IEC 62899-202:2016

(Main)Printed electronics - Part 202: Materials - Conductive ink

Printed electronics - Part 202: Materials - Conductive ink

IEC 62899-202:2016(E) defines the terms and specifies the standard methods for characterisation and evaluation. This International Standard is applicable to conductive inks and conductive layer that are made from conductive inks.

General Information

- Status

- Published

- Publication Date

- 24-Feb-2016

- Technical Committee

- TC 119 - Printed Electronics

- Drafting Committee

- WG 2 - TC 119/WG 2

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 02-May-2023

- Completion Date

- 30-Nov-2020

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 62899-202:2016 - Printed electronics - Part 202: Materials - Conductive ink - defines terminology and standardized methods for the characterisation, evaluation and storage of conductive inks and conductive layers made from conductive inks. Published by the IEC Technical Committee 119 (Printed electronics), this part of the IEC 62899 series provides a generic, test-method focused specification intended for producers, test labs and designers working with printed conductive materials.

Key Topics

The standard specifies measurement and evaluation methods across physical, electrical and optical properties. Major technical topics include:

- Terms and definitions specific to conductive inks and printed conductive layers.

- Atmospheric conditions for conditioning and testing (standard test environments).

- Characterisation of conductive ink: solid content, non‑volatile content, ash content, foreign matter.

- Physical properties: density, rheology (viscosity), surface tension, particle/flake size of conductive materials, flashpoint and evaporation rate.

- Evaluation of conductive layers: test-piece preparation, substrate guidance and dimensional requirements.

- Electrical properties: volume resistivity and surface resistivity (including four‑point probe methods and probe correction factors).

- Optical properties: luminous transmittance, chromaticity, colour uniformity, haze and refractive index.

- Storage and ageing: storage conditions, methods to measure aged deterioration and reporting requirements.

- Normative references to established test methods (many ISO standards) for density, viscosity, refractive index, flash point and surface tension.

Applications

IEC 62899-202 is practical for:

- Conductive ink manufacturers establishing batch quality controls and specification sheets.

- Printed electronics OEMs and designers validating conductive layers used in flexible circuits, RFID antennas, conductive traces, sensors, touch panels and transparent conductive coatings.

- Independent test laboratories and QC teams performing standardized resistivity, optical and rheological testing.

- Procurement, certification and compliance professionals requiring consistent test methods for material acceptance and comparative evaluation.

Using this standard helps ensure repeatable measurement practices, clearer material specifications and better interoperability between suppliers and device manufacturers in the printed electronics ecosystem.

Related Standards

- IEC 62899 series (printed electronics): Part 201 (Substrates), Part 203 (Semiconductor ink) - related parts covering other material classes.

- Normative references included in IEC 62899-202: ISO standards for viscosity (ISO 2555, ISO 2884-1, ISO 3219), density (ISO 758, ISO 1183-1), surface tension (ISO 304), refractive index (ISO 489), flash point (ISO 2592, ISO 2719) and ash/solids determinations.

Keywords: IEC 62899-202:2016, printed electronics, conductive ink, conductive layer, four-point probe, volume resistivity, surface resistivity, rheology, surface tension, material characterisation.

Get Certified

Connect with accredited certification bodies for this standard

BSMI (Bureau of Standards, Metrology and Inspection)

Taiwan's standards and inspection authority.

IMP NDT d.o.o.

Non-destructive testing services. Radiography, ultrasonic, magnetic particle, penetrant, visual inspection.

Inštitut za kovinske materiale in tehnologije

Institute of Metals and Technology. Materials testing, metallurgical analysis, NDT.

Sponsored listings

Frequently Asked Questions

IEC 62899-202:2016 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Printed electronics - Part 202: Materials - Conductive ink". This standard covers: IEC 62899-202:2016(E) defines the terms and specifies the standard methods for characterisation and evaluation. This International Standard is applicable to conductive inks and conductive layer that are made from conductive inks.

IEC 62899-202:2016(E) defines the terms and specifies the standard methods for characterisation and evaluation. This International Standard is applicable to conductive inks and conductive layer that are made from conductive inks.

IEC 62899-202:2016 is classified under the following ICS (International Classification for Standards) categories: 17.220.20 - Measurement of electrical and magnetic quantities; 19.080 - Electrical and electronic testing; 31.180 - Printed circuits and boards; 87.080 - Inks. Printing inks. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62899-202:2016 has the following relationships with other standards: It is inter standard links to IEC 62899-202:2023. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 62899-202:2016 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62899-202 ®

Edition 1.0 2016-02

INTERNATIONAL

STANDARD

Printed electronics –

Part 202: Materials – Conductive ink

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 20 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 15 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 65 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

IEC 62899-202 ®

Edition 1.0 2016-02

INTERNATIONAL

STANDARD

Printed electronics –

Part 202: Materials – Conductive ink

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 31.180; 87.080 ISBN 978-2-8322-3197-5

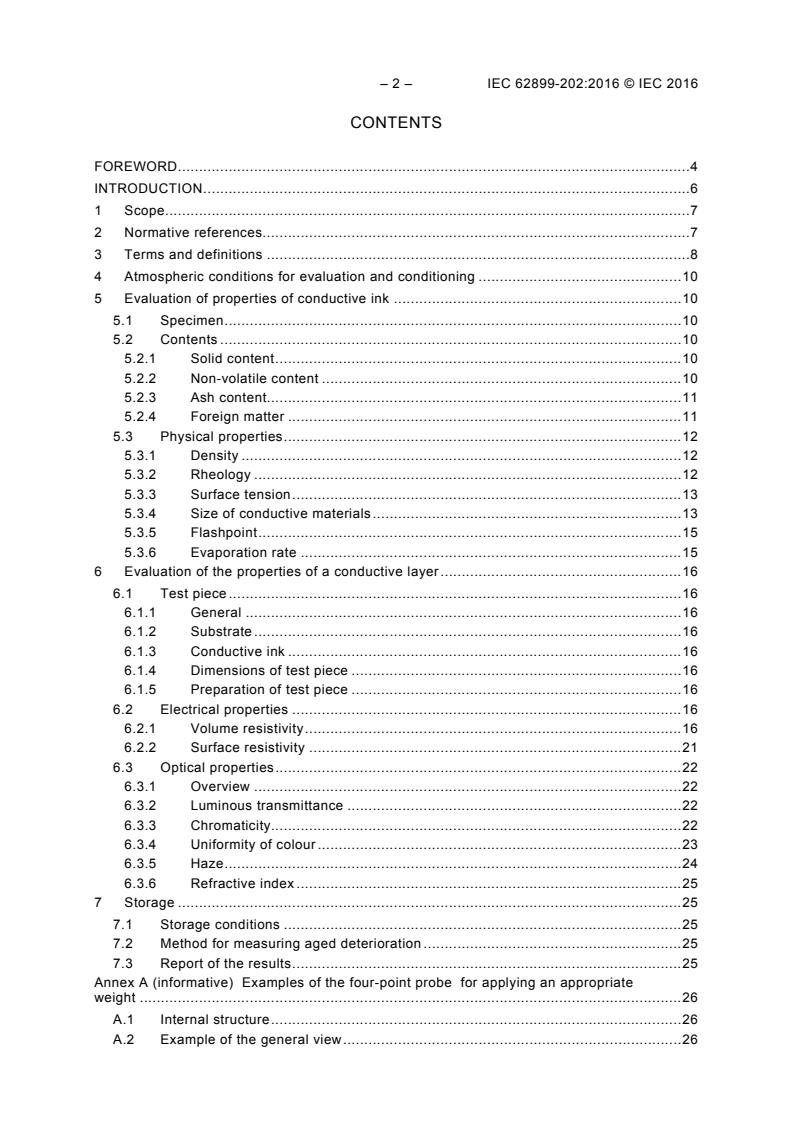

– 2 – IEC 62899-202:2016 © IEC 2016

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references. 7

3 Terms and definitions . 8

4 Atmospheric conditions for evaluation and conditioning . 10

5 Evaluation of properties of conductive ink . 10

5.1 Specimen . 10

5.2 Contents . 10

5.2.1 Solid content . 10

5.2.2 Non-volatile content . 10

5.2.3 Ash content. 11

5.2.4 Foreign matter . 11

5.3 Physical properties . 12

5.3.1 Density . 12

5.3.2 Rheology . 12

5.3.3 Surface tension . 13

5.3.4 Size of conductive materials . 13

5.3.5 Flashpoint . 15

5.3.6 Evaporation rate . 15

6 Evaluation of the properties of a conductive layer . 16

6.1 Test piece . 16

6.1.1 General . 16

6.1.2 Substrate . 16

6.1.3 Conductive ink . 16

6.1.4 Dimensions of test piece . 16

6.1.5 Preparation of test piece . 16

6.2 Electrical properties . 16

6.2.1 Volume resistivity . 16

6.2.2 Surface resistivity . 21

6.3 Optical properties . 22

6.3.1 Overview . 22

6.3.2 Luminous transmittance . 22

6.3.3 Chromaticity. 22

6.3.4 Uniformity of colour . 23

6.3.5 Haze . 24

6.3.6 Refractive index . 25

7 Storage . 25

7.1 Storage conditions . 25

7.2 Method for measuring aged deterioration . 25

7.3 Report of the results . 25

Annex A (informative) Examples of the four-point probe for applying an appropriate

weight . 26

A.1 Internal structure . 26

A.2 Example of the general view . 26

Annex B (informative) Equation of correction factor F . 27

B.1 General . 27

B.2 Conditions for correction factor F . 27

B.3 Equation of correction factor F . 28

Annex C (informative) Influence of the measuring position and the size of specimen on

resistance . 29

C.1 Influence of the measuring position on resistance . 29

C.2 Influence of the size of the specimen on resistance . 29

Bibliography . 31

Figure 1 – Example of four-point probe measurement . 17

Figure 2 – Example of four-probe measurement equipment . 17

Figure 3 – Measuring positions of resistance (Type A) . 19

Figure 4 – Measuring positions of resistance (Type B) . 19

Figure 5 – Measuring positions of resistance (Type C) . 20

Figure A.1 – Example of the internal structure of probe . 26

Figure A.2 – Example of the general view of the probe . 26

Figure B.1 – Schematic diagram of the geometry of the conductive layer and the

configuration of probes A, B, C, and D . 27

Figure C.1 – Measurement model for the influence of the measuring position on sheet

resistance . 29

Figure C.2 – Model measurement of the influence of the specimen size . 30

Table 1 – Resistance range of the test piece and the applied current . 18

Table 2 – List of the size of the specimen . 18

– 4 – IEC 62899-202:2016 © IEC 2016

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

PRINTED ELECTRONICS –

Part 202: Materials – Conductive ink

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62899-2-1 has been prepared by IEC technical committee 119:

Printed electronics.

The text of this standard is based on the following documents:

FDIS Report on voting

119/88/FDIS 119/101A/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 62899 series, published under the general title Printed electronics,

can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC website under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

– 6 – IEC 62899-202:2016 © IEC 2016

INTRODUCTION

The IEC 62899-20x series relates mainly to evaluation methods for materials of printed

electronics. The series also include storage methods, packaging and marking, and

transportation conditions.

The IEC 62899-20x series is divided into parts for each material. Each part is prepared as a

generic specification containing fundamental information for the area of printed electronics.

The IEC 62899-20x series consists of the following parts:

Part 201: Materials – Substrates

Part 202: Materials – Conductive ink

Part 203: Materials – Semiconductor ink

(Subsequent parts will be prepared for other materials.)

Furthermore, sectional specifications, blank detail specifications, and detail specifications of

each material will follow these parts.

This part of IEC 62899 is prepared for conductive materials used in printed electronics and

contains the test conditions, the evaluation methods and the storage conditions.

_____________

Under consideration.

PRINTED ELECTRONICS –

Part 202: Materials – Conductive ink

1 Scope

This part of IEC 62899 defines the terms and specifies the standard methods for

characterisation and evaluation.

This International Standard is applicable to conductive inks and conductive layer that are

made from conductive inks.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

ISO 5-2, Photography and graphic technology – Density measurements – Part 2: Geometric

conditions for transmittance density

ISO 5-3, Photography and graphic technology – Density measurements – Part 3: Spectral

conditions

ISO 124, Latex, rubber – Determination of total solids content

ISO 291, Plastics – Standard atmospheres for conditioning and testing

ISO 304, Surface active agents – Determination of surface tension by drawing up liquid films

ISO 489:1999, Plastics – Determination of refractive index

ISO 758, Liquid chemical products for industrial use – Determination of density at 20 degrees

C

ISO 1183-1, Plastics – Methods for determining the density of non-cellular plastics – Part 1:

Immersion method, liquid pyknometer method and titration method

ISO 2555, Plastics – Resins in the liquid state or as emulsions or dispersions – Determination

of apparent viscosity by the Brookfield Test method

ISO 2592, Determination of flash and fire points – Cleveland open cup method

ISO 2719, Determination of flash point – Pensky-Martens closed cup method

ISO 2811-1, Paints and varnishes – Determination of density – Part 1: Pyknometer method

ISO 2811-2, Paints and varnishes – Determination of density – Part 2: Immersed body

(plummet) method

– 8 – IEC 62899-202:2016 © IEC 2016

ISO 2884-1, Paints and varnishes – Determination of viscosity using rotary viscometers –

Part 1: Cone-and-plate viscometer operated at a high rate of shear

ISO 3219, Plastics – Polymers/resins in the liquid state or as emulsions or dispersions –

Determination of viscosity using a rotational viscometer with defined shear rate

ISO 3451-1, Plastics – Determination of ash – Part 1: General methods

ISO 3664, Graphic technology and photography – Viewing conditions

ISO 3679, Determination of flash no-flash and flash point – Rapid equilibrium closed cup

method

ISO 4576, Plastics – Polymer dispersions – Determination of sieve residue (gross particle and

coagulum content)

ISO 9276-6, Representation of results of particle size analysis – Part 6: Descriptive and

quantitative representation of particle shape and morphology

ISO 13319, Determination of particle size distributions – Electrical sensing zone method

ISO 13320, Particle size analysis – Laser diffraction methods

ISO 13321, Particle size analysis – Photon correlation spectroscopy

ISO 13322-1, Particle size analysis – Image analysis methods – Part 1: Static image analysis

methods

ISO 13468-1:1996, Plastics – Determination of the total luminous transmittance of transparent

materials – Part 1: Single beam instrument

ISO 13468-2:1999, Plastics – Determination of the total luminous transmittance of transparent

materials – Part 2: Double-beam instrument

ISO 13655, Graphic technology – Spectral measurement and colorimetric computation for

graphic arts images

ISO 14488, Particulate materials – Sampling and sample splitting for the determination of

particulate properties

ISO 14782, Plastics – Determination of haze for transparent materials

ISO 14887, Sample preparation – Dispersing procedures for powers in liquids

ISO 20998-1, Measurement and characterization of particles by acoustic methods – Part 1:

Concepts and procedures in ultrasonic attenuation spectroscopy

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

NOTE The terms in italic font are those defined in Clause 3.

3.1

conductive material

ingredient of a printing or coating material, which itself is electrically conductive or becomes

electrically conductive by post treatment such as heating

3.2

conductive ink

fluid in which one or more small molecules, polymers, or particles are dissolved or dispersed,

and which becomes an electrically conductive layer (3.3) by post treatment such as heating

3.3

conductive layer

film-like electrically conductive body made of conductive ink (3.2), which is printed or coated

on a substrate, followed as necessary by post treatment such as heating

3.4

conductive film

substrate (sheet or roll) with conductive layer (3.3)

3.5

solid content

mass fraction of an ingredient which effectively functions as a conductive substance, in

conductive ink (3.2)

3.6

non-volatile content

mass fraction of residue obtained by evaporation of the volatile solvent under specific

conditions, in conductive ink (3.2)

3.7

ash content

mass fraction of residue excluding ingredients which are combusted or carbonised by

pyrolysis, in conductive ink (3.2)

3.8

foreign matter

substances and/or particles of aggregated grains, filmed ink and ingredients which do not

function as a part of conductive ink (3.2)

3.9

spherical particle

particle with three approximately equal dimensions of length, width and height

3.10

rod

substance with thin elongated cylindrical shape

3.11

wire

substance with thin long fibre-like shape having electrically conductive or semi-conductive

property

3.12

tube

substance with fiber-like hollow cylindrical shape

– 10 – IEC 62899-202:2016 © IEC 2016

3.13

dispersion

heterogeneous system in which fine separated materials are distributed uniformly in other

materials

3.14

flash point

lowest liquid temperature at which, under certain standardized conditions, a liquid gives off

vapours in quantity such as to be capable of forming an ignitable vapour/air mixture

[SOURCE: IEC 60050-212:2010, 212-18-05]

4 Atmospheric conditions for evaluation and conditioning

The standard atmosphere for evaluation (test and measurement) and storage of the specimen

shall be a temperature of 23 °C ± 2 °C and relative humidity of (50 ± 10) %, conforming to

standard atmosphere class 2 specified in ISO 291. If a polymer substrate is used for a test

piece coated with a conductive layer, the standard atmosphere for evaluation shall be a

temperature of 23 °C ± 1 °C and relative humidity of (50 ± 5) %, conforming to standard

atmosphere class 1 specified in ISO 291.

If conditioning is necessary, the same standard atmosphere specified above shall apply.

5 Evaluation of properties of conductive ink

5.1 Specimen

The specimen for evaluation shall be prepared according to ISO 14488 or an equivalent

method. If necessary, dilution by a compatible solvent may be allowed.

5.2 Contents

5.2.1 Solid content

5.2.1.1 Determination of solid content

Solid content of conductive materials and non-conductive materials shall be determined by the

theoretical mass fraction (expressed as a percentage) of functional ingredients to the total ink

mass. Functional ingredients include conductive materials, their precursors or binders, or any

additives.

5.2.1.2 Report of the results

The report shall include the following items:

a) unique specimen identification;

b) atmospheric conditions of test;

c) solid content;

d) tester, test place, and test time (ex. company name, city, year).

5.2.2 Non-volatile content

5.2.2.1 Principle

Non-volatile content is determined by measuring the mass of residue after evaporation of the

volatile ingredients and calculating the mass fraction (expressed as a percentage) to the total

ink mass.

5.2.2.2 Test method

The test method shall be as specified in ISO 1625 with the following exceptions:

a) Air pressure: 86 kPa to 106 kPa.

b) If specified by the manufacturer, the test may be performed under reduced pressure. The

conditions and procedures for reducing the pressure shall be as specified in ISO 124 or by

the manufacturer.

c) The materials which do not react with the ink during an examination shall be used.

d) Repeat the test until the weight becomes constant within 5 %.

5.2.2.3 Report of the results

The report shall include the following items:

a) specimen identification;

b) test conditions (air pressure if reduced, drying temperature and time);

c) specimen mass;

d) results;

e) tester, test place, and test time (ex. company name, city, year).

5.2.3 Ash content

5.2.3.1 Test method

The test method shall be as specified in ISO 3451-1, method A, with the following exceptions:

a) If appropriate for the properties of the ink, a calcination temperature other than that

specified in ISO 3451-1 may be used.

b) If the ash content is very low, considering weighing accuracy, a specimen mass other than

that specified in ISO 3451-1 may be used.

The detailed product specifications shall specify the applicable calcination temperature and

specimen mass.

5.2.3.2 Report of the results

The report shall include the following items:

a) specimen identification;

b) calcination temperature;

c) specimen mass;

d) results and variation;

e) tester, test place, and test time (ex. company name, city, year).

5.2.4 Foreign matter

5.2.4.1 Principle

Foreign matter is determined by measuring the mass of filtration residue and calculating the

mass fraction (expressed as a percentage) to the total ink mass.

5.2.4.2 Test method

The test method shall be as specified in ISO 4576, with the following exceptions:

a) The specimen mass shall be 1 g to 10 g.

– 12 – IEC 62899-202:2016 © IEC 2016

b) For filtration of the specimen, a membrane filter with appropriate pore size shall be used

instead of a metal sieve. The pore size of the filter shall be as specified by the

manufacturer.

c) For diluting the specimen or cleaning the filtration residue, a solvent appropriate for the

properties of the ink shall be used.

d) Prior to filtering, the specimen may be diluted by an appropriate solvent if necessary. No

other treatment shall be allowed.

e) The drying temperature for the filter and filtration residue may be other than as specified

in ISO 4576.

f) The test shall be conducted until the difference between the results of two consecutive

tests is not more than 20 %; the higher result shall be used for the report.

5.2.4.3 Report of the results

The report shall include the following items:

a) specimen identification;

b) test conditions (filter pore size and drying temperature);

c) results;

d) tester, test place, and test time (ex. company name, city, year).

5.3 Physical properties

5.3.1 Density

5.3.1.1 Measuring method

The measuring method shall either be the pyknometer method as specified in ISO 758,

ISO 1183-1 and ISO 2811-1, the method using oscillation-type density meters as specified in

ISO 15212-1, or the immersed body (plummet) method as specified in ISO 2811-2. The

detailed product specifications shall specify the measuring method to be used.

5.3.1.2 Equipment

Equipment shall be as specified in the measurement method (see 5.3.1.1) or shall be

equipment considered equivalent or superior.

5.3.1.3 Report of the results

The report shall include the following items:

a) specimen identification;

b) measurement method;

c) measurement atmosphere (temperature and relative humidity);

d) results;

e) tester, test place, and test time (ex. company name, city, year).

5.3.2 Rheology

5.3.2.1 Measuring method

Viscosity shall be measured using a Brookfield type rotational viscometer as specified in

ISO 2555, cone-and-plate viscometer as specified in ISO 2884-1, or rotational viscometer as

specified in ISO 3219.

The detailed product specifications shall specify the measuring method and measuring

temperature to be used.

5.3.2.2 Report of the results

The report shall include the following items:

a) standard number of the measurement method;

b) specimen identification;

c) measuring temperature;

d) viscometer model;

e) viscosity expressed in millipascal second (mPa·s);

f) tester, test place, and test time (ex. company name, city, year).

5.3.3 Surface tension

5.3.3.1 Measuring method

Surface tension shall be measured using the drawing up liquid film (Wilhelmy) method as

specified in ISO 304 with the following exceptions:

a) equipment considered equivalent to that in ISO 304 may be used;

b) the test jig shall be made of platinum;

c) the equipment shall be calibrated using pure water and a hanging weight.

5.3.3.2 Report of the results

The report shall include the following items:

a) specimen identification;

b) measuring temperature;

c) surface tension expressed in millinewton per metre (mN/m);

d) tester, test place, and test time (ex. company name, city, year).

5.3.4 Size of conductive materials

5.3.4.1 Sampling

The specimen used for measuring the size of a conductive material shall be sampled

according to the method specified in ISO 14488 or a similar method. If re-dispersion is

required, perform re-dispersion according to the method specified in ISO 14887 or a similar

method.

5.3.4.2 Sphere

5.3.4.2.1 Measuring method

The mean particle size of spherical particles or near spherical particles (such as equants)

shall be measured using the electric sensing zone method specified in ISO 13319, the laser

diffraction method specified in ISO 13320, the photon correlation method specified in

ISO 13321, or the ultrasonic attenuation spectroscopy method specified in ISO 20998-1.

Measuring equipment shall be as specified in one of the above standards. Measuring

equipment which uses a method specified in any of these standards may be used.

Mean particle size is obtained as the sphere-equivalent diameter or circle-equivalent diameter,

depending on the measurement method. The type of diameter shall be recorded and included

in the report of the results.

NOTE Equants express the particles of similar length, width, and thickness. Both cubical and spherical particles

are included.

– 14 – IEC 62899-202:2016 © IEC 2016

5.3.4.2.2 Report of the results

The report shall include the following items:

a) specimen identification;

b) mean particle size;

c) type of diameter;

d) tester, test place, and test time (ex. company name, city, year).

5.3.4.3 Rod, wire and tube

5.3.4.3.1 Measuring method

Rods, wires and tubes shall be measured using the method specified in ISO 13322-1, or an

equivalent method. As this method measures the widths and lengths of particles from an

electron microscope image, it requires a standard length

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...