SIST EN 18071:2026

(Main)Inland navigation vessels - Methanol bunkering

Inland navigation vessels - Methanol bunkering

This document specifies requirements for methanol bunkering transfer systems to and from inland navigation vessels. The various scenarios for the bunker facility operator concern land, truck and vessel (barge). It concerns design, dimensions and technical requirements for the transfer of methanol, including the nozzle, connection, inner and outer flanges and failsafe features.

This document also specifies the process and procedures for the bunkering operations, as well as responsibilities and risk assessment scope, taking into consideration the specific hazards in handling and bunkering methanol fuel. Next to this, the requirement for the methanol provider to provide a bunker delivery note and training and qualification of personnel involved.

This document is not applicable to cargo operations.

Fahrzeuge der Binnenschifffahrt - Bunkerung von Methanol

Dieses Dokument legt Anforderungen an Systeme für das Bunkern von Methanol zum Transfer von und zu Fahrzeugen der Binnenschifffahrt fest. Die verschiedenen Szenarien für den Betreiber der Bunkereinrichtung beinhalten Land, Lastkraftwagen und Seefahrzeug (Schleppkahn). Es betrifft Auslegung, Maße und technische Anforderungen für den Transfer von Methanol einschließlich Füllstutzen, Anschluss, Vor- und Rücksprungflansch und Betriebssicherheitsmerkmale.

Dieses Dokument legt ebenfalls den Prozess und Verfahren für die Bunkervorgänge, Verantwortlichkeiten und Umfang der Risikobeurteilung unter Berücksichtigung der spezifischen Gefährdungen beim Handhaben und Bunkern von Methanolkraftstoff fest. Daneben gilt die Anforderung, dass der Methanollieferant einen Bunkerlieferschein ausstellen sowie für Schulung und Qualifizierung des betreffenden Personals sorgen muss.

Dieses Dokument gilt nicht für den Frachtbetrieb.

Bateaux de navigation intérieure - Avitaillement en méthanol

Le présent document définit les exigences relatives aux systèmes de transfert pour l’avitaillement en méthanol vers et depuis les bateaux de navigation intérieure. Pour l’exploitant d’une installation d’avitaillement, les divers scénarios ont trait à l’avitaillement depuis la terre, depuis un camion et depuis un bateau (barge). Sont concernées notamment la conception, les dimensions et les exigences techniques relatives au transfert de méthanol, y compris les caractéristiques des buses, des connexions, des brides internes et externes et des dispositifs à sécurité intégrée.

Le présent document spécifie également les processus et procédures applicables aux opérations d’avitaillement ainsi que le périmètre des responsabilités et de l’évaluation des risques, en prenant en considération les dangers spécifiques liés à la manutention et à l’avitaillement en méthanol. Par ailleurs, est également traitée l’exigence relative à la fourniture d’un bon de livraison de soute par le fournisseur de méthanol et à son obligation d’assurer la formation et la qualification du personnel impliqué.

Le présent document ne s’applique pas aux opérations de fret.

Plovila za celinske vode - Oskrba z metanolom

General Information

- Status

- Published

- Public Enquiry End Date

- 22-Oct-2024

- Publication Date

- 17-Nov-2025

- Technical Committee

- I13 - Imaginarni 13

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 14-Nov-2025

- Due Date

- 19-Jan-2026

- Completion Date

- 18-Nov-2025

Overview

EN 18071:2025 (CEN) - "Inland navigation vessels - Methanol bunkering" specifies safety, design and operational requirements for methanol bunkering of inland navigation vessels. It covers methanol transfer systems between land, truck and bunker vessels (barge) and the receiving vessel manifold. The standard addresses transfer equipment (nozzles, couplings, inner/outer flanges), failsafe features, emergency shutdown (ESD) links, procedural controls, risk assessment and personnel training. EN 18071:2025 is intended to harmonize bunkering practices across Europe and supports regulatory frameworks such as ES-TRIN.

Key Topics

- Transfer system design and technical requirements: design, dimensions and materials for nozzles, flanges, couplings and transfer arms or hoses; identification and maintenance requirements for methanol transfer systems.

- Failsafe features and emergency systems: requirements for Emergency Shut Down (ESD) systems and safety dry break‑away couplings (SBC) to limit spillage and mechanical loads during disconnection or pull‑away events.

- Operational procedures and controlled zones: defined procedures for safe bunkering operations, mooring, vapour management and establishment of safety and controlled zones during transfer.

- Risk assessment and safety management: scope and methodology for assessing methanol‑specific hazards, acceptable operational parameters and vessel safety assessments prior to bunkering.

- Documentation and traceability: requirement for a Bunker Delivery Note (BDN) specifying quantity and quality, procedures manuals and maintenance documentation.

- Personnel training and qualifications: training and record requirements for vessel crews, bunker facility personnel, hose/watch and manifold/watch roles in line with ES-QIN and safety management systems.

- Maintenance and inspection: maintenance manuals and inspection criteria to ensure ongoing compliance and safe operation of transfer systems.

Applications

EN 18071 is practical for:

- Vessel owners/operators converting or operating inland navigation vessels on methanol fuel.

- Bunker facility operators (fixed terminals, truck, train or barge suppliers) designing transfer interfaces and operational procedures.

- Port authorities, inspection bodies and classification societies enforcing compliance and conducting inspections.

- Designers and equipment manufacturers producing methanol‑compatible nozzles, flanges, hoses, couplings and ESD interfaces.

- Training organizations developing qualification programs and records for bunkering personnel.

Use cases include designing compliant bunkering manifolds, defining site procedures and checklists, conducting risk assessments, and producing compliant BDNs for methanol fuel deliveries.

Related Standards (if applicable)

- EN ISO 20519 - bunkering of LNG-fuelled vessels (reference model)

- EN 13765, EN 12115 - hose and hose assembly specifications

- EN 1092-1 - flanges and joints

- EN 14420-6 - tank truck couplings

- EN IEC 60309-1 - industrial plugs/sockets

- ASTM F1122-22 - quick disconnect couplings

- ES-TRIN, ES-QIN - inland navigation technical requirements and qualifications

Keywords: EN 18071, methanol bunkering, inland navigation vessels, bunkering transfer systems, Bunker Delivery Note, ESD, safety dry break‑away coupling, risk assessment, personnel training.

Frequently Asked Questions

SIST EN 18071:2026 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Inland navigation vessels - Methanol bunkering". This standard covers: This document specifies requirements for methanol bunkering transfer systems to and from inland navigation vessels. The various scenarios for the bunker facility operator concern land, truck and vessel (barge). It concerns design, dimensions and technical requirements for the transfer of methanol, including the nozzle, connection, inner and outer flanges and failsafe features. This document also specifies the process and procedures for the bunkering operations, as well as responsibilities and risk assessment scope, taking into consideration the specific hazards in handling and bunkering methanol fuel. Next to this, the requirement for the methanol provider to provide a bunker delivery note and training and qualification of personnel involved. This document is not applicable to cargo operations.

This document specifies requirements for methanol bunkering transfer systems to and from inland navigation vessels. The various scenarios for the bunker facility operator concern land, truck and vessel (barge). It concerns design, dimensions and technical requirements for the transfer of methanol, including the nozzle, connection, inner and outer flanges and failsafe features. This document also specifies the process and procedures for the bunkering operations, as well as responsibilities and risk assessment scope, taking into consideration the specific hazards in handling and bunkering methanol fuel. Next to this, the requirement for the methanol provider to provide a bunker delivery note and training and qualification of personnel involved. This document is not applicable to cargo operations.

SIST EN 18071:2026 is classified under the following ICS (International Classification for Standards) categories: 47.020.30 - Piping systems; 47.020.85 - Cargo spaces; 47.060 - Inland navigation vessels; 75.200 - Petroleum products and natural gas handling equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 18071:2026 is associated with the following European legislation: EU Directives/Regulations: 2014/94/EU, 2023/1804, 2023/1804-1; Standardization Mandates: M/581. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 18071:2026 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-januar-2026

Plovila za celinske vode - Oskrba z metanolom

Inland navigation vessels - Methanol bunkering

Fahrzeuge der Binnenschifffahrt - Bunkerung von Methanol

Bateaux de navigation intérieure - Avitaillement en méthanol

Ta slovenski standard je istoveten z: EN 18071:2025

ICS:

47.060 Jezerska in rečna plovila Inland navigation vessels

75.200 Oprema za skladiščenje Petroleum products and

nafte, naftnih proizvodov in natural gas handling

zemeljskega plina equipment

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 18071

EUROPEAN STANDARD

NORME EUROPÉENNE

November 2025

EUROPÄISCHE NORM

ICS 47.020.30; 47.060 Supersedes CWA 17540:2020

English Version

Inland navigation vessels - Methanol bunkering

Bateaux de navigation intérieure - Avitaillement en Fahrzeuge der Binnenschifffahrt - Bunkerung von

méthanol Methanol

This European Standard was approved by CEN on 8 September 2025.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2025 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 18071:2025 E

worldwide for CEN national Members.

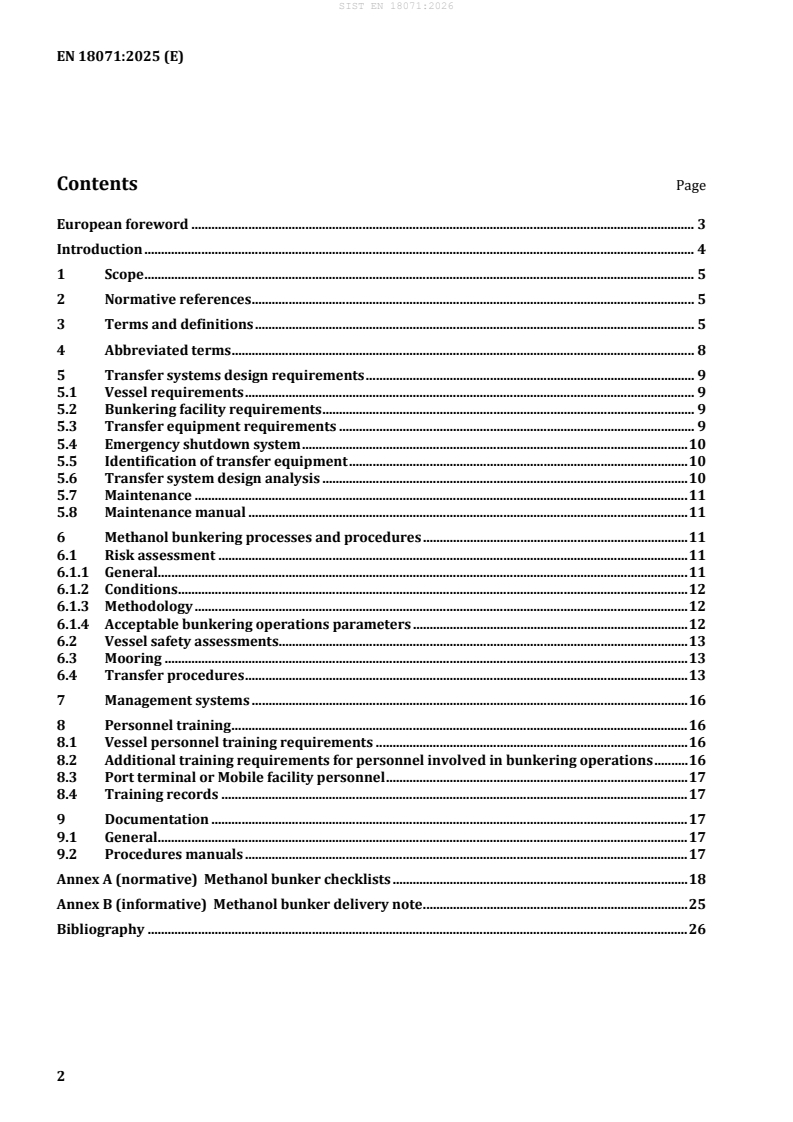

Contents Page

European foreword . 3

Introduction . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 5

4 Abbreviated terms . 8

5 Transfer systems design requirements . 9

5.1 Vessel requirements . 9

5.2 Bunkering facility requirements . 9

5.3 Transfer equipment requirements . 9

5.4 Emergency shutdown system . 10

5.5 Identification of transfer equipment . 10

5.6 Transfer system design analysis . 10

5.7 Maintenance . 11

5.8 Maintenance manual . 11

6 Methanol bunkering processes and procedures . 11

6.1 Risk assessment . 11

6.1.1 General. 11

6.1.2 Conditions . 12

6.1.3 Methodology . 12

6.1.4 Acceptable bunkering operations parameters . 12

6.2 Vessel safety assessments. 13

6.3 Mooring . 13

6.4 Transfer procedures . 13

7 Management systems . 16

8 Personnel training . 16

8.1 Vessel personnel training requirements . 16

8.2 Additional training requirements for personnel involved in bunkering operations . 16

8.3 Port terminal or Mobile facility personnel . 17

8.4 Training records . 17

9 Documentation . 17

9.1 General. 17

9.2 Procedures manuals . 17

Annex A (normative) Methanol bunker checklists . 18

Annex B (informative) Methanol bunker delivery note . 25

Bibliography . 26

European foreword

This document (EN 18071:2025) has been prepared by Technical Committee CEN/TC 15 “Inland

navigation vessels”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by May 2026, and conflicting national standards shall be

withdrawn at the latest by May 2026.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes CWA 17540:2020.

This document has been prepared under a standardization request M/581 addressed to CEN by the

European Commission. The Standing Committee of the EFTA States subsequently approves these

requests for its Member States.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

Introduction

Methanol also known as methyl alcohol is a polar covalent hydrocarbon fuel that can be made from non-

fossil sources and is very clean burning when compared to conventional marine fuels. Therefore

methanol is increasingly being used as sustainable fuel for vessels for environmental reasons. Its usage

is expected to expand significantly in the future. Therefore, there is a need to standardize the bunkering

requirements for inland navigation vessels to a reasonable degree, so that vessel operators have the tools

to select vessel fuel providers that meet set safety and fuel quality standards, in order to conduct

methanol bunkering operations safely.

This European Standard specifies safety requirements for methanol bunkering within the meaning of

European Parliament and Council Directive (EU) 2016/1629 of 14 September 2016 laying down technical

requirements for inland waterway vessels.

This document on the bunkering of methanol is based on research outcome of the Workshop CEN/WS

106 ‘Specification for bunkering of methanol’ in which was developed the CWA 17540 ‘Ships and marine

technology – Specification for bunkering of methanol fuelled vessels’. Next to this as a reference is used

the existing standard EN ISO 20519 ‘Ships and marine technology – Specification for bunkering of

liquefied natural gas fuelled vessels’.

1 Scope

This document specifies requirements for methanol bunkering transfer systems to and from inland

navigation vessels. The various scenarios for the bunker facility operator concern land, truck and vessel

(barge). It concerns design, dimensions and technical requirements for the transfer of methanol,

including the nozzle, connection, inner and outer flanges and failsafe features.

This document also specifies the process and procedures for the bunkering operations, as well as

responsibilities and risk assessment scope, taking into consideration the specific hazards in handling and

bunkering methanol fuel. Next to this, the requirement for the methanol provider to provide a bunker

delivery note and training and qualification of personnel involved.

This document is not applicable to cargo operations.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 13765:2018, Thermoplastic multi-layer (non-vulcanized) hoses and hose assemblies for the transfer of

hydrocarbons, solvents and chemicals - Specification

EN 12115:2021, Rubber and thermoplastics hoses and hose assemblies for liquid or gaseous chemicals -

Specification

EN 1092-1:2018, Flanges and their joints - Circular flanges for pipes, valves, fittings and accessories, PN

designated - Part 1: Steel flanges

ASTM F1122-22, Standard specification for Quick Disconnect Couplings (6 in. NPS and smaller)

EN 14420-6:2013, Hose fittings with clamp units - Part 6: TW tank truck couplings

EN IEC 60309-1, Plugs, fixed or portable socket-outlets and appliance inlets for industrial purposes - Part 1:

General requirements

ES-TRIN:2025, European Standard for laying down Technical Requirements for Inland Navigation vessels

ES-QIN, European Standard for Qualifications in Inland Navigation

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp/

— IEC Electropedia: available at https://www.electropedia.org/

3.1

bunker

vessel fuel primarily used to produce power for propulsion, heating and generating electricity through

combustion in machinery and equipment onboard

3.2

bunkering

transfer of bunker from land-based or floating facilities into a vessel’s permanent tanks or connection of

portable tanks to the vessel’s fuel supply system

3.3

bunkering agreement

contractual agreement applying to a bunker transfer

3.4

bunker delivery note

BDN

official document from the bunker facility operator providing information on the quantity, quality and

type of the fuel delivered to the vessel

3.5

bunkering operation supervisor

qualified person from the receiving vessel and at the methanol supplying facility (truck, train, bunker

vessel or bunker terminal) assigned with overall responsibility for bunkering operations

3.6

manifold watch

qualified person from the receiving vessel tasked with monitoring the transfer system

3.7

hose watch

qualified persons nominated by the bunker facility operator (truck, train, bunker vessel or bunker

terminal) to maintain a watch on the fuel supply side of the transfer system

3.8

bunker vessel

barge or tanker used for the delivery of fuel to the receiving vessel

3.9

bunker terminal

fixed facility on or near shore which can deliver fuel to the receiving vessel

3.10

truck

road tanker used for the delivery of fuel to the receiving vessel

3.11

train

rail vehicle used for the delivery of fuel to the receiving vessel

3.12

inspection

process in which the design and the condition of a vessel is evaluated to determine its compliance with

rules and standards

3.13

inspection body

competent authority assisting in the uniform and effective implementation of inland vessel navigation

codes and regulations, in charge to determine the compliance of the vessel with the requirements

3.14

controlled zone

area extending from the bunker manifold on the receiving vessel to the supply source (road tanker,

bunker vessel or bunker terminal) during the bunker operation which can have restrictions in place

3.15

safety dry break-away coupling

SBC

coupling that provides a safe release and isolation between the receiving vessel and the delivering vessel

or facility with a minimum of spill so as to protect the bunker equipment from advertent excessive loads

(pull away accidents)

3.16

facility

infrastructure used for storage and/or transfer of methanol

3.17

emergency shut down system

ESD

system that safely and effectively stops the transfer of fuel between the receiving vessel and the

delivering vessel or shore-based facility

3.18

safety management system

SMS

set of procedures an organisation needs to follow in order to meet its safety objectives

3.19

safety data sheet

SDS

detailed information bulletins prepared by the manufacturer or importer of a chemical that describes the

physical and chemical properties, physical and health hazards, routes of exposure, precautions for safe

handling and use, emergency and first-aid procedures, and control measures

3.20

methanol transfer system

equipment between the delivering facility and the bunker manifold on the receiving vessel

Note 1 to entry: Such equipment can include vessel to vessel transfer hoses, transfer arms, safety dry break-away

coupling (SBC), flanges, couplings. In addition, this includes the ESD vessel/shore or vessel/vessel link used to

connect the receiving and supplying ESD systems.

3.21

technical standard

standard that prescribe requirements for one or more of the following: operations, equipment

design/fabrications or testing methodology

3.22

transfer arm

bunker system of rigid pipe sections connected by swivelling joints, often combined with flexible hose

sections that together comprise an articulated system for transferring fuel to a vessel being bunkered

3.23

static electricity

electricity produced by movement between dissimilar materials through physical contact and separation

3.24

safety zone

area around the bunkering facility where only dedicated and essential personnel and activities are

allowed during bunkering

3.25

vapour management

treatment process of methanol vapour

Note 1 to entry: The treatment process is vapour recovery – inerting with nitrogen – vent.

4 Abbreviated terms

For the purpose of this document, the following abbreviated terms apply:

Term Description Explanation

CCNR Central Commission for the The Central Commission for the Navigation of the Rhine

navigation of the Rhine (CCNR) is an international organization (Belgium, France,

Germany, Switzerland and The Netherlands) that exercises an

essential regulatory role in the navigation of the Rhine. It is

active in the technical, legal, economic and environmental

fields. In all its areas of action, its work is guided by the

efficiency of transport on the Rhine, safety, social

considerations, and respect for the environment.

ES-TRIN European Standard laying Technical standards adopted by the European Committee

down Technical for drawing up standards in the field of inland navigation

Requirements for Inland (CESNI) in various areas, in particular standards for

Navigation vessels technical requirements for vessels, professional

qualifications, and information technologies. A vessel

operating on EU waterways or Rhine shall carry either a

Union inland navigation certificate or a Rhine vessel

inspection certificate. Both certificates are issued by the

competent national authorities (inspection bodies) and

confirm the full compliance of the vessel with the technical

requirements (ES-TRIN). ES-TRIN is binding in accordance

with Directive (EU) 2016/1629 and CCNR’s Rhine vessel

inspection regulations.

ES-QIN European standard for A set of standards, the so-called ‘Prague Standards’, adopted

qualification in inland in 2019 and divided into 5 main parts as follows: (1)

navigation standards for competences, (2) standards for practical

examinations, (3) standards for the approval of simulators,

(4) standards for medical fitness and (5) standards for

models of crew-related documents.

Term Description Explanation

IMO International Maritime A specialized agency of the United Nations whose purpose is

Organization “to provide machinery for cooperation among governments

in the field of governmental regulation and practices

relating to technical matters of all kinds affecting shipping

engaged in international trade; to encourage and facilitate

the general adoption of the highest practicable standards in

matters concerning efficiency of navigation, and prevention

and control of marine pollution from ships.”

5 Transfer systems design requirements

5.1 Vessel requirements

5.1.1 In order to be compliant with this document, vessels involved in methanol bunkering operations

shall meet the requirements in 5.1.2. These requirements apply to vessels of all sizes, in domestic as well

as international service.

5.1.2 Bunkering vessels and receiving vessels shall conform with this document and be approved by its

Inspection Body or competent authority complying with the applicable uniform interpretations and

requirements according to ES-TRIN.

NOTE In case of a receiving sea-going ship, it can meet at that end ISO standards (ISO/DIS 22120 ‘Specification

for bunkering methanol fuelled vessels’ under development), and therefore as a minimum, the applicable

requirements of the IGF Code (IMO) and IMO Interim Guidelines for the safety of ships using methyl/ethyl as fuel

(see bibliography [10] and [8]).

5.2 Bunkering facility requirements

5.2.1 Mobile facilities such as road tankers, rail tank cars and portable tanks, piping, hoses, pumps and

valves shall be fabricated and conform to meet applicable standard recognized by national standard

bodies, for handling methanol.

NOTE For more information about requirements, see ES-TRIN.

5.2.2 The bunker vessels shall conform to local codes for handling methanol.

5.2.3 The bunker terminal shall conform to local codes for handling methanol.

5.3 Transfer equipment requirements

5.3.1 All components of the methanol transfer system shall be fabricated to meet or exceed

requirements as specified in ES-TRIN, including methanol vapour management. Transfer hoses shall

meet the requirements of EN 13765:2018 or EN 12115:2021 with a minimum working pressure of 14

bar and shall be used for methanol transfer only. In addition to marking as specified in European

standards EN 13765:2018 and EN 12115:2021 methanol transfer hoses shall be permanently and legible

marked “FOR METHANOL TRANSFER ONLY”. For transfer hoses according EN 12115:2021 Grade Ω/T is

recommended.

NOTE In case of a receiving sea-going ship at that end it can meet or exceed IGF Code (IMO) and IBC Code (IMO)

Chapter 5 (see bibliography [10] and [9]).

5.3.2 The application of the methanol transfer system/hose with an ESD and a safety dry break-away

coupling (SBC) shall be considered in a risk assessment as described in Clause 6 of this document,

including methanol vapour management.

5.4 Emergency shutdown system

5.4.1 The methanol transfer system shall be connected to an emergency shut down system (ESD). The

delivering facility and the receiving vessel ESD system shall be interconnected with a vessel/shore or a

vessel/vessel ESD link to ensure the coordinated operation of both the delivering and the receiving

systems.

5.4.2 The ESD shall be designed to be activated by operator-initiated signal as well as sensor input. The

ESD shall stop the methanol transfer pumps and close the ESD valves.

At least the signal of the high-high level sensor shall be transmitted to the bunkering station by means of

a watertight connection plug meeting the requirements of EN IEC 60309-1.

NOTE As an example the ESD could be activated upon input in the event of: leakage detection (either leakage

in liquid form or as vapor), overfilling of the receiving methanol tank indicated by the high high-level alarm, vessel

drifting out of position, transfer arm (if any) being overstressed, fire detection and any other situations or alarms

which can endanger the bunkering operation.

5.5 Identification of transfer equipment

The methanol provider shall supply a list of equipment for use during bunkering operations, including

pertinent operating parameters. The list shall comprise:

a) connection types and sizes to which connection is possible;

All flanges used in the transfer system shall be in accordance with EN 1092-1:2018 and the coupling

of the bunkering system shall be in accordance with EN 14420-6:2013, if dry disconnect couplings of

up to and including 6 inches are used, the dimensions and tolerances shall be in accordance with

ASTM F1122-22 to meet compatibility requirements;

NOTE The coupling can be of the type safety dry break-away (SBC) as an outcome of the risk assessment in

Clause 6 in accordance with ES-TRIN.

b) ESD system or systems to be used;

c) maximum and minimum flow rates by pumps;

d) maximum and minimum working pressure of the transfer arm/hose;

e) maximum expected pressure the transfer system could experience during the bunkering operation

or in the event an emergency break-away release system is triggered, or ESD is activated.

5.6 Transfer system design analysis

Any fuel transfer system intended for bunkering methanol shall be analysed by qualified personnel or

other competent organization. Confirmation that the following critical design criteria can be met and also

sufficiently documented by a qualified engineer shall be given:

— that individual components are manufactured to appropriate industry standards;

— that any components used in assemblies are compatible in terms of construction materials and

functionality;

— the transfer system will operate within its design parameters;

— that controls have been made to ensure the transferring system will not be subjected to loads in

excess of acceptable design limits;

— that a full list of components listed along with information specified in 6.4.8 has been provided;

— that all sensors, manometers etc. should be possible to isolate;

— a procedure for vapour management shall have been determined or specified by the competent

parties.

5.7 Maintenance

Equipment shall be maintained and inspected according to the recommendations of the manufacturers.

The recommendations are stated in either the manufacturer manual or the operation manual. Equipment

certified by competent authorities shall be inspected and maintained according to these bodies' rules.

5.8 Maintenance manual

A maintenance manual shall be kept regarding the transferring system. The manual shall contain a listing

of each piece of equipment in the transferring system. The manual shall contain a list of the maintenance

procedures and inspections as specified by the competent personal or authority. A record of all

maintenance and inspections at least over the last 36 months shall be maintained.

6 Methanol bunkering processes and procedures

6.1 Risk assessment

6.1.1 General

The decision to allow a designated methanol bunkering area remains within the discretion of the port

and/or the competent authority. However, there is a need to determine if the proposed bunkering

location is acceptable from safety aspects.

A risk assessment shall be conducted and documented before bunkering operations can be allowed at a

specific location. The risk assessment shall be carried out by the competent authority having jurisdiction

over safety and security at the bunkering site. The assessment will remain valid as long as conditions and

presumptions remain unchanged. Upon changes the assessment shall be revised or performed again. Risk

assessments shall always be approved by the competent administration under whose jurisdiction the

bunkering operation is taking place.

When performing the risk assessment for methanol bunkering operations, physical and chemical

characteristics of methanol should be considered, including but not limited to:

— invisible burning behaviour of methanol flames in daylighting conditions;

NOTE In some daylight conditions with overcast skies there can be weak blue flames visible.

— barely visible behaviour of flames in indoor conditions;

— propensity to form flammable and explosive vapour cloud that can create overpressures in confined

spaces;

— corrosiveness which could lead to damage and reduction of material strength if incompatible

materials are selected for components for use, storage and transport systems;

— possibility of ‘running’ fires that result from spillage and improper containment of the spillage in case

of fire.

6.1.2 Conditions

As a minimum the risk assessment shall consider the following:

— proximity of the bunkering location to areas where personnel or other individuals and/or public can

be expected;

— measures for monitoring marine traffic that could impact bunkering operations are suitable and the

mechanism for passing traffic information to bunkering supervisors is robust and effective;

— measu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...