IEC 60695-6-1:2005+AMD1:2010 CSV

(Main)Fire hazard testing - Part 6-1: Smoke obscuration - General guidance

Fire hazard testing - Part 6-1: Smoke obscuration - General guidance

IEC 60695-6-1:2005+A1:2010 Gives guidance on:

a) optical measurement of smoke obscuration;

b) general aspects of optical smoke test methods;

c) consideration of test methods;

d) expression of smoke test data;

e) relevance of optical smoke data to hazard assessment.

The main changes with respect to the previous edition are listed below:

- Modified title.

- Updated normative references.

- Expanded terms and definitions.

- Numerous editorial changes of a technical nature throughout the publication.

- A flowchart has been added for the evaluation and consideration of smoke test methods.

Has the status of a basic safety publication in accordance with IEC Guide 104.

This publication is to be read in conjunction with IEC 60695-6-2:2005.

This consolidated version consists of the second edition (2005) and its amendment 1 (2010). Therefore, no need to order amendment in addition to this publication.

Essais relatifs aux risques du feu - Partie 6-1: Opacité des fumées - Lignes directrices générales

La CEI 60695-6-1:2005+A1:2010 Fournit des lignes directrices sur:

a) la mesure optique de l'obscurcissement par la fumée;

b) les aspects généraux des méthodes d'essais optiques de la fumée;

c) des considérations concernant les méthodes d'essais;

d) l'expression des résultats d'essais;

e) la pertinence des résultats des mesures optiques de la fumée pour l'évaluation des risques.

Les principales modifications par rapport à l'édition antérieure sont indiquées ci-dessous:

- Titre modifié.

- Mise à jour des références normatives.

- Ajout de termes et de définitions.

- Nombreuses modifications rédactionnelles de nature technique dans toute la publication.

- Ajout d'un logigramme pour l'évaluation et la considération des méthodes d'essais de fumée.

A le statut de publication fondamentale de sécurité, conformément au Guide CEI 104.

Cette publication doit être lue conjointement avec la CEI 60695-6-2:2005.

Cette version consolidée comprend la deuxième édition (2005) et son amendement 1 (2010). Il n'est donc pas nécessaire de commander l'amendement avec cette publication.

General Information

- Status

- Published

- Publication Date

- 15-Sep-2010

- Technical Committee

- TC 89 - Fire hazard testing

- Current Stage

- DELPUB - Deleted Publication

- Completion Date

- 05-Aug-2021

Overview

IEC 60695-6-1:2005+AMD1:2010 CSV is an international standard published by the International Electrotechnical Commission (IEC) that provides general guidance on smoke obscuration in fire hazard testing. This standard focuses on the optical measurement of smoke obscuration, which is a critical factor in assessing fire hazards associated with electrical and electronic equipment. Smoke generated during fires can severely reduce visibility, posing risks to safe evacuation and firefighting operations. IEC 60695-6-1 outlines methods for measuring, analyzing, and interpreting smoke obscuration data to better understand smoke behavior and its impact on safety.

This version consolidates the 2005 second edition with the 2010 amendment, offering updated terminology, normative references, and editorial improvements. A key addition is a flowchart designed to aid in the evaluation and consideration of smoke test methods. The standard is intended to be used alongside IEC 60695-6-2 and other parts of the 60695-6 series focusing on smoke testing.

Key Topics

Optical Smoke Measurement

Guidance on techniques and principles for measuring smoke obscuration optically, including the use of Bouguer’s law and extinction area concepts.General Test Method Aspects

Consideration of static and dynamic test approaches, selection of test specimens, and factors affecting smoke production.Expression and Presentation of Data

Uniform methods for expressing results such as extinction coefficients, log units, and mass optical density to facilitate consistent hazard assessment.Relevance to Hazard Assessment

Interpretation of smoke obscuration data to evaluate risks related to visibility reduction, aiding in safer design and material selection for electrotechnical products.Technical Updates

Expanded terms and definitions clarify smoke-related concepts; updated normative references ensure alignment with current international practices.Evaluation Tools

The addition of a clear flowchart supports test method selection and evaluation, improving decision-making in fire hazard testing.

Applications

IEC 60695-6-1 is primarily used in:

Fire Hazard Testing of Electrical Components and Equipment

Ensuring that components meet safety requirements by minimizing smoke generation and visibility impairment during fire events.Design and Material Selection

Informing engineers and manufacturers about smoke behavior to select materials and design products that limit smoke obscuration hazards.Safety Assessments and Compliance

Supporting regulatory compliance and certification efforts by providing standardized test methods and interpretation guidelines for smoke measurement.Risk Management in Buildings and Infrastructure

Enhancing fire safety plans by understanding smoke visibility impacts and integrating them into evacuation strategy and firefighting preparedness.Research and Development

Assisting in the development of new smoke measurement technologies and methods to improve fire hazard analysis and mitigation.

Related Standards

IEC 60695-6-1 forms part of the broader IEC 60695 series on Fire Hazard Testing, which includes:

IEC 60695-6-2: Smoke Obscuration – Summary and Relevance of Test Methods

Complements Part 6-1 by summarizing methods and their application relevance.IEC 60695-6-30 and IEC 60695-6-31: Small-Scale Static Smoke Test Methods

Detail apparatus descriptions and material-specific measurement procedures for assessing smoke opacity in electrotechnical products.

Other standards important for comprehensive fire hazard evaluation include:

IEC 60695-1-1: Fire Hazard Testing – Guidance for Assessment

Offers foundational principles for overall fire hazard evaluation, which pairs with the smoke obscuration guidance.ISO/TR 9122-1 and ISO 19706

Provide classification and characteristic details of fire stages that help contextualize smoke generation during fire development.

Conclusion

IEC 60695-6-1:2005+A1:2010 is an essential document for professionals involved in fire safety testing of electrical and electronic products. It delivers clear guidance on measuring smoke obscuration, interpreting smoke effects on visibility, and applying these insights to fire hazard assessments. By adopting this standard, manufacturers, safety engineers, and testing laboratories can improve fire safety design and compliance, ultimately reducing fire risks related to smoke hazards.

Keywords: IEC 60695-6-1, smoke obscuration, fire hazard testing, optical smoke measurement, extinction coefficient, fire safety standards, electrotechnical products, smoke visibility, fire hazard assessment, electrical safety testing.

Frequently Asked Questions

IEC 60695-6-1:2005+AMD1:2010 CSV is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Fire hazard testing - Part 6-1: Smoke obscuration - General guidance". This standard covers: IEC 60695-6-1:2005+A1:2010 Gives guidance on: a) optical measurement of smoke obscuration; b) general aspects of optical smoke test methods; c) consideration of test methods; d) expression of smoke test data; e) relevance of optical smoke data to hazard assessment. The main changes with respect to the previous edition are listed below: - Modified title. - Updated normative references. - Expanded terms and definitions. - Numerous editorial changes of a technical nature throughout the publication. - A flowchart has been added for the evaluation and consideration of smoke test methods. Has the status of a basic safety publication in accordance with IEC Guide 104. This publication is to be read in conjunction with IEC 60695-6-2:2005. This consolidated version consists of the second edition (2005) and its amendment 1 (2010). Therefore, no need to order amendment in addition to this publication.

IEC 60695-6-1:2005+A1:2010 Gives guidance on: a) optical measurement of smoke obscuration; b) general aspects of optical smoke test methods; c) consideration of test methods; d) expression of smoke test data; e) relevance of optical smoke data to hazard assessment. The main changes with respect to the previous edition are listed below: - Modified title. - Updated normative references. - Expanded terms and definitions. - Numerous editorial changes of a technical nature throughout the publication. - A flowchart has been added for the evaluation and consideration of smoke test methods. Has the status of a basic safety publication in accordance with IEC Guide 104. This publication is to be read in conjunction with IEC 60695-6-2:2005. This consolidated version consists of the second edition (2005) and its amendment 1 (2010). Therefore, no need to order amendment in addition to this publication.

IEC 60695-6-1:2005+AMD1:2010 CSV is classified under the following ICS (International Classification for Standards) categories: 01 - GENERALITIES. TERMINOLOGY. STANDARDIZATION. DOCUMENTATION; 13.220.99 - Other standards related to protection against fire; 29.020 - Electrical engineering in general; 33.120.10 - Coaxial cables. Waveguides. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60695-6-1:2005+AMD1:2010 CSV is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60695-6-1 ®

Edition 2.1 2010-09

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

BASIC SAFETY PUBLICATION

PUBLICATION FONDAMENTALE DE SÉCURITÉ

Fire hazard testing –

Part 6-1: Smoke obscuration – General guidance

Essais relatifs aux risques du feu –

Partie 6-1: Opacité des fumées – Lignes directrices générales

IEC 60695-6-1:2005+A1:2010

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 60695-6-1 ®

Edition 2.1 2010-09

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

BASIC SAFETY PUBLICATION

PUBLICATION FONDAMENTALE DE SÉCURITÉ

Fire hazard testing –

Part 6-1: Smoke obscuration – General guidance

Essais relatifs aux risques du feu –

Partie 6-1: Opacité des fumées – Lignes directrices générales

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CN

CODE PRIX

ICS 13.220.99; 29.020 ISBN 978-2-88912-122-9

– 2 – 60695-6-1 © IEC:2005+A1:2010

CONTENTS

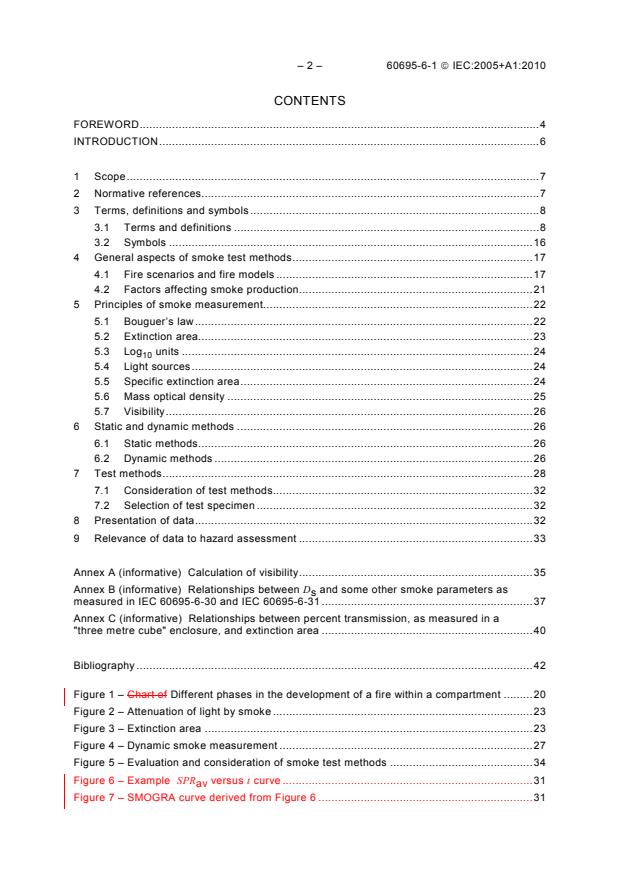

FOREWORD.4

INTRODUCTION.6

1 Scope.7

2 Normative references.7

3 Terms, definitions and symbols .8

3.1 Terms and definitions .8

3.2 Symbols .16

4 General aspects of smoke test methods.17

4.1 Fire scenarios and fire models .17

4.2 Factors affecting smoke production.21

5 Principles of smoke measurement.22

5.1 Bouguer’s law.22

5.2 Extinction area.23

5.3 Log units .24

5.4 Light sources.24

5.5 Specific extinction area.24

5.6 Mass optical density .25

5.7 Visibility.26

6 Static and dynamic methods .26

6.1 Static methods.26

6.2 Dynamic methods .26

7 Test methods.28

7.1 Consideration of test methods.32

7.2 Selection of test specimen .32

8 Presentation of data.32

9 Relevance of data to hazard assessment .33

Annex A (informative) Calculation of visibility.35

Annex B (informative) Relationships between D and some other smoke parameters as

s

measured in IEC 60695-6-30 and IEC 60695-6-31 .37

Annex C (informative) Relationships between percent transmission, as measured in a

"three metre cube" enclosure, and extinction area .40

Bibliography .42

Figure 1 – Chart of Different phases in the development of a fire within a compartment .20

Figure 2 – Attenuation of light by smoke .23

Figure 3 – Extinction area .23

Figure 4 – Dynamic smoke measurement .27

Figure 5 – Evaluation and consideration of smoke test methods .34

Figure 6 – Example SPR versus t curve .31

av

Figure 7 – SMOGRA curve derived from Figure 6 .31

60695-6-1 © IEC:2005+A1:2010 – 3 –

Figure A.1 – Visibility (ω) versus extinction coefficient (k).35

Figure B.1 – Smoke parameters related to D as measured in IEC 60695-6-30 and

s

IEC 60695-6-31.39

Figure C.1 – Extinction area (amount of smoke) related to percent transmission as

measured in the "three metre cube".41

Table 1 – General classification of fires (ISO/TR 9122-1) Characteristics of fire stages

(ISO 19706) .18

Table B.1 – Conversion from D to some other smoke parameters as measured in

s

IEC 60695-6-30 and IEC 60695-6-31.38

Table C.1 – Conversions from percent transmission, as measured in the “three metre

cube” to amount of smoke (extinction area) .40

– 4 – 60695-6-1 © IEC:2005+A1:2010

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

FIRE HAZARD TESTING –

Part 6-1: Smoke obscuration –

General guidance

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This consolidated version of IEC 60695-6-1 consists of the second edition (2005)

[documents 89/692/FDIS and 89/696/RVD] and its amendment 1 (2010) [documents

89/905/CDV and 89/946A/RVC]. It bears the edition number 2.1.

The technical content is therefore identical to the base edition and its amendment and

has been prepared for user convenience. A vertical line in the margin shows where the

base publication has been modified by amendment 1. Additions and deletions are

displayed in red, with deletions being struck through.

60695-6-1 © IEC:2005+A1:2010 – 5 –

International Standard IEC 60695-6-1 has been prepared by IEC technical committee 89: Fire

hazard testing.

The main changes with respect to the previous edition are listed below:

– Modified title.

– Updated normative references.

– Expanded terms and definitions.

– Numerous editorial changes of a technical nature throughout the publication.

– A flowchart has been added for the evaluation and consideration of smoke test methods.

It has the status of a basic safety publication in accordance with IEC Guide 104 and ISO/IEC

Guide 51.

This standard is to be used in conjunction with IEC 60695-6-2.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The IEC 60695-6 series, under the general heading Fire hazard testing, consists of the

following parts

Part 6-1: Smoke obscuration – General guidance

Part 6-2: Smoke obscuration – Summary and relevance of test methods

Part 6-30: Smoke obscuration – Guidance and test methods on the assessment of

obscuration hazard of vision caused by smoke opacity from electrotechnical

products involved in fires – Small scale static method - Determination of smoke

opacity - Description of the apparatus

Part 6-31: Smoke obscuration – Small-scale static test – Materials

The committee has decided that the contents of the base publication and its amendments will

remain unchanged until the stability date indicated on the IEC web site under "http://webstore.iec.ch"

in the data related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The “colour inside” logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this publication using a colour printer.

– 6 – 60695-6-1 © IEC:2005+A1:2010

INTRODUCTION

The risk of fire needs to be considered in any electrical circuit, and the objective of component,

circuit and equipment design, as well as the choice of material, is to reduce the likelihood of

fire, even in the event of foreseeable abnormal use, malfunction or failure.

Electrotechnical products, primarily victims of a fire, may nevertheless contribute to the fire.

One of the contributing hazards is the release of smoke, which may cause loss of vision and/or

disorientation which could impede escape from the building or fire fighting.

Smoke particles reduce the visibility due to light absorption and scattering. Consequently,

people may experience difficulties in finding exit signs, doors and windows. Visibility is often

determined as the distance at which an object is no longer visible. It depends on many factors,

but close relationships have been established between visibility and the measurements of the

extinction coefficient of smoke – see Annex A.

The production of smoke and its optical properties can be measured as well as other fire

properties, such as heat release, flame spread, and the production of toxic gas and corrosive

effluent. This part of IEC 60695-6 serves as a guidance document and focuses on obscuration

of light by smoke.

60695-6-1 © IEC:2005+A1:2010 – 7 –

FIRE HAZARD TESTING –

Part 6-1: Smoke obscuration –

General guidance

1 Scope

This part of IEC 60695 gives guidance on:

a) optical measurement of smoke obscuration;

b) general aspects of optical smoke test methods;

c) consideration of test methods;

d) expression of smoke test data;

e) relevance of optical smoke data to hazard assessment.

One of the responsibilities of a technical committee is, wherever applicable, to make use of

basic safety publications in the preparation of its publications.

2 Normative references

The following referenced documents are indispensable for the application of this document. For

dated references, only the edition cited applies. For undated references, the latest edition of

the referenced document (including any amendments) applies.

IEC 60695-1-1, Fire hazard testing – Part 1-1: Guidance for assessing the fire hazard of

electrotechnical products – General guidelines

IEC 60695-4:2001, Fire hazard testing – Part 4: Terminology concerning fire tests

IEC 60695-6-2:2001, Fire hazard testing – Part 6-2: Smoke obscuration – Summary and

relevance of test methods

IEC 60695-6-30, Fire hazard testing – Part 6: Guidance and test methods on the assessment of

obscuration hazard of vision caused by smoke opacity from electrotechnical products involved

in fires – Section 30: Small-scale static method – Determination of smoke opacity – Description

of the apparatus

IEC 60695-6-31, Fire hazard testing – Part 6-31: Smoke obscuration – Small-scale static test –

Materials

IEC Guide 104:1997, The preparation of safety publications and the use of basic safety

publications and group safety publications

ISO/TR 9122-1:1989, Toxicity testing of fire effluents – Part 1: General

ISO 5659-2:1994, Plastics – Smoke generation – Part 2: Determination of optical density by a

single-chamber test

ISO/IEC 13943:2000, Fire safety – Vocabulary

ISO/IEC Guide 51:1999. Safety aspects – Guidelines for inclusion in standards

– 8 – 60695-6-1 © IEC:2005+A1:2010

IEC 60695-1-10, Fire hazard testing – Part 1-10: Guidance for assessing the fire hazard of

electrotechnical products – General guidelines

IEC 60695-1-11 , Fire hazard testing – Part 1-11: Guidance for assessing the fire hazard of

electrotechnical products – Fire hazard assessment

IEC 60695-4:2005, Fire hazard testing – Part 4: Terminology concerning fire tests for

electrotechnical products

IEC 60695-6-2 , Fire hazard testing – Part 6-2: Smoke obscuration – Summary and relevance

of test methods

IEC 60695-6-30:1996, Fire hazard testing – Part 6: Guidance and test methods on the

assessment of obscuration hazard of vision caused by smoke opacity from electrotechnical

products involved in fires – Section 30: Small-scale static method – Determination of smoke

opacity – Description of the apparatus

IEC 60695-6-31:1999, Fire hazard testing – Part 6-31: Smoke obscuration – Small-scale static

test – Materials

IEC Guide 104:1997, The preparation of safety publications and the use of basic safety

publications and group safety publications

ISO/IEC Guide 51:1999. Safety aspects – Guidelines for inclusion in standards

ISO 5659-2:2006, Plastics – Smoke generation – Part 2: Determination of optical density by a

single-chamber test

ISO 5660-2:2002, Reaction-to-fire tests – Heat release, smoke production and mass loss rate –

Part 2: Smoke production rate (dynamic measurement)

ISO 13943:2008, Fire safety – Vocabulary

ISO 19706:2007, Guidelines for assessing the fire threat to people

NOTE ISO 9122-1:1989, Toxicity testing of fire effluents – Part 1: General, has been withdrawn and replaced by

ISO 19706:2007.

ASTM E 1354:2008, Standard Test Method for Heat and Visible Smoke Release Rates for

Materials and Products Using an Oxygen Consumption Calorimeter

EN 13823:2002, Reaction to fire tests for building products – Building products, excluding

floorings, exposed to thermal attack by a single burning item

3 Terms, definitions and symbols

3.1 Terms and definitions

For the purpose of this document, the terms and definitions and symbols given in ISO/IEC

13943, some of which are reproduced below for the uses’ convenience, as well as the following

apply.

___________

To be published.

To be published.

60695-6-1 © IEC:2005+A1:2010 – 9 –

3.1.1

combustion

exothermic reaction of a substance with an oxidizer

NOTE Combustion generally emits effluent accompanied by flames and/or visible light.

[ISO/IEC 13943, definition 23]

3.1.2

extinction area of smoke

product of the extinction coefficient and the volume occupied by the smoke

NOTE It is a measure of the amount of smoke.

[IEC 60695-4, definition 2.130]

3.1.3

extinction coefficient of smoke

natural logarithm of the opacity of smoke divided by the path length of the light used to

measure the smoke opacity

[IEC 60695-4, definition 2.131]

3.1.4

fire

a) process of combustion characterized by the emission of heat and effluent accompanied by

smoke, and/or flame, and/or glowing;

b) rapid combustion spreading uncontrolled in time and space

[IEC 60695-4, definition 2.29]

3.1.5

fire effluent

total gaseous, particulate or aerosol effluent from combustion or pyrolysis

[IEC 60695-4, definition 2.33]

3.1.6

fire hazard

potential for injury or loss of life and/or damage to property by fire

[IEC 60695-4, definition 2.36]

3.1.7

fire model

a laboratory process, including both the apparatus and the mode of operation, intended to

simulate a certain stage of a real fire

[IEC 60695-4, definition 2.120]

3.1.8

fire scenario

detailed description of conditions, including environmental, of one or more stages from before

ignition to after completion of combustion in an actual fire at a specific location or in a real-

scale simulation

[ISO/IEC 13943, definition 58]

3.1.9

flash-over

the rapid transition to a state of total surface involvement in a fire of combustible materials

within an enclosure

– 10 – 60695-6-1 © IEC:2005+A1:2010

[IEC 60695-4, definition 2.59]

3.1.10

heat flux

amount of thermal energy emitted, transmitted or received per unit area and unit time

NOTE It is expressed in watts per square metre.

[ISO/IEC 13943, definition 85]

3.1.11

ignition

initiation of combustion

NOTE The term "ignition" in French has a very different meaning [state of body combustion].

[ISO/IEC 13943, definition 96]

3.1.12

large scale test

a test, the size of which exceeds that of a typical laboratory bench test

[IEC 60695-4, definition 2.122]

3.1.13

mass optical density of smoke

optical density multiplied by a factor, V /(L × Δm), where V is the volume of the test chamber,

Δm is the mass loss of the test specimen and L is the light path length

[IEC 60695-4, definition 2.133]

3.1.14

opacity (of smoke)

the ratio (I/T) of incident luminous flux (I) to transmitted luminous flux (T) through smoke,

under specified test conditions

[IEC 60695-4, definition 2.89]

3.1.15

optical density (of smoke) [lg(I/T)]

common logarithm of the opacity of smoke (see also specific optical density)

[IEC 60695-4, definition 2.90]

3.1.16

realscale test

a test which simulates an end-use situation in both size and surroundings

[IEC 60695-4, definition 2.123]

3.1.17

small scale test

a test which may be made on a typical laboratory bench

[IEC 60695-4, definition 2.124]

3.1.18

smoke

a visible suspension of solid and/or liquid particles in gases resulting from combustion or

pyrolysis

60695-6-1 © IEC:2005+A1:2010 – 11 –

[IEC 60695-4, definition 2.101]

3.1.19

smoke obscuration

the reduction in visibility due to smoke

[IEC 60695-4, definition 2.102]

3.1.20

smoke production rate

extinction area of smoke produced, per unit time, by the combustion of a material under

specified test conditions

3.1.21

smoke release rate

see "smoke production rate"

3.1.22

specific extinction area of smoke

extinction area of smoke divided by the mass loss of the test specimen

[IEC 60695-4, definition 2.137]

3.1.23

specific optical density (of smoke)

optical density multiplied by a geometric factor V /AL, where V is the volume of the test

chamber, A is the exposed surface area of the test specimen and L is the light path length

NOTE The use of the term ‘specific’ does not, in this case, denote 'per unit mass’ but rather denotes a

dimensionless quantity associated with a particular test apparatus and exposed surface area of the test specimen.

3.1.24

visibility

maximum distance at which an object of defined size, brightness and contrast can be seen and

recognized

3.1.1

combustion

exothermic reaction of a substance with an oxidizing agent

NOTE Combustion generally emits fire effluent accompanied by flames and/or glowing.

[ISO/IEC 13943, definition 4.46]

3.1.2

extinction area of smoke

product of the volume occupied by smoke and the extinction coefficient of the smoke

NOTE It is a measure of the amount of smoke, and the typical units are square metres (m ).

[ISO /IEC 13943, definition 4.92]

3.1.3

extinction coefficient

natural logarithm of the ratio of incident light intensity to transmitted light intensity, per unit light

path length

–1

NOTE Typical units are reciprocal metres (m ).

[ISO/IEC 13943, definition 4.93]

– 12 – 60695-6-1 © IEC:2005+A1:2010

3.1.4

fire

〈general〉 process of combustion characterized by the emission of heat and fire effluent and

usually accompanied by smoke, flame or glowing or a combination thereof

NOTE In the English language the term "fire" is used to designate three concepts, two of which, fire (3.1.5) and

fire (3.1.6), relate to specific types of self-supporting combustion with different meanings and two of them are

designated using two different terms in both French and German.

[ISO/IEC 13943, definition 4.96]

3.1.5

fire

〈controlled〉 self-supporting combustion that has been deliberately arranged to provide useful

effects and is limited in its extent in time and space

[ISO/IEC 13943, definition 4.97]

3.1.6

fire

〈uncontrolled〉 self-supporting combustion that has not been deliberately arranged to provide

useful effects and is not limited in its extent in time and space

[ISO/IEC 13943, definition 4.98]

3.1.7

fire effluent

totality of gases and aerosols, including suspended particles, created by combustion or

pyrolysis in a fire

[ISO/IEC 13943, definition 4.105]

3.1.8

fire hazard

physical object or condition with a potential for an undesirable consequence from fire

[ISO/IEC 13943, definition 4.112]

3.1.9

fire model

fire simulation

calculation method that describes a system or process related to fire development, including

fire dynamics and the effects of fire

[ISO/IEC 13943, definition 4.116]

3.1.10

fire scenario

qualitative description of the course of a fire with respect to time, identifying key events that

characterise the studied fire and differentiate it from other possible fires

NOTE It typically defines the ignition and fire growth processes, the fully developed fire stage, the fire decay

stage, and the environment and systems that impact on the course of the fire.

[ISO/IEC 13943, definition 4.129]

3.1.11

flashover

〈stage of fire〉 transition to a state of total surface involvement in a fire of combustible materials

within an enclosure

[ISO/IEC 13943, definition 4.156]

60695-6-1 © IEC:2005+A1:2010 – 13 –

3.1.12

heat flux

amount of thermal energy emitted, transmitted or received per unit area and per unit time

–2

NOTE The typical units are watts per square metre (W·m ).

[ISO/IEC 13943, definition 4.173]

3.1.13

ignition

sustained ignition (deprecated)

〈general〉 initiation of combustion

[ISO/IEC 13943, definition 4.187]

3.1.14

ignition

sustained ignition (deprecated)

〈flaming combustion〉 initiation of sustained flame

[ISO/IEC 13943, definition 4.188]

3.1.15

large-scale fire test

fire test, that cannot be carried out in a typical laboratory chamber, performed on a test

specimen of large dimensions

NOTE A fire test performed on a test specimen of which the maximum dimension is greater than 3 m is usually

called a large-scale fire test.

[ISO/IEC 13943, definition 4.205]

3.1.16

mass optical density of smoke

optical density of smoke multiplied by a factor, V /(Δm L), where V is the volume of the test

chamber, Δm is the mass lost from the test specimen, and L is the light path length

2 -1

NOTE The typical units are square metres per gram (m ⋅g ).

[ISO/IEC 13943, definition 4.225]

3.1.17

obscuration by smoke

reduction in the intensity of light due to its passage through smoke

cf. extinction area of smoke (3.1.2) and specific extinction area of smoke (3.1.26).

NOTE 1 In practice, obscuration by smoke is usually measured as the transmittance, which is normally expressed

as a percentage.

NOTE 2 Obscuration by smoke causes a reduction in visibility.

[ISO/IEC 13943, definition 4.242]

– 14 – 60695-6-1 © IEC:2005+A1:2010

3.1.18

opacity of smoke

ratio of incident light intensity to transmitted light intensity through smoke, under specified

conditions

cf. obscuration by smoke (3.1.17)

NOTE 1 Opacity of smoke is the reciprocal of transmittance.

NOTE 2 The opacity of smoke is dimensionless.

[ISO/IEC 13943, definition 4.243]

3.1.19

optical density of smoke

measure of the attenuation of a light beam passing through smoke expressed as the logarithm

to the base 10 of the opacity of smoke

cf. specific optical density of smoke (3.1.26)

NOTE The optical density of smoke is dimensionless.

[ISO/IEC 13943, definition 4.244]

3.1.20

real-scale fire test

fire test that simulates a given application, taking into account the real scale, the real way the

item is installed and used, and the environment

NOTE Such a fire test normally assumes that the products are used in accordance with the conditions laid down

by the specifier and/or in accordance with normal practice.

[ISO/IEC 13943, definition 4.273]

3.1.21

small-scale fire test

fire test performed on a test specimen of small dimensions

NOTE A fire test performed on a test specimen of which the maximum dimension is less than 1 m is usually called

a small-scale fire test.

[ISO/IEC 13943, definition 4.292]

3.1.22

SMOGRA

smoke growth rate parameter that is a function of the rate of smoke production and the time of

smoke production

NOTE Further details are given in 6.2.4.

3.1.23

SMOGRA index

maximum value of SMOGRA during a defined test period

NOTE Further details are given in 6.2.4.

3.1.24

smoke

visible part of fire effluent

[ISO/IEC 13943, definition 4.293]

60695-6-1 © IEC:2005+A1:2010 – 15 –

3.1.25

smoke production rate

amount of smoke produced per unit time in a fire or fire test

NOTE 1 It is calculated as the product of the volumetric flow rate of smoke and the extinction coefficient of the

smoke at the point of measurement.

2 -1

NOTE 2 The typical units are square metres per second (m ⋅s ).

[ISO/IEC 13943, definition 4.295]

3.1.26

specific extinction area of smoke

extinction area of smoke produced by a test specimen in a given time period divided by the

mass lost from the test specimen in the same time period

2 -1

NOTE The typical units are square metres per gram (m ·g ).

[ISO/IEC 13943, definition 4.301]

3.1.27

specific optical density of smoke

optical density of smoke multiplied by a geometric factor

NOTE 1 The geometric factor is equal to V /(A⋅L), where V is the volume of the test chamber, A is the area of the

exposed surface of the test specimen, and L is the light path length.

NOTE 2 The use of the term “specific” does not denote “per unit mass” but rather denotes a quantity associated

with a particular test apparatus and area of the exposed surface of the test specimen.

NOTE 3 The specific optical density of smoke is dimensionless.

[ISO/IEC 13943, definition 4.303]

3.1.28

visibility

maximum distance at which an object of defined size, brightness and contrast can be seen and

recognized

[ISO/IEC 13943, definition 4.350]

– 16 – 60695-6-1 © IEC:2005+A1:2010

3.2 Symbols

Symbol Quantity Typical units

exposed area of test specimen m

A

linear decadic absorption coefficient

–1

m

D

(commonly called optical density per metre)

D ' optical density dimensionless

2 –1

D mass optical density m kg

mass

D specific optical density dimensionless

s

D (also D ) maximum specific optical density dimensionless

max m

intensity of incident light W

I

ratio of incident light to transmitted light dimensionless

I /T

linear Napierian absorption coefficient

–1

m

k

(commonly called extinction coefficient)

light path length through smoke m

L

mass loss of test specimen kg

Δm

–1

& mass loss rate kg s

m

smoke extinction area (also total smoke) m

S

smoke production rate

&

2 –1

S

(rate of change of extinction area) m s

t time s

sampling time interval s

Δt

intensity of transmitted light W

T

volume of chamber m

V

& 3 –1

volume flow rate of smoke m s

V

2 –1

σ specific extinction area m kg

f

a constant of proportionality between visibility and extinction

γ

dimensionless

coefficient

ω

visibility m

NOTE 1 The quantities based on log , i.e. D, D′, D , D and D , have similar symbols but they are

10 max mass s

different quantities and have different units.

NOTE 2 The use of the term "specific" in the case of specific optical density, D , does not denote "per unit

s

mass".

60695-6-1 © IEC:2005+A1:2010 – 17 –

4 General aspects of smoke test methods

4.1 Fire scenarios and fire models

During recent years, major advances have been made in the analysis of fire effluents. It is

recognized that the composition of the mixture of combustion products is particularly

dependent upon the nature of the combusting materials, the prevailing temperatures and

ventilation conditions, especially access of oxygen to the seat of the fire. Table 1 shows how

the different stages types of fire relate to the changing atmosphere. Conditions for use in

laboratory tests (small or large-scale) can be derived from the table in order to correspond, as

far as possible, to real-scale fires.

Fire involves a complex and interrelated array of physical and chemical phenomena. As a

result, it is difficult to simulate all aspects of a real-scale fire in a smaller scale apparatus. This

problem of fire model validity is perhaps the single most perplexing technical problem

associated with all fire testing.

General guidance for assessing the fire hazard assessment of electrotechnical products is

given in IEC 60695-1-1 60695-1-10.

After ignition, fire development may occur in different ways depending on the environmental

conditions, as well as on the physical arrangement of the combustible materials. However, a

general pattern can be established for fire development within a compartment, where the

general temperature-time curve shows three stages, plus a decay stage (see Figure 1).

Stage 1 is the incipient stage of the fire prior to sustained flaming, with little rise in the fire

room temperature. Ignition and smoke generation are the main hazards during this stage.

Stage 2 (developing fire) starts with ignition and ends with an exponential rise in the fire room

temperature. Spread of flame and heat release are the main hazards in addition to smoke

during this stage. Stage 3 (fully developed fire) starts when the surface of all of the

combustible contents of the room has decomposed to such an extent that sudden ignition

occurs all over the room, with a rapid and large increase in temperature (flash-over).

At the end of stage 3, the combustibles and/or oxygen have been largely consumed and hence

the temperature decreases at a rate which depends on the ventilation and the heat and mass

transfer characteristics of the system. This is known as decay.

In each of these stages, a different mixture of decomposition products may be formed and this,

in turn, influences the smoke density produced during that stage. Moreover, information is

required on the fire scenario being considered, in particular the conditions of incident heat flux,

oxygen availability and smoke-venting facilities.

– 18 – 60695-6-1 © IEC:2005+A1:2010

Table 1 – General classification of fires (ISO/TR 9122-1)

Oxygen * Ratio Temperature * Irradiance ***

Stages of fire 2

°C kW/m

% CO /CO **

Stage 1 Non-flaming decomposition

a) Smouldering 21 Not applicable <100 Not applicable

(self-sustaining)

b) Non-flaming (oxidative) 5 to 21 Not applicable <500 < 25

c) Non-flaming (pyrolytic) <5 Not applicable <1 000 Not applicable

Stage 2 Developing fire (flaming) 10 to 15 100 to 200 400 to 600 20 to 40

Stage 3 Fully developed fire (flaming)

a) Relatively low ventilation 1 to 5 <10 600 to 900 40 to 70

b) Relatively high ventilation 5 to 10 <100 600 to 1 200 50 to 150

*

General environmental condition (average) within compartment.

**

Mean value in fire plume near to fire.

***

Incident irradiance on to test specimen (average).

– 19 – 60695-6-1 © IEC:2005+A1:2010

Table 1 – Characteristics of fire stages (ISO 19706)

Max. temperature Oxygen

Heat flux [CO] 100×[CO2]

Fuel/air

volume %

°C

to fuel

Fire stage equivalence [CO2] ([CO2] + [CO])

surface

ratio (plume)

Fuel surface Upper layer Entrained Exhausted

kW/m

v/v % efficiency

1. Non-flaming

a) self-sustaining not

d

450 to 800 25 to 85 20 20 ⎯ 0,1 to 1 50 to 90

(smouldering) applicable

b) oxidative pyrolysis from

a b c c

⎯ 300 to 600 20 20 < 1

externally applied radiation

c) anaerobic pyrolysis from b c c

⎯ 100 to 500 0 0 >> 1

externally applied radiation

d e

2. Well-ventilated flaming 0 to 60 350 to 650 50 to 500 ≈ 20 ≈ 20 < 1 < 0,05 > 95

f

3. Under-ventilated flaming

a) small, localized fire,

a

generally in a poorly 0 to 30 300 to 600 50 to 500 15 to 20 5 to 10 0,2 to 0,4 70 to 80

> 1

ventilated compartment

g h i

b) post-flashover fire 50 to 150 350 to 650 0,1 to 0,4 70 to 90

> 600 < 15 < 5 > 1

a

The upper limit is lower than for well-ventilated flaming combustion of a given combustible.

b

The temperature in the upper layer of the fire room is most likely determined by the source of the externally applied radiation and room geometry.

c

There are few data; but for pyrolysis, this ratio is expected to vary widely depending on the material chemistry and the local ventilation and thermal conditions.

d

The fire’s oxygen consumption is small compared to that in the room or the inflow, the flame tip is below the hot gas upper layer or the upper layer is not yet

significantly vitiated to increase the CO yield significantly, the flames are not truncated by contact with another object, and the burning rate is controlled by the

availability of fuel.

e

The ratio may be up to an order of magnitude higher for materials that are fire-resistant. There is no significant increase in this ratio for equivalence ratios up

to ≈ 0,75. Between ≈ 0,75 and 1, some increase in this ratio may occur.

f

The fire’s oxygen demand is limited by the ventilation opening(s); the flames extend into the upper layer.

g

Assumed to be similar to well-ventilated flaming.

h

The plume equivalence ratio has not been measured; the use of a global equivalence ratio is inappropriate.

i

Instances of lower ratios have been measured. Generally, these result from secondary combustion outside the room vent.

– 20 – 60695-6-1 © IEC:2005+A1:2010

Stage 1 Stage 2 Stage 3

Decay stage

Non-flaming Developing fire Fully developed fire

decomposition

0 Ignition Flash-over

Time t

IEC 603/05

Stage 3

Stage 2

Developing fire

Stage 1

Well-ventilated Decay stage

Fully developed fire

Non-flaming

flaming

Fire types 1a),

Fire type 2 Fire type 3b)

1b) and 1c)

Ignition Flash-over Time

IEC 1111/10

Figure 1 – Chart of Different phases in the development of a fire within a compartment

Compartment temperature

Compartment temperature

60695-6-1 © IEC:2005+A1:2010 – 21 –

4.2 Factors affecting smoke production

4.2.1 General

Many factors affect the production of smoke and the properties of smoke. A full description of

such properties is not possible, but the influence of several important variables is recognized.

4.2.2 Modes of decomposition

Smoke is a consequence of combustion. Combustion may be flaming or non-flaming, including

smouldering, and these different modes of combustion may produce quite different types of

smoke. In non-flaming combustion, volatiles are evolved at elevated temperatures. When they

mix with cool air, they condense to form spherical droplets which appear as a light-coloured

smoke aerosol. Flaming combustion produces a black carbon-rich smoke in which the particles

have a very irregular shape. The smoke particles from flaming combustion are formed in the

gas phase and in regions where the oxygen concentrations are low enough to cause

incomplete combustion. The carbonaceous smoke particles in the flames emit radiant energy

(as black-body emission) which is seen as y

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...