IEC 60034-2-1:2007

(Main)Rotating electrical machines - Part 2-1:Standard methods for determining losses and efficiency from tests (excluding machines for traction vehicles)

Rotating electrical machines - Part 2-1:Standard methods for determining losses and efficiency from tests (excluding machines for traction vehicles)

Establishes methods of determining efficiencies from tests, and also specifies methods of obtaining specific losses. Applies to d.c. machines and to a.c. synchronous and induction machines of all sizes within the scope of IEC 60034-1

Machines électriques tournantes - Partie 2-1: Méthodes normalisées pour la détermination des pertes et du rendement à partir d'essais (à l'exclusion des machines pour véhicules de traction)

Définit les méthodes de détermination du rendement à partir d'essais et spécifie également les méthodes permettant de déterminer des pertes spécifiques. S'applique aux machines à courant continu ainsi qu'aux machines à courant alternatif, synchrones et à induction, de toutes dimensions, qui entrent dans le domaine d'application de la CEI 60034-1.

General Information

- Status

- Published

- Publication Date

- 09-Sep-2007

- Technical Committee

- TC 2 - Rotating machinery

- Drafting Committee

- WG 28 - TC 2/WG 28

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 27-Jun-2014

- Completion Date

- 14-Feb-2026

Relations

- Replaces

IEC 61972:2002 - Method for determining losses and efficiency of three-phase cage induction motors - Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 05-Sep-2023

Overview

IEC 60034-2-1:2007 is an international standard published by the International Electrotechnical Commission (IEC) that defines standard methods for determining losses and efficiency in rotating electrical machines through testing. This part of the IEC 60034 series focuses on machines within the scope of IEC 60034-1, including direct current (d.c.) machines, alternating current (a.c.) synchronous machines, and induction machines of all sizes. It explicitly excludes machines used for traction vehicles.

This standard establishes reliable and repeatable test methods to evaluate machine efficiency, which is critical for energy conservation, performance verification, and regulatory compliance. It is widely recognized and adopted for electrical machines testing in industries ranging from manufacturing to power generation.

Key Topics

Scope and Application

IEC 60034-2-1 applies primarily to d.c. machines, a.c. synchronous, and induction machines under load conditions. Its methodologies can also be adapted to rotary converters, a.c. commutator motors, and single-phase induction motors.Losses and Efficiency Determination

The standard provides detailed procedures to determine:- Specific losses such as iron losses, copper losses, stray load losses, and mechanical losses.

- Efficiency through both direct and indirect measurement methods, ensuring accurate and consistent evaluation under various test conditions.

Test Methods

Includes methods for:- Direct torque and power measurement using dynamometers.

- Back-to-back testing configurations for machines of similar ratings.

- Excitation circuit measurements crucial for synchronous machines.

- Reduced voltage tests and indirect calculations for efficiency estimation.

Instrumentation and Units

Provides guidance on instrumentation requirements, including precision measuring devices, power supplies, and measurement units, ensuring consistent and repeatable results.Uncertainty and Accuracy

Addresses test uncertainties and recommends preferred methods with minimized error margins for practical application.

Applications

IEC 60034-2-1 is essential for manufacturers, testing laboratories, and users of rotating electrical machines who require standardized methods to:

- Verify machine performance during manufacturing and commissioning.

- Ensure compliance with international energy efficiency regulations and market standards.

- Optimize machine design by accurately assessing various loss components.

- Conduct quality control and diagnostics for maintenance programs.

- Support energy efficiency initiatives by understanding and reducing losses.

The standard is relevant for industries including power generation, industrial manufacturing, transportation (excluding traction vehicles), and any other sectors utilizing rotating electrical machinery.

Related Standards

IEC 60034-2-1 operates in conjunction with several related IEC standards for a comprehensive approach to testing and classification of rotating electrical machines:

- IEC 60034-1: Rating and performance of rotating electrical machines, providing foundational machine specifications.

- IEC 60034-2A: Supplement covering calorimetric methods for loss measurement.

- IEC 60034-4: Methods for determining synchronous machine quantities from tests.

- IEC 60034-19: Specific test methods for d.c. machines on conventional and rectifier-fed supplies.

- IEC 61986 (under revision as IEC 60034-29): Equivalent loading and superposition techniques for indirect testing to determine temperature rise.

- IEC 60027-1: Letter symbols used in electrical technology to ensure standardized terminology.

Summary

IEC 60034-2-1:2007 delivers standardized, internationally recognized procedures to effectively determine the losses and efficiency of rotating electrical machines, pivotal for energy optimization and machine reliability. The standard's robust test methods support industries and laboratories in producing accurate, reproducible data essential for machine evaluation, energy audits, and compliance with global energy standards.

By adhering to IEC 60034-2-1, stakeholders can ensure consistent quality in machine performance assessments and contribute to sustainable electrical machine operation with improved efficiency.

Buy Documents

IEC 60034-2-1:2007 - Rotating electrical machines - Part 2-1:Standard methods for determining losses and efficiency from tests (excluding machines for traction vehicles) Released:9/10/2007 Isbn:2831892503

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

TL 9000 QuEST Forum

Telecommunications quality management system.

UL Solutions

Global safety science company with testing, inspection and certification.

Sponsored listings

Frequently Asked Questions

IEC 60034-2-1:2007 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Rotating electrical machines - Part 2-1:Standard methods for determining losses and efficiency from tests (excluding machines for traction vehicles)". This standard covers: Establishes methods of determining efficiencies from tests, and also specifies methods of obtaining specific losses. Applies to d.c. machines and to a.c. synchronous and induction machines of all sizes within the scope of IEC 60034-1

Establishes methods of determining efficiencies from tests, and also specifies methods of obtaining specific losses. Applies to d.c. machines and to a.c. synchronous and induction machines of all sizes within the scope of IEC 60034-1

IEC 60034-2-1:2007 is classified under the following ICS (International Classification for Standards) categories: 29.160.01 - Rotating machinery in general; 33.160.40 - Video systems. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60034-2-1:2007 has the following relationships with other standards: It is inter standard links to IEC 61972:2002, IEC 60034-2:1972/AMD2:1996, EN ISO 10438-3:2007, EN ISO 13631:2002, IEC 60034-2-1:2014. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60034-2-1:2007 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60034-2-1

Edition 1.0 2007-09

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Rotating electrical machines –

Part 2-1: Standard methods for determining losses and efficiency from tests

(excluding machines for traction vehicles)

Machines électriques tournantes –

Partie 2-1: Méthodes normalisées pour la détermination des pertes et du

rendement à partir d’essais (à l’exclusion des machines pour véhicules de

traction)

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 60034-2-1

Edition 1.0 2007-09

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Rotating electrical machines –

Part 2-1: Standard methods for determining losses and efficiency from tests

(excluding machines for traction vehicles)

Machines électriques tournantes –

Partie 2-1: Méthodes normalisées pour la détermination des pertes et du

rendement à partir d’essais (à l’exclusion des machines pour véhicules de

traction)

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

XB

CODE PRIX

ICS 29.160 ISBN 2-8318-9250-3

– 2 – 60034-2-1 © IEC:2007

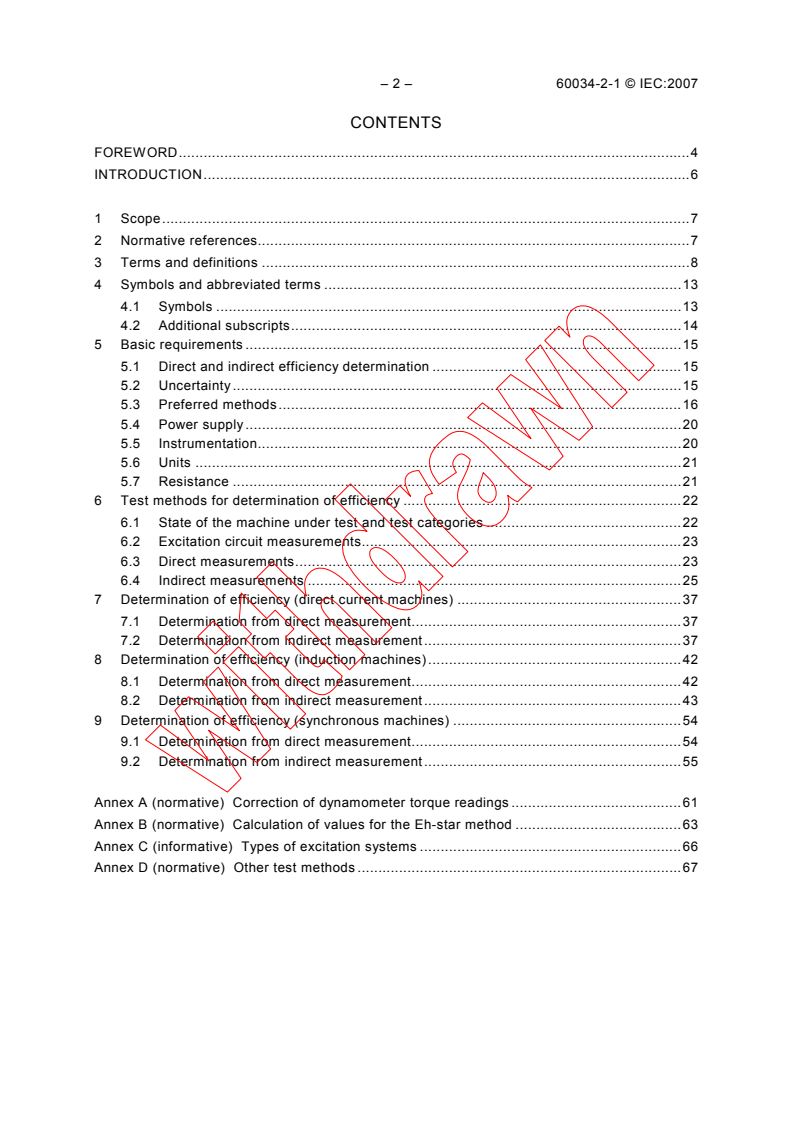

CONTENTS

FOREWORD.4

INTRODUCTION.6

1 Scope.7

2 Normative references.7

3 Terms and definitions .8

4 Symbols and abbreviated terms .13

4.1 Symbols .13

4.2 Additional subscripts.14

5 Basic requirements .15

5.1 Direct and indirect efficiency determination .15

5.2 Uncertainty .15

5.3 Preferred methods.16

5.4 Power supply.20

5.5 Instrumentation.20

5.6 Units .21

5.7 Resistance .21

6 Test methods for determination of efficiency .22

6.1 State of the machine under test and test categories .22

6.2 Excitation circuit measurements.23

6.3 Direct measurements.23

6.4 Indirect measurements .25

7 Determination of efficiency (direct current machines) .37

7.1 Determination from direct measurement.37

7.2 Determination from indirect measurement.37

8 Determination of efficiency (induction machines) .42

8.1 Determination from direct measurement.42

8.2 Determination from indirect measurement.43

9 Determination of efficiency (synchronous machines) .54

9.1 Determination from direct measurement.54

9.2 Determination from indirect measurement.55

Annex A (normative) Correction of dynamometer torque readings .61

Annex B (normative) Calculation of values for the Eh-star method .63

Annex C (informative) Types of excitation systems .66

Annex D (normative) Other test methods .67

60034-2-1 © IEC:2007 – 3 –

Figure 1 – Sketch for torque measurement test .24

Figure 2 – Sketch for dual supply back-to-back test (for synchronous machines:

I==If, f ) .24

MG M G

Figure 3 – Sketch for single supply back-to-back test, d.c. machines .26

Figure 4 – Sketch for single supply back-to-back test, synchronous machines .27

Figure 5 – Induction machine, T-model with equivalent iron loss resistor.31

Figure 6 – Sketch for single supply back-to-back, additional losses, d.c. machines .32

Figure 7 – Eh-star test circuit .35

Figure 8 – Vector diagram for obtaining current vector from reduced voltage test.46

Figure 9 – Induction machines, Reduced model for calculation .49

Figure 10 – Smoothing of the residual loss data.51

Figure 11 – Assigned allowance for additional load losses P , induction machines.53

LL

Table 1 – DC machines .17

Table 2 – Induction machines.18

Table 3 – Synchronous machines .19

Table 4 – Reference temperature .22

Table 5 – Multiplying factors for different speed ratios .42

– 4 – 60034-2-1 © IEC:2007

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ROTATING ELECTRICAL MACHINES –

Part 2-1: Standard methods for determining losses

and efficiency from tests

(excluding machines for traction vehicles)

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60034-2-1 has been prepared by IEC technical committee 2:

Rotating machinery.

This standard cancels and replaces IEC 60034-2 (1972), its amendment 1 (1995) and its

amendment 2 (1996). IEC 60034-2A (1974) is retained for the time being.

The text of this standard is based on the following documents:

FDIS Report on voting

2/1443/FDIS 2/1460/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

60034-2-1 © IEC:2007 – 5 –

A list of all parts of IEC 60034 series, under the general title Rotating electrical machines, can

be found on the IEC website.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this publication will remain unchanged until the

maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – 60034-2-1 © IEC:2007

INTRODUCTION

During the revision phase for IEC 60034-2: 1972 and its amendments IEC 60034-2 A1: 1995

(defining IEC 60034-2A: 1974 as Clause 17) and IEC 60034-2 A2: 1996, WG 28 proposed and

TC 2 agreed to separate the revised standard into three sections:

– the first part (IEC 60034-2-1) to cover machines within the scope of IEC 60034-1, which

are normally tested under load;

– the second part (IEC 60034-2-2) to cover tests applicable mainly for large machines

where the facility cost for other methods is not economical (especially the calibrated-

machine test, the retardation test and the calorimetric method);

– the third part (IEC 60034-2-3) for tests on machines for converter supply.

To retain in IEC 60034-2-1 as normative the test methods that will eventually become

IEC 60034-2-2, a temporary Annex D has been added. This annex contains elements from

IEC 60034-2:1972 and its amendment 1:1995. It also makes reference to IEC 60034-2A:1974.

Both will be incorporated in the future IEC 60034-2-2.

60034-2-1 © IEC:2007 – 7 –

ROTATING ELECTRICAL MACHINES –

Part 2-1: Standard methods for determining losses

and efficiency from tests

(excluding machines for traction vehicles)

1 Scope

This part of IEC 60034 is intended to establish methods of determining efficiencies from tests,

and also to specify methods of obtaining specific losses.

This standard applies to d.c. machines and to a.c. synchronous and induction machines of all

sizes within the scope of IEC 60034-1.

NOTE These methods may be applied to other types of machines such as rotary converters, a.c. commutator

motors and single-phase induction motors.

2 Normative references

The following referenced documents are indispensable for the application of this document. For

dated references, only the edition cited applies. For undated references, the latest edition of

the referenced document (including any amendments) applies.

IEC 60027-1, Letter symbols to be used in electrical technology – Part 1: General

IEC 60034-1, Rotating electrical machines – Part 1: Rating and performance

IEC 60034-2A, Rotating electrical machines – Part 2: Methods for determining losses and

efficiency of rotating electrical machinery form tests (excluding machines for traction vehicles)

– First supplement: Measurement of losses by the calorimetric method

IEC 60034-4, Rotating electrical machines – Part 4: Methods for determining synchronous

machine quantities from tests

IEC 60034-19, Rotating electrical machines – Part 19:Specific test methods for d.c. machines

on conventional and rectifier-fed supplies

IEC 60044 (all parts), Instrument transformers

IEC 60051-1, Direct acting indicating analogue electrical measuring instruments and their

accessories – Part 1: Definitions and general requirements common to all parts

IEC 61986, Rotating electrical machines – Equivalent loading and super-position techniques –

Indirect testing to determine temperature rise

NOTE A revision of IEC 61986 is under consideration; it will be published under reference IEC 60034-29.

– 8 – 60034-2-1 © IEC:2007

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60034-1, IEC 60051-

1 and the following definitions apply.

3.1

efficiency

ratio of output power to input power expressed in the same units and usually given as a

percentage

3.2 Tests for direct efficiency determination

3.2.1

general

method by which the direct determination of efficiency is made by measuring directly the input

power and the output power

3.2.2

torque meter test

test in which the mechanical power output of a machine acting as a motor is determined by

measurement of the shaft torque by means of a torque meter together with the rotational

speed. Alternatively, a test performed on a machine acting as a generator, by means of a

torque meter to determine the mechanical power input

3.2.3

dynamometer test

test in accordance with 3.2.2 but measuring the shaft torque by means of a dynamometer

3.2.4

dual-supply back-to-back test

test in which two identical machines are mechanically coupled together, and the total losses of

both machines are calculated from the difference between the electrical input to one machine

and the electrical output of the other machine

3.3 Tests for indirect efficiency determination

3.3.1

general

test in which the indirect determination of efficiency is made by measuring the input power or

the output power and determining the total losses. Those losses are added to the output power,

thus giving the input power, or subtracted from the input power, thus giving the output power

3.3.2

single-supply back-to-back test

test in which two identical machines are mechanically coupled together, and are both

connected electrically to the same power system. The total losses of both machines are taken

as the input power drawn from the system

3.3.3

no-load test

test in which a machine run as a motor provides no useful mechanical output from the shaft, or

when run as a generator with its terminals open-circuited

60034-2-1 © IEC:2007 – 9 –

3.3.4

zero power factor test (synchronous machines)

no-load test on a synchronous machine, which is over-excited and operates at a power factor

very close to zero

3.3.5

equivalent circuit method (induction machines)

test in which the losses are determined by help of an equivalent circuit model

3.3.6

test with rotor removed and reverse rotation test (induction machines)

combined test in which the additional load losses are determined from a test with rotor

removed and a test with the rotor running in reverse direction to the rotating magnetic field

3.3.7

short-circuit test (synchronous machines)

test in which a machine is run as a generator with its terminals short-circuited

3.3.8

locked rotor test

test in which the rotor is locked to prevent rotation

3.3.9

eh-star test

test in which the motor is run in star connection on unbalanced voltage.

3.4 Losses

3.4.1

total losses P

T

difference between the input power and the output power, equivalent to the sum of the constant

losses (see 3.4.2), the load losses (see 3.4.4), the addititional load losses (see 3.4.5) and the

excitation circuit losses (see 3.4.3)

3.4.2 Constant losses

3.4.2.1

constant losses P

k

sum of the iron losses and the friction and windage losses

3.4.2.2

iron losses P

fe

losses in active iron and additional no-load losses in other metal parts

3.4.2.3 Friction and windage losses P

fw

3.4.2.3.1

friction losses

losses due to friction (bearings and brushes, if not lifted at rated conditions) not including any

losses in a separate lubricating system. Losses in common bearings should be stated

separately, whether or not such bearings are supplied with the machine. The bearing losses

are based on the operating temperatures of the bearings, the type of oil and oil temperature.

NOTE 1 When the losses in a separate lubricating system are required these should be listed separately.

– 10 – 60034-2-1 © IEC:2007

For vertical machines, the losses in thrust bearings shall be determined excluding any external

thrust.

NOTE 2 Additional losses due to external thrust may be stated separately by agreement, which should then

include thrust load, temperature of the bearings, type of oil and also oil temperature.

NOTE 3 Friction losses due to thrust load may be included by agreement.

If the tested machine uses direct flow cooling of the bearings, these losses are distributed

between the tested machine and any other one coupled to it mechanically, such as a turbine, in

proportion to the masses of their rotating parts. If there is no direct flow cooling, the distribution

of bearing losses shall be determined from empirical formulae by agreement

3.4.2.3.2

windage losses

total losses due to aerodynamic friction in all parts of the machine, including power absorbed in

shaft mounted fans, and in auxiliary machines forming an integral part of the machine

NOTE 1 Losses in a separate ventilating system should be listed separately.

NOTE 2 For machines indirectly or directly cooled by hydrogen, see IEC 60034-1.

3.4.3 Excitation circuit losses

3.4.3.1

excitation circuit losses P

e

sum of the excitation winding losses (see 3.4.3.2), the exciter losses (see 3.4.3.3) and, for

synchronous machines, electrical brush loss (see 3.4.3.5), if any

3.4.3.2

excitation winding losses P

f

the excitation (field) winding losses are equal to the product of the exciting current I and the

e

excitation voltage U

e

3.4.3.3

exciter losses P

Ed

the exciter losses for the different excitation systems (see Annex C) are defined as follows:

a) Shaft driven exciter

The exciter losses are the power absorbed by the exciter at its shaft (reduced by friction

and windage losses) plus the power P drawn from a separate source at its excitation

1E

winding terminals, minus the useful power which the exciter provides at its terminals. The

useful power at the terminals of the exciter is equal to the excitation winding losses as per

3.4.3.2 plus (in the case of a synchronous machine) the electrical brush losses as per

3.4.3.5.

the exc

If iter can be decoupled and tested separately its losses can be determined

according to 5.3.

Whenever the exciter makes use of separate auxiliary supplies, their consumptions are to

be included in the exciter losses unless they are considered together with the main machine

auxiliaries consumption.

60034-2-1 © IEC:2007 – 11 –

b) Brushless exciter

The exciter losses are the power absorbed by the exciter at its shaft, reduced by friction

and windage losses (when the relevant test is performed on the set of main machine and

exciter), plus the electrical power P from a separate source (if any) absorbed by its field

1E

winding or its stator winding (in the case of an induction exciter), minus the useful power

which the exciter provides at the rotating power converter terminals.

Whenever the exciter makes use of separate auxiliary supplies their consumptions are to

be included in the exciter losses unless they are considered together with the main machine

auxiliaries consumption.

If the exciter can be decoupled and tested separately, its losses can be determined

according to 5.3.

c) Separate rotating exciter

The exciter losses are the difference between the power absorbed by the driving motor,

plus the power absorbed by separate auxiliary supplies, of both driving and driven

machines, including the power supplied by separate source to their excitation winding

terminals, and the excitation power supplied as per 3.4.3.2 and 3.4.3.4. The exciter losses

may be determined according to 5.3.

d) Static excitation system (static exciter)

The excitation system losses are the difference between the electrical power drawn from its

power source, plus the power absorbed by separate auxiliary supplies, and the excitation

supplied as per 3.4.3.2 and 3.4.3.4.

In the case of systems fed by transformers, the transformer losses shall be included in the

exciter losses.

e) Excitation from auxiliary winding (auxiliary winding exciter)

The exciter losses are the copper losses in the auxiliary (secondary) winding and the

additional iron losses produced by increased flux harmonics. The additional iron losses are

the difference between the losses which occur when the auxiliary winding is loaded and

when it is unloaded.

Because separation of the excitation component of losses is difficult, it is recommended to

consider these losses as an integral part of the stator losses when determining overall

losses.

In the cases c) and d) no allowance is made for the losses in the excitation source (if any) or in

the connections between the source and the brushes (synchronous machine) or between the

source and the excitation winding terminals (d.c. machine).

If the excitation is supplied by a system having components as described in b) to e) the exciter

losses shall include the relevant losses of the components pertaining to the categories listed in

Annex C as applicable.

3.4.3.4

separately supplied excitation power P

1E

the excitation power P supplied from a separate power source is:

1E

– for exciter types a) and b) the exciter excitation power (d.c. or synchronous exciter) or

(and

stator winding input power (induction exciter). It covers a part of the exciter losses P

Ed

further losses in induction exciters) while a larger part of P is supplied via the shaft;

e

– 12 – 60034-2-1 © IEC:2007

– for exciter types c) and d) equal to the excitation circuit losses, P = P ;

1E e

– for exciter type e) P = 0, the excitation power being delivered entirely by the shaft. Also,

1E

= 0 for machines with permanent magnet excitation.

P

1E

Exciter types shall be in accordance with 3.4.3.3

3.4.3.5

brush losses P (excitation circuit)

b

electrical brush loss (including contact loss) of separately excited synchronous machines

3.4.4 Load losses

3.4.4.1

load losses P

L

the sum of the winding (I R) losses (see 3.4.4.2) and the electrical brush losses (see 3.4.4.3),

if any

3.4.4.2

winding losses

winding losses are I R losses:

– in the armature circuit of d.c. machines;

– in the stator and rotor windings of induction machines;

– in the armature windings of synchronous machines

3.4.4.3

brush losses P (load circuits)

b

electrical brush loss (including contact loss) in the armature circuit of d.c. machines and in

wound-rotor induction machines

3.4.5

additional load losses P (stray-load losses)

LL

losses produced by the load current in active iron and other metal parts other than conductors;

eddy current losses in winding conductors caused by load current-dependent flux pulsations

and additional brush losses caused by commutation

NOTE These losses do not include the additional no-load losses of 3.4.2.2.

3.4.6

short-circuit losses P

sc

current-dependent losses in a synchronous machine and in a d.c. machine when the armature

winding is short-circuited

3.5 Test quantities (polyphase a.c. machines)

3.5.1

terminal voltage

for polyphase a.c. machines the arithmetic average of line voltages

3.5.2

line current

for polyphase a.c. machines the arithmetic average of line currents

60034-2-1 © IEC:2007 – 13 –

3.5.3

line-to-line resistance

for polyphase a.c. machines, the arithmetic average of line-to-line resistance across each set

of terminals

NOTE 1 For Y-connected three-phase machines, the phase-resistance is 0,5 line-to-line resistance. For Δ-

connected machines, the phase-resistance is 1,5 line-to-line resistance.

NOTE 2 In Clauses 7, 8 and 9, explanations and equations given are for three-phase machines, unless otherwise

indicated.

4 Symbols and abbreviated terms

4.1 Symbols

cos ϕ is the power factor

f is the supply frequency, Hz

I is the average line current, A

k is the temperature correction factor

θ

–1

n is the operating speed, s

p is the number of pole pairs

P is the power, W

P is the input power at no-load, W

P is the input power, excluding excitation , W

P is the output power, W

P is the brush loss, W

b

P is the excitation circuit losses, W

e

P is the excitation power supplied by a separate source, W

1E

P is the exciter losses, W

Ed

P is the electrical power, excluding excitation, W

el

P is the excitation (field) winding losses, W

f

P is the iron losses, W

fe

P is the friction and windage losses, W

fw

P is the constant losses, W

C

P is the load losses, W

L

P is the residual losses, W

Lr

P is the additional-load losses, W

LL

P is the mechanical power, W

mech

P is the short-circuit losses, W

k

P is the total losses, W

T

P is the winding losses, W,

w

where subscript w is generally replaced by a, f, e, s or r

___________

This definition assumes sinusoidal voltage and current.

Unless otherwise indicated, the tests in this document are described for motor operation, where P and P are

1 2

electrical input and mechanical output power, respectively.

– 14 – 60034-2-1 © IEC:2007

R is a winding resistance, Ω

R is the actual value of the auxiliary resistor used for the Eh-star test (see 6.4.5.5), Ω

eh

R’ is the typical value of the auxiliary resistor, Ω

eh

R is the field winding resistance, Ω

f

R is the average line-to-line-resistance, Ω

II

R is the average phase-resistance, Ω

ph

s is the slip, in per unit value of synchronous speed

T is the machine torque, N·m

T is the reading of the torque measuring device, N·m

d

T is the torque correction, N·m

c

U is the average terminal voltage, V

U is the terminal voltage at no-load, V

U is the rated terminal voltage, V

N

X is the reactance, Ω

Z=+Rj×X is the notation for a complex quantity (impedance as example)

Z==ZR+X is the absolute value of a complex quantity (impedance as example)

Z is the impedance, Ω

η is the efficiency

is the initial winding temperature, ºC

θ

θ is the ambient temperature, ºC

a

θ primary coolant inlet temperature, ºC

c

θ is the winding temperature, ºC

w

τ is a time constant, s

4.2 Additional subscripts

The following subscripts may be added to symbols to clarify the machine function and to

differentiate values.

Machine components:

a armature

e excitation

f field winding

r rotor

s stator

w winding

U, V, W phase designations

Machine categories:

B booster

D dynamometer

E exciter

G generator

M motor

60034-2-1 © IEC:2007 – 15 –

Operating conditions:

0 no-load

1 input

2 output

av average, mean

d dissipated

el electrical

i internal

L test load

lr locked rotor

mech mechanical

N rated

red at reduced voltage

t test

zpf zero power factor test

θ corrected to a reference coolant temperature.

NOTE Further additional subscripts are introduced in relevant subclauses.

5 Basic requirements

5.1 Direct and indirect efficiency determination

Tests can be grouped into the three following categories:

a) input-output measurement on a single machine. This involves the measurement of

electrical or mechanical power into, and mechanical or electrical power out of a machine;

b) input and output measurement on two identical machines mechanically connected back-to-

back. This is done to eliminate the measurement of mechanical power into or out of the

machine;

c) measurement of the actual loss in a machine under a particular condition. This is not

usually the total loss but comprises certain loss components. The method may, however,

be used to calculate the total loss or to calculate a loss component.

The determination of total losses shall be carried out by one of the following methods:

– measurement of total losses;

– determination of separate losses for summation;

NOTE The methods for determining the efficiency of machines are based on a number of assumptions. Therefore,

it is not possible to make a comparison between the values of efficiency obtained by different methods.

5.2 Uncertainty

Uncertainty as used in this standard is the uncertainty of determining a true efficiency. It

reflects variations in the test procedure and the test equipment.

Although uncertainty should be expressed as a numerical value, such a requirement needs

sufficient testing to determine representative and comparative values. This standard uses the

following relative uncertainty terms:

– 16 – 60034-2-1 © IEC:2007

– "low" applies to efficiency determinations based solely upon test results;

– "medium" applies to efficiency determinations based upon limited approximations;

– "high" applies to efficiency determinations based upon assumptions.

5.3 Preferred methods

It is difficult to establish specific rules for the determination of efficiency. The choice of test to

be made depends on the information required, the accuracy required, the type and size of the

machine involved and the available field test equipment (supply, load or driving machine).

Preferred methods are given for each machine configuration in Tables 1 to 3. The test method

should be selected from the procedures with the lowest uncertainty.

60034-2-1 © IEC:2007 – 17 –

Table 1 – DC machines

Method Clause Preferred method Required facilities Uncertainty

Direct

Calibrated machine test Annex D Calibrated machine See Note 3

Machine size: Torquemeter/dynamometer

Torque measurement 7.1.1 Low

H ≤ 180 for full-load

Total losses

Single-supply, back-to-back Two identical units

7.2.1.1 Low

test Booster generator

Summation of losses,

with load test

P d.c. component: single Two ident

LL ical units

7.2.2.6.1 Low

supply back-to-back test Booster generator

P d.c. component from

LL

7.2.2.6.3 Medium

assigned value

P a.c. component from Machine size:

LL

7.2.2.6.2 Specified rectifier Low

specified rectifier supply H > 180

Summation of losses, without load test

Excitation loss from an If test equipment for other

assigned ratio of load to no- tests is not available (no

7.2.2.5 High

load excitation current

possibility of loading, no

P from assigned value duplicate machine)

LL

NOTE 1 Due to instrumentation inaccuracies the direct test method is limited to efficiencies up to 95 % to 96 %.

For practical purposes, this standard recommends direct tests for machines up to shaft height 180 mm since these

are not likely to exceed 95 % efficiency. Machines of larger size and efficiencies below 95 % to 96 % may also be

tested successfully using the direct test method.

NOTE 2 In the "Uncertainty" column, “Low” indicates a procedure determining all loss-components from tests;

“Medium” indicates a procedure which is based on a simplified physical model of the machine; “High” indicates a

procedure that does not determine all loss-components by tests.

NOTE 3 Uncertainty to be determined.

– 18 – 60034-2-1 © IEC:2007

Table 2 – Induction machines

Method Clause Preferred method Required facilities Uncertainty

Direct

All single phase

Torquemeter/dynamometer for

Torque measurement 8.1.1 and polyphase Low

full-load

≤ 1 kW

Calibrated machine test Annex D Calibrated machine See Note 4

Dual-supply, back-to-back Machine set for full-load

8.1.2 Low

test Two identical units

Total losses

Calorimetric method Annex D Special thermal enclosure See Note 4

Single supply back-to-back Two identical units (wound

8.2.1 Low

test rotor)

Summation of losses,

with and without load test

Three phase

P determined from residual Torquemeter/dynamometer for

LL

8.2.2.5.1 > 1 kW up to Low

loss ≥ 1,25 × full-load

150 kW

P from assigned value 8.2.2.5.3 Medium to high

LL

P from removed rotor and Auxiliary motor with rated

LL

8.2.2.5.2 High

reverse rotation test power ≤ 5 × total losses P

T

Resistor for 150 % rated

P from Eh-star test 8.2.2.5.4 (see Note 3) Medium

LL

phase current

Summation of losses,

without load test

Currents, powers and slip If test equipment for other

from the equivalent circuit tests is not available (no

Medium/high

8.2.2.4.3

method possibility of applying rated

P from assigned value load, no duplicate machine)

LL

NOTE 1 Due to measurement inaccuracies, the determination of P from residual losses is limited to correlation

LL

coefficients (see 8.2.2.5.1.2) greater than 0,95 and may have uncertainties of the determined efficiency exceeding

±0,5 %.

NOTE 2 In the "Uncertainty" column, “Low” indicates a procedure determining all loss-components from tests;

“Medium” indicates a procedure which is based on a simplified physical model of the machine; “High” indicates a

procedure that does not determine all loss-components by tests.

NOTE 3 The method for P from Eh-star test is suitable for motors between 1 kW and 150 kW; larger ratings are

LL

under consideration. The method requires that the winding can be connected in star.

NOTE 4 Uncertainty to be determined.

60034-2-1 © IEC:2007 – 19 –

Table 3 – Synchronous machines

Method Clause Preferred method Required facilities Uncertainty

Direct

Machine size: Torquemeter/dynamometer for

Torque measurement 9.1.1 Low

H ≤ 180 full-load

Calibrated machine test Annex D Calibrated machine See Note 3

Dual-supply, back-to-back

9.1.2 Two identical units Medium

test

Total losses

Zero power factor with

Supply for full voltage and

excitation current from 9.2.1.2 Medium

current

Potier/ASA/Swedish diagram

Calorimetric method Annex D Special thermal enclosure See Note 3

Single supply back-to-back

9.2.1.1 Two identical units Low

test

Summation of losses,

with load test

Summation except P 9.2.1 Machine set for full-load High

LL

Machine size

P from short-circuit test 9.2.2.6 Low

LL

H > 180

Summation of losses,

without load test

If test equipment for other

Excitation current from 9.2.2.4

tests is not available (no

Potier/ASA/Swedish diagram Medium

possibility of applying rated

P from short-circuit test 9.2.2.6

LL

load, no duplicate machine)

NOTE 1 Due to instrumentation inaccuracies, the direct test method is limited to efficiencies up to 95 % to 96 %.

For practical purposes, this standard recommends direct tests for machines up to shaft heights of 180 mm since

these are not likely to exceed 95 % efficiency. Machines of larger size and efficiencies below 95 % to 96 % may also

be tested successfully using the direct test method.

NOTE 2 In the "Uncertainty" column, “Low” indicates a procedure determining all loss-components from tests;

“Medium” indicates a procedure which is based on a simplified physical model of the machine; “High” indicates a

procedure that does not determine all loss-components by tests.

NOTE 3 Uncertainty to be determined.

NOTE In the tables, H is the shaft height (distance from the centre line of the shaft to the bottom of the feet), in

millimetres (see frame numbers in IEC 60072-1).

– 20 – 60034-2-1 © IEC:2007

5.4 Power supply

5.4.1 Voltage

The voltage shall be in accordance with 7.2 (and 8.3.1 for thermal tests) of

IEC 60034-1.

5.4.2 Frequency

The frequency shall be within ±0,3 % of the rated frequency during measurements.

NOTE This requirement does not apply for the equivalent-circuit method (6.4.4.4).

5.5 Instrumentation

5.5.1 General

Since instrument accuracy is generally expressed as a percentage of full scale, the range of

the instruments chosen shall be as small as practical.

NOTE For analog instruments the observed values should be in the upper third of the instrument range.

5.5.2 Measuring instruments for electrical quantities

The measuring instruments shall have an accuracy class of 0,2 in accordance with IEC 60051.

NOTE For a routine test as described in 9.1 of IEC 60034-1, an accuracy class of 0,5 is sufficient.

Unless otherwise stated in this standard, the arithmetic average of the three line currents and

voltages shall be used.

5.5.3 Instrument transformers

Instrument transformers shall have an accuracy according to IEC 60044-1 so that the errors of

the instrument transformers are not greater than ±0,5 % for general testing or not greater tha

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...