IEC 62137-4:2014

(Main)Electronics assembly technology - Part 4: Endurance test methods for solder joint of area array type package surface mount devices

Electronics assembly technology - Part 4: Endurance test methods for solder joint of area array type package surface mount devices

IEC 62137-4:2014 specifies the test method for the solder joints of area array type packages mounted on the printed wiring board to evaluate solder joint durability against thermo-mechanical stress. This part of IEC 62137 applies to the surface mounting semiconductor devices with area array type packages (FBGA, BGA, FLGA and LGA) including peripheral termination type packages (SON and QFN) that are intended to be used in industrial and consumer electrical or electronic equipment. IEC 62137-4 includes the following significant technical changes with respect to IEC 62137:2004:

- test conditions for use of lead-free solder are included;

- test conditions for lead-free solders are added;

- accelerations of the temperature cycling test for solder joints are added.

Technique d'assemblage des composants électroniques - Partie 4: Méthodes d'essais d'endurance des joints brasés des composants pour montage en surface à boîtiers de type matriciel

L'IEC 62137-4:2014 spécifie la méthode d'essai des joints brasés des boîtiers de type matriciel montés sur la carte de câblage imprimé, visant à évaluer la durabilité des joints brasés par rapport aux contraintes thermiques et mécaniques. La présente partie de l'IEC 62137 s'applique aux dispositifs à semiconducteurs pour montage en surface avec boîtiers de type matriciel (FBGA, BGA, FLGA et LGA) incluant les boîtiers de type à bornes périphériques (SON et QFN) qui sont destinés à être utilisés dans des matériels électriques ou électroniques industriels ou grand public. L'IEC 62137-4 inclut les modifications techniques majeures suivantes par rapport à l'IEC 62137:2004:

- les conditions d'essai pour l'utilisation d'une soudure sans plomb ont été incluses;

- les conditions d'essai pour des soudures sans plomb ont été ajoutées;

- les accélérations de l'essai de cycle de température pour des joints brasés ont été ajoutées.

General Information

- Status

- Published

- Publication Date

- 08-Oct-2014

- Technical Committee

- TC 91 - Electronics assembly technology

- Drafting Committee

- WG 3 - TC 91/WG 3

- Current Stage

- PPUB - Publication issued

- Start Date

- 09-Oct-2014

- Completion Date

- 15-Oct-2014

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 62137-4:2014 is an international standard developed by the International Electrotechnical Commission (IEC) focusing on the endurance test methods for solder joints of area array type package surface mount devices (SMDs). This standard specifically defines procedures to evaluate the durability and reliability of solder joints on semiconductor devices with area array packaging such as FBGA, BGA, FLGA, LGA, including peripheral termination types SON and QFN. These devices are commonly used across industrial and consumer electrical or electronic equipment sectors.

The standard addresses the critical need to assess solder joint performance under thermo-mechanical stresses, especially important as devices transition from traditional leaded to lead-free solder technologies. IEC 62137-4:2014 updates previous editions to include specific test conditions for lead-free solders and accelerated temperature cycling tests, reflecting industry trends towards RoHS compliance and enhanced product lifespan.

Key Topics

Scope and Test Methods

Focuses on solder joint endurance testing methods for area array type packages mounted on printed wiring boards (PWBs). Establishes criteria for evaluating solder joint integrity under temperature cycling-a key stress factor in electronics reliability.Lead-Free Solder Test Conditions

Incorporates test protocols tailored for lead-free solder alloys, such as Sn-Ag-Cu, recognizing their distinct mechanical and thermal behaviors compared to traditional Sn-Pb solders.Temperature Cycling Tests

Defines temperature cycling procedures, including pre-conditioning, temperature ranges, cycle rates, and electrical resistance monitoring, to simulate real-life thermo-mechanical stresses on solder joints.Test Apparatus and Materials

Specifies requirements for test substrates, solder paste, reflow soldering equipment, temperature cycling chambers, and electrical resistance measurement systems, ensuring consistent and reproducible test conditions.Acceleration Techniques

Details methods to accelerate temperature cycling tests for faster assessment of solder joint life expectancy without compromising test validity.Measurement and Assessment

Provides guidance on initial and final measurements of electrical resistance and visual inspections to determine the end-of-life criteria for solder joints.

Applications

IEC 62137-4:2014 is essential for:

Semiconductor Manufacturers

Ensuring that area array package solder joints meet durability requirements before product release.Printed Circuit Board (PCB) Designers and Assemblers

Validating soldering processes and materials are compatible with the thermal and mechanical cycles expected during device operation.Quality Assurance and Reliability Engineers

Implementing standardized endurance testing as part of product qualification and failure analysis to improve product lifecycle and customer satisfaction.Consumer and Industrial Electronics Production

Assessing solder joint robustness in devices ranging from mobile phones and computers to industrial control systems that use area array type surface mount packages.Research and Development

Facilitating innovative solder materials and assembly technologies by providing a rigorous framework to evaluate solder joint performance.

Related Standards

IEC 62137 (Series) - Covers electronics assembly technology test methods, encompassing various parts related to solder joint reliability.

IEC 60068-2-14 - Environmental testing guidance that complements solder joint endurance verification.

IPC-A-610 - Acceptability of electronic assemblies, providing criteria for solder joint quality.

JEDEC JESD22-A104 - Temperature cycling test methods for semiconductor devices, used alongside IEC guidelines.

RoHS Directive Compliance - Ensures solder materials and test procedures align with environmental and health regulatory requirements affecting solder alloy selection.

By adhering to IEC 62137-4:2014, manufacturers and engineers can reliably evaluate solder joint endurance on area array surface mount devices, particularly in the context of growing lead-free solder adoption and the demand for longer-lasting electronics. This standard provides a clear, uniform methodology critical for maintaining quality and performance across global electronics markets.

Get Certified

Connect with accredited certification bodies for this standard

TL 9000 QuEST Forum

Telecommunications quality management system.

ANCE

Mexican certification and testing association.

Intertek Slovenia

Intertek testing, inspection, and certification services in Slovenia.

Sponsored listings

Frequently Asked Questions

IEC 62137-4:2014 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Electronics assembly technology - Part 4: Endurance test methods for solder joint of area array type package surface mount devices". This standard covers: IEC 62137-4:2014 specifies the test method for the solder joints of area array type packages mounted on the printed wiring board to evaluate solder joint durability against thermo-mechanical stress. This part of IEC 62137 applies to the surface mounting semiconductor devices with area array type packages (FBGA, BGA, FLGA and LGA) including peripheral termination type packages (SON and QFN) that are intended to be used in industrial and consumer electrical or electronic equipment. IEC 62137-4 includes the following significant technical changes with respect to IEC 62137:2004: - test conditions for use of lead-free solder are included; - test conditions for lead-free solders are added; - accelerations of the temperature cycling test for solder joints are added.

IEC 62137-4:2014 specifies the test method for the solder joints of area array type packages mounted on the printed wiring board to evaluate solder joint durability against thermo-mechanical stress. This part of IEC 62137 applies to the surface mounting semiconductor devices with area array type packages (FBGA, BGA, FLGA and LGA) including peripheral termination type packages (SON and QFN) that are intended to be used in industrial and consumer electrical or electronic equipment. IEC 62137-4 includes the following significant technical changes with respect to IEC 62137:2004: - test conditions for use of lead-free solder are included; - test conditions for lead-free solders are added; - accelerations of the temperature cycling test for solder joints are added.

IEC 62137-4:2014 is classified under the following ICS (International Classification for Standards) categories: 31.190 - Electronic component assemblies; 33.160.40 - Video systems. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62137-4:2014 has the following relationships with other standards: It is inter standard links to IEC 62137:2004, IEC 62137:2004/COR1:2005. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 62137-4:2014 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62137-4 ®

Edition 1.0 2014-10

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Electronics assembly technology –

Part 4: Endurance test methods for solder joint of area array type package

surface mount devices

Technique d'assemblage des composants électroniques –

Partie 4: Méthodes d'essais d'endurance des joints brasés des composants

pour montage en surface à boîtiers de type matriciel

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing more than 30 000 terms and

Technical Specifications, Technical Reports and other definitions in English and French, with equivalent terms in 14

documents. Available for PC, Mac OS, Android Tablets and additional languages. Also known as the International

iPad. Electrotechnical Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a More than 55 000 electrotechnical terminology entries in

variety of criteria (reference number, text, technical English and French extracted from the Terms and Definitions

committee,…). It also gives information on projects, replaced clause of IEC publications issued since 2002. Some entries

and withdrawn publications. have been collected from earlier publications of IEC TC 37,

77, 86 and CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient plus de 30 000 termes et définitions en

Spécifications techniques, Rapports techniques et autres

anglais et en français, ainsi que les termes équivalents dans

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

14 langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

Plus de 55 000 entrées terminologiques électrotechniques, en

La recherche avancée permet de trouver des publications IEC

en utilisant différents critères (numéro de référence, texte, anglais et en français, extraites des articles Termes et

comité d’études,…). Elle donne aussi des informations sur les Définitions des publications IEC parues depuis 2002. Plus

projets et les publications remplacées ou retirées. certaines entrées antérieures extraites des publications des

CE 37, 77, 86 et CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 62137-4 ®

Edition 1.0 2014-10

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Electronics assembly technology –

Part 4: Endurance test methods for solder joint of area array type package

surface mount devices

Technique d'assemblage des composants électroniques –

Partie 4: Méthodes d'essais d'endurance des joints brasés des composants

pour montage en surface à boîtiers de type matriciel

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX X

ICS 31.190 ISBN 978-2-8322-1873-0

– 2 – IEC 62137-4:2014 © IEC 2014

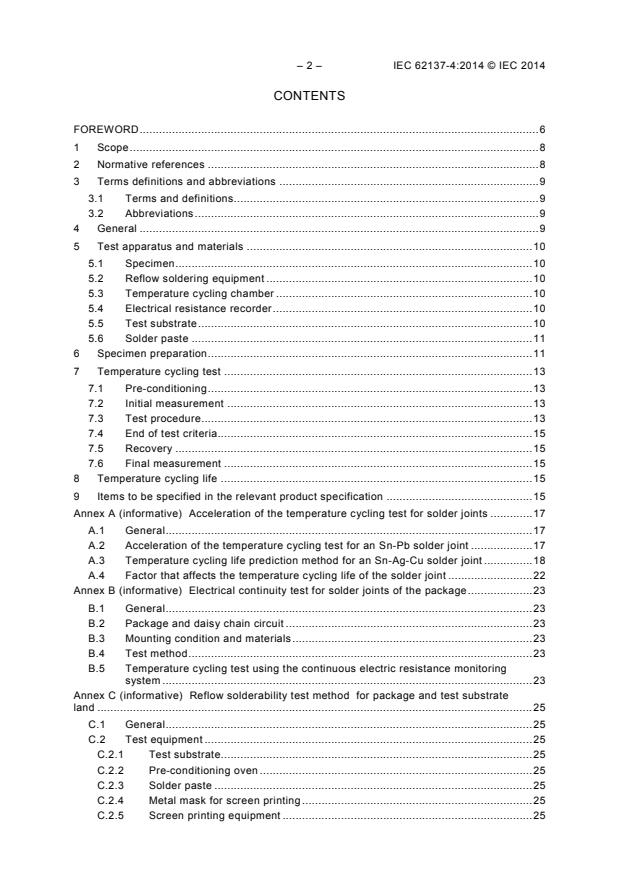

CONTENTS

FOREWORD . 6

1 Scope . 8

2 Normative references . 8

3 Terms definitions and abbreviations . 9

3.1 Terms and definitions . 9

3.2 Abbreviations . 9

4 General . 9

5 Test apparatus and materials . 10

5.1 Specimen . 10

5.2 Reflow soldering equipment . 10

5.3 Temperature cycling chamber . 10

5.4 Electrical resistance recorder . 10

5.5 Test substrate . 10

5.6 Solder paste . 11

6 Specimen preparation . 11

7 Temperature cycling test . 13

7.1 Pre-conditioning . 13

7.2 Initial measurement . 13

7.3 Test procedure . 13

7.4 End of test criteria. 15

7.5 Recovery . 15

7.6 Final measurement . 15

8 Temperature cycling life . 15

9 Items to be specified in the relevant product specification . 15

Annex A (informative) Acceleration of the temperature cycling test for solder joints . 17

A.1 General . 17

A.2 Acceleration of the temperature cycling test for an Sn-Pb solder joint . 17

A.3 Temperature cycling life prediction method for an Sn-Ag-Cu solder joint . 18

A.4 Factor that affects the temperature cycling life of the solder joint . 22

Annex B (informative) Electrical continuity test for solder joints of the package . 23

B.1 General . 23

B.2 Package and daisy chain circuit . 23

B.3 Mounting condition and materials . 23

B.4 Test method . 23

B.5 Temperature cycling test using the continuous electric resistance monitoring

system . 23

Annex C (informative) Reflow solderability test method for package and test substrate

land . 25

C.1 General . 25

C.2 Test equipment . 25

C.2.1 Test substrate. 25

C.2.2 Pre-conditioning oven . 25

C.2.3 Solder paste . 25

C.2.4 Metal mask for screen printing . 25

C.2.5 Screen printing equipment . 25

C.2.6 Package mounting equipment . 25

C.2.7 Reflow soldering equipment . 25

C.2.8 X-ray inspection equipment . 26

C.3 Standard mounting process . 26

C.3.1 Initial measurement . 26

C.3.2 Pre-conditioning . 26

C.3.3 Package mounting on test substrate . 26

C.3.4 Recovery . 27

C.3.5 Final measurement . 27

C.4 Examples of faulty soldering of area array type packages . 27

C.4.1 Repelled solder by contamination on the ball surface of the BGA

package . 27

C.4.2 Defective solder ball wetting caused by a crack in the package . 27

C.5 Items to be given in the product specification . 28

Annex D (informative) Test substrate design guideline . 29

D.1 General . 29

D.2 Design standard . 29

D.2.1 General . 29

D.2.2 Classification of substrate specifications . 29

D.2.3 Material of the test substrate . 31

D.2.4 Configuration of layers of the test substrate . 31

D.2.5 Land shape of test substrate . 31

D.2.6 Land dimensions of the test substrate . 31

D.3 Items to be given in the product specification . 32

Annex E (informative) Heat resistance to reflow soldering for test substrate . 33

E.1 General . 33

E.2 Test apparatus . 33

E.2.1 Pre-conditioning oven . 33

E.2.2 Reflow soldering equipment . 33

E.3 Test procedure . 33

E.3.1 General . 33

E.3.2 Pre-conditioning . 33

E.3.3 Initial measurement . 33

E.3.4 Moistening process (1) . 34

E.3.5 Reflow heating (1) . 34

E.3.6 Moistening process (2) . 34

E.3.7 Reflow heating process (2) . 34

E.3.8 Final measurement . 34

E.4 Items to be given in the product specification . 34

Annex F (informative) Pull strength measurement method for the test substrate land . 35

F.1 General . 35

F.2 Test apparatus and materials . 35

F.2.1 Pull strength measuring equipment . 35

F.2.2 Reflow soldering equipment . 35

F.2.3 Test substrate. 35

F.2.4 Solder ball . 35

F.2.5 Solder paste . 35

F.2.6 Flux . 35

F.3 Measurement procedure . 36

– 4 – IEC 62137-4:2014 © IEC 2014

F.3.1 Pre-conditioning . 36

F.3.2 Solder paste printing . 36

F.3.3 Solder ball placement . 36

F.3.4 Reflow heating process . 36

F.3.5 Pull strength measurement . 36

F.3.6 Final measurement . 37

F.4 Items to be given in the product specification . 37

Annex G (informative) Standard mounting process for the packages . 38

G.1 General . 38

G.2 Test apparatus and materials . 38

G.2.1 Test substrate. 38

G.2.2 Solder paste . 38

G.2.3 Metal mask for screen printing . 38

G.2.4 Screen printing equipment . 38

G.2.5 Package mounting equipment . 38

G.2.6 Reflow soldering equipment . 38

G.3 Standard mounting process . 39

G.3.1 Initial measurement . 39

G.3.2 Solder paste printing . 39

G.3.3 Package mounting . 39

G.3.4 Reflow heating process . 39

G.3.5 Recovery . 40

G.3.6 Final measurement . 40

G.4 Items to be given in the product specification . 40

Annex H (informative) Mechanical stresses to the packages . 41

H.1 General . 41

H.2 Mechanical stresses . 41

Bibliography . 42

Figure 1 – Region for evaluation of the endurance test . 10

Figure 2 – Typical reflow soldering profile for Sn63Pb37 solder alloy . 12

Figure 3 – Typical reflow soldering profile for Sn96,5Ag3Cu,5 solder alloy . 13

Figure 4 – Test conditions of temperature cycling test. 14

Figure A.1 – FBGA package device and FEA model for calculation of acceleration

factors AF . 20

Figure A.2 – Example of acceleration factors AF with an FBGA package device using

Sn96,5Ag3Cu,5 solder alloy . 21

Figure A.3 – Fatigue characteristics of Sn96,5Ag3Cu,5 an alloy micro solder joint

(N = 20 % load drop from initial load) . 22

f

Figure B.1 – Example of a test circuit for the electrical continuity test of a solder joint . 23

Figure B.2 – Measurement example of continuously monitored resistance in the

temperature cycling test . 24

Figure C.1 – Temperature measurement of specimen using thermocouples . 26

Figure C.2 – Repelled solder caused by contamination on the solder ball surface . 27

Figure C.3 – Defective soldering as a result of a solder ball drop . 28

Figure D.1 – Standard land shapes of the test substrate . 31

Figure F.1 – Measuring methods for pull strength . 36

Figure G.1 – Example of printed conditions of solder paste . 39

Figure G.2 – Temperature measurement of the specimen using thermocouples . 40

Table 1 – Test conditions of temperature cycling test . 14

Table A.1 – Example of test results of the acceleration factor (Sn63Pb37 solder alloy) . 18

Table A.2 – Example test results of the acceleration factor (Sn96,5Ag3Cu,5 solder

alloy) . 20

Table A.3 – Material constant and inelastic strain range calculated by FEA for FBGA

package devices as shown in Figure A.1 (Sn96,5Ag3Cu,5 solder alloy) . 21

Table D.1 – Types classification of the test substrate . 30

Table D.2 – Standard layers' configuration of test substrates . 31

Table G.1 – Stencil design standard for packages . 38

Table H.1 – Mechanical stresses to mounted area array type packages . 41

– 6 – IEC 62137-4:2014 © IEC 2014

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTRONICS ASSEMBLY TECHNOLOGY –

Part 4: Endurance test methods for solder joint

of area array type package surface mount devices

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62137-4 has been prepared by IEC technical committee 91:

Electronics assembly technology.

IEC 62137-4 (first edition) cancels and replaces IEC 62137:2004. This edition constitutes a

technical revision.

IEC 62137-4 includes the following significant technical changes with respect to

IEC 62137:2004:

• test conditions for use of lead-free solder are included;

• test conditions for lead-free solders are added;

• accelerations of the temperature cycling test for solder joints are added.

The text of this standard is based on the following documents:

FDIS Report on voting

91/1188/FDIS 91/1205/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 62137 series, published under the general title Electronics

assembly technology can be found in the IEC website.

Future standards in this series will carry the new general title as cited above. Titles of existing

standards in this series will be updated at the time of the next edition.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 8 – IEC 62137-4:2014 © IEC 2014

ELECTRONICS ASSEMBLY TECHNOLOGY –

Part 4: Endurance test methods for solder joint

of area array type package surface mount devices

1 Scope

This part of IEC 62137 specifies the test method for the solder joints of area array type

packages mounted on the printed wiring board to evaluate solder joint durability against

thermo-mechanical stress.

This part of IEC 62137 applies to the surface mounting semiconductor devices with area array

type packages (FBGA, BGA, FLGA and LGA) including peripheral termination type packages

(SON and QFN) that are intended to be used in industrial and consumer electrical or

electronic equipment.

An acceleration factor for the degradation of the solder joints of the packages by the

temperature cycling test due to the thermal stress when mounted, is described Annex A.

Annex H provides some explanations concerning various types of mechanical stress when

mounted.

The test method specified in this standard is not intended to evaluate semiconductor devices

themselves.

NOTE 1 Mounting conditions, printed wiring boards, soldering materials, and so on, significantly affect the result

of the test specified in this standard. Therefore, the test specified in this standard is not regarded as the one to be

used to guarantee the mounting reliability of the packages.

NOTE 2 The test method is not necessary, if there is no stress (mechanical or other) to solder joints in field use

and handling after mounting.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60068-2-14, Environmental testing – Part 2-14: Tests – Test N: Change of temperature

IEC 60191-6-2, Mechanical standardization of semiconductor devices – Part 6-2: General

rules for the preparation of outline drawings of surface mounted semiconductor device

packages – Design guide for 1,50 mm, 1,27 mm and 1,00 mm pitch ball and column terminal

packages

IEC 60191-6-5, Mechanical standardization of semiconductor devices – Part 6-5: General

rules for the preparation of outline drawings of surface mounted semiconductor device

packages – Design guide for fine-pitch ball grid array (FBGA)

IEC 60194, Printed board design, manufacture and assembly – Terms and definitions

IEC 61190-1-3, Attachment materials for electronic assembly – Part 1-3: Requirements for

electronic grade solder alloys and fluxed and non-fluxed solid solders for electronic soldering

applications

IEC 61249-2-7, Materials for printed boards and other interconnecting structures – Part 2-7:

Reinforced base materials clad and unclad – Epoxide woven E-glass laminated sheet of

defined flammability (vertical burning test), copper-clad

IEC 61249-2-8, Materials for printed boards and other interconnecting structures – Part 2-8:

Reinforced base materials clad and unclad – Modified brominated epoxide woven fibreglass

reinforced laminated sheets of defined flammability (vertical burning test), copper-clad

IEC 62137-3:2011, Electronics assembly technology – Part 3: Selection guidance of

environmental and endurance test methods for solder joints

3 Terms definitions and abbreviations

3.1 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60191-6-2,

IEC 60191-6-5 and IEC 60194, as well as the following, apply.

3.1.1

temperature cycling life

period of time to reach a lost performance state as agreed between the trading partners

during the temperature cycling test

3.1.2

momentary interruption detector

instrument capable to detect an electrical discontinuity in the daisy chain circuits

Note 1 to entry: See Annex B for the electrical continuity test of solder joint.

3.2 Abbreviations

FBGA Fine-pitch ball grid array

BGA Ball grid array

FLGA Fine-pitch land grid array

LGA Land grid array

SON Small outline non-leaded package

QFN Quad flat-pack non-leaded package

SMD Surface mounting device

OSP Organic solderability preservative

FR-4 Flame retardant type 4

FEA Finite element method analysis

CGA Column grid array

4 General

The regions of the solder joints to be evaluated are shown in Figure 1. The test method in this

standard is applicable to evaluate the durability of the solder joints against thermal stress to

the package mounted on substrate but not to test the mechanical strength of the package

itself.

– 10 – IEC 62137-4:2014 © IEC 2014

Therefore, the conditions for accelerated stress conditioning by a temperature cycling test

may exceed the maximum allowable temperature range for the package.

The test method specified in this standard is mainly applicable to the solder joint between

substrates of printed wiring board and the package as an evaluation target. However, the test

results depend on conditions such as the mounting method and the condition, materials and

the printed wiring board, etc. See Annex C to Annex G.

SMD (array type)

Substrate

Device

Device

Solder

Substrate

Device termination

Plating layers

Evaluation

Solder

area

Inter-metallic

Substrate

compound layers

Substrate Substrate land

IEC

Figure 1 – Region for evaluation of the endurance test

5 Test apparatus and materials

5.1 Specimen

Specimen is the package mounted on the test substrate (refer to Clause 6 for preparation).

5.2 Reflow soldering equipment

The reflow soldering equipment shall be able to realize the reflow soldering temperature

profile specified in Clause 6. Examples of temperature profile are shown in Figure 2 and

Figure 3.

NOTE A standard mounting process for the package is shown in Annex G.

5.3 Temperature cycling chamber

The temperature cycling chamber shall be able to realize the temperature cycling profile

specified in Figure 4. The general requirements for the temperature cycling chamber are

specified in IEC 60068-2-14.

5.4 Electrical resistance recorder

The electrical resistance recorder shall be able to detect electrical continuity interruption in

the daisy chain circuit. If there is no doubt of the measuring result, an electrical resistance

measuring instrument featured with a momentary interruption detector and/or a continuous

electrical resistance data logger should be used.

The interruption detector should be sufficiently sensitive to detect a 100 µs momentary

interruption. Furthermore, the electrical resistance measuring instrument should be able to

measure a resistance exceeding 1 000 Ω.

5.5 Test substrate

Unless otherwise specified in the product specification, the test substrate shall be as follows.

a) Test substrate material

Test substrate material shall be a single sided printed wiring board for general use, for

example, copper-clad epoxide woven fiberglass reinforced laminated sheets as specified

in IEC 61249-2-7 or IEC 61249-2-8. The thickness shall be (1,6 ± 0,2) mm including

copper foil. The copper foil thickness shall be (35 ± 10) µm.

NOTE 1 Heat resistance to reflow soldering for the test substrate is described in Annex E.

b) Test substrate dimensions

The test substrate dimensions depend on the mounted package size and shape. However,

the test substrate dimensions shall be fixed on the pull strength test equipment.

c) Land shape and land dimensions

Land shape and land dimensions should be as specified in IEC 61188-5-8 or as

recommended by the package manufacturer.

Moreover, the test substrate and the test package shall be designed in such a way that

their land pattern forms a daisy chain circuit after mounting for the electrical continuity

measurement.

NOTE 2 Annex D provides a test substrate design guide.

NOTE 3 Annex C provides a solderability test for the substrate land. And Annex F provides a strength test for

the substrate land.

d) Surface finish of land pattern

If specified in the product specification, a solderable region (land pattern of the test

substrate) shall be treated suitably against oxidization, for example, by means of an

organic solderability preservative (OSP) layer. The surface protection shall not interfere

with the solderability of the land pattern being soldered by using the reflow soldering

equipment specified in 5.2.

5.6 Solder paste

Solder paste is made of flux, finely divided particles of solder and additives to promote wetting

and to control viscosity, tackiness, slumping, drying rate, etc. Unless otherwise specified in

the product specification, one of the solder alloys listed below (as specified in IEC 61190-1-3)

shall be used. The product specification shall specify details of the solder paste.

The major composition of the solder alloys are as follows:

a) 63 % mass fraction of Sn (tin) and 37 % mass fraction on Pb (lead);

b) from 3,0 % to 4,0 % mass fraction of Ag (silver), from 0,5 % to 1,0 % mass fraction of Cu

(copper) and the remainder of Sn (tin).

Example: Sn-Ag-Cu ternary alloy such as Sn96,5Ag3Cu,5 alloy is used.

6 Specimen preparation

The package shall be mounted on the test substrate using the following reflow soldering

process. The package for the specimen shall be modified as for test dummy package to form

a daisy chain circuit with a land pattern of the test substrate after reflow soldering.

NOTE The solderability test to confirm the termination of the package and the test substrate land which affects

the solder joint strength is described in Annex C.

The specimen preparation process and the conditions are as follows.

a) Unless otherwise specified in the product specification, the solder paste specified in 5.6

shall be printed on the test substrate land specified in 5.5, using a stencil made of

stainless steel being 120 µm to 150 µm thick, and that have the same aperture

dimensions as the dimensions, shape and arrangement of the test substrate land.

b) The package shall be placed onto the printed solder paste.

– 12 – IEC 62137-4:2014 © IEC 2014

c) The reflow soldering equipment specified in 5.2 shall be used for soldering the package

terminals under the conditions shown in Figure 2 or Figure 3. The measuring point of the

temperature shall be on the land portion.

Figure 2 shows an example of a typical reflow soldering profile using Sn63Pb37 solder alloy,

as stated in IEC 61760-1:2006, Figure 13.

Figure 3 shows an example of a typical reflow soldering profile using Sn96,5Ag3Cu,5 solder

alloy, as stated in IEC 61760-1:2006, Figure 14.

SnPb Reflow

250 240 °C

230 °C

215 °C

180 °C

160 °C

ca. 60 s > 180 °C

150 °C

130 °C

Pre-heating

Ramp down rate < 6 K/s

Typical

Ramp up rate < 3 K/s

0 20 40 60 80 100 120 140 160 180 200 220 240

Time s

Continous line: typical process (terminal temperature)

Dotted line: process limits. Bottom process limit (terminal temperature). Upper process limit (top surface

temperature)

IEC

Figure 2 – Typical reflow soldering profile for Sn63Pb37 solder alloy

Temperature °C

SnAgCu Reflow

250 °C

245 °C

235 °C

220 °C

180 °C

Pre-heating

ca 45 s … 90 s > 220 °C

150 °C

Typical

Ramp down rate < 6 K/s

Ramp up rate < 3 K/s

0 30 60 90 120 150 180 210 240 270 300 330 360

Time s

Continous line: typical process (terminal temperature)

Dotted line: process limits. Bottom process limit (terminal temperature). Upper process limit (top surface

temperature)

IEC

Figure 3 – Typical reflow soldering profile for Sn96,5Ag3Cu,5 solder alloy

7 Temperature cycling test

7.1 Pre-conditioning

If the specimen needs to be cleaned, the product specification should specify the cleaning

method.

7.2 Initial measurement

The specimen shall be subjected to visual examination. There shall be no defect, which may

impair the validity of the test.

Electrical resistance as electrical continuity of the specimen (daisy chain circuit) shall be

confirmed using the momentary interruption detector specified in 5.4.

7.3 Test procedure

The temperature cycling test is according to test Na (rapid change of temperature within the

prescribed time of transfer) specified in IEC 60068-2-14 with the following details.

Place the specimen in the temperature cycling chamber where the best airflow is obtained

and where there is sufficient airflow around the specimen.

The test condition shall be selected from Figure 4 and Table 1, and the test shall be

performed to the specified cycles in the product specification.

The electrical resistance of the daisy chain circuit shall be monitored continuously during the

test using the momentary interruption detector specified in 5.4.

Temperature °C

– 14 – IEC 62137-4:2014 © IEC 2014

Maximum storage

temperature

(T )

max

Normal ambient

temperature

(T )

n

Minimum storage

temperature

Hold Hold

(T )

min

time

time

t t

1 2

One cycle period

t

cyc

IEC

Key

t Hold time at T

T Maximum storage temperature

1 min

max

t Hold time at T

T Normal ambient temperature

2 max

n

t One temperature cycle

T Minimum storage temperature

cyc

min

Figure 4 – Test conditions of temperature cycling test

Table 1 – Test conditions of temperature cycling test

Step Test condition A Test condition B Test condition C Test condition D

Minimum storage

T ± 5

−40 ± 5 −25 ± 5 −30 ± 5

op, min

temperature: T °C

min

Maximum storage

T ± 5

125 ± 5 125 ± 5 80 ± 5

op, max

temperature: T °C

max

t = t ≥ 7 min for Sn63Pb37 solder alloy

1 2

Hold time: t , t

1 2

t ≤ 30 min, t ≥ 15 min for Sn96,5Ag3Cu,5 solder alloy

1 2

For Sn96,5Ag3Cu,5 solder alloy, the dwell time in the temperature cycling chamber shall be set to 30 min at

maximum storage temperature, including the hold time t ; 15 min for stress relaxation and 15 min for stable

temperature. Refer to IEC 62137-3:2011, Annex A. At minimum storage temperature, it may not be necessary

that the stress r

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...