IEC TS 62885-1:2026

(Main)Surface cleaning appliances - Part 1: General requirements on test material and test equipment

Surface cleaning appliances - Part 1: General requirements on test material and test equipment

IEC TS 62885-1:2026 specifies the physical characteristics of test equipment and material used in tests common to several products covered by IEC 62285 series for surface cleaning appliances. In addition, it provides guidance regarding the evaluation of Wilton and other types of carpets to determine their acceptability for testing and regarding the pre-treatment of test dust.

This fourth edition cancels and replaces the third edition published in 2020.

This edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous edition:

a) Almost all of the test equipment is adopted from IEC 62885-2:2021.

b) Test equipment and materials for wet cleaning is included.

c) A description of the verification of an in-house reference vacuum cleaner is added.

d) Information about the reference vacuum cleaner system RSB is added.

General Information

- Status

- Published

- Publication Date

- 02-Feb-2026

- Technical Committee

- SC 59F - Surface cleaning appliances

- Drafting Committee

- WG 9 - TC 59/SC 59F/WG 9

- Current Stage

- PPUB - Publication issued

- Start Date

- 03-Feb-2026

- Completion Date

- 27-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC TS 62885-1:2026 is the fourth edition of the International Electrotechnical Commission’s (IEC) technical specification for surface cleaning appliances. Titled “Surface cleaning appliances - Part 1: General requirements on test material and test equipment,” this document defines the physical characteristics and requirements for test materials and equipment used in standardized tests across various surface cleaning devices, as covered by the IEC 62885 series. This edition introduces updates reflecting the adoption of equipment from IEC 62885-2:2021, expands coverage to wet cleaning test apparatus and materials, and includes guidance on in-house and standardized reference vacuum cleaners, notably the RSB system.

By providing a harmonized framework for test equipment and materials, IEC TS 62885-1:2026 ensures accurate, reproducible performance testing for manufacturers, laboratories, and certification bodies in the surface cleaning appliance industry.

Key Topics

Test Equipment Specifications

- Physical attributes and setups for both dry and wet cleaning performance evaluations

- Adoption of most equipment now aligned with IEC 62885-2:2021

- Mechanical operators, dust spreaders, test plates, embedding rollers, and specialized devices

Test Materials

- Requirements for carpets (such as Wilton and level loop) and hard floor surfaces

- Guidance for simulated household dust, mineral dust, and granular debris parameters

- Instructions for pre-treating test dust and carpets to standardize testing

Wet Cleaning Additions

- Inclusion of test equipment and materials specifically for wet cleaners, such as tools for applying stains and soils, water measuring equipment, and floor tile preparation fixtures

Reference Vacuum Cleaners

- Procedures for verifying in-house reference vacuum cleaners for reliable internal comparison

- Introduction and application of the RSB reference vacuum cleaner system for interlaboratory testing, supporting better reproducibility and result consistency

Evaluation Guidance

- Criteria for assessing the suitability of carpets and other surfaces for testing purposes

- Maintenance directions for reference devices (detailed in annexes)

Applications

IEC TS 62885-1:2026 is essential for:

- Testing Laboratories: Ensures that equipment and materials used in performance tests (for suction, filtration, noise, and surface suitability) are consistent, accurate, and repeatable.

- Appliance Manufacturers: Facilitates the development and validation of floor-cleaning devices-including vacuum cleaners and wet cleaning machines-by providing reliable benchmarks for performance claims and regulatory compliance.

- Certification and Quality Assurance: Supports third-party certification schemes by establishing standardized test conditions, enhancing market confidence in product comparability.

- Research and Development: Provides a consistent foundation for product improvement and innovation in cleaning appliance technology, leveraging standardized test materials and methods.

The specification also improves international comparability for results, which is critical for global market access and conformity assessment.

Related Standards

Organizations applying IEC TS 62885-1:2026 should also be aware of related and referenced standards in the sector, including:

- IEC 62885-2:2021: Methods for measuring the performance of dry vacuum cleaners for household or similar use

- IEC/ASTM 62885-7:2020: Methods for measuring the performance of dry-cleaning robots

- IEC 60704-2-1:2020: Test code for airborne acoustical noise of dry vacuum cleaners

- ISO Standards:

- ISO 1763 & ISO 1765: Specifications for textile floor coverings

- ISO 12103-1: Test contaminants for filter evaluation

- ISO 5011: Inlet air cleaning equipment performance testing

- ISO 13320: Particle size analysis by laser diffraction

- BS Standards:

- BS 4223, BS 8459: Methods for determining carpet and textile details

Adherence to IEC TS 62885-1:2026 ensures compatibility with ongoing updates in the IEC 62885 series and supports global uniformity in surface cleaning appliance testing. This contributes to improved product quality, consumer safety, and streamlined market approval processes worldwide.

Frequently Asked Questions

IEC TS 62885-1:2026 is a technical specification published by the International Electrotechnical Commission (IEC). Its full title is "Surface cleaning appliances - Part 1: General requirements on test material and test equipment". This standard covers: IEC TS 62885-1:2026 specifies the physical characteristics of test equipment and material used in tests common to several products covered by IEC 62285 series for surface cleaning appliances. In addition, it provides guidance regarding the evaluation of Wilton and other types of carpets to determine their acceptability for testing and regarding the pre-treatment of test dust. This fourth edition cancels and replaces the third edition published in 2020. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) Almost all of the test equipment is adopted from IEC 62885-2:2021. b) Test equipment and materials for wet cleaning is included. c) A description of the verification of an in-house reference vacuum cleaner is added. d) Information about the reference vacuum cleaner system RSB is added.

IEC TS 62885-1:2026 specifies the physical characteristics of test equipment and material used in tests common to several products covered by IEC 62285 series for surface cleaning appliances. In addition, it provides guidance regarding the evaluation of Wilton and other types of carpets to determine their acceptability for testing and regarding the pre-treatment of test dust. This fourth edition cancels and replaces the third edition published in 2020. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) Almost all of the test equipment is adopted from IEC 62885-2:2021. b) Test equipment and materials for wet cleaning is included. c) A description of the verification of an in-house reference vacuum cleaner is added. d) Information about the reference vacuum cleaner system RSB is added.

IEC TS 62885-1:2026 is classified under the following ICS (International Classification for Standards) categories: 97.080 - Cleaning appliances. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TS 62885-1:2026 has the following relationships with other standards: It is inter standard links to IEC TS 62885-1:2020. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC TS 62885-1:2026 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC TS 62885-1 ®

Edition 4.0 2026-02

TECHNICAL

SPECIFICATION

Surface cleaning appliances -

Part 1: General requirements on test material and test equipment

ICS 97.080 ISBN 978-2-8327-1027-2

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or

by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either

IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC copyright

or have an enquiry about obtaining additional rights to this publication, please contact the address below or your local

IEC member National Committee for further information.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - IEC Products & Services Portal - products.iec.ch

webstore.iec.ch/advsearchform Discover our powerful search engine and read freely all the

The advanced search enables to find IEC publications by a publications previews, graphical symbols and the glossary.

variety of criteria (reference number, text, technical With a subscription you will always have access to up to date

committee, …). It also gives information on projects, content tailored to your needs.

replaced and withdrawn publications.

Electropedia - www.electropedia.org

The world's leading online dictionary on electrotechnology,

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published containing more than 22 500 terminological entries in English

details all new publications released. Available online and and French, with equivalent terms in 25 additional languages.

once a month by email. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer

Service Centre: sales@iec.ch.

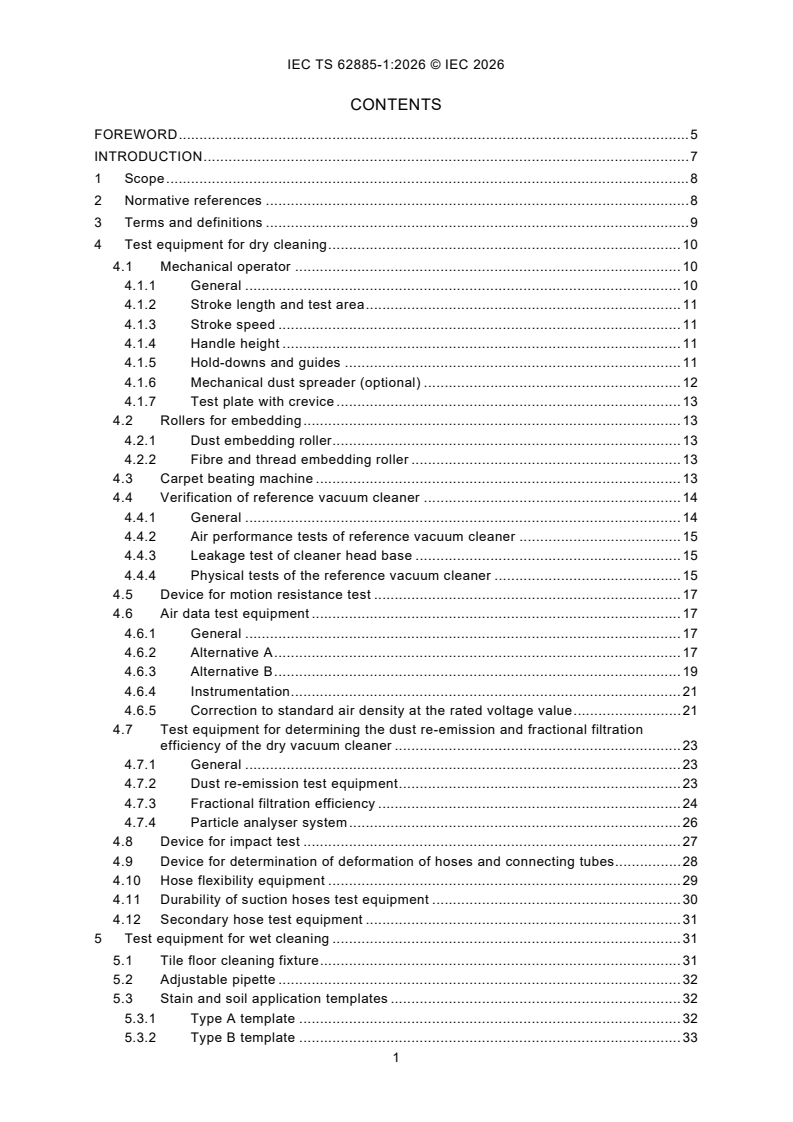

CONTENTS

FOREWORD . 5

INTRODUCTION . 7

1 Scope . 8

2 Normative references . 8

3 Terms and definitions . 9

4 Test equipment for dry cleaning . 10

4.1 Mechanical operator . 10

4.1.1 General . 10

4.1.2 Stroke length and test area . 11

4.1.3 Stroke speed . 11

4.1.4 Handle height . 11

4.1.5 Hold-downs and guides . 11

4.1.6 Mechanical dust spreader (optional) . 12

4.1.7 Test plate with crevice . 13

4.2 Rollers for embedding . 13

4.2.1 Dust embedding roller . 13

4.2.2 Fibre and thread embedding roller . 13

4.3 Carpet beating machine . 13

4.4 Verification of reference vacuum cleaner . 14

4.4.1 General . 14

4.4.2 Air performance tests of reference vacuum cleaner . 15

4.4.3 Leakage test of cleaner head base . 15

4.4.4 Physical tests of the reference vacuum cleaner . 15

4.5 Device for motion resistance test . 17

4.6 Air data test equipment . 17

4.6.1 General . 17

4.6.2 Alternative A . 17

4.6.3 Alternative B . 19

4.6.4 Instrumentation . 21

4.6.5 Correction to standard air density at the rated voltage value . 21

4.7 Test equipment for determining the dust re-emission and fractional filtration

efficiency of the dry vacuum cleaner . 23

4.7.1 General . 23

4.7.2 Dust re-emission test equipment . 23

4.7.3 Fractional filtration efficiency . 24

4.7.4 Particle analyser system . 26

4.8 Device for impact test . 27

4.9 Device for determination of deformation of hoses and connecting tubes. 28

4.10 Hose flexibility equipment . 29

4.11 Durability of suction hoses test equipment . 30

4.12 Secondary hose test equipment . 31

5 Test equipment for wet cleaning . 31

5.1 Tile floor cleaning fixture . 31

5.2 Adjustable pipette . 32

5.3 Stain and soil application templates . 32

5.3.1 Type A template . 32

5.3.2 Type B template . 33

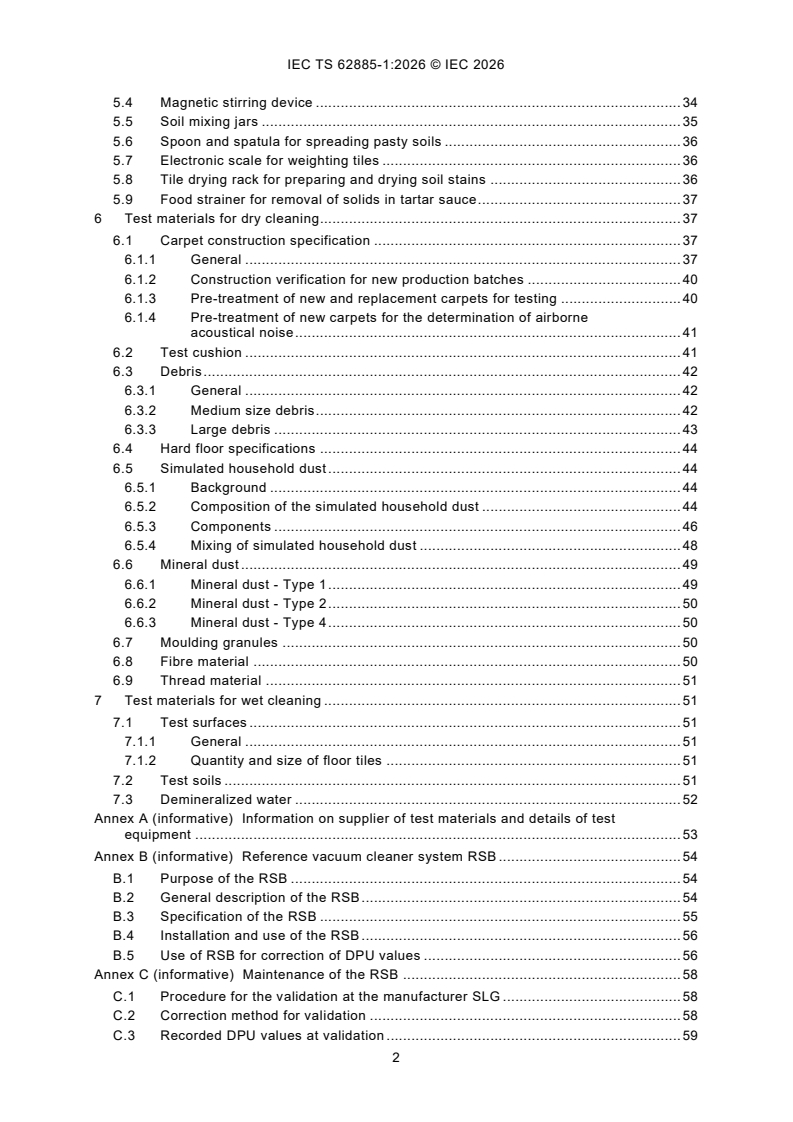

5.4 Magnetic stirring device . 34

5.5 Soil mixing jars . 35

5.6 Spoon and spatula for spreading pasty soils . 36

5.7 Electronic scale for weighting tiles . 36

5.8 Tile drying rack for preparing and drying soil stains . 36

5.9 Food strainer for removal of solids in tartar sauce . 37

6 Test materials for dry cleaning . 37

6.1 Carpet construction specification . 37

6.1.1 General . 37

6.1.2 Construction verification for new production batches . 40

6.1.3 Pre-treatment of new and replacement carpets for testing . 40

6.1.4 Pre-treatment of new carpets for the determination of airborne

acoustical noise . 41

6.2 Test cushion . 41

6.3 Debris . 42

6.3.1 General . 42

6.3.2 Medium size debris . 42

6.3.3 Large debris . 43

6.4 Hard floor specifications . 44

6.5 Simulated household dust . 44

6.5.1 Background . 44

6.5.2 Composition of the simulated household dust . 44

6.5.3 Components . 46

6.5.4 Mixing of simulated household dust . 48

6.6 Mineral dust . 49

6.6.1 Mineral dust - Type 1 . 49

6.6.2 Mineral dust - Type 2 . 50

6.6.3 Mineral dust - Type 4 . 50

6.7 Moulding granules . 50

6.8 Fibre material . 50

6.9 Thread material . 51

7 Test materials for wet cleaning . 51

7.1 Test surfaces . 51

7.1.1 General . 51

7.1.2 Quantity and size of floor tiles . 51

7.2 Test soils . 51

7.3 Demineralized water . 52

Annex A (informative) Information on supplier of test materials and details of test

equipment . 53

Annex B (informative) Reference vacuum cleaner system RSB . 54

B.1 Purpose of the RSB . 54

B.2 General description of the RSB . 54

B.3 Specification of the RSB . 55

B.4 Installation and use of the RSB . 56

B.5 Use of RSB for correction of DPU values . 56

Annex C (informative) Maintenance of the RSB . 58

C.1 Procedure for the validation at the manufacturer SLG . 58

C.2 Correction method for validation . 58

C.3 Recorded DPU values at validation . 59

C.4 Procedure for checking the air-technical data by the user . 60

Annex D (informative) Determination of carpet pile direction . 62

Annex E (normative) Hard floorboard realization, floor support and floor pattern . 63

Annex F (informative) Information on materials for wet cleaning tests . 64

Bibliography . 65

Figure 1 – Mechanical operator for tests of dust or debris removal from carpets or hard

floors and of motion resistance . 10

Figure 2 – Carpet hold-downs and guides . 12

Figure 3 – Dust spreader and roller for embedding dust into carpets . 12

Figure 4 – Test plate with crevice . 13

Figure 5 – Carpet beating machine . 14

Figure 6 – Alternative A equipment for air data tests . 18

Figure 7 – Measuring box for alternative A . 18

Figure 8 – Alternative B equipment for air data tests . 20

Figure 9 – Test hood . 23

Figure 10 – Intake aerosol channel with sampling probe . 24

Figure 11 – Exhaust channel with sampling probe . 24

Figure 12 – Equipment diagram for filtrationand dust re-emission testing . 25

Figure 13 – Modified test hood . 26

Figure 14 – Drum for impact test . 28

Figure 15 – Device for testing deformation of hoses and connecting tubes. 29

Figure 16 – Hose flexibility equipment . 30

Figure 17 – Equipment for repeated bending of hoses . 30

Figure 18 – Equipment for durability testing of secondary hoses . 31

Figure 19 – Tile floor cleaning fixture with guides and stroke pacing device . 32

Figure 20 – Adjustable pipette . 32

Figure 21 – Stain application template (type A) . 33

Figure 22 – Silicone soil grime application template (type B) . 34

Figure 23 – Magnetic stirring device (example) . 35

Figure 24 – 475 ml glass mixing jar example . 35

Figure 25 – Spoon and spatula examples . 36

Figure 26 – Electronic scale example . 36

Figure 27 – Tile drying rack example . 37

Figure 28 – Food strainer example . 37

Figure 29 – Comparison between non-organic and organic medium size debris . 43

Figure 30 – Comparison between non-organic and organic large debris . 43

Figure 31 – Household dust . 45

Figure 32 – Ready mixed simulated household dust . 46

Figure 33 – Tumbler mixer . 48

Figure 34 – Order of sampling (star-shaped) . 49

Figure 35 – Sampling of simulated household dust . 49

Figure B.1 – RSB with passive and active nozzle and vacuum measuring box . 55

Figure D.1 – Looking against the pile direction . 62

Figure D.2 – Looking with the pile direction . 62

Figure E.1 – Dimensions of the floorboard and mounting on a test rig . 63

Figure E.2 – Pattern of hard floor planks . 63

Table 1 – Nominal diameters of orifices . 20

Table 2 – Graduation of eight size classes for particle sizes 0,3 µm to 10 µm . 27

Table 3 – Distance between holes . 33

Table 4 – Inside dimension (b) . 34

Table 5 – Wilton test carpet construction specifications . 38

Table 6 – Level loop test carpet construction specifications . 39

Table 7 – Cushion slip specification . 42

Table 8 – Specifications of nuts and set crews . 43

Table 9 – Specification of cap nuts . 44

Table 10 – Particle size distribution: Type 3 mineral dust . 46

Table 11 – Cellulose dust composition . 47

Table 12 – Cellulose dust fibre size distribution . 47

Table 13 – Cotton linters characteristics . 47

Table 14 – Grain size distribution: Type 1 mineral dust . 50

Table 15 – Grain size distribution: Type 2 mineral dust . 50

Table 16 – Soils, composition, tools . 51

Table B.1 – Dust removal from SLG Wilton master carpets BIC4 with passive nozzle . 55

Table B.2 – Dust removalfrom SLG Wilton master carpets BIC4 with active nozzle . 56

Table B.3 – Environmental conditions . 56

Table C.1 – Correction method - Key . 59

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

Surface cleaning appliances -

Part 1: General requirements on test material and test equipment

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for

standardization comprising all national electrotechnical committees (IEC National Committees).

The object of IEC is to promote international co-operation on all questions concerning

standardization in the electrical and electronic fields. To this end and in addition to other

activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National

Committee interested in the subject dealt with may participate in this preparatory work.

International, governmental and non-governmental organizations liaising with the IEC also

participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two

organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as

possible, an international consensus of opinion on the relevant subjects since each technical

committee has representation from all interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted

by IEC National Committees in that sense. While all reasonable efforts are made to ensure that

the technical content of IEC Publications is accurate, IEC cannot be held responsible for the

way in which they are used or for any misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC

Publications transparently to the maximum extent possible in their national and regional

publications. Any divergence between any IEC Publication and the corresponding national or

regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies

provide conformity assessment services and, in some areas, access to IEC marks of conformity.

IEC is not responsible for any services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including

individual experts and members of its technical committees and IEC National Committees for

any personal injury, property damage or other damage of any nature whatsoever, whether direct

or indirect, or for costs (including legal fees) and expenses arising out of the publication, use

of, or reliance upon, this IEC Publication or any other IEC Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced

publications is indispensable for the correct application of this publication.

9) IEC draws attention to the possibility that the implementation of this document may involve

the use of (a) patent(s). IEC takes no position concerning the evidence, validity or applicability

of any claimed patent rights in respect thereof. As of the date of publication of this document,

IEC had not received notice of (a) patent(s), which may be required to implement this document.

However, implementers are cautioned that this may not represent the latest information, which

may be obtained from the patent database available at https://patents.iec.ch. IEC shall not be

held responsible for identifying any or all such patent rights.

IEC TS 62885-1 has been prepared by subcommittee 59F: Surface cleaning appliances, of IEC

technical committee 59: Performance of household and similar electrical appliances. It is a

Technical Specification.

This fourth edition cancels and replaces the third edition published in 2020. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) Almost all of the test equipment is adopted from IEC 62885-2:2021.

b) Test equipment and materials for wet cleaning is included.

c) A description of the verification of an in-house reference vacuum cleaner is added.

d) Information about the reference vacuum cleaner system RSB is added.

The text of this Technical Specification is based on the following documents:

Draft Report on voting

59F/540/DTS 59F/554/RVDTS

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this Technical Specification is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/publications.

A list of all the parts in the IEC 62885 series, under the general title Surface cleaning

appliances, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

– reconfirmed,

– withdrawn, or

– revised.

INTRODUCTION

IEC subcommittee 59F has agreed to make a collection of test material and test equipment

used in standards for testing surface cleaning appliances and to publish this collection as a

technical specification.

Regular maintenance of the technical specification ensures that other standards that refer to

this TS always reference the current status regarding test material and test equipment.

The intention with this document is to ensure a minimum of test material types and common

use of these materials in tests of various surface cleaning appliances.

For information on supplies of test materials and details of test equipment, see Annex A.

1 Scope

This part of IEC 62885, which is a Technical Specification, specifies the physical characteristics

of test equipment and material used in tests common to several products covered by IEC 62885

(all parts) for surface cleaning appliances. In addition, it provides guidance regarding the

evaluation of Wilton and other types of carpets to determine their acceptability for testing and

regarding the pre-treatment of test dust.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60688, Electrical measuring transducers for converting AC and DC electrical quantities to

analogue or digital signals

IEC 60704-2-1:2020, Household and similar electrical appliances - Test code for the

determination of airborne acoustical noise - Part 2-1: Particular requirements for dry vacuum

cleaners

IEC 60734:2012, Household electrical appliances - Performance - Water for testing

IEC 62885-2:2021, Surface cleaning appliances - Part 2: Dry vacuum cleaners for household

or similar use - Methods for measuring the performance

IEC 62885-2, Surface cleaning appliances - Part 2: Dry vacuum cleaners for household or

similar use - Methods for measuring the performance

IEC/ASTM 62885-7:2020, Surface cleaning appliances - Part 7: Dry-cleaning robots for

household or similar use - Methods for measuring the performance

IEC/ASTM 62885-7:2020/AMD1:2022, Amendment 1 - Surface cleaning appliances - Part 7:

Dry cleaning robots for household or similar use - Methods for measuring the performance

ISO 1763, Textile floor coverings - Determination of number of tufts and/or loops per unit length

and per unit area

ISO 1765, Machine-made textile floor coverings - Determination of thickness

ISO 1766, Textile floor coverings - Determination of thickness of pile above the substrate

ISO 1833-1, Textiles - Quantitative chemical analysis - General principles of testing

ISO 2060, Textiles - Yarn from packages - Determination of linear density (mass per unit length)

by the skein method

ISO 2061, Textiles - Determination of twist in yarns - Direct counting method

ISO 2424, Textile floor coverings - Vocabulary

ISO 2439, Title missing - Legacy paper document

ISO 3386-1, Polymeric materials, cellular flexible — Determination of stress-strain

characteristics in compression — Part 1: Low-density materials

ISO 4032, Hexagon nuts (style 1) - Product grades A and B

ISO 4766, Slotted set screws with flat point

ISO 5011:2020, Inlet air cleaning equipment for internal combustion engines and compressors

— Performance testing

ISO 5167-1:2022, Measurement of fluid flow by means of pressure differential devices inserted

in circular cross-section conduits running full — Part 1: General principles and requirements

ISO 5167-1, Measurement of fluid flow by means of pressure differential devices inserted in

circular cross-section conduits running full — Part 1: General principles and requirements

ISO 5167-2:2022, Measurement of fluid flow by means of pressure differential devices inserted

in circular cross-section conduits running full — Part 2: Orifice plates

ISO 6989, Textile fibres - Determination of length and length distribution of staple fibres (by

measurement of single fibres)

ISO 8543, Textile floor coverings - Methods for determination of mass

ISO 12103-1, Road vehicles — Test contaminants for filter evaluation — Part 1: Arizona test

dust

ISO 13320, Particle size analysis — Laser diffraction methods

BS 4223, Methods for determination of constructional details of carpets with yarn pile

BS 8459, Determination of extractable matter in textiles - Method

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

– IEC Electropedia: available at http://www.electropedia.org/

– ISO Online browsing platform: available at http://www.iso.org/obp

3.1

interlaboratory testing

testing the same samples in different laboratories, with different operators, and comparing the

results

3.2

in-house reference vacuum cleaner

electrically operated laboratory equipment designated for internal comparison within a

laboratory

3.3

reference vacuum cleaner system

RSB

electrically operated laboratory equipment intended to provide different laboratories with a

similarly constructed vacuum cleaner to measure the reference dust removal ability on Wilton

test carpets for passive and active nozzles to improve the reproducibility of results

Note 1 to entry: The reference vacuum cleaner system RSB can be used with active or passive nozzles.

Note 2 to entry: The reference vacuum cleaner system RSB is not intended for tests other than dust pick-up and

motion resistance using Wilton test carpets.

Note 3 to entry: The reference vacuum cleaner system RSB is described in Annex B. Maintenance of the RSB is

described in Annex C.

4 Test equipment for dry cleaning

4.1 Mechanical operator

4.1.1 General

The construction principle of a mechanical operator is indicated in Figure 1. It consists of a rigid

support with a linear drive capable of carrying out single and double strokes over the test

surface (carpet or hard floor), and is kept in position by hold-downs. As shown in Figure 1, the

equipment can be adapted to tests of motion resistance as described in IEC 62885-2:2021 [2]

(motion resistance), allowing its wooden plate a sufficient freedom of movement in the direction

of the strokes.

NOTE The linear drive can be motorized or operated by hand.

Figure 1 – Mechanical operator for tests of dust or debris removal from carpets or hard

floors and of motion resistance

The spur racks, which suggest a way to bring about the vibratory action to the dust spreader

depicted in Figure 1, have no function in the motion resistance test.

4.1.2 Stroke length and test area

Unless otherwise specified within the particular product standard, the length of the test area is

(700 ± 5) mm and the width of the test area is equal to the cleaning head width.

A length of at least 200 mm shall be added before the beginning of the test area and at least

300 mm after the end of the test area in order to allow acceleration and deceleration of the

cleaning head.

Thus, the stroke length is at least 1 200 mm for the given test length of 700 mm. The centre

line of the front edge of the cleaning head is aligned to the centre line of the beginning of the

acceleration area at the commencement of the stroke, allowing the distance of 200 mm to be

used for acceleration. The cleaning head shall reach the end of the stroke when the rear edge

of the active depth of the cleaning head is at least 200 mm past the end of the test area, thus

allowing a suitable distance for deceleration. The return stroke is carried out in the same

manner until the front edge of the cleaning head is once again lined up with the beginning of

the acceleration length in front of the test area.

4.1.3 Stroke speed

Unless otherwise specified within the particular product standard, the active depth of the

cleaning head shall move at uniform stroke speed (0,50 ± 0,02) m/s and in a straight line over

the test area.

Two hold-downs in accordance with 4.1.5 act as guides to keep the cleaning head in a straight

line as it is moved over the test area and to ensure an undisturbed flow.

Dry vacuum cleaners equipped with a self-drive device shall be operated at the prescribed

stroke speed of (0,5 ± 0,02) m/s, if possible. Otherwise, the stroke speed will be determined by

the dry vacuum cleaner.

4.1.4 Handle height

Unless otherwise specified in the particular product standard, the grip of cleaners with suction

hose or the handle of other cleaners pivot at a height of (800 ± 50) mm above the test surface.

Any telescopic tubes or sticks shall be extended to maximum length. For nozzles without

pivoting connectors, it shall be ensured that the bottom of the cleaning head be made parallel

with the test surface by adjusting the handle height within the tolerances. If this is not possible,

the length of a telescopic tube or stick can be adjusted. Any adjustment shall be reported.

4.1.5 Hold-downs and guides

The two hold-downs shall be at least 1,4 m × 0,05 m × 0,05 m in dimension and weigh 10 kg/1,4

m each. They shall be designed in such a way so as not to obstruct the air flow at the sides of

the cleaning head (see Figure 2). The edges of the hold-downs adjacent to the cleaning head

should be treated to reduce friction. Pegs can be omitted within the test length.

Low-friction adhesive tape can be used to reduce friction.

The hold-downs shall be placed on either side of the test area with a clearance of not more

than 2 mm on both sides of the cleaning head.

Dimensions in millimetres

Figure 2 – Carpet hold-downs and guides

4.1.6 Mechanical dust spreader (optional)

The device consists of a tray extending across the width of the test area and mounted on a

trolley, which can be moved along the length of the test area without impinging upon it. When

the trolley is moved back and forth over the test area, a vibratory action causes the test dust,

which has been placed evenly along the tray, to emerge from a line of suitably sized holes along

the base of the tray, equally spaced and sufficient in number to cover the test area uniformly

with test dust.

The vibratory action can be brought about by an incorporated vibrator or by the trolley running

on spur racks as indicated in Figure 3.

Figure 3 – Dust spreader and roller for embedding dust into carpets

4.1.7 Test plate with crevice

The equipment consists of a wood panel provided with a removable insert of aluminium having

a (3 ± 0,05) mm wide and (10 ± 0,05) mm deep smooth crevice (see Figure 4).

The crevice insert shall lie at the same level as the rest of the surface used for floor simulation.

Figure 4 – Test plate with crevice

The length of the crevice should be approximately twice the outside width of the cleaning head.

4.2 Rollers for embedding

4.2.1 Dust embedding roller

The roller shall have a diameter of 50 mm and a length of at least 380 mm such that it is at

least 20 mm longer than the width of the dust-covered area. The roller is preferably made of

steel and polished. It can be provided with a handle for rolling by hand or be driven by a

motorized unit.

The mass of the roller, if applicable, shall be 10 kg/m. The roller can be incorporated into the

dust spreader as indicated in Figure 3.

4.2.2 Fibre and thread embedding roller

The roller shall have a diameter of 70 mm and a mass of 30 kg/m. The roller is preferably made

of solid steel and polished. It can be provided with a handle for rolling by hand or be driven by

a motorized unit. A convenient mass for rolling by hand is 15 kg.

4.3 Carpet beating machine

Whatever method or machine is used for the removal of residual test dust from the test carpet

shall not damage the carpet or the carpet backing. Figure 5 illustrates one example of a machine

suitable for removing all residual dust. This particular design consists of a horizontal cylinder

provided with thongs to beat the backing of the carpet when it is fed back and forth under the

rotating cylinder. Verification of reconditioning shall follow the procedure provided in the

particular product standard.

Figure 5 – Carpet beating machine

4.4 Verification of reference vacuum cleaner

4.4.1 General

In-house reference vacuum cleaners are devices used to control or determine variations in test

materials. All in-house reference vacuum cleaners utilized within a laboratory are recommended

to be verified on a regular basis using an appropriate method. Verification of an in-house

reference vacuum cleaner means to proof or improve its accuracy, i.e. its precision and

trueness.

In addition to in-house reference vacuum cleaners in general, the uniform reference vacuum

cleaner system RSB is a measuring aid exclusively used for the observation or correction of

dust pick-up test results on Wilton carpet related to daily variations of the carpet condition,

panel-to-panel deviations and changes in laboratory conditions. Thus, the RSB is a reference

vacuum cleaner designed to improve reproducibility in order to compare results across

laboratories. Therefore, the RSB shall be regularly validated by the RSB manufacturer every 3

years or 2 000 trials, whichever occurs first. Validation of the RSB means to improve the degree

of validity of this measuring aid by finding suitable validation values. Thus, the validation is

associated with the determination of the validation value DPUcal by means of testing the RSB

together with RSB 00 and is reported in a validation protocol.

The performance of the in-house reference vacuum cleaners utilized within a laboratory shall

be verified on a regular bases using an appropriate method. This also applies to the RSB if

used as an in-house reference vacuum cleaner. Appropriate verification methods are listed in

4.4.2 to 4.4.4.

Proper verification requires both air data tests of the in-house reference vacuum cleaner and

physical tests of its cleaner head appropriate to the floor type the in-house reference vacuum

cleaner is intended for. Measured and calculated values for the initial evaluations shall be

recorded as baseline values for future verification test results. The future verification tests shall

be conducted at least every 50 trials. Previous test results should be questioned if any issues

occur.

4.4.2 Air performance tests of reference vacuum cleaner

The air data of the reference vacuum cleaner shall be tested per IEC 62885-2:2021, 5.11,

alternative B with the base of the floor nozzle being connected to the plenum chamber. The

connecting tube, if present, shall be fully extended. The reference vacuum cleaner shall be set

to its maximum continuous performance level and all manual pressure relief valves shall be

closed. The corrected vacuum and input power (P ) for the 30 mm orifice plate from the initial

evaluation shall be recorded as the baseline values for future comparisons. Additional orifice

plates can be used if desired.

).

There shall be no greater than a ±10 % variation allowed for either vacuum or imput power (P

Should the values differ by more than the ±10 % limit, the in-house reference vacuum cleaner

shall be examined for possible damage including misplaced seals, cracked hoses or tubes,

incorrectly set power settings or fatigue of the fan.

4.4.3 Leakage test of cleaner head base

Additionally to the determination of air data, it can be helpful to check the leakage of the floor

nozzle or cleaner head.

Use a vacuum test box with a height of at least 100 mm, with a pressure probe in the centre of

the backmost wall, with a fixed or adjustable orifice in the middle of the front wall and with a top

surface larger than the cleaner head to be tested and on which the cleaner head can be placed

in a clearly repeatable manner. T

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...