CEN/TS 19103:2021

(Main)Eurocode 5: Design of Timber Structures - Structural design of timber-concrete composite structures - Common rules and rules for buildings

Eurocode 5: Design of Timber Structures - Structural design of timber-concrete composite structures - Common rules and rules for buildings

1.1 Scope of CEN/TS 19103

(1) CEN/TS 19103 gives general design rules for timber-concrete composite structures.

(2) It provides requirements for materials, design parameters, connections, detailing and execution for timber-concrete composite structures. Recommendations for environmental parameters (temperature and moisture content), design methods and test methods are given in the Annexes.

(3) It includes rules common to many types of timber-concrete composite, but does not include details for the design of glued timber-concrete composites, nor for bridges.

NOTE For the design of glued timber-concrete composites or bridges alternative references are available.

(4) It covers the design of timber-concrete composite structures in both quasi-constant and variable environmental conditions. For ease of use, it provides simple design rules for quasi-constant environmental conditions and more complex rules for variable environmental conditions.

1.2 Assumptions

(1) The general assumptions of EN 1990 apply.

(2) CEN/TS 19103 is intended to be used in conjunction with EN 1990, EN 1991 (all parts), EN 1992 (all parts), EN 1994 (all parts), EN 1995 (all parts), EN 1998 (all parts) when timber structures are built in seismic regions, and ENs for construction products relevant to timber structures.

Eurocode 5: Bemessung und Konstruktion von Holzbauten - Berechnung von Holz-Beton-Verbundbauteilen - Allgemeine Regeln und Regeln für den Hochbau

1.1 Anwendungsbereich von FprCEN/TS 19103

(1) FprCEN/TS 19103 enthält grundlegende Bemessungsregeln für Holz-Beton-Verbundbauteile.

(2) Sie enthält Anforderungen an Baustoffe, an Bemessungsparameter, an Verbindungen, an konstruktive Ausführung sowie an die Ausführung von Holz-Beton-Verbundbauteilen. Empfehlungen für Umgebungsparameter (Temperatur und Holzfeuchte), Bemessungsverfahren und Prüfverfahren sind den Anhängen zu entnehmen.

(3) Sie enthält Regeln, die für viele Typen von Holz-Beton-Verbundwerkstoffen gelten. Die Bemessung von Verbundbauteilen mit geklebter Verbindung zwischen Holz und Beton oder von Brücken ist nicht Gegenstand dieses Dokumentes.

ANMERKUNG Für die Bemessung von Verbundbauteilen mit geklebter Verbindung aus Holz und Beton oder Brücken sind Verweise auf andere Berechnungsvorschriften verfügbar.

(4) Sie behandelt die Bemessung von Holz-Beton-Verbundbauteilen sowohl unter quasi-konstanten als auch unter veränderlichen Umgebungsbedingungen. Für die Vereinfachung der Anwendung enthält das Dokument Bemessungsregeln für quasi-konstante Umgebungsbedingungen sowie komplexere Regeln für veränderliche Umgebungsbedingungen

1.2 Annahmen

(1) Es gelten die allgemeinen Annahmen nach EN 1990.

(2) FprCEN/TS 19103 ist vorgesehen zur Anwendung in Zusammenhang mit EN 1990, EN 1991 (alle Teile), EN 1992 (alle Teile), EN 1994 (alle Teile), EN 1995 (alle Teile), EN 1998 (alle Teile), für die Erdbebenbemessung , sowie mit den für Holztragwerke maßgebenden EN für Bauprodukte.

Eurocode 5 : Conception et calcul des structures en bois - Calcul des structures mixtes bois-béton - Règles communes et règles pour les bâtiments

1.1 Domaine d’application de la CEN/TS 19103

(1) La CEN/TS 19103 spécifie des règles générales de calcul pour les structures mixtes bois-béton.

(2) Elle fournit des exigences relatives aux matériaux, aux paramètres de calcul, aux assemblages, aux dispositions constructives et à l’exécution des structures mixtes bois-béton. Les recommandations relatives aux paramètres environnementaux (température et humidité), aux méthodes de calcul et aux méthodes d’essai sont données dans les annexes.

(3) Ce document inclut les règles communes à de nombreux types de composites bois béton, mais ne comprend pas les détails du calcul des composites bois-béton collés, ni des ponts.

NOTE Pour le calcul des composites bois-béton collés ou des ponts, d’autres références sont disponibles.

(4) Il couvre le calcul des structures mixtes bois-béton dans des conditions d’environnement quasi constantes et variables. Pour en faciliter l’utilisation, il fournit des règles de calcul simples pour les conditions d’environnement quasi constantes et des règles plus complexes pour les conditions d’environnement variables.

1.2 Hypothèses

(1) Les hypothèses générales de l’EN 1990 s’appliquent.

(2) La CEN/TS 19103 est destinée à être utilisée conjointement avec l’EN 1990, l’EN 1991 (toutes parties), l’EN 1992 (toutes parties), l’EN 1994 (toutes parties), l’EN 1995 (toutes parties), l’EN 1998 (toutes parties) lorsque les structures en bois sont construites dans des régions sismiques, ainsi qu’avec les normes EN relatives aux produits de construction des structures en bois.

Evrokod 5: Projektiranje lesenih konstrukcij - Projektiranje sovprežnih konstrukcij iz lesa in betona - Splošna pravila in pravila za stavbe

1.1 Področje uporabe CEN/TS 19103

(1) CEN/TS 19103 podaja splošna pravila za projektiranje sovprežnih konstrukcij iz lesa in betona.

(2) Zagotavlja zahteve za materiale, konstrukcijske parametre, povezave, detajle in izvedbo sovprežnih konstrukcij iz lesa in betona. Priporočila za okoljske parametre (temperatura in vsebnost vlage), metode projektiranja in preskusne metode so podane v dodatkih.

(3) Vključuje pravila, ki so skupna za številne vrste sovprežnih konstrukcij iz lesa in betona, vendar ne vključuje podrobnosti za projektiranje lepljenih sovprežnih konstrukcij iz lesa in betona niti za mostove.

OPOMBA: Za projektiranje lepljenih sovprežnih konstrukcij iz lesa in betona ali mostov so na voljo alternativne reference.

(4) Zajema projektiranje sovprežnih konstrukcij iz lesa in betona v navidezno nespremenljivih in spremenljivih okoljskih pogojih. Za lažjo uporabo zagotavlja preprosta pravila projektiranja za navidezno nespremenljive okoljske pogoje in kompleksnejša pravila za spremenljive okoljske pogoje.

1.2 Predpostavke

(1) Splošne predpostavke za standard EN 1990 so:

(2) CEN/TS 19103 je namenjen za uporabo skupaj s standardi EN 1990, EN 1991 (vsi deli), EN 1992 (vsi deli), EN 1994 (vsi deli), EN 1995 (vsi deli), EN 1998 (vsi deli) pri gradnji konstrukcij iz lesa v potresnih območjih in s standardi za gradbene proizvode, ki veljajo za konstrukcije iz lesa.

General Information

- Status

- Published

- Publication Date

- 16-Nov-2021

- Technical Committee

- CEN/TC 250 - Structural Eurocodes

- Drafting Committee

- CEN/TC 250/SC 5/WG 2 - Timber concrete composites

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 17-Oct-2024

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 1991-1-5:2003 - Eurocode 1: Actions on structures - Part 1-5: General actions - Thermal actions - Effective Date

- 28-Jan-2026

Overview

CEN/TS 19103:2021 - Eurocode 5: Structural design of timber‑concrete composite structures - sets out general design rules for timber‑concrete composite systems used in buildings. Published by CEN as a Technical Specification (approved July 2021), it provides requirements for materials, design parameters, connections, detailing and execution, plus informative annexes covering environmental parameter guidance, design methods and test procedures. The document covers both quasi‑constant and variable environmental conditions and offers simpler rules for the former and more detailed rules for the latter. It does not cover glued timber‑concrete composites or bridge design.

Key topics

- Scope and assumptions: Intended to be used with EN 1990 and other Eurocodes (EN 1991–EN 1998 and relevant product standards) for a consistent basis of design and verification.

- Materials and design parameters: Requirements for timber, concrete and composite components under different environmental conditions (temperature, moisture content).

- Connections and shear transfer: Rules for mechanical connections between timber and concrete, including testing and mechanical properties (see Annex C).

- Detailing and execution: Guidance on cross‑section detailing, shear connection configuration and the influence of execution on performance.

- Limit state verifications: Procedures for ultimate and serviceability limit states specific to composite behaviour (deflection, vibration, cracking).

- Durability and environmental effects: Design approaches for both quasi‑constant and variable humidity/temperature scenarios; Annex A provides yearly moisture‑content variation guidance.

- Analytical and test methods: Annex B addresses inelastic strain effects and stiffness calculations; Annex C gives experimental protocols for determining connection capacity and stiffness.

Applications

- Design of building elements combining timber and concrete, such as composite floors, slabs and beams where timber and concrete act compositely.

- Structural engineering design checks for load resistance, serviceability (deflection, vibration) and durability in buildings.

- Preparation of test programmes to characterise shear connectors and composite behaviour in laboratory or certification settings.

- Detailing and execution planning for contractors installing timber‑concrete composite systems in residential, commercial or institutional buildings.

Who should use this standard

- Structural engineers and designers specifying timber‑concrete composite solutions.

- Contractors and fabricators responsible for connections, assembly and on‑site execution.

- Testing laboratories and product manufacturers validating connector performance.

- National standards bodies and code officials implementing Eurocode provisions.

Related standards

- EN 1990 (Basis of structural design)

- EN 1991–EN 1998 (Actions, concrete, composite, timber and seismic design parts)

- Product and test standards relevant to timber and concrete components

Note: CEN/TS 19103 is a provisional Technical Specification with an initial limited validity period; users should check national adoption and any National Annex entries for locally determined parameters.

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

CEN/TS 19103:2021 is a technical specification published by the European Committee for Standardization (CEN). Its full title is "Eurocode 5: Design of Timber Structures - Structural design of timber-concrete composite structures - Common rules and rules for buildings". This standard covers: 1.1 Scope of CEN/TS 19103 (1) CEN/TS 19103 gives general design rules for timber-concrete composite structures. (2) It provides requirements for materials, design parameters, connections, detailing and execution for timber-concrete composite structures. Recommendations for environmental parameters (temperature and moisture content), design methods and test methods are given in the Annexes. (3) It includes rules common to many types of timber-concrete composite, but does not include details for the design of glued timber-concrete composites, nor for bridges. NOTE For the design of glued timber-concrete composites or bridges alternative references are available. (4) It covers the design of timber-concrete composite structures in both quasi-constant and variable environmental conditions. For ease of use, it provides simple design rules for quasi-constant environmental conditions and more complex rules for variable environmental conditions. 1.2 Assumptions (1) The general assumptions of EN 1990 apply. (2) CEN/TS 19103 is intended to be used in conjunction with EN 1990, EN 1991 (all parts), EN 1992 (all parts), EN 1994 (all parts), EN 1995 (all parts), EN 1998 (all parts) when timber structures are built in seismic regions, and ENs for construction products relevant to timber structures.

1.1 Scope of CEN/TS 19103 (1) CEN/TS 19103 gives general design rules for timber-concrete composite structures. (2) It provides requirements for materials, design parameters, connections, detailing and execution for timber-concrete composite structures. Recommendations for environmental parameters (temperature and moisture content), design methods and test methods are given in the Annexes. (3) It includes rules common to many types of timber-concrete composite, but does not include details for the design of glued timber-concrete composites, nor for bridges. NOTE For the design of glued timber-concrete composites or bridges alternative references are available. (4) It covers the design of timber-concrete composite structures in both quasi-constant and variable environmental conditions. For ease of use, it provides simple design rules for quasi-constant environmental conditions and more complex rules for variable environmental conditions. 1.2 Assumptions (1) The general assumptions of EN 1990 apply. (2) CEN/TS 19103 is intended to be used in conjunction with EN 1990, EN 1991 (all parts), EN 1992 (all parts), EN 1994 (all parts), EN 1995 (all parts), EN 1998 (all parts) when timber structures are built in seismic regions, and ENs for construction products relevant to timber structures.

CEN/TS 19103:2021 is classified under the following ICS (International Classification for Standards) categories: 81.040.20 - Glass in building; 91.010.30 - Technical aspects; 91.080.20 - Timber structures; 91.080.40 - Concrete structures; 91.080.99 - Other structures. The ICS classification helps identify the subject area and facilitates finding related standards.

CEN/TS 19103:2021 has the following relationships with other standards: It is inter standard links to EN 1990:2002, EN 1992-1-1:2004/A1:2014, EN 1992-1-1:2004, EN 1994-2:2005, EN 14592:2022, EN 1995-1-1:2004/A2:2014, EN 1991-1-5:2025, EN 1991-4:2006, EN 1994-1-1:2004, EN 1995-1-1:2004, EN 1991-1-2:2024, EN 1991-1-9:2025, EN 1991-2:2023, EN 1991-1-4:2005/A1:2010, EN 1991-1-5:2003. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

CEN/TS 19103:2021 is associated with the following European legislation: EU Directives/Regulations: 305/2011; Standardization Mandates: M/515. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

CEN/TS 19103:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-februar-2022

Evrokod 5: Projektiranje lesenih konstrukcij - Projektiranje sovprežnih konstrukcij

iz lesa in betona - Splošna pravila in pravila za stavbe

Eurocode 5: Design of Timber Structures - Structural design of timber-concrete

composite structures - Common rules and rules for buildings

Eurocode 5: Berechnung und Konstruktion von Holzbauten - Bemessung und

Berechnung von Holz-Beton-Verbundbauteilen - Allgemeine Regeln und Regeln für den

Hochbau

Eurocode 5 : Conception et calcul des structures en bois - Calcul des structures mixtes

bois-béton - Règles communes et règles pour les bâtiments

Ta slovenski standard je istoveten z: CEN/TS 19103:2021

ICS:

91.010.30 Tehnični vidiki Technical aspects

91.080.20 Lesene konstrukcije Timber structures

91.080.40 Betonske konstrukcije Concrete structures

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

CEN/TS 19103

TECHNICAL SPECIFICATION

SPÉCIFICATION TECHNIQUE

November 2021

TECHNISCHE SPEZIFIKATION

ICS 91.010.30; 91.080.40

English Version

Eurocode 5: Design of Timber Structures - Structural

design of timber-concrete composite structures - Common

rules and rules for buildings

Eurocode 5 : Conception et calcul des structures en Eurocode 5: Berechnung und Konstruktion von

bois - Calcul des structures mixtes bois-béton - Règles Holzbauten - Bemessung und Berechnung von Holz-

communes et règles pour les bâtiments Beton-Verbundbauteilen - Allgemeine Regeln und

Regeln für den Hochbau

This Technical Specification (CEN/TS) was approved by CEN on 25 July 2021 for provisional application.

The period of validity of this CEN/TS is limited initially to three years. After two years the members of CEN will be requested to

submit their comments, particularly on the question whether the CEN/TS can be converted into a European Standard.

CEN members are required to announce the existence of this CEN/TS in the same way as for an EN and to make the CEN/TS

available promptly at national level in an appropriate form. It is permissible to keep conflicting national standards in force (in

parallel to the CEN/TS) until the final decision about the possible conversion of the CEN/TS into an EN is reached.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2021 CEN All rights of exploitation in any form and by any means reserved Ref. No. CEN/TS 19103:2021 E

worldwide for CEN national Members.

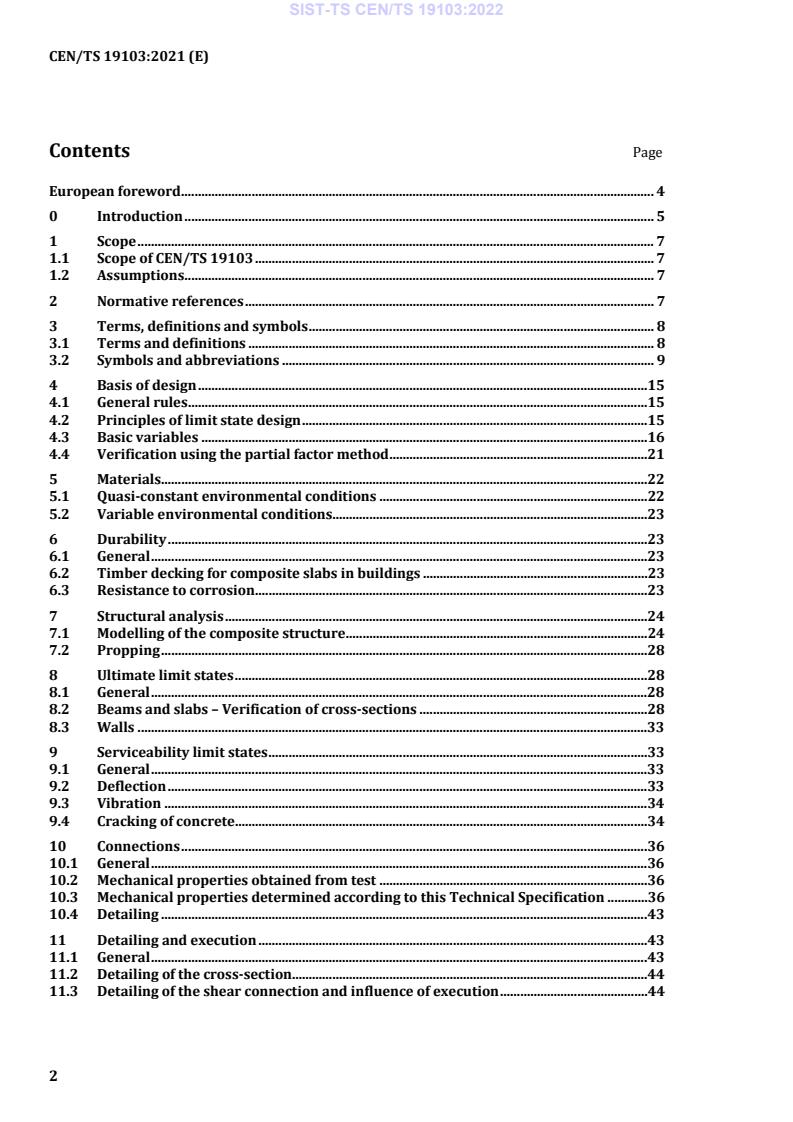

Contents Page

European foreword . 4

0 Introduction . 5

1 Scope . 7

1.1 Scope of CEN/TS 19103 . 7

1.2 Assumptions . 7

2 Normative references . 7

3 Terms, definitions and symbols . 8

3.1 Terms and definitions . 8

3.2 Symbols and abbreviations . 9

4 Basis of design .15

4.1 General rules .15

4.2 Principles of limit state design .15

4.3 Basic variables .16

4.4 Verification using the partial factor method .21

5 Materials .22

5.1 Quasi-constant environmental conditions .22

5.2 Variable environmental conditions.23

6 Durability .23

6.1 General .23

6.2 Timber decking for composite slabs in buildings .23

6.3 Resistance to corrosion .23

7 Structural analysis .24

7.1 Modelling of the composite structure .24

7.2 Propping .28

8 Ultimate limit states .28

8.1 General .28

8.2 Beams and slabs – Verification of cross-sections .28

8.3 Walls .33

9 Serviceability limit states .33

9.1 General .33

9.2 Deflection .33

9.3 Vibration .34

9.4 Cracking of concrete .34

10 Connections .36

10.1 General .36

10.2 Mechanical properties obtained from test .36

10.3 Mechanical properties determined according to this Technical Specification .36

10.4 Detailing .43

11 Detailing and execution .43

11.1 General .43

11.2 Detailing of the cross-section.44

11.3 Detailing of the shear connection and influence of execution .44

Annex A (informative) Yearly variations of moisture content averaged over the timber

cross-section for timber-concrete composite structures under variable

environmental conditions . 46

A.1 Use of this Annex . 46

A.2 Scope and field of application . 46

A.3 Yearly variations of timber moisture content . 46

Annex B (informative) Calculation of the effect of inelastic strains . 49

B.1 Use of this Annex . 49

B.2 Scope and field of application . 49

B.3 Effective bending stiffness . 50

B.4 Bending moment in the concrete slab (sub. 1) and the timber beam (sub. 2) . 52

B.5 Axial forces . 52

B.6 Shear force in the connection due to shrinkage . 53

Annex C (informative) Experimental determination of the load-carrying capacity and

stiffness of timber to concrete connections . 55

C.1 Use of this Annex . 55

C.2 Scope and field of application . 55

C.3 Specimen configuration . 55

C.4 Testing protocol . 56

C.5 Determination of mechanical properties . 57

Bibliography . 58

European foreword

This document (CEN/TS 19103:2021) has been prepared by Technical Committee CEN/TC 250

“Structural Eurocodes”, the secretariat of which is held by BSI. CEN/TC 250 is responsible for all

Structural Eurocodes and has been assigned responsibility for structural and geotechnical design matters

by CEN.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document has been prepared under Mandate M/515 issued to CEN by the European Commission

and the European Free Trade Association.

This document has been drafted to be used in conjunction with relevant execution, material, product and

test standards, and to identify requirements for execution, materials, products and testing that are relied

upon by this document.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organizations of the

following countries are bound to announce this Technical Specification: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

0 Introduction

0.1 Introduction to the Eurocodes

The Structural Eurocodes comprise the following standards generally consisting of a number of parts:

— EN 1990 Eurocode: Basis of structural design;

— EN 1991 Eurocode 1: Actions on structures;

— EN 1992 Eurocode 2: Design of concrete structures;

— EN 1993 Eurocode 3: Design of steel structures;

— EN 1994 Eurocode 4: Design of composite steel and concrete structures;

— EN 1995 Eurocode 5: Design of timber structures;

— EN 1996 Eurocode 6: Design of masonry structures;

— EN 1997 Eurocode 7: Geotechnical design;

— EN 1998 Eurocode 8: Design of structures for earthquake resistance;

— EN 1999 Eurocode 9: Design of aluminium structures;

— New Eurocodes under development.

0.2 Introduction to EN 1995 (all parts)

(1) EN 1995 (all parts) applies to the design of buildings and civil engineering works in timber (solid

timber, sawn, planed or in pole form, glued laminated timber or wood-based structural products, e.g.

LVL) or wood-based panels jointed together with adhesives or mechanical fasteners. It complies with the

principles and requirements for the safety and serviceability of structures and the basis of design and

verification given in EN 1990.

(2) EN 1995 (all parts) is concerned only with requirements for mechanical resistance, serviceability,

durability and fire resistance of timber structures. Other requirements concerning thermal or sound

insulation, for example, are not considered.

(3) EN 1995 (all parts) is subdivided into various parts:

— EN 1995-1 General;

— EN 1995-2 Bridges.

(4) EN 1995-1 “General” in itself does not exist as a physical document, but comprises the following two

separate parts:

— EN 1995-1-1 General – Common rules and rules for buildings;

— EN 1995-1-2 General – Structural fire design.

EN 1995-2 refers to the General rules in EN 1995-1-1.

This document supplements EN 1995.

0.3 Verb forms used in this Technical Specification

The verb “shall” expresses a requirement strictly to be followed and from which no deviation is permitted

in order to comply with the Eurocodes.

The verb “should” expresses a highly recommended choice or course of action. Subject to national

regulation and/or any relevant contractual provisions, alternative approaches may be used/adopted

where technically justified.

The verb "may” expresses a course of action permissible within the limits of the Eurocodes.

The verb “can” expresses possibility and capability; it is used for statements of fact and clarification of

concepts.

0.4 National annex for CEN/TS 19103

This document provides values within notes, indicating where national choices can be made. Therefore,

a national document implementing CEN/TS 19103 can have a National Annex containing all Nationally

Determined Parameters to be used for the assessment of buildings and civil engineering works in the

relevant country.

National choice is allowed in CEN/TS 19103 through the following subclauses:

• 4.3.1.2(5) Average timber moisture content due to the environmental conditions

• 4.4.1.1 Partial factor for shrinkage action

• 4.4.1.2 Partial factor for temperature action

• 4.4.1.2 Partial factor for moisture content action

• 4.4.2 Partial factor for connection shear strength

National choice is allowed in CEN/TS 19103 on the application of the following informative annexes:

• Annex A Yearly variations of moisture content averaged over the timber cross-section for timber-

concrete composite structures in variable environmental conditions

The National Annex can contain, directly or by reference, non-contradictory complementary information

for ease of implementation, provided it does not alter any provisions of the Eurocodes.

1 Scope

1.1 Scope of CEN/TS 19103

(1) CEN/TS 19103 gives general design rules for timber-concrete composite structures.

(2) It provides requirements for materials, design parameters, connections, detailing and execution for

timber-concrete composite structures. Recommendations for environmental parameters (temperature

and moisture content), design methods and test methods are given in the Annexes.

(3) It includes rules common to many types of timber-concrete composite, but does not include details

for the design of glued timber-concrete composites, nor for bridges.

NOTE For the design of glued timber-concrete composites or bridges alternative references are available.

(4) It covers the design of timber-concrete composite structures in both quasi-constant and variable

environmental conditions. For ease of use, it provides simple design rules for quasi-constant

environmental conditions and more complex rules for variable environmental conditions.

1.2 Assumptions

(1) The general assumptions of EN 1990 apply.

(2) CEN/TS 19103 is intended to be used in conjunction with EN 1990, EN 1991 (all parts), EN 1992 (all

parts), EN 1994 (all parts), EN 1995 (all parts), EN 1998 (all parts) when timber structures are built in

seismic regions, and ENs for construction products relevant to timber structures.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

NOTE See the Bibliography for a list of other documents cited that are not normative references, including

those referenced as recommendations (i.e. in ‘should’ clauses), permissions (‘may’ clauses), possibilities ('can'

clauses), and in notes.

1)

EN 1990:2002 , Eurocode - Basis of structural design

EN 1991 (all parts), Eurocode 1: Actions on structures

EN 1991-1-5:2003, Eurocode 1: Actions on structures - Part 1-5: General actions - Thermal actions

2)

EN 1992-1-1:2004 , Eurocode 2: Design of concrete structures - Part 1-1: General rules and rules for

buildings

EN 1993-1-8, Eurocode 3: Design of steel structures - Part 1-8: Design of joints

EN 1994-1-1:2004, Eurocode 4: Design of composite steel and concrete structures - Part 1-1: General rules

and rules for buildings

1) As impacted by EN 1990:2002/A1:2005.

2) As impacted by EN 1992-1-1:2004/A1:2014.

EN 1994-2:2005, Eurocode 4 - Design of composite steel and concrete structures - Part 2: General rules and

rules for bridges

3)

EN 1995-1-1:2004 , Eurocode 5: Design of timber structures - Part 1-1: General - Common rules and rules

for buildings

EN 14592, Timber structures - Dowel-type fasteners - Requirements

3 Terms, definitions and symbols

3.1 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 1990, EN 1995-1-1 and the

following apply.

3.1.1

continuous fastener

fastener that is continuous along the length of the timber component

3.1.2

connection

any device or system formed of connected parts and an associated fastener or fasteners as well as, where

applicable, notches, which resists slip and transfers the related shear force at the interface between

timber and concrete

Note 1 to entry: Examples include dowel-type fasteners of any material, notches, plates and continuous fasteners,

any of which can be either mechanically fixed or bonded.

Note 2 to entry: Staples fall beyond the scope of this standard.

3.1.3

inelastic strain

strain which is caused not by stresses but by shrinkage, swelling or thermal expansion, for example

3.1.4

moisture content

mass of water in wood, expressed as a percentage of its oven-dry mass

3.1.5

quasi-constant environmental conditions

environmental conditions where

— timber is installed close to its expected moisture content in use mc and

use

— for softwood timber, the variation of average moisture content in use (Δmc, see Formula (4.5)) does

not exceed 6 % and

— the temperature variations of the air do not exceed 20 °C

Note 1 to entry: The indoor conditions of a heated building are a typical example of quasi-constant conditions.

3) As impacted by EN 1995-1-1:2004/A1:2008 and EN 1995-1-1:2004/A2:2014.

3.1.6

shrinkage of concrete

decrease in dimension of a piece of concrete due to the hardening process

3.1.7

shrinkage of timber

decrease in dimension of a piece of timber due to reduction of moisture content

3.1.8

swelling of timber

increase in dimension of a piece of timber due to increase of moisture content

3.1.9

thermal expansion

linear thermal expansion between given temperatures

3.1.10

variable environmental conditions

conditions that do not comply with quasi-constant environmental conditions

Note 1 to entry: Typical examples where variable environmental conditions can be experienced are balconies,

unheated roof spaces and outdoor covered and uncovered spaces.

3.2 Symbols and abbreviations

For the purposes of this document, the symbols given in EN 1995-1-1 and the following apply.

Latin upper-case letters

A Area of cross-section 1

A Area of cross-section 2

A Area of longitudinal reinforcement in concrete flange

b

A Effective area of the concrete cross-section

conc,ef

A Area of longitudinal reinforcement in concrete flange

s

A

Area of transverse reinforcement in concrete flange

sf

A Area of the timber cross-section

tim

C

Coefficient which considers the interaction between vertical load q and inelastic

d

J,sls

strains in terms of slip in the joint

C Coefficient which correlates the inelastic strains with a fictitious load

p,sls

E Modulus of elasticity of cross-section 1

E Modulus of elasticity of cross-section 2

E Modulus of elasticity of concrete

conc

E Effective long-term modulus of elasticity of concrete

conc,fin

E Characteristic combination of actions

k

E Quasi-permanent combination of actions

q,per

E Fundamental combination of actions

u

E Design value of the modulus of elasticity of the steel reinforcement as given in

s

EN 1992-1-1:2004, 3.2.7

E Mean modulus of elasticity of timber parallel to the grain

tim

E Effective long-term modulus of elasticity of timber parallel to the grain

tim,fin

(EI) Bending stiffness of the cross-section i

i

(EI) Effective bending stiffness according to EN 1995-1-1:2004, Annex B

ef,EC5-AnnexB

(EI) Modified effective bending stiffness according to EN 1995-1-1:2004, Annex B,

ef,sls

which accounts for the interaction between vertical load and inelastic strains

F Characteristic axial withdrawal capacity of the fastener

ax,Rk

F

Estimated load-carrying capacity as defined in accordance with EN 26891 and

est

used in determining the mean slip modulus for ultimate limit states

F Characteristic load-carrying capacity in an Annex C test, as determined in

max

accordance with EN 26891

F Design load-carrying capacity for a notched connection

Rd

F Design tensile force between the timber and the concrete cross-section

t,Ed

F Design shear force per connection

v,Ed

F

Design load-carrying capacity per connection

v,Rd

F Characteristic connection shear strength

v,Rk

F Characteristic load-carrying capacity in shear per connection at time t

c

v,R,t ,k

c

I Moment of inertia of cross-section 1

I Moment of inertia of cross-section 2

I Moment of inertia of the timber cross-section

tim

K Stiffness of the connection

K

Maximum stiffness of the connection

max

K Minimum stiffness of the connection

min

K

Reference stiffness of connection

ref

K Slip modulus for serviceability limit states

ser

K Final slip modulus

ser,fin

K Mean slip modulus for serviceability at time t

c

ser,t

c

K Instantaneous slip modulus of the connection for ultimate limit states

u

K Final slip modulus for ultimate limit states

u,fin

K Slip modulus for ultimate limit states at time t

c

u,t

c

L Span of the beam

M(q + 0.8p ) Resulting bending moment due to external loads and part (80 %) of the fictitious

d sls

load equivalent to inelastic strains

M(q ) Resulting bending moment due to external load only

d

M Bending moment of component i

i

M Maximum bending moment in cross-section 2

max,2

M Bending moment in the timber cross-section

tim

N Axial force in cross-section i

i

N

Maximum axial force in cross-section 2

max,2

N Axial force in the timber cross-section

tim

T Initial average temperature in the concrete at time t

c

0,conc

T Initial average temperature in the timber at time t

c

0,tim

T Maximum temperature in the concrete (averaged over the cross-section)

max,conc

T Maximum temperature in the timber (averaged over the cross-section)

max,tim

T Minimum temperature in the concrete (averaged over the cross-section)

min,conc

T Minimum temperature in the timber (averaged over the cross-section)

min,tim

V Effective maximum shear force

max

V(q ) Resulting shear force due to external load

d

V

Ultimate slip determined in an Annex C test in accordance with EN 12512

u

X Design value of a strength property of timber or a wood-based product

d

Latin lower-case letters

a Distance

a spacing of fasteners parallel to the grain

a Distance from the centroid of cross-section 1 to the centroid of the effective

1↔c

composite cross-section

a Distance between the fastener and the unloaded edge

3c

a Distance between the fastener and the loaded edge

3t

a spacing of fasteners perpendicular to the grain

a Cross-sectional area of the transverse reinforcement of the concrete flange when

s

checking in-plane shear in the concrete

a Cross-sectional area of the longitudinal reinforcement of the concrete flange when

b

checking in-plane shear in the concrete

b Width of the concrete

conc

b Effective width of the concrete

conc,ef

b Notch width

n

b Width of the timber

tim

b Width of the timber element (in verification of concrete for in-plane shear)

w

c Minimum concrete cover for durability of steel reinforcement

min,dur

c Nominal concrete cover

nom

d Fastener diameter or rebar diameter

d Diameter of the aggregate

g

d Diameter of the concrete reinforcement bar diameter

r

f Design value of the compressive strength of concrete

cd

f Characteristic compressive cylinder strength of the concrete at 28 days

ck

f Design value of the tensile strength of concrete

ctd

f characteristic embedment strength of the concrete member for evaluation of the

c,h,2,k

load-carrying capacity based on the Johansen models

f

Effective design shear strength for the concrete

vcd

f Design shear strength of the timber member

v,t,d

f Design value of the yield strength of steel reinforcement

yd

h Nominal height of the connector

s,conn

h Thickness of the concrete flange

f

h Notch depth

n

k Deformation factor of timber

def

k ' Deformation factor for connections between concrete and timber

def

k Modification factor for duration of load and moisture content for timber strength

mod

k ' Modification factor for duration of load and moisture content for the strength of

mod

connections between concrete and timber

k Mean slip modulus for serviceability limit states, determined from Annex C tests in

s

accordance with EN 26891

k Coefficient for concrete, taking into account the effect of high sustained loads on

tc

compressive strength

l Notch length

n

l Distance between notches

s

l Length of timber in front of the notch

v

mc Moisture content of timber (averaged over the timber cross-section)

mc Moisture content of timber at time t

c

mc Maximum moisture content of timber during annual cycles

max

mc Minimum moisture content of timber during annual cycles

min

mc Expected moisture content of timber in use (mean over the year, averaged over the

use

timber cross-section)

mc Variation in moisture content over an annual cycle

var

p Fictitious vertical load which represents the effects of inelastic strains on the

sls

structure

s Effective spacing of the connections

ef

s

Spacing of the transverse reinforcement bars in the concrete slab when checking in-

f

plane actions in the concrete

s Longitudinal spacing of the fasteners when checking in-plane shear in the concrete

l

s Maximum spacing of the connections

max

s Minimum spacing of the connections

min

s Transverse spacing of the fasteners when checking in-plane shear in the concrete

t

t

A point in time

t The time when the concrete achieves the design strength or the time when the design-

imposed load is applied to the composite structure, whichever is the earlier

t Time for design for long-term condition

∞

t Time according to EN 13670:2009, 8.5(6) when curing and protection of the concrete

c

are complete

t Time of removal of props

p

t

Age of concrete at which drying shrinkage begins according to EN 1992-1-1:2004,

s

3.1.4(6)

q Design value of the external loads

d

u Mean ultimate slip

u,tc

w Crack width in concrete

k

w Recommended maximum crack width in concrete EN 1992-1-1:2004, Table 7.1N

max

z Distance between the centres of gravity of the cross-sections

Greek upper-case letters

ΔF Design longitudinal shear over a certain length of beam in verification of concrete for

d

in-plane shear (including diaphragm actions)

Δmc Total change over the annual cycle of the average timber moisture content due to

environmental conditions

-

Reduction in average moisture content in timber over the annual cycle with respect

Δmc

to the expected moisture content in use mc

use

+

Increase in average moisture content in timber over the annual cycle with respect to

Δmc

the expected moisture content in use mc

use

Δmc Timber moisture content variation (averaged over the timber cross-section) to be

calc

considered in the design

Δmc Difference between the average timber moisture content in use mc and the average

use

d

value mc at time t

0 c

ΔT Non-linear temperature difference component of the composite section

E

ΔT Temperature difference component about the z-z axis, with linear variation

MY

ΔT Temperature difference component about the y-y axis, with linear variation

MZ

Change in the average temperature of the concrete in the composite section from

-

ΔT

u,conc

initial to minimum

Change in the average temperature of the concrete in the composite section from

+

ΔT

u,conc

initial to maximum

ΔT Temperature variation of the cross-section i (1 or 2) to be considered in the design

u,i,calc

Change in the average temperature of the timber in the composite section from initial

-

ΔT

u,tim

to minimum

+ Change in the average temperature of the timber in the composite section from initial

ΔT

u,tim

to maximum

Δε Difference in inelastic strain between the timber part and the concrete part

Δx Length under consideration in verification of concrete for in-plane shear (including

diaphragm actions)

Greek lower-case letters

α Angle of a notch

α Coefficient of linear thermal expansion of concrete

c,T

α Coefficient of thermal expansion of the cross-section i

i,T

α Coefficient of linear moisture expansion of timber parallel to the grain

t,u

α Coefficient of linear thermal expansion of timber parallel to the grain

t,T

γ Composite factor of the concrete cross-section

γ Partial factor for shrinkage action

SH

γ

Partial factor for thermal action

T

γ Partial factor for moisture content action

u

γ Partial factor for connection shear strength

v

ε Shrinkage of concrete according to EN 1992-1-1:2004

conc

ε Effective shrinkage of concrete

ef,conc

ε Inelastic strain of the cross-section

i

Angle of the concrete strut

θ

ν

Strength reduction factor for concrete cracked in shear

ρ Mean value of timber member density

m

σ

Design compressive stress in the concrete member, caused by axial force and bending

conc,c,d

σ Design tensile stress in the concrete member, caused by axial force and bending

conc,t,d

τ Design longitudinal shear stress for verification of concrete for in-plane shear

Ed

φ Creep coefficient of the concrete

ψ Factor for combination value of yearly variations of average timber moisture content

0,mc

ψ Factor for frequent value of yearly variations of average timber moisture content

1,mc

ψ Factor for quasi-permanent value of average timber moisture content variations

2,mc

ψ Coefficient for the effect of composite action on the creep coefficient of the concrete

conc

cross-section

ψ Coefficient for the effect of composite action on the creep coefficient of the connection

conn

ψ Coefficient for the effect of composite action on the creep coefficient of the timber

tim

cross-section

4 Basis of design

4.1 General rules

(1) The design of timber-concrete composite structures shall be in accordance with the general rules

stated in EN 1990 and the supplementary provisions for timber-concrete composite structures stated in

this document.

(2) The basic requirements of EN 1990:2002, Clause 2, are deemed to be satisfied for timber-concrete

composite structures when all the following are applied:

— Limit state design in conjunction with the partial factor method in accordance with EN 1990;

— Actions in accordance with EN 1991 (all parts);

— Action combinations in accordance with EN 1990;

— Resistances, durability and serviceability in accordance with this standard, EN 1992-1-1,

EN 1994-1-1 and EN 1995-1-1.

4.2 Principles of limit state design

(1) In addition to the general principles stated in EN 1995-1-1:2004, 2.2 the effects of construction

sequence and changes of environmental conditions should be considered where relevant for the design.

NOTE Refer to 4.3.1.2 for the effect of changes of environmental conditions, where relevant.

(2) Due to the different creep behaviours of the concrete, the timber and the connection system, the final

long-term stress distribution in the composite structure at ultimate limit state, due to the fundamental

combination of actions E , should be calculated by superimposing:

u

— the stress distribution in the long-term due to the quasi-permanent combination of actions E

q,per

calculated using the effective moduli of elasticity of concrete and timber and the

E E

conc,fin tim,fin

effective slip modulus of the connection K (refer to 4.3.2(7))

u,fin

and

— the instantaneous stress distribution due to the difference between the fundamental combination of

actions E and the quasi-permanent combination of actions E , calculated using the moduli of

u qper

elasticity of concrete E and timber E and the slip modulus of the connection K .

conc tim u

(3) Due to the different creep behaviours of the concrete, the timber and the connection system, the final

deformation of the composite structure at serviceability limit state, due to the characteristic combination

of actions E , should be calculated by superimposing:

k

— the total deformation in the long-term due to the quasi-permanent combination of actions E

q,per

calculated using the effective moduli of elasticity of concrete E and timber E and the

conc,fin tim,fin

effective slip modulus of the connection K (refer to 4.3.2(7))

ser,fin

and

— the instantaneous deformation due to the difference between the characteristic combination of

actions E and the quasi-permanent combination of actions E , calculated using the moduli of

k qper

E E K

elasticity of concrete and timber and the slip modulus of the connection .

conc tim ser

4.3 Basic variables

4.3.1 Actions and environmental influences

4.3.1.1 General – Quasi-constant environmental conditions

(1) Actions to be used in design shall be obtained from the relevant parts of EN 1991.

(2) Duration of load and moisture content should be taken into account in the design for mechanical

resistance and serviceability in accordance with EN 1995-1-1 and in accordance with this document.

NOTE Duration of load and moisture content affect the strength and stiffness properties of timber as well as

the strength and stiffness properties of the connection between timber and concrete.

(3) Shrinkage of concrete should be considered in design for verification of both the ultimate limit state

and the serviceability limit state. For timber-concrete composite structures with a cast-in-situ concrete

slab, the shrinkage of concrete should be calculated from the time of concrete curing t , irrespective of

c

whether the timber member is propped or not.

NOTE The calculation of the effects of concrete shrinkage is given in Annex B. Concrete shrinkage is regarded

as an inelastic strain applied to the timber-concrete composite structure.

(4) The increase in moisture content of the timber due to casting may be disregarded (see 11.1 (3)).

4.3.1.2 General – Variable environmental conditions

(1) In variable environmental conditions, the provisions given in 4.3.1.2 shall apply in addition to the

provisions in 4.3.1.1.

(2) Due to the different linear expansion coefficients of timber and concrete, temperature differences

should be considered for verifications of both the ultimate limit state and the serviceability limit state. In

most cases, only the variations of the uniform temperature component in the concrete (ΔT ) and the

u,conc

timber ( ), as defined in Clause 4(3) of EN 1991-1-5:2003, need to be considered. The effects of the

ΔT

u,tim

linear and non-linear temperature difference components of the composite section (ΔT , ΔT and ΔT ),

MY MZ E

as defined in 4(3) of EN 1991-1-5:2003, may be neglected.

(3) The maximum and minimum temperature differences in the concrete and timber should be

calculated using Formulae (4.1) to (4.4):

+

∆=TT −T (4.1)

u,conc max,conc 0,conc

+

∆=TT −T (4.2)

u,tim max,tim 0,tim

and

−

∆TT= −T (4.3)

u,conc min,conc 0,conc

−

∆=TT −T (4.4)

u,tim min,tim 0,tim

where

+

is the change in the average temperature of the concrete in the composite section from

∆T

u,conc

initial to maximum;

is the maximum value of the average temperature in the concrete (refer to EN 1991-1-

T

max,conc

5:2003, Clause 5);

is the initial average temperature in the concrete at time t when the concrete has been

T c

0,conc

cured;

+

is the change in the average temperature of the timber in the composite section from

∆T

u,tim

initial to maximum;

is the maximum value of the average temperature in the timber (refer to EN 1991-1-

T

max,tim

5:2003, Clause 5);

is the initial average temperature in the timber at time t when the concrete has been

c

T

0,tim

cured;

NOTE If the initial temperatures when the structure is erected are unknown, reference can be made to

EN 1991-1-5:2003, Annex A.

−

is the change in the average temperature of the concrete in the composite section from

∆T

u,conc

initial to minimum;

is the minimum value of the average temperature in the concrete (refer to

T

min,conc

EN 1991-1-5:2003, Clause 5);

−

is the change in the average temperature of the timber in the composite section from

∆T

u,tim

initial to minimum;

is the minimum value of the average temperature in the timber (refer to

T

min,tim

EN 1991-1-5:2003, Clause 5).

(4) Shrinkage/swelling of timber in the longitudinal direction due to reductions/increases in moisture

content should be considered in design for verification of both the ultimate limit state and the

serviceability limit state. In general, shrinkage/swelling of the timber should be calculated by considering

only the variation over time of moisture content, averaged over the timber cross-section.

(5) When the timber is conditioned (see EN 1995-1-1:2004, 10.2) to the expected moisture content in

use mc , the annual variation of the average timber moisture content due to the environmental

use

conditions Δmc (see Formula (4.5)) should be taken into account:

+ -

— The increase (Δmc = Δmc/2 > 0) and the decrease Δmc = Δmc/2 < 0) with respect to the expected

moisture content in use mc should be considered.

use

NOTE 1 Guidance for the evaluation of the variation Δmc is given in Annex A.

Δmc mc− mc (4.5)

max min

where

is the maximum annual average timber moisture content;

mc

max

is the minimum annual average timber moisture content.

mc

min

— For structures in Europe, moisture content variations should be considered with a sign opposite to

that of the temperature variations

− −

+

NOTE 2 Δmc > 0; ΔT < 0 and ΔT < 0

u,conc u,tim

and

+ +

-

Δmc < 0; ΔT > 0 and ΔT > 0.

u,conc u,tim

mc

(6) When timber is not conditioned to the expected moisture content in use , in addition to

use

4.3.1.2(5), the difference between the average timber moisture content due to the environmental

conditions in use mc and the average value mc at the time t when the concrete was cured should

use 0 c

also be considered in design.

NOTE Annex B Formulae provide a method for calculation of the effects of temperature differences and

shrinkage/swelling of timber. In these Formulae, temperature difference, shrinkage of concrete and

shrinkage/swelling of timber are inelastic strains applied to the timber-concrete composite structure.

=

4.3.1.3 Load duration classes – Quasi-constant environmental conditions

(1) The load duration classes according to EN 1995-1-1 shall apply.

(2) The effect of concrete shrinkage on the timber-co

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...