IEC 62899-202:2023

(Main)Printed electronics - Part 202: Materials - Conductive ink

Printed electronics - Part 202: Materials - Conductive ink

IEC 62899-202:2023 defines the terms and specifies the standard test methods for characterization and evaluation of conductive inks. This document also provides measurement methods for evaluating the properties of conductive layers made both from an additive process using conductive inks and from a subtractive process used in printed electronics. This edition includes the following significant technical changes with respect to the previous edition:

a) definitions of conductive material, conductive ink and conductive layer have been revised;

b) a summary of test methods is added;

c) mechanical tests for conductive layer are added.

General Information

- Status

- Published

- Publication Date

- 01-May-2023

- Technical Committee

- TC 119 - Printed Electronics

- Drafting Committee

- WG 2 - TC 119/WG 2

- Current Stage

- PPUB - Publication issued

- Start Date

- 02-May-2023

- Completion Date

- 02-Jun-2023

Relations

- Effective Date

- 05-Sep-2023

Overview - IEC 62899-202:2023 (Printed electronics - Conductive ink)

IEC 62899-202:2023 is the International Electrotechnical Commission standard that defines terms and specifies standard test methods for characterization and evaluation of conductive inks used in printed electronics. It covers measurement and reporting methods for both the ink formulation (additive processes) and the resulting conductive layers (including layers produced by subtractive processes). This second edition (2023) updates and refines definitions, adds a summary of test methods and introduces mechanical tests for conductive layers.

Key topics and technical requirements

The standard focuses on measurable properties and standardized test procedures to ensure consistent communication across the printed electronics supply chain. Key topics include:

- Definitions and terminology for conductive material, conductive ink and conductive layer - clarifying industry vocabulary.

- Atmospheric conditions and pre-conditioning for reliable, reproducible measurements.

- Ink composition & contents: solid content, non-volatile content, ash content, and foreign matter.

- Physical and handling properties: density, rheology (viscosity behavior), surface tension, particle/flake size of conductive materials, flashpoint, evaporation rate, and visual appearance.

- Electrical characterization of conductive layers: volume resistivity, surface resistivity (four-point probe and contactless methods), measurement specimen preparation and probe geometry considerations.

- Mechanical tests for conductive layers: bending/flex testing, abrasion resistance, and adhesion strength to substrates.

- Optical properties where applicable: transmittance, chromaticity, haze and refractive index for transparent conductive films.

- Storage, packaging and ageing: recommended storage conditions and methods for measuring aged deterioration, plus reporting templates for results.

- Informative annexes covering four-point probe examples, correction factors and the influence of specimen size/measurement position on resistance.

Practical applications

IEC 62899-202:2023 is intended to standardize how conductive inks and printed conductive layers are characterized so results are comparable between suppliers, manufacturers, test houses and end users. Typical practical uses:

- Qualification and R&D of conductive ink formulations (silver, copper, carbon-based inks).

- Process control and quality assurance for printed electronics manufacturing (inkjet, screen, gravure, flexo, etc.).

- Electrical performance verification for printed interconnects, antennas, RFID, sensors, heaters and transparent electrodes.

- Evaluation of mechanical robustness for flexible and wearable electronics.

- Test laboratories producing certified measurement reports for suppliers and OEMs.

Who should use this standard

- Conductive ink manufacturers and formulators

- Printed electronics OEMs and contract manufacturers

- Materials and process R&D teams

- Independent testing laboratories and certification bodies

- Procurement and quality assurance teams in electronics supply chains

Related standards

- IEC 62899-201: Materials - Substrates

- IEC 62899-203: Materials - Semiconductor ink

- IEC 62899-204: Materials - Insulator ink

Using IEC 62899-202:2023 helps align terminology, measurement practice and reporting across the printed electronics ecosystem, supporting reliable material selection and reproducible performance data.

IEC 62899-202:2023 - Printed electronics - Part 202: Materials - Conductive ink Released:5/2/2023

REDLINE IEC 62899-202:2023 - Printed electronics - Part 202: Materials - Conductive ink Released:5/2/2023 Isbn:9782832269558

Frequently Asked Questions

IEC 62899-202:2023 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Printed electronics - Part 202: Materials - Conductive ink". This standard covers: IEC 62899-202:2023 defines the terms and specifies the standard test methods for characterization and evaluation of conductive inks. This document also provides measurement methods for evaluating the properties of conductive layers made both from an additive process using conductive inks and from a subtractive process used in printed electronics. This edition includes the following significant technical changes with respect to the previous edition: a) definitions of conductive material, conductive ink and conductive layer have been revised; b) a summary of test methods is added; c) mechanical tests for conductive layer are added.

IEC 62899-202:2023 defines the terms and specifies the standard test methods for characterization and evaluation of conductive inks. This document also provides measurement methods for evaluating the properties of conductive layers made both from an additive process using conductive inks and from a subtractive process used in printed electronics. This edition includes the following significant technical changes with respect to the previous edition: a) definitions of conductive material, conductive ink and conductive layer have been revised; b) a summary of test methods is added; c) mechanical tests for conductive layer are added.

IEC 62899-202:2023 is classified under the following ICS (International Classification for Standards) categories: 31.180 - Printed circuits and boards; 87.080 - Inks. Printing inks. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62899-202:2023 has the following relationships with other standards: It is inter standard links to IEC 62899-202:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 62899-202:2023 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62899-202 ®

Edition 2.0 2023-05

INTERNATIONAL

STANDARD

Printed electronics –

Part 202: Materials – Conductive ink

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always have

committee, …). It also gives information on projects, replaced access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 300 terminological entries in English

details all new publications released. Available online and once

and French, with equivalent terms in 19 additional languages.

a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 62899-202 ®

Edition 2.0 2023-05

INTERNATIONAL

STANDARD

Printed electronics –

Part 202: Materials – Conductive ink

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 31.180; 87.080 ISBN 978-2-8322-6936-7

– 2 – IEC 62899-202:2023 © IEC 2023

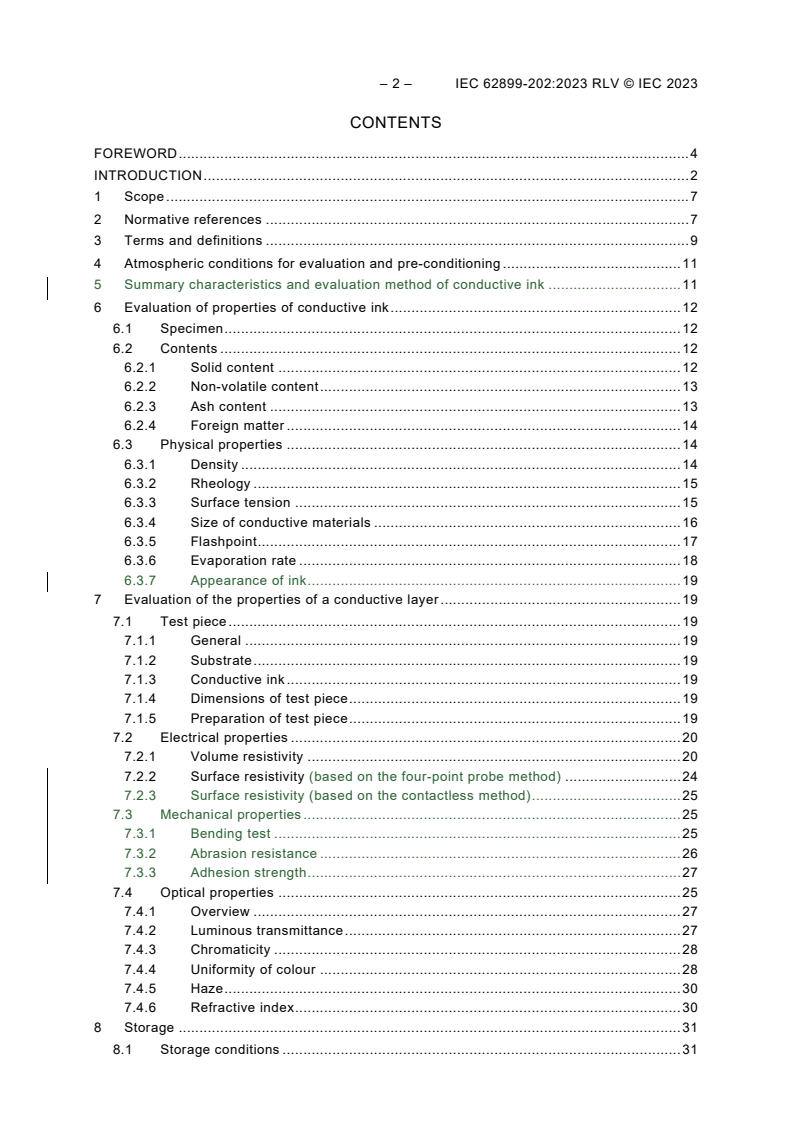

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 9

4 Atmospheric conditions for evaluation and pre-conditioning . 11

5 Summary characteristics and evaluation method of conductive ink . 11

6 Evaluation of properties of conductive ink . 12

6.1 Specimen . 12

6.2 Contents . 12

6.2.1 Solid content . 12

6.2.2 Non-volatile content . 12

6.2.3 Ash content . 13

6.2.4 Foreign matter . 13

6.3 Physical properties . 14

6.3.1 Density . 14

6.3.2 Rheology . 14

6.3.3 Surface tension . 15

6.3.4 Size of conductive materials . 16

6.3.5 Flashpoint . 17

6.3.6 Evaporation rate . 18

6.3.7 Appearance of ink . 19

7 Evaluation of the properties of a conductive layer . 19

7.1 Test piece . 19

7.1.1 General . 19

7.1.2 Substrate . 19

7.1.3 Conductive ink . 19

7.1.4 Dimensions of test piece . 19

7.1.5 Preparation of test piece . 19

7.2 Electrical properties . 20

7.2.1 Volume resistivity . 20

7.2.2 Surface resistivity (based on the four-point probe method) . 24

7.2.3 Surface resistivity (based on the contactless method) . 25

7.3 Mechanical properties . 25

7.3.1 Bending test . 25

7.3.2 Abrasion resistance . 26

7.3.3 Adhesion strength . 27

7.4 Optical properties . 27

7.4.1 Overview . 27

7.4.2 Luminous transmittance . 27

7.4.3 Chromaticity . 28

7.4.4 Uniformity of colour . 28

7.4.5 Haze . 30

7.4.6 Refractive index . 30

8 Storage . 31

8.1 Storage conditions . 31

8.2 Method for measuring aged deterioration . 31

8.3 Report of the results . 31

Annex A (informative) Example of four-point probe for applying an appropriate weight . 32

A.1 Internal structure . 32

A.2 Example of overall view . 32

Annex B (informative) Formula of correction factor F . 33

B.1 General . 33

B.2 Conditions for correction factor F . 34

B.3 Formula of correction factor F . 34

Annex C (informative) Influence of the measuring position and size of the specimen on

resistance . 35

C.1 Influence of the measuring position on resistance . 35

C.2 Influence of the size of the specimen on resistance . 36

Bibliography . 37

Figure 1 – Example of four-point probe measurement . 20

Figure 2 – Example of four-probe measurement equipment . 20

Figure 3 – Measuring positions of resistance (Type A) . 22

Figure 4 – Measuring positions of resistance (Type B) . 22

Figure 5 – Measuring positions of resistance (Type C) . 23

Figure A.1 – Example of the internal structure of probe . 32

Figure A.2 – Example of the overall view of the probe . 32

Figure B.1 – Schematic diagram of the geometry of the conductive layer and the

configuration of probes A, B, C and D . 33

Figure C.1 – Measurement model for the influence of the measuring position on sheet

resistance . 35

Figure C.2 – Model measurement of the influence of the specimen size . 36

Table 1 – Test methods for conductive inks used in PE. 11

Table 2 – Resistance range of the test piece and the applied current . 21

Table 3 – List of the size of the specimen . 22

– 4 – IEC 62899-202:2023 © IEC 2023

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

PRINTED ELECTRONICS –

Part 202: Materials – Conductive ink

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

IEC 62899-202 has been prepared by IEC technical committee 119: Printed electronics. It is

an International Standard.

This second edition cancels and replaces the first edition published in 2016. This

edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) definitions of conductive material, conductive ink and conductive layer have been revised;

b) a summary of test methods is added;

c) mechanical tests for conductive layer are added.

The text of this International Standard is based on the following documents:

Draft Report on voting

119/423/FDIS 119/428/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/publications.

A list of all parts in the IEC 62899 series, published under the general title Printed electronics,

can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – IEC 62899-202:2023 © IEC 2023

INTRODUCTION

Printed electronics is a technology that spans the printing and electrical/electronic area, and it

provides a variety of products. Since participants in this industry come from different areas,

their backgrounds and customs can be barriers to smooth communication and transactions in

the supply chain. The printed electronics industry continues to grow, but many barriers still

remain. Particularly, the lack of standardised terms and evaluation methods is one of the major

factors that inhibit smooth communication.

This document focuses on measurement and evaluation methods for conductive inks and

provides tools to promote the smooth communication within the supply chain.

This document specifies the basic items to be communicated and their measurement or

evaluation methods. This document includes the measurement methods for the basic properties

of inks and electrical conductivity, which is obtained by the post treatment of inks. Additionally,

storage methods, packaging and marking, and transportation conditions are also included.

This document is part of the IEC 62899-202 series and similar documents are available for other

materials used in printed electronics.

The IEC 62899-20x series consists of the following parts:

IEC 62899-201: Materials – Substrates

IEC 62899-202: Materials – Conductive ink

IEC 62899-203: Materials – Semiconductor ink

IEC 62899-204: Materials – Insulator ink

Furthermore, sectional specifications, blank detail specifications, and detail specifications of

each material will follow these parts.

PRINTED ELECTRONICS –

Part 202: Materials – Conductive ink

1 Scope

This part of IEC 62899 defines the terms and specifies the standard test methods for

characterization and evaluation of conductive inks.

This document also provides measurement methods for evaluating the properties of conductive

layers made both from an additive process using conductive inks and from a subtractive process

used in printed electronics.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 62899-202-3, Printed electronics – Part 202-3: Materials – Conductive ink – Measurement

of sheet resistance of conductive films – Contactless method

IEC 62899-202-5, Printed electronics – Part 202-5: Materials – Conductive ink – Mechanical

bending test of a printed conductive layer on an insulating substrate

ISO 5-2, Photography and graphic technology – Density measurements – Part 2: Geometric

conditions for transmittance density

ISO 5-3, Photography and graphic technology – Density measurements – Part 3: Spectral

conditions

ISO 124, Latex, rubber – Determination of total solids content

ISO 291, Plastics – Standard atmospheres for conditioning and testing

ISO 304, Surface active agents – Determination of surface tension by drawing up liquid films

ISO 489:2022, Plastics – Determination of refractive index

ISO 758, Liquid chemical products for industrial use – Determination of density

at 20 degrees C

ISO 1183-1, Plastics – Methods for determining the density of non-cellular plastics – Part 1:

Immersion method, liquid pycnometer method and titration method

ISO 2409:2020, Paints and varnishes – Cross-cut test

ISO 2471, Paper and board – Determination of opacity (paper backing) – Diffuse reflectance

method

– 8 – IEC 62899-202:2023 © IEC 2023

ISO 2555, Plastics – Resins in the liquid state or as emulsions or dispersions – Determination

of apparent viscosity using a single cylinder type rotational viscometer method

ISO 2592, Petroleum and related products – Determination of flash and fire points – Cleveland

open cup method

ISO 2719, Determination of flash point – Pensky-Martens closed cup method

ISO 2811-1, Paints and varnishes – Determination of density – Part 1: Pycnometer method

ISO 2811-2, Paints and varnishes – Determination of density – Part 2: Immersed body (plummet)

method

ISO 2884-1, Paints and varnishes – Determination of viscosity using rotary viscometers – Part 1:

Cone-and-plate viscometer operated at a high rate of shear

ISO 3219, Plastics – Polymers/resins in the liquid state or as emulsions or dispersions –

Determination of viscosity using a rotational viscometer with defined shear rate

ISO 3251, Paints, varnishes and plastics – Determination of non-volatile-matter content

ISO 3451-1, Plastics – Determination of ash – Part 1: General methods

ISO 3664, Graphic technology and photography – Viewing conditions

ISO 3679, Determination of flash no-flash and flash point – Rapid equilibrium closed cup

method

ISO 4576, Plastics – Polymer dispersions – Determination of sieve residue (gross particle and

coagulum content)

ISO 9276-6, Representation of results of particle size analysis – Part 6: Descriptive and

quantitative representation of particle shape and morphology

ISO 11664-4, Colorimetry – Part 4: CIE 1976 L*a*b* colour space

ISO 13319, Determination of particle size distributions – Electrical sensing zone method

ISO 13320, Particle size analysis – Laser diffraction methods

ISO 13321, Particle size analysis – Photon correlation spectroscopy

ISO 13322-1, Particle size analysis – Image analysis methods – Part 1: Static image analysis

methods

ISO 13468-1:2019, Plastics – Determination of the total luminous transmittance of transparent

materials – Part 1: Single beam instrument

ISO 13468-2:2021, Plastics – Determination of the total luminous transmittance of transparent

materials – Part 2: Double-beam instrument

ISO 13655, Graphic technology – Spectral measurement and colorimetric computation for

graphic arts images

ISO 14488, Particulate materials – Sampling and sample splitting for the determination of

particulate properties

ISO 14782, Plastics – Determination of haze for transparent materials

ISO 14887, Sample preparation – Dispersing procedures for powders in liquids

ISO 15212-1, Oscillation-type density meters – Part 1: Laboratory instruments

ISO 18947-1:2021, Imaging materials and prints – Abrasion resistance – Part 1: General rub

testing methods

ISO 20379, Fine ceramics (advanced ceramics, advanced technical ceramics) – Measurement

of thixotropic behaviour of ceramic slurry by use of a rotational viscometer

ISO 20998-1, Measurement and characterization of particles by acoustic methods – Part 1:

Concepts and procedures in ultrasonic attenuation spectroscopy

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at https://www.electropedia.org/

• ISO Online browsing platform: available at https://www.iso.org/obp

NOTE Words in italics are defined within Clause 3.

3.1

conductive material

ingredient of a printing or coating component with intrinsic property providing electrical

conductivity

Note 1 to entry: The ingredient can be one or more small molecules, precursors, polymers, or particles.

Note 2 to entry: The ingredient can require post treatment to provide electrical conductivity

3.2

conductive ink

fluid in which one or more conductive materials (3.1) are dissolved or dispersed, and which is

used to form an electrically conductive structure

3.3

conductive layer

film-like structure formed by printing or coating and post treatment (3.4) of conductive ink (3.2)

on a substrate, which is electrically conductive

3.4

post treatment

process step following the deposition of ink to generate the intended functionality

Note 1 to entry: Process steps can be evaporation, annealing, curing or sintering

3.5

conductive film

substrate (sheet or roll) with conductive layer (3.3)

– 10 – IEC 62899-202:2023 © IEC 2023

3.6

solid content

mass fraction of an ingredient which effectively functions as a conductive substance, in

conductive ink (3.2)

3.7

non-volatile content

mass fraction of residue obtained by evaporation of the volatile solvent under specific conditions,

in conductive ink (3.2)

3.8

ash content

mass fraction of residue in conductive ink (3.2) excluding ingredients which are combusted or

carbonised by pyrolysis

3.9

foreign matter

substances, particles of aggregated grains, solidified ingredients of ink and ingredients which

do not function as a part of conductive ink (3.2)

3.10

spherical particle

particle with three approximately equal dimensions of length, width and height

3.11

rod

substance with thin elongated cylindrical shape

3.12

wire

flexible cylindrical conductor, with or without an insulating covering, the length of which is large

with respect to its cross-sectional dimensions

Note 1 to entry: The cross-section of a wire may have any shape, but the term "wire" is not generally used for

ribbons or tapes.

[SOURCE: IEC 60050-151:2001, 151-12-28]

3.13

tube

substance with fiber-like hollow cylindrical shape

3.14

dispersion

system consisting of two or more phases one of which is continuous and at least one other is

finely dispersed

[SOURCE: IEC 62899-101:2019, 3.31]

3.15

flash point

lowest liquid temperature at which, under certain standardized conditions, a liquid gives off

vapours in quantity such as to be capable of forming an ignitable vapour/air mixture

[SOURCE: IEC 60050-212:2010, 212-18-05]

4 Atmospheric conditions for evaluation and pre-conditioning

The standard atmosphere for evaluation (test and measurement) and storage of the specimen

shall be a temperature of 23 °C ± 2 °C and relative humidity of (50 ± 10) %, conforming to

standard atmosphere class 2 specified in ISO 291. If a polymer substrate is used for a test

piece coated with a conductive layer, the standard atmosphere for evaluation shall be a

temperature of 23 °C ± 1 °C and relative humidity of (50 ± 5) %, conforming to standard

atmosphere class 1 specified in ISO 291. Atmospheric pressure in test and measurement may

be specified in a prior agreement of trade partners, but it shall be reported.

If pre-conditioning is necessary, the same standard atmosphere specified above shall apply.

5 Summary characteristics and evaluation method of conductive ink

The conductive inks used in printed electronics shall be tested in accordance with the methods

specified in Table 1. Unless there is a prior agreement between the user and supplier these test

methods shall be applied without modification. In cases where the test has been modified, the

changed condition shall be described in the report.

Table 1 – Test methods for conductive inks used in PE

Items Standards for each test method

Non-volatile content ISO 3251

Ash content ISO 3451-1 method A

Foreign matter ISO 4576

Pyknometer (specified in ISO 758, ISO 1183-1

or ISO 2811-1)

Oscillation-type density meters (specified in

Density

ISO 15212-1)

Immersed body (plummet) method (specified in

ISO 2811-2)

Brookfield type rotational viscometer (specified

in ISO 2555)

Rheology (viscosity) Cone-and-plate viscometer (specified in

ISO 2884-1)

Rotational viscometer (specified in ISO 3219)

Rheology (thixotropic index) ISO 20379 using rotational viscometers

Liquid film (Wilhelmy) method (specified in

Surface tension

ISO 304)

Ink properties

Electric sensing zone method (specified in

ISO 13319)

Laser diffraction method (specified in

Size of conductive materials ISO 13320)

(spherical particles) Photon correlation method (specified in

ISO 13321)

Ultrasonic attenuation spectroscopy method

(specified in ISO 20998-1)

Size of conductive materials

Static image analysis method (specified in

ISO 13322-1)

(rods, wires and tubes)

Size of conductive materials

ISO 9276-6

(other shapes)

Open system; ISO 2592

Flashpoint

Closed system; ISO 2719, ISO 3679

Evaporation rate Subclause 6.3.6 in this document

Absorbance is measured by equipment

Appearance of ink

specified in ISO 13468-1 or ISO 13468-2.

– 12 – IEC 62899-202:2023 © IEC 2023

Items Standards for each test method

Four-point probe method (7.2.1 in this

Volume resistivity

document)

Properties of a

Surface resistivity (four-point

conductive layer

Subclause 7.2.2 in this document

probe method)

(Electrical properties)

Surface resistivity (contactless

IEC 62899-202-3

method)

Bending test IEC 62899-202-5

Properties of a

conductive layer

Abrasion resistance ISO 18947-1

(Mechanical properties)

Adhesion strength ISO 2409

Opacity ISO 2471 (diffuse reflectance)

Single-beam method (specified in ISO 13468-1)

Luminous transmittance

Double-beam method (specified in

ISO 13468-2)

Properties of a

Presented as the CIE (1976) L*a*b* (according

conductive layer

Chromaticity

to ISO 11664-4)

(Optical properties)

Measure of the chromaticity at 10 points and

Uniformity of colour

express with colour difference

Haze ISO 14782

Refractive index ISO 489 method A

6 Evaluation of properties of conductive ink

6.1 Specimen

The specimen for evaluation shall be prepared in accordance with ISO 14488 or an equivalent

method. If necessary, dilution by a compatible solvent is allowed.

6.2 Contents

6.2.1 Solid content

6.2.1.1 Determination of solid content

Solid content of conductive materials and non-conductive materials shall be determined by the

theoretical mass fraction (expressed as a percentage) of functional ingredients to the total ink

mass. Functional ingredients include conductive materials, their precursors or binders, or any

additives.

6.2.1.2 Report of the results

The report shall include the following items:

a) unique specimen identification;

b) atmospheric conditions of test;

c) solid content;

d) tester, test place, and test time (for example company name, city, year).

6.2.2 Non-volatile content

6.2.2.1 Principle

Non-volatile content is determined by measuring the mass of residue after evaporation of the

volatile ingredients and calculating the mass fraction (expressed as a percentage) to the total

ink mass.

6.2.2.2 Test method

The test method shall be as specified in ISO 3251 with the following exceptions:

a) Air pressure: 86 kPa to 106 kPa.

b) If specified by the manufacturer, the test may be performed under reduced pressure. The

conditions and procedures for reducing the pressure shall be as specified in ISO 124 or by

the manufacturer.

c) Materials which do not react with the ink during an examination shall be used.

d) Repeat the test until the weight becomes constant within 5 %.

6.2.2.3 Report of the results

The report shall include the following items:

a) specimen identification;

b) test conditions (air pressure if reduced, drying temperature and time);

c) specimen mass;

d) results;

e) tester, test place, and test time (for example company name, city, year).

6.2.3 Ash content

6.2.3.1 Test method

The test method shall be as specified in ISO 3451-1, method A, with the following exceptions:

a) If appropriate for the properties of the ink, a calcination temperature other than that specified

in ISO 3451-1 may be used.

b) If the ash content is very low, considering weighing accuracy, a specimen mass other than

that specified in ISO 3451-1 may be used.

The detailed product specifications shall specify the applicable calcination temperature and

specimen mass.

6.2.3.2 Report of the results

The report shall include the following items:

a) specimen identification;

b) calcination temperature;

c) specimen mass;

d) results and variation;

e) tester, test place, and test time (for example company name, city, year).

6.2.4 Foreign matter

6.2.4.1 Principle

Foreign matter is determined by measuring the mass of filtration residue and calculating the

mass fraction (expressed as a percentage) to the total ink mass.

– 14 – IEC 62899-202:2023 © IEC 2023

6.2.4.2 Test method

The test method shall be as specified in ISO 4576, with the following exceptions:

a) The specimen mass shall be 1 g to 10 g.

b) For filtration of the specimen, a membrane filter with appropriate pore size shall be used

instead of a metal sieve. The pore size of the filter shall be as specified by the manufacturer.

c) For diluting the specimen or cleaning the filtration residue, a solvent appropriate for the

properties of the ink shall be used.

d) Prior to filtering, the specimen may be diluted by an appropriate solvent if necessary. No

other treatment shall be allowed.

e) The drying temperature for the filter and filtration residue may be different from that specified

in ISO 4576.

f) The test shall be conducted until the difference between the results of two consecutive tests

is not more than 20 %; the higher result shall be used for the report.

6.2.4.3 Report of the results

The report shall include the following items:

a) specimen identification;

b) test conditions (filter pore size, drying temperature and filter type (material));

c) results;

d) tester, test place, and test time (for example company name, city, year).

6.3 Physical properties

6.3.1 Density

6.3.1.1 Measurement method

The measurement method shall either be the pyknometer method as specified in ISO 758,

ISO 1183-1 and ISO 2811-1, the method using oscillation-type density meters as specified in

ISO 15212-1, or the immersed body (plummet) method as specified in ISO 2811-2. The detailed

product specifications shall specify the measurement method to be used.

6.3.1.2 Equipment

Equipment shall be as specified in the measurement method (see 6.3.1.1) or shall be equipment

considered equivalent or superior.

6.3.1.3 Report of the results

The report shall include the following items:

a) specimen identification;

b) measurement method;

c) measurement atmosphere (temperature and relative humidity);

d) results;

e) tester, test place, and test time (for example company name, city, year).

6.3.2 Rheology

6.3.2.1 Measurement method for viscosity

Viscosity shall be measured using a Brookfield type rotational viscometer as specified in

ISO 2555, cone-and-plate viscometer as specified in ISO 2884-1, or rotational viscometer as

specified in ISO 3219.

The detailed product specifications shall specify the measurement method and measuring

temperature to be used.

6.3.2.2 Report of the results

The report shall include the following items:

a) standard number of the measurement method;

b) specimen identification;

c) measuring temperature;

d) viscometer model;

e) type of liquidity (such as newtonian, non-newtonian, Ostwald, extended Ostwald, Bingham);

f) viscosity expressed in millipascal second (mPa·s);

g) tester, test place, and test time (for example company name, city, year).

6.3.2.3 Measurement for thixotropic index

The thixotropic index can be measured using the methods described in ISO 20379. The

rotational viscometers in 6.3.2.1 can be used in this measurement, when the rotational

viscometer used is reported.

6.3.2.4 Report of the results

The report shall include the following items:

a) specimen identification;

b) measuring temperature;

c) viscometer model;

d) measurement conditions (maximum shear rate, standing time, time interval for ascending

and descending operation, number of steps when ascending and descending stepwise,

shear rate at each step, and sampling interval of data);

e) viscosity expressed in millipascal second (mPa·s);

6.3.3 Surface tension

6.3.3.1 Measurement method

Surface tension shall be measured using the drawing up liquid film (Wilhelmy) method as

specified in ISO 304 with the following exceptions:

a) equipment considered equivalent to that in ISO 304 may be used;

b) the test jig shall be made of platinum;

c) the equipment shall be calibrated using pure water and a hanging weight.

6.3.3.2 Report of the results

The report shall include the following items:

a) specimen identification;

b) measuring temperature;

c) surface tension expressed in millinewton per metre (mN/m);

d) tester, test place, and test time (for example company name, city, year).

– 16 – IEC 62899-202:2023 © IEC 2023

6.3.4 Size of conductive materials

6.3.4.1 Sampling

The specimen used for measuring the size of a conductive material shall be sampled in

accordance with the method specified in ISO 14488 or a similar method. If re-dispersion is

required, perform re-dispersion in accordance with the method specified in ISO 14887 or a

similar method.

6.3.4.2 Sphere

6.3.4.2.1 Measurement method

The mean particle size of spherical particles or near spherical particles (such as equants) shall

be measured using the electric sensing zone method specified in ISO 13319, the laser

diffraction method specified in ISO 13320, the photon correlation method specified in

ISO 13321, or the ultrasonic attenuation spectroscopy method specified in ISO 20998-1.

Measuring equipment shall be as specified in one of the above standards. Measuring equipment

which uses a method specified in any of these standards may be used.

Mean particle size is obtained as the sphere-equivalent diameter or circle-equivalent diameter,

depending on the measurement method. The type of diameter shall be recorded and included

in the report of the results.

NOTE Equants express the particles of similar length, width, and thickness. Both cubical and spherical particles

are included.

The DLS (dynamic light scattering) method according to ISO 22412 can be applied in a case

where particle size is in submicrometre. However, since proper use of the instrument and

interpretation of the result require certain precautions, good practices described in ISO/TR

22814 should be referred to when the DLS method is used.

6.3.4.2.2 Report of the results

The report shall include the following items:

a) specimen identification;

b) mean particle size;

c) type of diameter;

d) tester, test place, and test time (for example company name, city, year).

6.3.4.3 Rod, wire and tube

6.3.4.3.1 Measurement method

Rods, wires and tubes shall be measured using the method specified in ISO 13322-1, or an

equivalent method. As this method measures the widths and lengths of particles from an

electron microscope image, it requires a standard length. The scale shown on the image may

be used as the standard length. In order to decide the standard length, particles having known

accurate size may be mixed in with the specimen as a reference and photographed with the

specimen to calibrate the scale in the photograph. The smallest number of particles required

for obtaining the mean width and length is determined according to ISO 13322-1.

ISO 9276-6 treats rods, wires and tubes as acicular or columnar particles and specifies a

method for measuring their lengths. The width and length may be obtained using this method

and software based on it.

NOTE 1 The acicular particle is a slender, needle-like particle of similar width and thickness.

NOTE 2 The columnar particle is a long, thin particle with the width and thickness that are greater than those of an

acicular particle.

6.3.4.3.2 Report of the results

The report shall include the following items:

a) specimen identification;

b) width and length of particles;

c) definition of the standard of length;

d) number of particles used for calculating width and length;

e) tester, test place, and test time (for example company name, city, year).

6.3.4.4 Other shapes

6.3.4.4.1 Measurement method

For irregularly shaped particles which are not classified in 6.3.4.2 and 6.3.4.3, the mean particle

size shall be calculated in accordance with the method specified in ISO 9276-6 or software

based on it.

6.3.4.4.2 Report of the results

The report shall include the following items:

a) specimen identification;

b) mean particle size;

c) items whose defaults have been changed during data processing;

d) tester, test place, and test time (for example company name, city, year).

6.3.5 Flashpoint

6.3.5.1 Measurement method

Flashpoint shall be measured in accordance with ISO 2592 (open system). The method of "open

system" is preferable for safety, however, "closed systems" are also widely used. The

measurement method based on ISO 2719 (closed system) or ISO 3679 (closed system) may be

applied if a closed system is required.

6.3.5.2 Report of the results

The report shall include the following items:

a) specimen identification;

b) test conditions (temperature, humidity and atmospheric pressure);

c) sampling conditions (type of ink used, dispersive media and concentration);

d) results;

e) tester, test place, and test time (for example company name, city, year).

f) others (special items).

– 18 – IEC 62899-202:2023 © IEC 2023

6.3.6 Evaporation rate

6.3.6.1 General

The evaporation rate is a property which is necessary for the PE ink, but the details of the

evaluation condition and the measurement method are significantly different for the ink. In this

document, a common framework for the method is specified as a guideline. The detailed

conditions and measurements may be determined between trading partners depending on the

properties of the ink.

6.3.6.2 Measurement method

The evaporation rate of solvent from an ink formulation can be determined by measuring the

time taken to evaporate, for example, up to 90 % of the mass of the solvent content of the ink

formulation.

A flat absorbent material (such as a filter paper) is positioned on a sensitive mass balance

located inside a dry air (< 5 % relative humidity) or nitrogen cabinet at atmospheric pressure. A

known volume of ink (such as 1 mL) is dispensed in a straight line on the absorbent material to

produce a repeatable area of wetted film on the filter paper. Dried air or nitrogen is passed

through the cabinet at a controlled temperature and flow rate. The temperature and flow rate

may be determined between trading partners depending on the properties of the ink, but these

conditions shall be included in the report. The location of the entry and exit ports for the dry air

or nitrogen should be chosen so as not to disturb the mass balance readings throughout the

test.

The evaporation rate can be calculated by measuring the difference in mass over a period of

time. It is recommended that sufficient measurements be made to allow five or more points to

be plotted on a graph of mass loss versus time for val

...

IEC 62899-202 ®

Edition 2.0 2023-05

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Printed electronics –

Part 202: Materials – Conductive ink

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always have

committee, …). It also gives information on projects, replaced access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 300 terminological entries in English

details all new publications released. Available online and once

and French, with equivalent terms in 19 additional languages.

a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 62899-202 ®

Edition 2.0 2023-05

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Printed electronics –

Part 202: Materials – Conductive ink

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 31.180; 87.080 ISBN 978-2-8322-6955-8

– 2 – IEC 62899-202:2023 RLV © IEC 2023

CONTENTS

FOREWORD . 4

INTRODUCTION . 2

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 9

4 Atmospheric conditions for evaluation and pre-conditioning . 11

5 Summary characteristics and evaluation method of conductive ink . 11

6 Evaluation of properties of conductive ink . 12

6.1 Specimen . 12

6.2 Contents . 12

6.2.1 Solid content . 12

6.2.2 Non-volatile content . 13

6.2.3 Ash content . 13

6.2.4 Foreign matter . 14

6.3 Physical properties . 14

6.3.1 Density . 14

6.3.2 Rheology . 15

6.3.3 Surface tension . 15

6.3.4 Size of conductive materials . 16

6.3.5 Flashpoint . 17

6.3.6 Evaporation rate . 18

6.3.7 Appearance of ink . 19

7 Evaluation of the properties of a conductive layer . 19

7.1 Test piece . 19

7.1.1 General . 19

7.1.2 Substrate . 19

7.1.3 Conductive ink . 19

7.1.4 Dimensions of test piece . 19

7.1.5 Preparation of test piece . 19

7.2 Electrical properties . 20

7.2.1 Volume resistivity . 20

7.2.2 Surface resistivity (based on the four-point probe method) . 24

7.2.3 Surface resistivity (based on the contactless method) . 25

7.3 Mechanical properties . 25

7.3.1 Bending test . 25

7.3.2 Abrasion resistance . 26

7.3.3 Adhesion strength . 27

7.4 Optical properties . 25

7.4.1 Overview . 27

7.4.2 Luminous transmittance . 27

7.4.3 Chromaticity . 28

7.4.4 Uniformity of colour . 28

7.4.5 Haze . 30

7.4.6 Refractive index . 30

8 Storage . 31

8.1 Storage conditions . 31

8.2 Method for measuring aged deterioration . 31

8.3 Report of the results . 31

Annex A (informative) Example of four-point probe for applying an appropriate weight . 32

A.1 Internal structure . 32

A.2 Example of the general overall view . 32

Annex B (informative) Formula of correction factor F . 33

B.1 General . 33

B.2 Conditions for correction factor F . 34

B.3 Formula of correction factor F . 34

Annex C (informative) Influence of the measuring position and size of the specimen on

resistance . 35

C.1 Influence of the measuring position on resistance . 35

C.2 Influence of the size of the specimen on resistance . 36

Bibliography . 37

Figure 1 – Example of four-point probe measurement . 20

Figure 2 – Example of four-probe measurement equipment . 20

Figure 3 – Measuring positions of resistance (Type A) . 22

Figure 4 – Measuring positions of resistance (Type B) . 22

Figure 5 – Measuring positions of resistance (Type C) . 23

Figure A.1 – Example of the internal structure of probe . 32

Figure A.2 – Example of the general overall view of the probe . 32

Figure B.1 – Schematic diagram of the geometry of the conductive layer and the

configuration of probes A, B, C and D . 33

Figure C.1 – Measurement model for the influence of the measuring position on sheet

resistance . 35

Figure C.2 – Model measurement of the influence of the specimen size . 36

Table 1 – Test methods for conductive inks used in PE. 11

Table 2 – Resistance range of the test piece and the applied current . 21

Table 3 – List of the size of the specimen . 22

– 4 – IEC 62899-202:2023 RLV © IEC 2023

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

PRINTED ELECTRONICS –

Part 202: Materials – Conductive ink

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

This redline version of the official IEC Standard allows the user to identify the changes made

to the previous edition IEC 62899-202:2016. A vertical bar appears in the margin wherever a

change has been made. Additions are in green text, deletions are in strikethrough red text.

IEC 62899-202 has been prepared by IEC technical committee 119: Printed electronics. It is

an International Standard.

This second edition cancels and replaces the first edition published in 2016. This

edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) definitions of conductive material, conductive ink and conductive layer have been revised;

b) a summary of test methods is added;

c) mechanical tests for conductive layer are added.

The text of this International Standard is based on the following documents:

Draft Report on voting

119/423/FDIS 119/428/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/publications.

A list of all parts in the IEC 62899 series, published under the general title Printed electronics,

can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The "colour inside" logo on the cover page of this document indicates that it

contains colours which are considered to be useful for the correct understanding of its

contents. Users should therefore print this document using a colour printer.

– 6 – IEC 62899-202:2023 RLV © IEC 2023

INTRODUCTION

The IEC 62899-20x series relates mainly to evaluation methods for materials of printed

electronics. The series also include storage methods, packaging and marking, and

transportation conditions.

The IEC 62899-20x series is divided into parts for each material. Each part is prepared as a

generic specification containing fundamental information for the area of printed electronics.

Printed electronics is a technology that spans the printing and electrical/electronic area, and it

provides a variety of products. Since participants in this industry come from different areas,

their backgrounds and customs can be barriers to smooth communication and transactions in

the supply chain. The printed electronics industry continues to grow, but many barriers still

remain. Particularly, the lack of standardised terms and evaluation methods is one of the major

factors that inhibit smooth communication.

This document focuses on measurement and evaluation methods for conductive inks and

provides tools to promote the smooth communication within the supply chain.

This document specifies the basic items to be communicated and their measurement or

evaluation methods. This document includes the measurement methods for the basic properties

of inks and electrical conductivity, which is obtained by the post treatment of inks. Additionally,

storage methods, packaging and marking, and transportation conditions are also included.

This document is part of the IEC 62899-202 series and similar documents are available for other

materials used in printed electronics.

The IEC 62899-20x series consists of the following parts:

IEC 62899-201: Materials – Substrates

IEC 62899-202: Materials – Conductive ink

IEC 62899-203: Materials – Semiconductor ink

IEC 62899-204: Materials – Insulator ink

(Subsequent parts will be prepared for other materials.)

Furthermore, sectional specifications, blank detail specifications, and detail specifications of

each material will follow these parts.

This part of IEC 62899 is prepared for conductive materials used in printed electronics and

contains the test conditions, the evaluation methods and the storage conditions.

_____________

Under consideration.

PRINTED ELECTRONICS –

Part 202: Materials – Conductive ink

1 Scope

This part of IEC 62899 defines the terms and specifies the standard test methods for

characterization and evaluation of conductive inks.

This International Standard is applicable to conductive inks and conductive layer that are made

from conductive inks.

This document also provides measurement methods for evaluating the properties of conductive

layers made both from an additive process using conductive inks and from a subtractive process

used in printed electronics.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 62899-202-3, Printed electronics – Part 202-3: Materials – Conductive ink – Measurement

of sheet resistance of conductive films – Contactless method

IEC 62899-202-5, Printed electronics – Part 202-5: Materials – Conductive ink – Mechanical

bending test of a printed conductive layer on an insulating substrate

ISO 5-2, Photography and graphic technology – Density measurements – Part 2: Geometric

conditions for transmittance density

ISO 5-3, Photography and graphic technology – Density measurements – Part 3: Spectral

conditions

ISO 124, Latex, rubber – Determination of total solids content

ISO 291, Plastics – Standard atmospheres for conditioning and testing

ISO 304, Surface active agents – Determination of surface tension by drawing up liquid films

ISO 489:19992022, Plastics – Determination of refractive index

ISO 758, Liquid chemical products for industrial use – Determination of density

at 20 degrees C

ISO 1183-1, Plastics – Methods for determining the density of non-cellular plastics – Part 1:

Immersion method, liquid pycnometer method and titration method

ISO 2409:2020, Paints and varnishes – Cross-cut test

– 8 – IEC 62899-202:2023 RLV © IEC 2023

ISO 2471, Paper and board – Determination of opacity (paper backing) – Diffuse reflectance

method

ISO 2555, Plastics – Resins in the liquid state or as emulsions or dispersions – Determination

of apparent viscosity by the Brookfield Test using a single cylinder type rotational viscometer

method

ISO 2592, Petroleum and related products – Determination of flash and fire points – Cleveland

open cup method

ISO 2719, Determination of flash point – Pensky-Martens closed cup method

ISO 2811-1, Paints and varnishes – Determination of density – Part 1: Pycnometer method

ISO 2811-2, Paints and varnishes – Determination of density – Part 2: Immersed body (plummet)

method

ISO 2884-1, Paints and varnishes – Determination of viscosity using rotary viscometers – Part 1:

Cone-and-plate viscometer operated at a high rate of shear

ISO 3219, Plastics – Polymers/resins in the liquid state or as emulsions or dispersions –

Determination of viscosity using a rotational viscometer with defined shear rate

ISO 3251, Paints, varnishes and plastics – Determination of non-volatile-matter content

ISO 3451-1, Plastics – Determination of ash – Part 1: General methods

ISO 3664, Graphic technology and photography – Viewing conditions

ISO 3679, Determination of flash no-flash and flash point – Rapid equilibrium closed cup

method

ISO 4576, Plastics – Polymer dispersions – Determination of sieve residue (gross particle and

coagulum content)

ISO 9276-6, Representation of results of particle size analysis – Part 6: Descriptive and

quantitative representation of particle shape and morphology

ISO 11664-4, Colorimetry – Part 4: CIE 1976 L*a*b* colour space

ISO 13319, Determination of particle size distributions – Electrical sensing zone method

ISO 13320, Particle size analysis – Laser diffraction methods

ISO 13321, Particle size analysis – Photon correlation spectroscopy

ISO 13322-1, Particle size analysis – Image analysis methods – Part 1: Static image analysis

methods

ISO 13468-1:19962019, Plastics – Determination of the total luminous transmittance of

transparent materials – Part 1: Single beam instrument

ISO 13468-2:19992021, Plastics – Determination of the total luminous transmittance of

transparent materials – Part 2: Double-beam instrument

ISO 13655, Graphic technology – Spectral measurement and colorimetric computation for

graphic arts images

ISO 14488, Particulate materials – Sampling and sample splitting for the determination of

particulate properties

ISO 14782, Plastics – Determination of haze for transparent materials

ISO 14887, Sample preparation – Dispersing procedures for powders in liquids

ISO 15212-1, Oscillation-type density meters – Part 1: Laboratory instruments

ISO 18947-1:2021, Imaging materials and prints – Abrasion resistance – Part 1: General rub

testing methods

ISO 20379, Fine ceramics (advanced ceramics, advanced technical ceramics) – Measurement

of thixotropic behaviour of ceramic slurry by use of a rotational viscometer

ISO 20998-1, Measurement and characterization of particles by acoustic methods – Part 1:

Concepts and procedures in ultrasonic attenuation spectroscopy

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at https://www.electropedia.org/

• ISO Online browsing platform: available at https://www.iso.org/obp

NOTE Words in italics are defined within Clause 3.

3.1

conductive material

ingredient of a printing or coating material, which itself is electrically conductive or becomes

electrically conductive by post treatment such as heating component with intrinsic property

providing electrical conductivity

Note 1 to entry: The ingredient can be one or more small molecules, precursors, polymers, or particles.

Note 2 to entry: The ingredient can require post treatment to provide electrical conductivity

3.2

conductive ink

fluid in which one or more small molecules, polymers, or particles are dissolved or dispersed,

and which becomes an electrically conductive layer (3.3) by post treatment such as heating

fluid in which one or more conductive materials (3.1) are dissolved or dispersed, and which is

used to form an electrically conductive structure

3.3

conductive layer

film-like electrically conductive body made of conductive ink (3.2), which is printed or coated on

a substrate, followed as necessary by post treatment such as heating

film-like structure formed by printing or coating and post treatment (3.4) of conductive ink (3.2)

on a substrate, which is electrically conductive

– 10 – IEC 62899-202:2023 RLV © IEC 2023

3.4

post treatment

process step following the deposition of ink to generate the intended functionality

Note 1 to entry: Process steps can be evaporation, annealing, curing or sintering

3.5

conductive film

substrate (sheet or roll) with conductive layer (3.3)

3.6

solid content

mass fraction of an ingredient which effectively functions as a conductive substance, in

conductive ink (3.2)

3.7

non-volatile content

mass fraction of residue obtained by evaporation of the volatile solvent under specific conditions,

in conductive ink (3.2)

3.8

ash content

mass fraction of residue in conductive ink (3.2) excluding ingredients which are combusted or

carbonised by pyrolysis

3.9

foreign matter

substances and/or, particles of aggregated grains, filmed solidified ingredients of ink and

ingredients which do not function as a part of conductive ink (3.2)

3.10

spherical particle

particle with three approximately equal dimensions of length, width and height

3.11

rod

substance with thin elongated cylindrical shape

3.11

wire

substance with thin long fibre-like shape having electrically conductive or semi-conductive

property

3.12

wire

flexible cylindrical conductor, with or without an insulating covering, the length of which is large

with respect to its cross-sectional dimensions

Note 1 to entry: The cross-section of a wire may have any shape, but the term "wire" is not generally used for

ribbons or tapes.

[SOURCE: IEC 60050-151:2001, 151-12-28]

3.13

tube

substance with fiber-like hollow cylindrical shape

3.14

dispersion

heterogeneous system in which fine separated materials are distributed uniformly in other

materials

system consisting of two or more phases one of which is continuous and at least one other is

finely dispersed

[SOURCE: IEC 62899-101:2019, 3.31]

3.15

flash point

lowest liquid temperature at which, under certain standardized conditions, a liquid gives off

vapours in quantity such as to be capable of forming an ignitable vapour/air mixture

[SOURCE: IEC 60050-212:2010, 212-18-05]

4 Atmospheric conditions for evaluation and pre-conditioning

The standard atmosphere for evaluation (test and measurement) and storage of the specimen

shall be a temperature of 23 °C ± 2 °C and relative humidity of (50 ± 10) %, conforming to

standard atmosphere class 2 specified in ISO 291. If a polymer substrate is used for a test

piece coated with a conductive layer, the standard atmosphere for evaluation shall be a

temperature of 23 °C ± 1 °C and relative humidity of (50 ± 5) %, conforming to standard

atmosphere class 1 specified in ISO 291. Atmospheric pressure in test and measurement may

be specified in a prior agreement of trade partners, but it shall be reported.

If pre-conditioning is necessary, the same standard atmosphere specified above shall apply.

5 Summary characteristics and evaluation method of conductive ink

The conductive inks used in printed electronics shall be tested in accordance with the methods

specified in Table 1. Unless there is a prior agreement between the user and supplier these test

methods shall be applied without modification. In cases where the test has been modified, the

changed condition shall be described in the report.

Table 1 – Test methods for conductive inks used in PE

Items Standards for each test method

Non-volatile content ISO 3251

Ash content ISO 3451-1 method A

Foreign matter ISO 4576

Pyknometer (specified in ISO 758, ISO 1183-1

or ISO 2811-1)

Oscillation-type density meters (specified in

Density

ISO 15212-1)

Immersed body (plummet) method (specified in

Ink properties ISO 2811-2)

Brookfield type rotational viscometer (specified

in ISO 2555)

Rheology (viscosity) Cone-and-plate viscometer (specified in

ISO 2884-1)

Rotational viscometer (specified in ISO 3219)

Rheology (thixotropic index) ISO 20379 using rotational viscometers

Liquid film (Wilhelmy) method (specified in

Surface tension

ISO 304)

– 12 – IEC 62899-202:2023 RLV © IEC 2023

Items Standards for each test method

Electric sensing zone method (specified in

ISO 13319)

Laser diffraction method (specified in

Size of conductive materials ISO 13320)

(spherical particles) Photon correlation method (specified in

ISO 13321)

Ultrasonic attenuation spectroscopy method

(specified in ISO 20998-1)

Size of conductive materials

Static image analysis method (specified in

ISO 13322-1)

(rods, wires and tubes)

Size of conductive materials

ISO 9276-6

(other shapes)

Open system; ISO 2592

Flashpoint

Closed system; ISO 2719, ISO 3679

Evaporation rate Subclause 6.3.6 in this document

Absorbance is measured by equipment

Appearance of ink

specified in ISO 13468-1 or ISO 13468-2.

Four-point probe method (7.2.1 in this

Volume resistivity

document)

Properties of a

Surface resistivity (four-point

conductive layer

Subclause 7.2.2 in this document

probe method)

(Electrical properties)

Surface resistivity (contactless

IEC 62899-202-3

method)

Bending test IEC 62899-202-5

Properties of a

conductive layer

Abrasion resistance ISO 18947-1

(Mechanical properties)

Adhesion strength ISO 2409

Opacity ISO 2471 (diffuse reflectance)

Single-beam method (specified in ISO 13468-1)

Luminous transmittance

Double-beam method (specified in

ISO 13468-2)

Properties of a

Presented as the CIE (1976) L*a*b* (according

conductive layer

Chromaticity

to ISO 11664-4)

(Optical properties)

Measure of the chromaticity at 10 points and

Uniformity of colour

express with colour difference

Haze ISO 14782

Refractive index ISO 489 method A

6 Evaluation of properties of conductive ink

6.1 Specimen

The specimen for evaluation shall be prepared in accordance with ISO 14488 or an equivalent

method. If necessary, dilution by a compatible solvent may be is allowed.

6.2 Contents

6.2.1 Solid content

6.2.1.1 Determination of solid content

Solid content of conductive materials and non-conductive materials shall be determined by the

theoretical mass fraction (expressed as a percentage) of functional ingredients to the total ink

mass. Functional ingredients include conductive materials, their precursors or binders, or any

additives.

6.2.1.2 Report of the results

The report shall include the following items:

a) unique specimen identification;

b) atmospheric conditions of test;

c) solid content;

d) tester, test place, and test time (for example company name, city, year).

6.2.2 Non-volatile content

6.2.2.1 Principle

Non-volatile content is determined by measuring the mass of residue after evaporation of the

volatile ingredients and calculating the mass fraction (expressed as a percentage) to the total

ink mass.

6.2.2.2 Test method

The test method shall be as specified in ISO 1625 ISO 3251 with the following exceptions:

a) Air pressure: 86 kPa to 106 kPa.

b) If specified by the manufacturer, the test may be performed under reduced pressure. The

conditions and procedures for reducing the pressure shall be as specified in ISO 124 or by

the manufacturer.

c) Materials which do not react with the ink during an examination shall be used.

d) Repeat the test until the weight becomes constant within 5 %.

6.2.2.3 Report of the results

The report shall include the following items:

a) specimen identification;

b) test conditions (air pressure if reduced, drying temperature and time);

c) specimen mass;

d) results;

e) tester, test place, and test time (for example company name, city, year).

6.2.3 Ash content

6.2.3.1 Test method

The test method shall be as specified in ISO 3451-1, method A, with the following exceptions:

a) If appropriate for the properties of the ink, a calcination temperature other than that specified

in ISO 3451-1 may be used.

b) If the ash content is very low, considering weighing accuracy, a specimen mass other than

that specified in ISO 3451-1 may be used.

The detailed product specifications shall specify the applicable calcination temperature and

specimen mass.

6.2.3.2 Report of the results

The report shall include the following items:

a) specimen identification;

b) calcination temperature;

– 14 – IEC 62899-202:2023 RLV © IEC 2023

c) specimen mass;

d) results and variation;

e) tester, test place, and test time (for example company name, city, year).

6.2.4 Foreign matter

6.2.4.1 Principle

Foreign matter is determined by measuring the mass of filtration residue and calculating the

mass fraction (expressed as a percentage) to the total ink mass.

6.2.4.2 Test method