IEC 62561-1:2017

(Main)Lightning protection system components (LPSC) - Part 1: Requirements for connection components

Lightning protection system components (LPSC) - Part 1: Requirements for connection components

IEC 62561-1:2017 specifies the requirements and tests for metallic connection components that form part of a lightning protection system (LPS). Typically, these can be connectors, clamps, bonding and bridging components, expansion pieces and test joints.

For the purposes of this document the following connection types are considered as connection components: exothermic, brazing, welding, clamping, crimping, seaming, screwing or bolting. Testing of components for an explosive atmosphere is not covered by this document.

This second edition cancels and replaces the first edition, published in 2012. This edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous edition:

a. classification of connection components in permanent and non-permanent connection;

b. requirements and corresponding tests for permanent connection components such as exothermic, brazing, welding, crimping, seaming;

c. flow chart of tests for connection components.

Composants des systèmes de protection contre la foudre (CSPF) - Parte 1: Exigences pour les composants de connexion

L' IEC 62561-1:2017 spécifie les exigences et les essais à appliquer aux composants métalliques de connexion faisant partie d'un système de protection contre la foudre (SPF). Il peut s'agir, typiquement, des connecteurs, des colliers de serrage, des composants de pontage, des pièces d'expansion et des joints de contrôle.

Pour les besoins du présent document, les types de connexions suivants sont considérés comme des composants de connexion: la soudure exothermique et autres procédés de soudage, le brasage, le serrage, le sertissage, l'agrafage, le vissage et le boulonnage. Les essais de composants pour atmosphère explosive ne sont pas concernés par le présent document.

Cette deuxième édition annule et remplace la première édition publiée en 2012. Cette édition constitue une révision technique.

Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

a. la classification des composants de connexion permanente et non permanente;

b. les exigences et essais correspondants concernant les composants de connexion permanente, par exemple la soudure exothermique et d'autres procédés de soudage, le brasage, le sertissage ou l'agrafage;

c. un organigramme des essais destinés aux composants de connexion.

General Information

- Status

- Published

- Publication Date

- 08-Mar-2017

- Technical Committee

- TC 81 - Lightning protection

- Drafting Committee

- MT 14 - TC 81/MT 14

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 30-Mar-2023

- Completion Date

- 31-Dec-2020

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 62561-1:2017 - part of the IEC 62561 series - defines requirements and tests for metallic connection components used in lightning protection systems (LPS). It covers items such as connectors, clamps, bonding and bridging components, expansion pieces and test joints, and the common connection methods: exothermic, brazing, welding, clamping, crimping, seaming, screwing and bolting. This second edition (2017) is a technical revision of the 2012 edition and introduces a formal classification of permanent and non‑permanent connections, expanded requirements and tests for permanent connections, and a flow chart for test selection.

Key Topics and Requirements

- Scope and classification: Specifies which connection types are covered and classifies components by installation, mechanical behaviour and permanence (permanent vs non‑permanent).

- Electrical performance: Tests and requirements for lightning current carrying capability (impulse current testing) to ensure safe dissipation of lightning currents.

- Mechanical performance: Static mechanical stress tests to verify structural integrity under load.

- Permanent connection requirements: Specific requirements and tests for methods such as exothermic welding, brazing, crimping and seaming.

- Environmental conditioning / ageing: Conditioning procedures (e.g., salt mist, humid sulphurous and ammonia atmospheres) to assess long‑term durability.

- Marking, installation instructions and documentation: Clear marking, installation guidance, and structure of the test report (clause 8) to support correct use and traceability.

- Test programme and flow chart: Annexed flow chart (Annex C) guides selection of tests for different component types.

- EMC considerations: Electromagnetic compatibility is addressed to avoid unintended interference from LPS components.

- Limitations: Testing for explosive atmospheres is explicitly excluded.

Practical Applications and Who Uses This Standard

- Manufacturers of connectors, clamps and bonding components use IEC 62561-1 to design and type‑test products for LPS compliance.

- Test laboratories and certification bodies apply the specified electrical, mechanical and environmental tests when assessing conformity.

- Specifiers and designers of lightning protection systems (installers, consulting engineers) use the standard to select appropriate connection components and follow installation/marking requirements.

- Asset owners and facility managers reference the standard to verify that installed LPS components meet recognized safety and durability criteria.

Related Standards

- IEC 62305-1 - Protection against lightning: general principles (LPS design context)

- IEC 62561-2 - Requirements for conductors and earth electrodes

- Environmental test references cited: IEC 60068-2-52, ISO 6957, ISO 6988

By following IEC 62561-1:2017, stakeholders ensure connection components in lightning protection systems are tested and documented for safe lightning current handling, mechanical reliability and environmental durability.

Buy Documents

REDLINE IEC 62561-1:2017 - Lightning protection system components (LPSC) - Part 1: Requirements for connection components Released:3/9/2017 Isbn:9782832241042

IEC 62561-1:2017 - Lightning protection system components (LPSC) - Part 1: Requirements for connection components

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

Sponsored listings

Frequently Asked Questions

IEC 62561-1:2017 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Lightning protection system components (LPSC) - Part 1: Requirements for connection components". This standard covers: IEC 62561-1:2017 specifies the requirements and tests for metallic connection components that form part of a lightning protection system (LPS). Typically, these can be connectors, clamps, bonding and bridging components, expansion pieces and test joints. For the purposes of this document the following connection types are considered as connection components: exothermic, brazing, welding, clamping, crimping, seaming, screwing or bolting. Testing of components for an explosive atmosphere is not covered by this document. This second edition cancels and replaces the first edition, published in 2012. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a. classification of connection components in permanent and non-permanent connection; b. requirements and corresponding tests for permanent connection components such as exothermic, brazing, welding, crimping, seaming; c. flow chart of tests for connection components.

IEC 62561-1:2017 specifies the requirements and tests for metallic connection components that form part of a lightning protection system (LPS). Typically, these can be connectors, clamps, bonding and bridging components, expansion pieces and test joints. For the purposes of this document the following connection types are considered as connection components: exothermic, brazing, welding, clamping, crimping, seaming, screwing or bolting. Testing of components for an explosive atmosphere is not covered by this document. This second edition cancels and replaces the first edition, published in 2012. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a. classification of connection components in permanent and non-permanent connection; b. requirements and corresponding tests for permanent connection components such as exothermic, brazing, welding, crimping, seaming; c. flow chart of tests for connection components.

IEC 62561-1:2017 is classified under the following ICS (International Classification for Standards) categories: 11.040.50 - Radiographic equipment; 29.020 - Electrical engineering in general; 91.120.40 - Lightning protection. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62561-1:2017 has the following relationships with other standards: It is inter standard links to IEC 62561-1:2012, IEC 62561-1:2023. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 62561-1:2017 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62561-1 ®

Edition 2.0 2017-03

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Lightning protection system components (LPSC) –

Part 1: Requirements for connection components

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 20 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 65 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

IEC 62561-1 ®

Edition 2.0 2017-03

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Lightning protection system components (LPSC) –

Part 1: Requirements for connection components

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 29.020; 91.120.40 ISBN 978-2-8322-4104-2

– 2 – IEC 62561-1:2017 RLV © IEC 2017

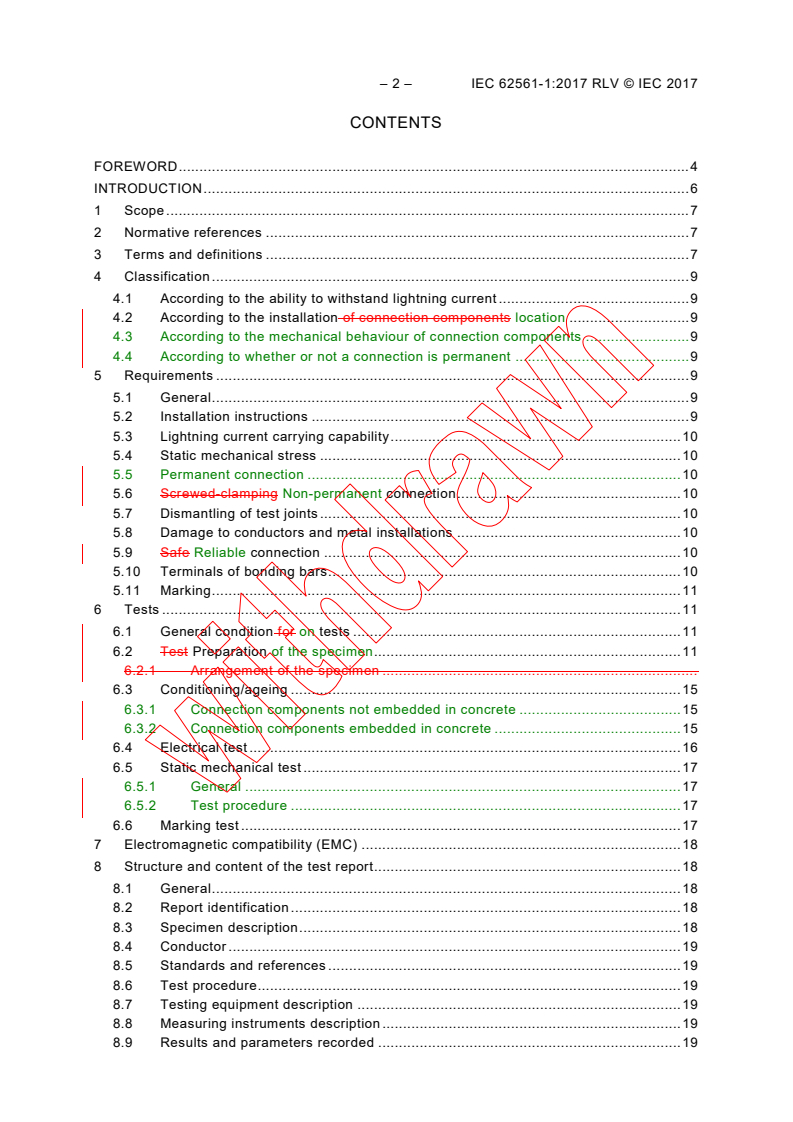

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 7

4 Classification . 9

4.1 According to the ability to withstand lightning current . 9

4.2 According to the installation of connection components location . 9

4.3 According to the mechanical behaviour of connection components . 9

4.4 According to whether or not a connection is permanent . 9

5 Requirements . 9

5.1 General . 9

5.2 Installation instructions . 9

5.3 Lightning current carrying capability . 10

5.4 Static mechanical stress . 10

5.5 Permanent connection . 10

5.6 Screwed-clamping Non-permanent connection . 10

5.7 Dismantling of test joints . 10

5.8 Damage to conductors and metal installations . 10

5.9 Safe Reliable connection . 10

5.10 Terminals of bonding bars . 10

5.11 Marking . 11

6 Tests . 11

6.1 General condition for on tests . 11

6.2 Test Preparation of the specimen . 11

6.2.1 Arrangement of the specimen .

6.3 Conditioning/ageing . 15

6.3.1 Connection components not embedded in concrete . 15

6.3.2 Connection components embedded in concrete . 15

6.4 Electrical test . 16

6.5 Static mechanical test . 17

6.5.1 General . 17

6.5.2 Test procedure . 17

6.6 Marking test . 17

7 Electromagnetic compatibility (EMC) . 18

8 Structure and content of the test report . 18

8.1 General . 18

8.2 Report identification . 18

8.3 Specimen description . 18

8.4 Conductor . 19

8.5 Standards and references . 19

8.6 Test procedure . 19

8.7 Testing equipment description . 19

8.8 Measuring instruments description . 19

8.9 Results and parameters recorded . 19

8.10 Statement of pass/fail . 19

Annex A (informative normative) Summary of the requirements and

corresponding tests . 20

Annex B (informative) Typical arrangements connection configurations

for various LPSCs . 21

Annex C (normative) Flow chart of tests for connection components . 22

Annex D (normative) Conditioning/ageing for connection components . 24

D.1 General . 24

D.2 Salt mist treatment . 24

D.3 Humid sulphurous atmosphere treatment . 24

D.4 Ammonia atmosphere treatment. 24

Bibliography . 25

Figure 1 – Basic arrangement of specimen with cross-connection component . 12

Figure 2 – Basic arrangement of specimen with parallel connection component . 13

Figure 3 – Basic arrangement of specimen with bridging component . 14

Figure 4 – Basic arrangement of specimen with equipotential bonding bar . 15

Figure 5 – Basic arrangement for contact measurement of expansion piece. 17

Figure B.1 – Typical arrangements for various LPSCs . 21

Figure C.1 – Flow chart of tests for connection components . 23

Table 1 – Lightning impulse current (I ) parameters . 16

imp

Table A.1 – Requirements and corresponding tests . 20

– 4 – IEC 62561-1:2017 RLV © IEC 2017

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

LIGHTNING PROTECTION SYSTEM COMPONENTS (LPSC) –

Part 1: Requirements for connection components

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This redline version of the official IEC Standard allows the user to identify the changes

made to the previous edition. A vertical bar appears in the margin wherever a change

has been made. Additions are in green text, deletions are in strikethrough red text.

International Standard IEC 62561-1 has been prepared by IEC technical committee 81:

Lightning protection.

This second edition cancels and replaces the first edition, published in 2012. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) classification of connection components in permanent and non-permanent connection;

b) requirements and corresponding tests for permanent connection components such as

exothermic, brazing, welding, crimping, seaming;

c) flow chart of tests for connection components.

The text of this standard is based on the following documents:

FDIS Report on voting

81/551/FDIS 81/559/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 62561 series, published under the general title Lightning

protection system components (LPSC), can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The “colour inside” logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this publication using a colour printer.

– 6 – IEC 62561-1:2017 RLV © IEC 2017

INTRODUCTION

This part of IEC 62561 deals with the requirements and tests for lightning protection system

components (LPSC) used for the installation of a lightning protection system (LPS) designed

and implemented according to the IEC 62305 series.

LIGHTNING PROTECTION SYSTEM COMPONENTS (LPSC) –

Part 1: Requirements for connection components

1 Scope

This part of IEC 62561 specifies the requirements and tests for metallic connection

components that form part of a lightning protection system (LPS). Typically, these can be

connectors, clamps, bonding and bridging components, expansion pieces and test joints.

For the purposes of this document the following connection types are considered as

connection components: exothermic, brazing, welding, clamping, crimping, seaming, screwing

or bolting.

Testing of components for an explosive atmosphere is not covered by this document.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60068-2-52:1996, Environmental testing – Part 2-52: Tests – Test Kb: Salt mist, cyclic

(sodium chloride solution)

IEC 62305-1, Protection against lightning – Part 1: General principles

IEC 62561-2, Lightning protection system components (LPSC) – Part 2: Requirements for

conductors and earth electrodes

ISO 6957:1988, Copper alloys – Ammonia test for stress corrosion resistance

ISO 6988:1985, Metallic and other non-organic coatings – Sulphur dioxide test with general

condensation of moisture

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

connection component

part of an external LPS which is used for the connection of conductors to each other or to

metallic installations

– 8 – IEC 62561-1:2017 RLV © IEC 2017

Note 1 to entry: Connection components include connectors, clamps, bridging components, expansion pieces and

test joints.

3.2

metal installation

extended metal items in the structure to be protected which may form a path for lightning

current, such as pipes, staircases, elevator guide rails, ventilation, heating and air

conditioning ducts, and interconnected reinforcing steel

3.3

bridging component

connection component for the connection of metal installations

3.4

expansion piece

connection component designed to compensate for changes in length in conductors and/or

metal installations caused by temperature changes

3.5

connector

connection component to interconnect two or more conductors

3.6

clamp

connection component for the connection of conductors to metal installations

3.7

pipe clamp

clamp for the connection of conductors to metal pipes

3.8

test joint

joint designed to facilitate electrical testing and measurement of LPS components

3.9

connection range

minimum to maximum range for which a specific connection component is designed to be

used

3.10

bonding bar

metal bar on which metal installations, external conductive parts, electric power and

telecommunication lines and other cables can be connected to an LPS

3.11

type test

test required to be made before supplying a type of material covered by IEC 62561-1 on a

general commercial basis, in order to demonstrate satisfactory performance characteristics to

meet the intended application

Note 1 to entry: These tests are of such a nature that, after they have been made, they need not be repeated

unless changes are made to the accessory materials, design or type of manufacturing process which might change

the performance characteristics.

3.12

permanent connection

connection that cannot or is not intended to be dismantled

3.13

non-permanent connection

connection that can or is intended to be dismantled

4 Classification

4.1 Classification of components depends on the According to the ability to

withstand lightning current

a) class H for heavy duty;

b) class N for normal duty.

The selection of classes H and N should be performed by the manufacturer in accordance

with the test parameters identified in Table 1.

4.2 Classification is also made According to the installation of connection

components location

a) general use;

b) embedded in concrete.

b) not embedded in concrete.

4.3 According to the mechanical behaviour of connection components

a) intended to withstand a static mechanical load;

b) not intended to withstand a static mechanical load.

The manufacturer’s declaration of ability to withstand a static load shall determine the need or

otherwise to carry out the static mechanical test as identified in 6.5.

4.4 According to whether or not a connection is permanent

a) permanent connection such as exothermic process, brazing, welding, crimping, seaming;

b) non-permanent connection such as screwing or bolting.

5 Requirements

5.1 General

Connection components shall be designed in such a manner that when they are installed in

accordance with the manufacturer’s instructions their performance shall be reliable, stable

and safe to persons and surrounding equipment.

NOTE A summary of the requirements and their corresponding tests is given in Annex A.

5.2 Installation instructions

The manufacturer of the connection components shall provide at least the following

information:

a) the classification of the component;

b) the recommended tightening torque;

c) the range of conductor sizes and materials;

d) the connection configuration.

Compliance is checked by inspection.

– 10 – IEC 62561-1:2017 RLV © IEC 2017

5.3 Lightning current carrying capability

Connection components shall have sufficient lightning current carrying capability.

Compliance is checked in accordance with 6.4 following the manufacturer’s declaration for the

class (H or N) of the connection components in accordance with 4.1.

5.4 Static mechanical stress

Connection components shall have a sufficient withstand capability against static mechanical

stresses.

Equipotential bonding bars are excluded from this requirement.

Compliance is checked in accordance with 6.5.

5.5 Permanent connection

Where exothermic process, brazing, welding, crimping or seaming are used as connection,

the design shall be such that the conductor and/or the metal installation is always securely

bonded.

Compliance is checked by inspection and in accordance with 6.4 a), b), e).

5.6 Screwed clamping Non-permanent connection

Where screws and/or nuts are used as the clamping connection, the design shall be such that

the conductor and/or the metal installation is always securely fastened by the screw and/or

nut application.

Compliance is checked by inspection and in accordance with 6.4,a), b), c), d).

5.7 Dismantling of test joints

It shall be possible to dismantle the test joints after lightning current stress.

Compliance is checked by inspection and in accordance with 6.4, a), b), c), d).

5.8 Damage to conductors and metal installations

Connection components shall be so designed that they connect the conductors and/or the

metal installations without undue damage to the conductors, the metal installations and/or the

connection components.

Compliance is checked by inspection.

5.9 Safe Reliable connection

Connection components shall guarantee safe connection within the connection range declared

by the manufacturer.

Compliance is checked by inspection and in accordance with 6.4.

5.10 Terminals of bonding bars

The input terminals of bonding bars used for lightning protection installations shall have a

diameter of connection equal to or greater than 6 mm.

Compliance is checked by inspection.

5.11 Marking

The connection components shall be marked at least with the following:

a) manufacturer’s or responsible vendor’s name or trade mark;

b) identifying symbol (picture, product number, etc.);

c) classification, i.e. class N or H.

Where this proves to be impractical the marking in accordance with b) and c) may be given on

the smallest packing unit label or on the accompanying documentation.

The marking shall be durable and legible.

NOTE Marking can be applied for example by moulding, pressing, engraving, printing adhesive labels or water

slide transfers.

Compliance is checked in accordance with 6.6.

6 Tests

6.1 General condition for on tests

The tests in accordance with this document are type tests (see 3.11).

• Unless otherwise specified, tests are carried out with the specimens assembled and

installed as in normal use according to the manufacturer's or supplier's installation

instructions with the recommended conductor materials, sizes and tightening torques. If

the connection component is suitable for various conductors’ materials, then it shall be

tested on each material combination.

• All tests are carried out on new specimens.

• Unless otherwise specified, three specimens are subjected to the tests and the

requirements are satisfied if all the tests are met.

• If only one of the specimens does not satisfy a test due to an assembly or a manufacturing

fault, that test and any preceding one which may have influenced the results of the test

shall be repeated and also the tests which follow shall be carried out in the required

sequence on another full set of specimens, all of which shall comply with the

requirements.

• The electrical test shall be carried out in the order given, after conditioning/ageing of the

arrangement of the specimen in accordance with 6.3.

The applicant, when submitting the sets of specimens, may also submit an additional set of

specimens which may be necessary, should one specimen fail. The testing station will then,

without further request, test the additional set of specimens and will reject it only if a further

failure occurs. If the additional set of specimens is not submitted at the same time, the failure

of one specimen will entail rejection.

6.2 Test Preparation of the specimen

6.2.1 Arrangement of the specimen

If not otherwise specified by the manufacturer, the conductors and the specimens shall be

cleaned by using a suitable degreasing agent followed by cleaning in demineralized water and

drying. They shall then be assembled in accordance with the manufacturer’s instructions, for

example with the recommended conductors and tightening torques.

– 12 – IEC 62561-1:2017 RLV © IEC 2017

The connection component shall be tested in all the connection configurations declared by the

manufacturer. Typical connection configurations for various LPSCs are illustrated in Annex B.

Any connection components accommodating a range of conductors with a variation on any

dimension equal to or less than 2 mm shall be tested using the minimum conductor size

recommended. If the range of conductor sizes is greater than 2 mm, it shall be tested using

the minimum and maximum size of conductors recommended.

The basic arrangement of the specimen with cross-connection component, parallel connection

component, bridging component and equipotential bonding bar is shown in Figures 1, 2, 3 and

4, respectively. Terminals of bonding bars are only tested if the connection size is equal to or

greater than 16 mm . The test is carried out using the smallest conductor size within the

range of the terminal with a minimum of 16 mm conductor. Typical arrangements for various

LPSCs are shown in Annex B.

Dimension in millimetres

Flexible lead

IEC

Key

1 Cross-connection component

2 Plate made of insulating material

3 Rigid fastener

4 Conductor and/or metal installation in accordance with Annex C

Figure 1 – Basic arrangement of specimen with cross-connection component

Flexible lead

Dimension in millimetres

Flexible lead

4 1

20 20

IEC

Key

1 Parallel connection component

2 Plate made of insulating material

3 Rigid fastener

4 Conductor and/or metal installation in accordance with Annex C

Figure 2 – Basic arrangement of specimen with parallel connection component

Flexible lead

– 14 – IEC 62561-1:2017 RLV © IEC 2017

Dimension in millimetres

4 1

3 3

IEC

Key

1 Bridging component

2 Plate made of insulating material

3 Rigid fastener

4 Metal installation in accordance with Annex C

Figure 3 – Basic arrangement of specimen with bridging component

Flexible lead

Flexible lead

Dimension in millimetres

Flexible lead

400 100

IEC

Key

1 Equipotential bonding bar

2 Plate made of insulating material

3 Rigid fastener

4 Conductor

5 Fixing points of equipotential bonding bar

6 Connection to be tested

Figure 4 – Basic arrangement of specimen with equipotential bonding bar

6.3 Conditioning/ageing

6.3.1 Connection components not embedded in concrete

Following the manufacturer’s declaration for the location of the connection components in

accordance with 4.2, the arrangement of the specimen shall be subjected to a

conditioning/ageing, as per Annex C, consisting of a salt mist treatment as specified in C.1

followed by a humid sulphurous atmosphere treatment as specified in C.2, and an additional

ammonia atmosphere treatment for specimens made of copper alloy with copper content less

than 80 % as specified in C.3 in accordance with Annex D.

The manufacturer shall provide proof of the copper content of any part of the assembly made

from an alloy having a copper content ≥ 80 %.

After the treatment, the arrangement is fixed on an insulated plate, taking care to avoid any

damage to the specimen due to handling.

6.3.2 Connection components embedded in concrete

This treatment is not necessary for connection components designed to be completely

embedded in concrete. Connection components designed to be partially embedded in

concrete shall be subjected to the conditioning/ageing in accordance with 6.3.

Flexible lead

– 16 – IEC 62561-1:2017 RLV © IEC 2017

Bonding bars destined designed for indoor applications only are tested without

conditioning/ageing.

6.4 Electrical test

After 6.3 and without cleaning the arrangement, the specimen shall be stressed three times by

a test current as given in Table 1. The time interval between individual shots shall allow the

arrangement of the specimen to cool down to approximately ambient temperature.

The impulse discharge current passing through the device under test is defined by the crest

value I , and the specific energy W/R. The impulse current shall show no reversal and

imp

reach I within 50 µs. The transfer of the specific energy W/R shall be dissipated within

imp

5 ms.

Table 1 – Lightning impulse current (I ) parameters

imp

Classification I W/R

imp

kA ±10 %

kJ/Ω ±35 %

H 100 2 500

N 50 625

NOTE The parameters specified in Table 1 can typically be achieved by an exponentially decaying lightning

impulse current having a time to half value in the range of 350 μs according to IEC 62305-1.

The connection component is deemed to have passed the test if:

a) the contact resistance, measured with a source of at least 10 A as close as possible to the

connection component is equal to or less than 1 mΩ. In the case where the connection

component or the conductor(s) is of stainless steel, a value of 2,5 3 mΩ is allowed;

b) it does not exhibit any crack to normal or corrected vision without magnification nor does it

have any loose parts or deformation impairing its normal use;

c) for screwed clamping a non-permanent connections component, in accordance with 4.4 b),

utilizing screws, the loosening torque is greater than 0,25 and less than 1,5 times the

tightening torque. In the case of connectors with more than one screw, only the loosening

torque of the first screw is relevant to this test;

d) the 20 mm length of conductor from the connector (see Figures 1, 2 and 4), prior to the

test is not less than 3 mm after completion of the test. For examples B3, B4, B6 and B8 as

shown in Annex B, the requirement of not less than 3 mm is not applicable;

e) the measurement of the contact resistance of the expansion components (E) and the

connected conductors (F) is performed between the clamped ends A-B and C-D, as close

as possible to the expansion component (see Figure 5);

f) the expansion conductor (E, see Figure 5) shall be tested according to IEC 62561-2 and

shall fulfill the requirements for air termination conductors;

d) for a non-permanent connection component, in accordance with 4.4 b), the 20 mm length

of conductor from the connector (see Figures 1, 2 and 4), prior to the test, is not less than

3 mm after completion of the test;

e) for screw-less or permanent connection components, such as compressed connection

components in accordance with 4.4 a), each conductor of the specimen assemblies shall

be subjected independently to a mechanical tensile force of 900 N ± 20 N, for 1 min.

Each conductor shall be tested independently for multiple conductor connectors. The

connection component is deemed to have passed the test if there is less than 1 mm

movement of the conductor during the test and no damage on the connector connection

component or conductor.

_____________

To be published.

NOTE 1 For the examples B3 and B6 as shown in Figure B.1, the requirement of not less than 3 mm is not

applicable.

NOTE 2 The measurement of the contact resistance of the expansion components (E) and the connected

conductors (F) is performed between the clamped ends A-B and C-D, as close as possible to the expansion

component (see Figure 5);

The expansion conductor (E, see Figure 5), shall be tested according to IEC 62561-2 and

shall fulfill the requirements for air termination conductors.

B

C

A

D

E

F

F

IEC

Key

A-B, C-D Measuring points to verify the clamp contact resistances

E Solid material or stranded material according to IEC 62561-2

F Lightning protection system conductor according to IEC 62561-2

Figure 5 – Basic arrangement for contact measurement of expansion piece

6.5 Static mechanical test

6.5.1 General

The test shall be performed with all conductor materials permitted according to the

manufacturer's declaration.

Alternatively, to minimize the number of tests, connection components that are used with

several different conductor materials may be tested using stainless steel only.

Any connection components with a connection range equal to or less than 2 mm shall be

tested on the minimum conductor size recommended. If the connection range is greater than

2 mm it shall be tested on the minimum and maximum size of conductor recommended.

6.5.2 Test procedure

A second set of 3 new specimens connection components shall be arranged according to the

manufacturer's or supplier's installation instructions with the recommended conductor

materials, sizes and tightening torques.

Each conductor of the specimen assemblies shall be subjected independently to a mechanical

tensile force of 900 N ± 20 N for 1 min. Each conductor shall be tested independently for

multiple conductor connectors.

The connection component is deemed to have passed the test if there is less than 1 mm

movement of the conductor during the test and no damage to the connector connection

component or conductor.

6.6 Marking test

The marking is checked by inspection and by rubbing it by hand for 15 s with a piece of cloth

soaked with water and again for 15 s with a piece of cloth soaked with white spirit/mineral

spirit.

– 18 – IEC 62561-1:2017 RLV © IEC 2017

NOTE Markings made by moulding, pressing or engraving are not subjected to this test.

The specimen is deemed to have passed the test if the marking remains legible.

7 Electromagnetic compatibility (EMC)

Products covered by this document are, in normal use, passive in respect of electromagnetic

influences (emission and immunity).

8 Structure and content of the test report

8.1 General

The purpose of Clause 8 is to provide general requirements for laboratory test reports. It is

intended to promote clear, complete reporting procedures for laboratories submitting test

reports.

The results of each test carried out by the laboratory shall be reported accurately, clearly,

unambiguously and objectively, in accordance with any instructions in the test methods. The

results shall be reported in a test report and shall include all the information necessary for the

interpretation of the test results and all information required by the method used.

Particular care and attention shall be paid to the arrangement of the report, especially with

regard to presentation of the test data and ease of assimilation by the reader. The format

shall be carefully and specifically designed for each type of test carried out, but the headings

shall be standardized as indicated below.

The structure of each report shall include at least information according to 8.2 to 8.10.

8.2 Report identification

The following information shall be included.

a) A title or subject of the report.

b) Name, address and email or telephone number of the test laboratory.

c) Name, address and email or telephone number of the sub test laboratory where the test

was carried out if different from the company which has been assigned to perform the test.

d) Unique identification number (or serial number) of the test report.

e) Name and address of the vendor.

f) Report shall be paginated and Page numbers, including the total number of pages

indicated.

g) Date of issue of report.

h) Date(s) of performance of test(s).

i) Signature and title, or an equivalent identification of the person(s) authorized to sign for

the testing laboratory for the content of the report.

j) Signature and title of person(s) conducting the test.

8.3 Specimen description

a) Sample description.

b) Detailed description and unambiguous identification of the test sample and/or test

assembly.

c) Characterization and condition of the test sample and/or test assembly.

d) Sampling procedure, where relevant.

e) Date of receipt of test items.

f) Photographs, drawings or any other visual documentation, if available.

8.4 Conductor

a) Conductor material.

b) Nominal cross-sectional area, dimensions and shape. It is recommended that the actual

cross-sectional area should also be given.

8.5 Standards and references

a) Identification of the test standard used and the date of issue of the standard.

b) Other relevant documentation with the documentation date.

8.6 Test procedure

a) Description of the test procedure.

b) Justification for any deviations from, additions to or exclusions from the referenced

standard.

c) Any other information relevant to a specific test such as environmental conditions.

d) Configuration of testing assembly.

e) Location of the arrangement in the testing area and measuring techniques.

8.7 Testing equipment description

Description of equipment used for every test conducted, i.e. generator, conditioning/ageing

device.

8.8 Measuring instruments description

Characteristics and calibration date of all instruments used for measuring the values specified

in the standard i.e. radius gauge, shunts, tensile testing machine, extensometer, ohmmeter,

torque meter, thickness calliper gauge, etc.

8.9 Results and parameters recorded

The measured, observed or derived results shall be clearly identified at least for:

a) current;

b) charge;

c) specific energy;

d) front time of the impulse;

e) duration of the impulse;

f) ohmic resistance;

g) tightening torque;

h) loosening torque.

The above shall be presented in by means of tables, graphs, drawings, photographs or other

documentation of visual observations as appropriate.

8.10 Statement of pass/fail

A statement that the specimen passed or failed the tests shall be reported. If the specimen

has failed, a description of failure is necessary.

– 20 – IEC 62561-1:2017 RLV © IEC 2017

Annex A

(informative normative)

Summary of the requirements and corresponding tests

See Table A.1.

Table A.1 – Requirements and corresponding tests

Test Requirements Requirements in Compliance is

sequence accordance with checked by

1 Installation instructions 5.2 Inspection

2 Lightning current carrying capability for non- 5.3 and 5.6 6.4 a),b),c),d)

permanent connection

3 Lightning current carrying capability for 5.3 and 5.5 6.4 a),b),e)

permanent connection

4 Screwed clamping connection 5.5 Inspection and 6.3

4 Dismantling of test joints 5.7 Inspection and 6.4 a),b),c),d)

5 Damage to conductors and metal installations 5.8 Inspection

6 Safe Reliable connection 5.9 Inspection and 6.4

7 Marking 5.11 Inspection and 6.6

8 Static mechanical test 5.4 6.5

9 Terminals of bonding bars 5.10 Inspection

Annex B

(informative)

Typical arrangements connection configurations for various LPSCs

See Figure B.1.

B2

B1 B3B3

Parallel connector

Cross connector

In line connector

B4 B5 B6

Clamp for T

Clamp for parallel

T connector

connection

connection

Metal installation Metal installation

B7 B8 B9

Pipe clamp for T

Pipe clamp for Bridging component

connection

parallel connection aa

Metal installation

Metal pipe Metal pipe

B10

Equipotential bonding bar

IEC

NOTE 1 B1, B4, B6 and B8 – for more information see Figure 1.

NOTE 2 B2, B3, B5 and B7 – for more information see Figure 2.

NOTE 3 B9 – for more information see Figure 3.

NOTE 4 B10 – for more information see Figure 4.

Figure B.1 – Typical arrangements for various LPSCs

– 22 – IEC 62561-1:2017 RLV © IEC 2017

Annex C

(normative)

Flow chart of

...

IEC 62561-1 ®

Edition 2.0 2017-03

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Lightning protection system components (LPSC) –

Part 1: Requirements for connection components

Composants des systemes de protection contre la foudre (CSPF) –

Partie 1: Exigences pour les composants de connexion

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 20 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 65 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient 20 000 termes et définitions en anglais

Spécifications techniques, Rapports techniques et autres

et en français, ainsi que les termes équivalents dans 16

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

65 000 entrées terminologiques électrotechniques, en anglais

La recherche avancée permet de trouver des publications IEC

en utilisant différents critères (numéro de référence, texte, et en français, extraites des articles Termes et Définitions des

comité d’études,…). Elle donne aussi des informations sur les publications IEC parues depuis 2002. Plus certaines entrées

projets et les publications remplacées ou retirées. antérieures extraites des publications des CE 37, 77, 86 et

CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 62561-1 ®

Edition 2.0 2017-03

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Lightning protection system components (LPSC) –

Part 1: Requirements for connection components

Composants des systemes de protection contre la foudre (CSPF) –

Partie 1: Exigences pour les composants de connexion

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 29.020; 91.120.40 ISBN 978-2-8322-4050-2

– 2 – IEC 62561-1:2017 © IEC 2017

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 7

4 Classification . 9

4.1 According to the ability to withstand lightning current . 9

4.2 According to the installation location . 9

4.3 According to the mechanical behaviour of connection components . 9

4.4 According to whether or not a connection is permanent . 9

5 Requirements . 9

5.1 General . 9

5.2 Installation instructions . 9

5.3 Lightning current carrying capability . 9

5.4 Static mechanical stress . 10

5.5 Permanent connection . 10

5.6 Non-permanent connection . 10

5.7 Dismantling of test joints . 10

5.8 Damage to conductors and metal installations . 10

5.9 Reliable connection . 10

5.10 Terminals of bonding bars . 10

5.11 Marking . 10

6 Tests . 11

6.1 General condition on tests . 11

6.2 Preparation of the specimen . 11

6.3 Conditioning/ageing . 15

6.3.1 Connection components not embedded in concrete . 15

6.3.2 Connection components embedded in concrete . 15

6.4 Electrical test . 16

6.5 Static mechanical test . 17

6.5.1 General . 17

6.5.2 Test procedure . 17

6.6 Marking test . 17

7 Electromagnetic compatibility (EMC) . 17

8 Structure and content of the test report . 18

8.1 General . 18

8.2 Report identification . 18

8.3 Specimen description . 18

8.4 Conductor . 18

8.5 Standards and references . 18

8.6 Test procedure . 19

8.7 Testing equipment description . 19

8.8 Measuring instruments description . 19

8.9 Results and parameters recorded . 19

8.10 Statement of pass/fail . 19

Annex A (normative) Summary of the requirements and corresponding tests . 20

Annex B (informative) Typical connection configurations for various LPSCs . 21

Annex C (normative) Flow chart of tests for connection components . 22

Annex D (normative) Conditioning/ageing for connection components . 24

D.1 General . 24

D.2 Salt mist treatment . 24

D.3 Humid sulphurous atmosphere treatment . 24

D.4 Ammonia atmosphere treatment. 24

Bibliography . 25

Figure 1 – Basic arrangement of specimen with cross-connection component . 12

Figure 2 – Basic arrangement of specimen with parallel connection component . 13

Figure 3 – Basic arrangement of specimen with bridging component . 14

Figure 4 – Basic arrangement of specimen with equipotential bonding bar . 15

Figure 5 – Basic arrangement for contact measurement of expansion piece. 17

Figure B.1 – Typical arrangements for various LPSCs . 21

Figure C.1 – Flow chart of tests for connection components . 23

Table 1 – Lightning impulse current (I ) parameters . 16

imp

Table A.1 – Requirements and corresponding tests . 20

– 4 – IEC 62561-1:2017 © IEC 2017

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

LIGHTNING PROTECTION SYSTEM COMPONENTS (LPSC) –

Part 1: Requirements for connection components

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62561-1 has been prepared by IEC technical committee 81:

Lightning protection.

This second edition cancels and replaces the first edition, published in 2012. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) classification of connection components in permanent and non-permanent connection;

b) requirements and corresponding tests for permanent connection components such as

exothermic, brazing, welding, crimping, seaming;

c) flow chart of tests for connection components.

The text of this standard is based on the following documents:

FDIS Report on voting

81/551/FDIS 81/559/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 62561 series, published under the general title Lightning

protection system components (LPSC), can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – IEC 62561-1:2017 © IEC 2017

INTRODUCTION

This part of IEC 62561 deals with the requirements and tests for lightning protection system

components (LPSC) used for the installation of a lightning protection system (LPS) designed

and implemented according to the IEC 62305 series.

LIGHTNING PROTECTION SYSTEM COMPONENTS (LPSC) –

Part 1: Requirements for connection components

1 Scope

This part of IEC 62561 specifies the requirements and tests for metallic connection

components that form part of a lightning protection system (LPS). Typically, these can be

connectors, clamps, bonding and bridging components, expansion pieces and test joints.

For the purposes of this document the following connection types are considered as

connection components: exothermic, brazing, welding, clamping, crimping, seaming, screwing

or bolting.

Testing of components for an explosive atmosphere is not covered by this document.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60068-2-52:1996, Environmental testing – Part 2-52: Tests – Test Kb: Salt mist, cyclic

(sodium chloride solution)

IEC 62561-2, Lightning protection system components (LPSC) – Part 2: Requirements for

conductors and earth electrodes

ISO 6957:1988, Copper alloys – Ammonia test for stress corrosion resistance

ISO 6988:1985, Metallic and other non-organic coatings – Sulphur dioxide test with general

condensation of moisture

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

connection component

part of an external LPS which is used for the connection of conductors to each other or to

metallic installations

Note 1 to entry: Connection components include connectors, clamps, bridging components, expansion pieces and

test joints.

– 8 – IEC 62561-1:2017 © IEC 2017

3.2

metal installation

extended metal items in the structure to be protected which may form a path for lightning

current, such as pipes, staircases, elevator guide rails, ventilation, heating and air

conditioning ducts, and interconnected reinforcing steel

3.3

bridging component

connection component for the connection of metal installations

3.4

expansion piece

connection component designed to compensate for changes in length in conductors and/or

metal installations caused by temperature changes

3.5

connector

connection component to interconnect two or more conductors

3.6

clamp

connection component for the connection of conductors to metal installations

3.7

pipe clamp

clamp for the connection of conductors to metal pipes

3.8

test joint

joint designed to facilitate electrical testing and measurement of LPS components

3.9

connection range

minimum to maximum range for which a specific connection component is designed to be

used

3.10

bonding bar

metal bar on which metal installations, external conductive parts, electric power and

telecommunication lines and other cables can be connected to an LPS

3.11

type test

test required to be made before supplying a type of material covered by IEC 62561-1 on a

general commercial basis, in order to demonstrate satisfactory performance characteristics to

meet the intended application

Note 1 to entry: These tests are of such a nature that, after they have been made, they need not be repeated

unless changes are made to the accessory materials, design or type of manufacturing process which might change

the performance characteristics.

3.12

permanent connection

connection that cannot or is not intended to be dismantled

3.13

non-permanent connection

connection that can or is intended to be dismantled

4 Classification

4.1 According to the ability to withstand lightning current

a) class H for heavy duty;

b) class N for normal duty.

The selection of classes H and N should be performed by the manufacturer in accordance

with the test parameters identified in Table 1.

4.2 According to the installation location

a) general use;

b) embedded in concrete.

4.3 According to the mechanical behaviour of connection components

a) intended to withstand a static mechanical load;

b) not intended to withstand a static mechanical load.

The manufacturer’s declaration of ability to withstand a static load shall determine the need or

otherwise to carry out the static mechanical test as identified in 6.5.

4.4 According to whether or not a connection is permanent

a) permanent connection such as exothermic process, brazing, welding, crimping, seaming;

b) non-permanent connection such as screwing or bolting.

5 Requirements

5.1 General

Connection components shall be designed in such a manner that when they are installed in

accordance with the manufacturer’s instructions their performance shall be reliable, stable

and safe to persons and surrounding equipment.

NOTE A summary of the requirements and their corresponding tests is given in Annex A.

5.2 Installation instructions

The manufacturer of the connection components shall provide at least the following

information:

a) the classification of the component;

b) the recommended tightening torque;

c) the range of conductor sizes and materials;

d) the connection configuration.

Compliance is checked by inspection.

5.3 Lightning current carrying capability

Connection components shall have sufficient lightning current carrying capability.

Compliance is checked in accordance with 6.4 following the manufacturer’s declaration for the

class (H or N) of the connection components in accordance with 4.1.

– 10 – IEC 62561-1:2017 © IEC 2017

5.4 Static mechanical stress

Connection components shall have a sufficient withstand capability against static mechanical

stresses.

Equipotential bonding bars are excluded from this requirement.

Compliance is checked in accordance with 6.5.

5.5 Permanent connection

Where exothermic process, brazing, welding, crimping or seaming are used as connection,

the design shall be such that the conductor and/or the metal installation is always securely

bonded.

Compliance is checked by inspection and in accordance with 6.4 a), b), e).

5.6 Non-permanent connection

Where screws and/or nuts are used as the clamping connection, the design shall be such that

the conductor and/or the metal installation is always securely fastened by the screw and/or

nut application.

Compliance is checked by inspection and in accordance with 6.4,a), b), c), d).

5.7 Dismantling of test joints

It shall be possible to dismantle the test joints after lightning current stress.

Compliance is checked by inspection and in accordance with 6.4, a), b), c), d).

5.8 Damage to conductors and metal installations

Connection components shall be so designed that they connect the conductors and/or the

metal installations without undue damage to the conductors, the metal installations and/or the

connection components.

Compliance is checked by inspection.

5.9 Reliable connection

Connection components shall guarantee safe connection within the connection range declared

by the manufacturer.

Compliance is checked by inspection and in accordance with 6.4.

5.10 Terminals of bonding bars

The input terminals of bonding bars used for lightning protection installations shall have a

diameter of connection equal to or greater than 6 mm.

Compliance is checked by inspection.

5.11 Marking

The connection components shall be marked at least with the following:

a) manufacturer’s or responsible vendor’s name or trade mark;

b) identifying symbol (picture, product number, etc.);

c) classification, i.e. class N or H.

Where this proves to be impractical the marking in accordance with b) and c) may be given on

the smallest packing unit label or on the accompanying documentation.

The marking shall be durable and legible.

NOTE Marking can be applied for example by moulding, pressing, engraving, printing adhesive labels or water

slide transfers.

Compliance is checked in accordance with 6.6.

6 Tests

6.1 General condition on tests

The tests in accordance with this document are type tests (see 3.11).

• Unless otherwise specified, tests are carried out with the specimens assembled and

installed as in normal use according to the manufacturer's or supplier's installation

instructions with the recommended conductor materials, sizes and tightening torques. If

the connection component is suitable for various conductors’ materials, then it shall be

tested on each material combination.

• All tests are carried out on new specimens.

• Unless otherwise specified, three specimens are subjected to the tests and the

requirements are satisfied if all the tests are met.

• If only one of the specimens does not satisfy a test due to an assembly or a manufacturing

fault, that test and any preceding one which may have influenced the results of the test

shall be repeated and also the tests which follow shall be carried out in the required

sequence on another full set of specimens, all of which shall comply with the

requirements.

• The electrical test shall be carried out in the order given, after conditioning/ageing of the

arrangement of the specimen in accordance with 6.3.

The applicant, when submitting the sets of specimens, may also submit an additional set of

specimens which may be necessary, should one specimen fail. The testing station will then,

without further request, test the additional set of specimens and will reject it only if a further

failure occurs. If the additional set of specimens is not submitted at the same time, the failure

of one specimen will entail rejection.

6.2 Preparation of the specimen

If not otherwise specified by the manufacturer, the conductors and the specimens shall be

cleaned by using a suitable degreasing agent followed by cleaning in demineralized water and

drying. They shall then be assembled in accordance with the manufacturer’s instructions, for

example with the recommended conductors and tightening torques.

The connection component shall be tested in all the connection configurations declared by the

manufacturer. Typical connection configurations for various LPSCs are illustrated in Annex B.

Any connection components accommodating a range of conductors with a variation on any

dimension equal to or less than 2 mm shall be tested using the minimum conductor size

recommended. If the range of conductor sizes is greater than 2 mm, it shall be tested using

the minimum and maximum size of conductors recommended.

– 12 – IEC 62561-1:2017 © IEC 2017

The basic arrangement of the specimen with cross-connection component, parallel connection

component, bridging component and equipotential bonding bar is shown in Figures 1, 2, 3 and

4, respectively. Terminals of bonding bars are only tested if the connection size is equal to or

greater than 16 mm . The test is carried out using the smallest conductor size within the

range of the terminal with a minimum of 16 mm conductor. Typical arrangements for various

LPSCs are shown in Annex B.

Dimension in millimetres

Flexible lead

IEC

Key

1 Cross-connection component

2 Plate made of insulating material

3 Rigid fastener

4 Conductor and/or metal installation in accordance with Annex C

Figure 1 – Basic arrangement of specimen with cross-connection component

Flexible lead

Dimension in millimetres

Flexible lead

4 1

20 20

IEC

Key

1 Parallel connection component

2 Plate made of insulating material

3 Rigid fastener

4 Conductor and/or metal installation in accordance with Annex C

Figure 2 – Basic arrangement of specimen with parallel connection component

Flexible lead

– 14 – IEC 62561-1:2017 © IEC 2017

Dimension in millimetres

4 1

3 3

IEC

Key

1 Bridging component

2 Plate made of insulating material

3 Rigid fastener

4 Metal installation in accordance with Annex C

Figure 3 – Basic arrangement of specimen with bridging component

Flexible lead

Flexible lead

Dimension in millimetres

Flexible lead

400 100

IEC

Key

1 Equipotential bonding bar

2 Plate made of insulating material

3 Rigid fastener

4 Conductor

5 Fixing points of equipotential bonding bar

6 Connection to be tested

Figure 4 – Basic arrangement of specimen with equipotential bonding bar

6.3 Conditioning/ageing

6.3.1 Connection components not embedded in concrete

Following the manufacturer’s declaration in accordance with 4.2, the arrangement of the

specimen shall be subjected to a conditioning/ageing in accordance with Annex D.