical hazard.

First, determine whether the laser is pulsed or continuous wave. If the emission duration is

greater than 0,25 s, the laser is considered continuous wave. For a continuous wave laser, refer

to the flowchart in Figure 1, and for a pulsed laser, refer to the flowchart in Figure 2.

Next, the wavelength shall be determined.

If the laser is pulsed or scanned, the pulse trains, pulse width (PW) and pulse repetition

frequency (PRF) shall also be determined.

Determine the applicable class or classes. For instance, for a low power application not in the

400 nm to 700 nm region, Class 1, Class 1M, Class 1C and Class 3R can be considered. For a

visible wavelength source, Class 1, Class 1M, Class 1C, Class 2, Class 2M and Class 3R can

be considered.

Next, the classification time base shall be established. This can be determined in terms of

default values from 4.3 e) of IEC 60825-1:2014, or by considering the particular temporal output

properties of the product in question.

This information is needed to locate the row and column entries of Tables 3 to 8 of

IEC 60825-1:2014 containing the numerical values or formulas of interest, and thus to

determine the AELs.

Next, the measurement conditions shall be determined (5.4 and Table 10 of IEC 60825-1:2014).

For a pulsed laser, several conditions given in 4.3 f) of IEC 60825-1:2014 shall be evaluated to

ensure all fall within the AEL.

Once the AEL has been determined, the output data should be evaluated. The output data can

be provided by the manufacturer or measured directly. If output data are provided by the

manufacturer, it shall be confirmed that the measurements were performed in accordance with

Clause 4 of IEC 60825-1:2014. If the accessible emission is less than the AEL, the laser can

be assigned to that class. For a pulsed laser, the AEL of the class applies for all emission

durations within the time base.

If the accessible emission is not less than the AEL, a higher class AEL should be chosen and

assessed. This is repeated until the AEL is not exceeded or the laser product is assigned to

Class 4.

The system shall be evaluated in accordance with IEC 60825-1:2014 to ensure that a

reasonably foreseeable single fault condition cannot cause the laser to emit radiation higher

than the AEL for the assigned class. If this criterion is met, the laser classification is known.

Risk analysis can be applied to determine whether a single fault condition is reasonably

foreseeable. A method to analyse the single fault condition is to impose the single component

faults, one at a time, that have been identified as reasonably foreseeable. Single fault conditions

can also be assessed by other methods than physically inducing the fault for the test, but that

is not treated in this document.

The unit should be emitting radiation as in normal operation or reduced when the single

component fault is imposed. If the single component fault causes the laser to emit sustained

radiation higher than the AEL for the assigned class, then the higher class is assigned. If the

single component fault causes the laser to emit radiation higher than the AEL for the assigned

class but only for a short spike, for example by automatic emission reduction, and an exposure

to a person is unlikely during that time, the system should remain in the assigned class.

Figure 1 – Continuous wave laser classification flow

Figure 2 – Pulsed laser classification flow

NOTE 1 There can be more than one condition to be met if a product is to be assigned a certain class. For instance,

in the wavelength region 400 nm to 600

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...