IEC 60079-1:2014

(Main)Explosive atmospheres - Part 1: Equipment protection by flameproof enclosures "d"

Explosive atmospheres - Part 1: Equipment protection by flameproof enclosures "d"

IEC 60079-1:2014 contains specific requirements for the construction and testing of electrical equipment with the type of protection flameproof enclosure "d", intended for use in explosive gas atmospheres. This standard supplements and modifies the general requirements of IEC 60079-0. Where a requirement of this standard conflicts with a requirement of IEC 60079-0, the requirement of this standard will take precedence. This seventh edition cancels and replaces the sixth edition, published in 2007, and constitutes a technical revision. The numerous changes are identified in the Foreward of the document. Keywords: flameproof enclosure "d", explosive gas atmospheres

The contents of the corrigendum of June 2018 and Interpretation sheet of May 2020 have been included in this copy.

Feuille d'interprétation 1 - Atmosphères explosives - Partie 1: Protection du matériel par enveloppes antidéflagrantes "d"

IEC 60079-1:2014 est disponible sous forme de IEC 60079-1:2014 RLV qui contient la Norme internationale et sa version Redline, illustrant les modifications du contenu technique depuis l'édition précédente.

IEC 60079-1:2014 contient les exigences spécifiques de construction et d'essai du matériel électrique à enveloppe antidéflagrante, mode de protection "d", destiné à être utilisé dans les atmosphères explosives gazeuses. La présente Norme complète et modifie les exigences générales de l'IEC 60079-0. Lorsqu'une exigence de cette norme entre en conflit avec une exigence de l'IEC 60079-0, l'exigence de la présente norme prévaudra. Cette septième édition annule et remplace la sixième édition parue en 2007. Cette édition constitue une révision technique. Les nombreux changements sont identifiés dans l'avant-propos du document. Mots clés: enveloppe antidéflagrante "d", atmosphères explosives gazeuses

Le contenu du corrigendum de juin 2018 et de la feuille d'interprétation de mai 2020 (seulement en anglais) a été pris en considération dans cet exemplaire.

General Information

- Status

- Published

- Publication Date

- 26-Jun-2014

- Technical Committee

- TC 31 - Equipment for explosive atmospheres

- Drafting Committee

- MT 60079-1 - TC 31/MT 60079-1

- Current Stage

- PPUB - Publication issued

- Start Date

- 27-Jun-2014

- Completion Date

- 15-Jul-2014

Relations

- Effective Date

- 10-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Revises

IEC 60079-1:2007 - Explosive atmospheres - Part 1: Equipment protection by flameproof enclosures "d" - Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 60079-1:2014 - Edition 7.0, "Explosive atmospheres – Part 1: Equipment protection by flameproof enclosures 'd'" defines specific construction and test requirements for electrical equipment using the flameproof enclosure "d" type of protection for use in explosive gas atmospheres. This part supplements and modifies the general requirements of IEC 60079-0; where conflicts occur, IEC 60079-1 takes precedence. This edition (2014) supersedes the 2007 edition and includes subsequent corrigendum (June 2018) and an interpretation sheet (May 2020) incorporated in the text.

Key topics and technical requirements

The standard provides detailed, normative guidance on design, materials, verification and testing, including:

- Levels of protection (EPLs) - requirements for “da”, “db” and “dc” devices.

- Flameproof joints - required joint forms, widths and gaps for non-threaded, spigot, conical and serrated joints.

- Threaded and sealed joints - rules for threaded entries and restrictions related to thread forms; Clause 13 and Interpretation Sheet clarify permitted thread types and marking requirements.

- Entries for enclosures - requirements for threaded holes, cable glands, conduit sealing devices, plugs, sockets, bushings and blanking elements.

- Breathing and draining devices - dimensions, mounting, composition limits and tests for devices that form part of a flameproof enclosure.

- Materials and mechanical strength - material selection and strength verification for enclosures and internal components.

- Type, routine and acceptance tests - explosion pressure determination, overpressure tests, internal ignition non-transmission tests, thermal tests and tests specific to “dc” devices.

- Special topics - shafts/bearings, light-transmitting parts, fasteners, cemented and fused joints, and tests for enclosures with breathing/draining devices.

Important note from the Interpretation Sheet: Clause 13 restricts threaded entries for flameproof enclosures to metric and NPT threads to minimize thread-form mismatch. Thread adapters fitted and assessed as factory-assembled parts may use other forms (see Annex C).

Practical applications and users

IEC 60079-1 is essential for:

- Manufacturers and designers of electrical equipment intended for hazardous (gas) areas

- Test laboratories and certification bodies performing Ex testing and conformity assessment

- Safety and compliance engineers in oil & gas, petrochemical, chemical processing, mining, pharmaceuticals and utilities

- Procurement and maintenance teams specifying or servicing equipment used in explosive gas atmospheres

Related standards

- IEC 60079-0 (general requirements for equipment for explosive atmospheres) - this part is supplementary and takes precedence when in conflict.

- IEC 60079 series (other parts) - for complementary protection methods, installation, inspection and maintenance requirements.

Keywords: flameproof enclosure "d", explosive gas atmospheres, IEC 60079-1, flameproof joints, cable glands, Ex equipment, level of protection.

REDLINE IEC 60079-1:2014 - Explosive atmospheres - Part 1: Equipment protection by flameproof enclosures "d" Released:8/27/2014 Isbn:9782832218501

IEC 60079-1:2014 - Explosive atmospheres - Part 1: Equipment protection by flameproof enclosures "d"

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60079-1:2014 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Explosive atmospheres - Part 1: Equipment protection by flameproof enclosures "d"". This standard covers: IEC 60079-1:2014 contains specific requirements for the construction and testing of electrical equipment with the type of protection flameproof enclosure "d", intended for use in explosive gas atmospheres. This standard supplements and modifies the general requirements of IEC 60079-0. Where a requirement of this standard conflicts with a requirement of IEC 60079-0, the requirement of this standard will take precedence. This seventh edition cancels and replaces the sixth edition, published in 2007, and constitutes a technical revision. The numerous changes are identified in the Foreward of the document. Keywords: flameproof enclosure "d", explosive gas atmospheres The contents of the corrigendum of June 2018 and Interpretation sheet of May 2020 have been included in this copy.

IEC 60079-1:2014 contains specific requirements for the construction and testing of electrical equipment with the type of protection flameproof enclosure "d", intended for use in explosive gas atmospheres. This standard supplements and modifies the general requirements of IEC 60079-0. Where a requirement of this standard conflicts with a requirement of IEC 60079-0, the requirement of this standard will take precedence. This seventh edition cancels and replaces the sixth edition, published in 2007, and constitutes a technical revision. The numerous changes are identified in the Foreward of the document. Keywords: flameproof enclosure "d", explosive gas atmospheres The contents of the corrigendum of June 2018 and Interpretation sheet of May 2020 have been included in this copy.

IEC 60079-1:2014 is classified under the following ICS (International Classification for Standards) categories: 29.260.20 - Electrical apparatus for explosive atmospheres; 31.140 - Piezoelectric devices. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60079-1:2014 has the following relationships with other standards: It is inter standard links to EN 61800-2:2015, EN ISO 16904:2016, EN ISO/IEC 80079-49:2024, EN ISO 80079-36:2016, EN ISO 16852:2016, EN ISO 20257-1:2020, EN ISO 12643-1:2023, EN ISO 16315:2016, IEC 60079-1:2014/COR1:2018, IEC 60079-1:2007/COR1:2008, IEC 60079-1:2007, IEC 60079-1:2014/ISH1:2020. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60079-1:2014 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60079-1 ®

Edition 7.0 2014-08

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Explosive atmospheres –

Part 1: Equipment protection by flameproof enclosures "d"

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 21 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - webstore.iec.ch/advsearchform IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 67 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 60079-1 ®

Edition 7.0 2014-08

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Explosive atmospheres –

Part 1: Equipment protection by flameproof enclosures "d"

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 29.260.20 ISBN 978-2-8322-1850-1

IEC 2020

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

IEC 60079-1

Edition 7.0 2014-06

EXPLOSIVE ATMOSPHERES –

Part 1: Equipment protection by flameproof enclosures "d"

INTERPRETATION SHEET 1

This interpretation sheet has been prepared by IEC technical committee 31: Equipment for

explosive atmospheres.

The text of this interpretation sheet is based on the following documents:

DISH Report on voting

31/1536/DISH 31/1542/RVDISH

Full information on the voting for the approval of this interpretation sheet can be found in the

report on voting indicated in the above table.

___________

flameproof enclosures "d"

Question 1:

The requirements given in 13.1 of IEC 60079-1:2014 (Edition 7) restrict threaded entries for

flameproof enclosures to only metric and NPT. Does this restriction represent a major

technical change between IEC 60079-1:2014 (Edition 7) and IEC 60079-1:2007 (Edition 6)?

Answer 1:

Yes, the restriction to only metric and NPT regarding threaded entries for flameproof

enclosures does represent a major technical change between IEC 60079-1:2014 (Edition 7)

and IEC 60079-1:2007 (Edition 6). The requirements given in Clause 13 of IEC 60079-1:2007

(Edition 6) had no such normative restriction, with reference to metric and NPT only as

examples of threaded entries for flameproof enclosures.

ICS 29.260.20

– 2 – IEC 60079-1:2014/ISH1:2020

IEC 2020

While IEC 60079-1:2014 (Edition 7) only permits the use of metric and NPT threads for entry

into flameproof enclosures, cable glands/conduit entry devices, thread adapters and blanking

elements are permitted to use other thread forms (see Annex C of IEC 60079-1:2014

(Edition 7)).

NOTE 1 The intention of the restriction to only metric and NPT regarding threaded entries for flameproof

enclosures is to minimize the mismatch of thread forms in enclosure entries.

NOTE 2 In the Foreword of IEC 60079-1:2014 (Edition 7), the table detailing the significance of the changes

between IEC 60079-1:2014 (Edition 7) and IEC 60079-1:2007 (Edition 6) mistakenly did not identify this metric and

NPT restriction as a major technical change. Unfortunately, the IEC Directives do not permit a corrigendum to be

issued to correct errors in non-normative text such as the table detailing the significance of changes.

Question 2:

Where a thread adapter is fitted and assessed as a factory-assembled part of the flameproof

enclosure, what are the permitted thread forms?

Answer 2:

A thread adapter may use thread forms other than metric and NPT, whether as an Ex

Equipment thread adapter or as a thread adapter fitted and assessed as a factory-assembled

part of the flameproof enclosure (see Annex C of IEC 60079-1:2014 (Edition 7)).

Question 3:

Can a blanking element be installed in a thread adapter which is fitted and assessed as a

factory-assembled part of the flameproof enclosure?

Answer 3:

Yes, the requirements given in Clause 13 of IEC 60079-1:2014 (Edition 7) regarding thread

adapters are for separately certified Ex equipment thread adapters, not those fitted and

assessed as a factory-assembled part of the flameproof enclosure.

Question 4:

What is the required marking when a thread adapter is fitted and assessed as a factory-

assembled part of the flameproof enclosure?

Answer 4:

Clause 13 of IEC 60079-1:2014 (Edition 7) requires identification of the specific thread type

and size of threaded entries into flameproof enclosures. In the case where the thread adapter

is fitted and assessed as a factory-assembled part of the flameproof enclosure, the

requirement for identification applies to the thread form of the adapter for the field wiring

connection.

– 2 – IEC 60079-1:2014 RLV © IEC 2014

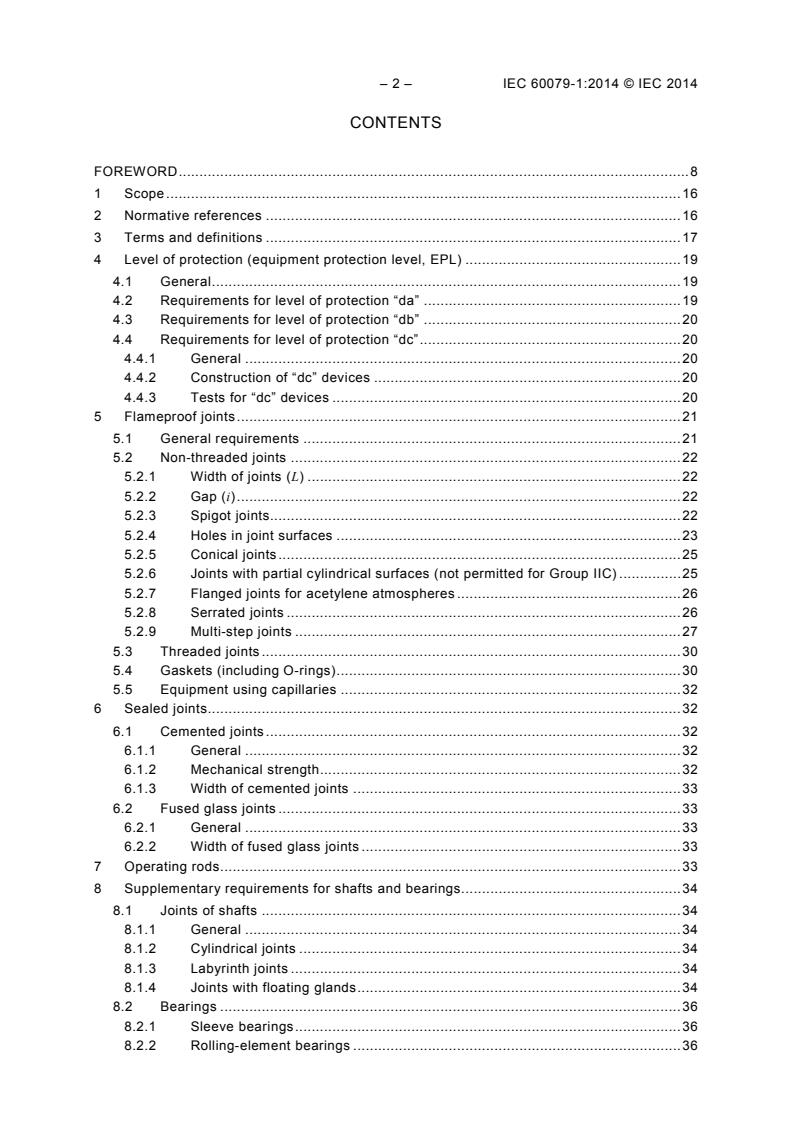

CONTENTS

CONTENTS . 2

FOREWORD . 8

1 Scope . 16

2 Normative references. 16

3 Terms and definitions . 17

4 Level of protection (equipment protection level, EPL) . 20

4.1 General . 20

4.2 Requirements for level of protection “da” . 20

4.3 Requirements for level of protection “db” . 20

4.4 Requirements for level of protection “dc” . 20

4.4.1 General . 20

4.4.2 Construction of “dc” devices . 21

4.4.3 Tests for “dc” devices . 21

5 Flameproof joints . 21

5.1 General requirements . 21

5.2 Non-threaded joints . 22

5.2.1 Width of joints (L) . 22

5.2.2 Gap (i) . 23

5.2.3 Spigot joints . 23

5.2.4 Holes in joint surfaces . 24

5.2.5 Conical joints . 26

5.2.6 Joints with partial cylindrical surfaces (not permitted for Group IIC) . 26

5.2.7 Flanged joints for acetylene atmospheres . 27

5.2.8 Serrated joints . 27

5.2.9 Multi-step joints. 28

5.3 Threaded joints . 30

5.4 Gaskets (including O-rings) . 31

5.5 Equipment using capillaries . 33

6 Sealed joints . 33

6.1 Cemented joints . 33

6.1.1 General . 33

6.1.2 Mechanical strength . 33

6.1.3 Width of cemented joints . 34

6.2 Fused glass joints . 34

6.2.1 General . 34

6.2.2 Width of fused glass joints . 34

7 Operating rods . 35

8 Supplementary requirements for shafts and bearings . 35

8.1 Joints of shafts . 35

8.1.1 General . 35

8.1.2 Cylindrical joints. 35

8.1.3 Labyrinth joints . 35

8.1.4 Joints with floating glands . 35

8.2 Bearings . 37

8.2.1 Sleeve bearings . 37

8.2.2 Rolling-element bearings . 37

9 Light-transmitting parts . 37

10 Breathing and draining devices which form part of a flameproof enclosure . 38

10.1 General . 38

10.2 Openings for breathing or draining . 38

10.3 Composition limits . 38

10.4 Dimensions . 38

10.5 Elements with measurable paths . 38

10.6 Elements with non-measurable paths . 38

10.7 Removable devices . 39

10.7.1 General . 39

10.7.2 Mounting arrangements of the elements . 39

10.8 Mechanical strength . 39

10.9 Breathing devices and draining devices when used as Ex components . 39

10.9.1 General . 39

10.9.2 Mounting arrangements of the elements and components . 39

10.9.3 Type tests for breathing and draining devices used as Ex components . 40

10.9.4 Ex component certificate . 43

11 Fasteners, associated holes and blanking elements and openings . 43

12 Materials and mechanical strength of enclosures – Materials inside the enclosures . 46

13 Entries for flameproof enclosures . 47

13.1 General . 47

13.2 Threaded holes . 47

13.3 Non-threaded holes (for Group I only) . 47

13.4 Cable glands . 48

13.5 Conduit sealing devices . 48

13.6 Plugs and sockets and cable couplers . 49

13.7 Bushings . 50

13.8 Blanking elements . 50

14 Verification and tests . 50

15 Type tests . 51

15.1 General . 51

15.2 Tests of ability of the enclosure to withstand pressure . 52

15.2.1 General . 52

15.2.2 Determination of explosion pressure (reference pressure) . 52

15.2.3 Overpressure test . 55

15.3 Test for non-transmission of an internal ignition . 56

15.3.1 General . 56

15.3.2 Electrical equipment of Groups I, IIA and IIB . 58

15.3.3 Electrical equipment of Group lIC . 59

15.4 Tests of flameproof enclosures with breathing and draining devices . 61

15.4.1 General . 61

15.4.2 Tests of ability of the enclosure to withstand pressure . 61

15.4.3 Thermal tests . 61

15.4.4 Test for non-transmission of an internal ignition . 62

– 4 – IEC 60079-1:2014 RLV © IEC 2014

15.5 Tests for “dc” devices . 63

15.5.1 General . 63

15.5.2 Preparation of “dc” samples . 63

15.5.3 Test conditions for “dc” devices . 63

16 Routine tests . 63

16.1 General . 63

16.2 Enclosures not incorporating a welded construction . 64

16.3 Enclosures incorporating a welded construction . 65

16.4 Bushings not specific to one flameproof enclosure . 65

16.5 Acceptance criteria . 65

16.6 Batch testing . 65

17 Switchgear for Group I . 65

17.1 General . 65

17.2 Means of isolation . 66

17.2.1 General . 66

17.3 Doors or covers . 66

17.3.1 Quick-acting doors or covers . 66

17.3.2 Doors or covers fixed by screws . 66

17.3.3 Threaded doors or covers . 66

18 Lampholders and Iamp caps . 67

18.1 General . 67

18.2 Device preventing lamps working loose . 67

18.3 Holders and caps for lamps with cylindrical caps . 67

18.4 Holders for lamps with threaded caps . 67

19 Non-metallic enclosures and non-metallic parts of enclosures . 67

19.1 General . 67

19.2 Resistance to tracking and creepage distances on internal surfaces of the

enclosure walls . 68

19.3 Supplementary Requirements for type tests . 68

19.4 Test of erosion by flame . 68

20 Marking . 69

20.1 General . 69

20.2 Caution and warning markings . 69

20.3 Informative markings . 70

21 Instructions. 70

Annex A (normative) Additional requirements for crimped ribbon elements and

multiple screen elements of breathing and draining devices . 71

Annex B (normative) Additional requirements for elements, with non-measurable

paths of breathing and draining devices . 72

B.1 Sintered metal elements . 72

B.2 Pressed metal wire elements . 72

B.3 Metal foam elements . 73

Annex C (normative) Additional requirements for flameproof entry devices . 74

C.1 General . 74

C.2 Constructional requirements . 74

C.2.1 Sealing methods . 74

C.2.2 Threads Flameproof joints . 75

C.2.3 Constructional requirements for Ex blanking elements . 76

C.2.4 Constructional requirements for Ex thread adapters . 78

C.3 Type tests . 78

C.3.1 Sealing test . 78

C.3.2 Test of mechanical strength . 79

C.3.3 Type tests for Ex blanking elements . 80

C.3.4 Type tests for Ex thread adapters . 81

Annex D (normative) Empty flameproof enclosures as Ex components . 83

D.1 General . 83

D.2 Introductory remarks . 83

D.3 Ex component enclosure requirements . 83

D.4 Utilization of an Ex component enclosure certificate to prepare an equipment

certificate . 85

D.4.1 Procedure . 85

D.4.2 Application of the schedule of limitations . 85

Annex E (normative) Cells and batteries used in flameproof “d” enclosures . 86

E.1 Introductory remarks . 86

E.2 Acceptable electrochemical systems . 86

E.3 General requirements for cells (or batteries) inside flameproof enclosures . 87

E.4 Arrangement of safety devices. 87

E.4.1 Prevention of excessive temperature and cell damage . 87

E.4.2 Prevention of cell polarity reversal or reverse charging by another cell

in the same battery . 88

E.4.3 Prevention of inadvertent charging of a battery by other voltage sources

in the enclosure . 89

E.5 Recharging of secondary cells inside flameproof enclosures . 89

E.6 Rating of protection diodes and reliability of protection devices . 90

Annex F (informative) Mechanical properties for screws and nuts . 91

Annex G (normative) Additional requirements for flameproof enclosures with an

internal source of release (containment system) . 97

G.1 General . 97

G.2 Release conditions . 97

G.2.1 No release . 97

G.2.2 Limited release of a gas or vapour . 98

G.2.3 Limited release of a liquid . 98

G.3 Design requirements for the containment system . 98

G.3.1 General design requirements . 98

G.3.2 Infallible containment system . 98

G.3.3 Containment system with a limited release . 99

G.4 Type tests for the containment system . 99

G.4.1 Overpressure test . 99

G.4.2 Leakage test for an infallible containment system . 99

G.4.3 Leakage test for a containment system with a limited release . 100

Annex H (normative) Requirements for machines with flameproof “d” enclosures fed

from converters . 101

H.1 General . 101

H.2 Construction requirements for bearings . 101

H.3 Temperature requirements . 101

– 6 – IEC 60079-1:2014 RLV © IEC 2014

Bibliography . 102

Figure 1 – Example of construction for indirect checking of a flanged Group I

flameproof joint . 23

Figure 2 – Spigot joints . 24

Figure 3 – Holes in surfaces of flanged joints, example 1 . 25

Figure 4 – Holes in surfaces of flanged joints, example 2 . 25

Figure 5 – Holes in surfaces of flanged joints, example 3 . 25

Figure 6 – Holes in surfaces of spigot joints, example 1 . 25

Figure 7 – Holes in surfaces of spigot joints, example 2 . 26

Figure 8 – Holes in surfaces of spigot joints, example 3 . 26

Figure 9 – Examples of joint constructions . 27

Figure 10 – Illustration of the requirements concerning gaskets – Example 1 . 32

Figure 11 – Illustration of the requirements concerning gaskets – Example 2 . 32

Figure 12 – Illustration of the requirements concerning gaskets – Example 3 . 32

Figure 13 – Illustration of the requirements concerning gaskets – Example 4 . 32

Figure 14 – Illustration of the requirements concerning gaskets – Example 5 . 32

Figure 15 – Illustration of the requirements concerning gaskets – Example 6 . 32

Figure 16 – Illustration of the requirements concerning gaskets – Example 7 . 33

Figure 17 – Example of cylindrical joint for shaft of rotating electrical machine . 36

Figure 18 – Example of labyrinth joint for shaft of rotating electrical machine . 36

Figure 19 – Example of joint with floating gland for shaft of rotating electrical machine . 36

Figure 20 – Joints of shaft glands of rotating electrical machines . 37

Figure 21 – Component test rig for breathing and draining devices . 41

Figure 22 – Example of possible documentation . 48

Figure 23 – Example of a regular shaped waveform . 54

Figure 24 – Example of an irregular shaped waveform . 54

Figure C.1 – Examples of blanking elements for unused entries . 77

Figure C.2 – Device for the sealing tests for cable glands . 79

Figure C.3 – Examples of Ex thread adapters . 82

Figure E.1 – Fitting of diode arrangement for three cells in series . 88

Figure E.2 – Fitting of blocking diodes to meet E.4.3 (third example). 89

Figure G.1 – Flameproof enclosure with containment system . 97

Table 1 – Number of non-transmission tests for level of protection “da” . 20

Table 2 – Minimum width of joint and maximum gap for enclosures of Groups I, IIA

and IIB . 29

Table 3 – Minimum width of joint and maximum gap for Group IIC enclosures . 30

Table 4 – Cylindrical threaded joints . 31

a, c

Table 5 – Taper threaded joints . 31

Table 6 – Conditions for the determination of maximum surface temperature . 51

Table 7 – Test factors for reduced ambient conditions . 53

Table 8 – Relative pressures for small equipment . 55

Table 9 – Reduction in length of a threaded joint for non-transmission test . 57

Table 10 – Test factors to increase pressure or test gap (i ) . 57

E

Table 11 – Minimum distance of obstructions from flameproof “d” flange openings . 58

Table 12 – Gas/air mixtures . 59

Table 13 – Static pressures . 64

Table 14 – Text of caution or warning markings . 69

Table 15 – Text of informative markings . 70

Table C.1 – Tightening torque values, metric . 81

Table C.2 – Tightening torque values, NPT . 82

Table E.1 – Acceptable primary cells . 86

Table E.2 – Acceptable secondary cells . 87

Table F.1 – Mechanical properties for screws and nuts . 91

– 8 – IEC 60079-1:2014 RLV © IEC 2014

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

EXPLOSIVE ATMOSPHERES –

Part 1: Equipment protection by flameproof enclosures “d”

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This redline version of the official IEC Standard allows the user to identify the changes

made to the previous edition. A vertical bar appears in the margin wherever a change

has been made. Additions are in green text, deletions are in strikethrough red text.

International Standard IEC 60079-1 has been prepared by IEC technical committee 31:

Equipment for explosive atmospheres.

This seventh edition cancels and replaces the sixth edition, published in 2007, and constitutes

a technical revision.

The significance of the changes between IEC 60079-1, Edition 7.0 (2014) and IEC 60079-1

Edition 6.0 (2007) (including Corrigendum 1 (2008)), is as listed below:

Type

Explanation of the significance of the changes Clause Minor and Extension Major

editorial technical

changes changes

Normative references

2 X

(Removal of the edition date from the reference for

IEC 60079-0)

Requirements for level of protection “da”

4.2 X

(Catalytic sensors of portable combustible gas detectors)

Requirements for level of protection “dc”

4.4, 15.5 X

(“Enclosed break” devices from IEC 60079-15)

Flameproof joints, General requirements

5.1 X

(Documentation clarification and examples of corrosion

inhibiting grease)

Flameproof joints, General requirements

5.1 X

(Specific Conditions of Use that joints are not intended to

be repaired)

Flameproof joints, General requirements

5.1 X

(Electroplating more than 0,008 mm thick)

Non-threaded joints, Gap (i)

5.2.2 X

(Intentional gaps between surface for flanged joints)

Serrated joints

5.2.8 X

(Use and test requirements)

Multi-step joints

5.2.9 X

(Not less than 3 adjacent segments and two path changes)

Minimum width of joint and maximum gap for enclosures of

Table 2 X

groups IIA and IIB

(Maximum gaps for flanged, cylindrical or spigot joints of

9,5 mm minimum width and volume greater than 2 000 cm3)

Minimum width of joint and maximum gap for enclosures of

Table 2, X

groups I, IIA, IIB and IIC

Table 3

(ISO 80000-1 for constructional value rounding)

Cylindrical threaded joints

Table 4 X

(ISO 965-1 standard in respect of thread form or quality of fit)

Taper threaded joints

Table 5 X

(External and internal thread construction)

Cemented joints 6.1.2

C1

(Supplemental mechanical means of securement)

Cemented joints

6.1.2 X

(Evaluation criteria if there is leakage)

Fused glass joints

6.2 X

(Glass-to-metal joints)

– 10 – IEC 60079-1:2014 RLV © IEC 2014

Type

Explanation of the significance of the changes Clause Minor and Extension Major

editorial technical

changes changes

Thermal tests of breathing and draining devices

10.9.3.2 X

(Temperature class based on external surface temperature

after the 10 min test period)

Test of the ability of the breathing and draining device to

10.9.3.4 X

withstand pressure

(Relocated from before thermal tests to after the non-

transmission test)

Ex component certificate

10.9.4 X

(Service temperature range for non-metallic enclosures per

IEC 60079-0)

Fasteners and openings

11 X

(Relocation of blanking element content to 13.8 and C.2.3)

Fasteners and openings, Property class or yield stress

11.3 X

(Certificate specific condition of use)

Fasteners and openings

11.8 X

(Openings in the wall of the enclosure)

Materials

12.8 C2

(Material limitation in acetylene atmospheres)

Entries for flameproof enclosures, General

13.1 X

(Metric and NPT threaded entries)

Entries for flameproof enclosures, General

13.1 X

(Group I non-threaded joints)

Entries for flameproof enclosures, Non-threaded holes

13.3 X

(Group I application)

Entries for flameproof enclosures, Cable glands

13.4 X

(Group I application)

Cable glands, Conduit sealing devices

13.4,13.5 X

(Documentation to facilitate mounting)

Plugs and sockets and cable couplers

13.6.4 C3

(Load requirement for arc-quenching test)

Bushings

13.7 X

(Documentation to facilitate mounting)

Blanking elements

13.8 X

(Relocated from Clause 11)

Verification and tests

Table 6 X

(Maximum surface temperature conditions)

Type tests

15 X

(Sequence and number of samples for tests)

Determination of explosion pressure, General

15.2.2.2 X

(Devices that can cause turbulence)

Determination of explosion pressure, General

15.2.2.2 X

(Number of tests for Group IIC)

Determination of explosion pressure, General

15.2.2.4 X

(Pressure pilling for Group IIB)

Type

Explanation of the significance of the changes Clause Minor and Extension Major

editorial technical

changes changes

Determination of explosion pressure, General

15.2.2.5 X

(Equipment marked for a single gas)

Overpressure test, General

15.2.3 X

(Low ambient overpressure tests not required)

Overpressure test – First method (static)

15.2.3.2 X

(3 times option when routine batch testing)

Overpressure test – First method (static)

15.2.3.2 X

(Adjustment for low ambient due to small size of equipment)

Overpressure test – Second method (dynamic)

15.2.3.3 X

(Number of tests to be made)

Test for non-transmission of an internal ignition

15.3 X

(Clarification regarding grease)

Reduction in length of a threaded joint for non-transmission

Table 9 X

test

(ISO 965-1 and 965-3 standards in respect of thread form

and quality of fit)

Test factors to increase pressure or test gap

Table 10 X

(Group IIC adjustments for elevated ambients)

Test for non-transmission of an internal ignition, Groups I,

15.3.2.3 X

IIA and IIB

(Number of tests to be made)

Test for non-transmission of an internal ignition, Group IIC

15.3.3.2 X

testing by increased gap

(Number of te

...

IEC 60079-1 ®

Edition 7.0 2014-06

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Explosive atmospheres –

Part 1: Equipment protection by flameproof enclosures “d”

Atmosphères explosives –

Partie 1: Protection du matériel par enveloppes antidéflagrantes «d»

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing more than 30 000 terms and

Technical Specifications, Technical Reports and other definitions in English and French, with equivalent terms in 14

documents. Available for PC, Mac OS, Android Tablets and additional languages. Also known as the International

iPad. Electrotechnical Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a More than 55 000 electrotechnical terminology entries in

variety of criteria (reference number, text, technical English and French extracted from the Terms and Definitions

committee,…). It also gives information on projects, replaced clause of IEC publications issued since 2002. Some entries

and withdrawn publications. have been collected from earlier publications of IEC TC 37,

77, 86 and CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient plus de 30 000 termes et définitions en

Spécifications techniques, Rapports techniques et autres

anglais et en français, ainsi que les termes équivalents dans

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

14 langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

Plus de 55 000 entrées terminologiques électrotechniques, en

La recherche avancée permet de trouver des publications IEC

en utilisant différents critères (numéro de référence, texte, anglais et en français, extraites des articles Termes et

comité d’études,…). Elle donne aussi des informations sur les Définitions des publications IEC parues depuis 2002. Plus

projets et les publications remplacées ou retirées. certaines entrées antérieures extraites des publications des

CE 37, 77, 86 et CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 60079-1 ®

Edition 7.0 2014-06

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Explosive atmospheres –

Part 1: Equipment protection by flameproof enclosures “d”

Atmosphères explosives –

Partie 1: Protection du matériel par enveloppes antidéflagrantes «d»

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX XD

ICS 29.260.20 ISBN 978-2-8322-1663-7

– 2 – IEC 60079-1:2014 © IEC 2014

CONTENTS

FOREWORD . 8

1 Scope . 16

2 Normative references . 16

3 Terms and definitions . 17

4 Level of protection (equipment protection level, EPL) . 19

4.1 General . 19

4.2 Requirements for level of protection “da” . 19

4.3 Requirements for level of protection “db” . 20

4.4 Requirements for level of protection “dc” . 20

4.4.1 General . 20

4.4.2 Construction of “dc” devices . 20

4.4.3 Tests for “dc” devices . 20

5 Flameproof joints . 21

5.1 General requirements . 21

5.2 Non-threaded joints . 22

5.2.1 Width of joints (L) . 22

5.2.2 Gap (i) . 22

5.2.3 Spigot joints. 22

5.2.4 Holes in joint surfaces . 23

5.2.5 Conical joints . 25

5.2.6 Joints with partial cylindrical surfaces (not permitted for Group IIC) . 25

5.2.7 Flanged joints for acetylene atmospheres . 26

5.2.8 Serrated joints . 26

5.2.9 Multi-step joints . 27

5.3 Threaded joints . 30

5.4 Gaskets (including O-rings) . 30

5.5 Equipment using capillaries . 32

6 Sealed joints. 32

6.1 Cemented joints . 32

6.1.1 General . 32

6.1.2 Mechanical strength. 32

6.1.3 Width of cemented joints . 33

6.2 Fused glass joints . 33

6.2.1 General . 33

6.2.2 Width of fused glass joints . 33

7 Operating rods . 33

8 Supplementary requirements for shafts and bearings. 34

8.1 Joints of shafts . 34

8.1.1 General . 34

8.1.2 Cylindrical joints . 34

8.1.3 Labyrinth joints . 34

8.1.4 Joints with floating glands . 34

8.2 Bearings . 36

8.2.1 Sleeve bearings . 36

8.2.2 Rolling-element bearings . 36

9 Light-transmitting parts . 36

10 Breathing and draining devices which form part of a flameproof enclosure . 37

10.1 General . 37

10.2 Openings for breathing or draining . 37

10.3 Composition limits . 37

10.4 Dimensions . 37

10.5 Elements with measurable paths . 37

10.6 Elements with non-measurable paths . 37

10.7 Removable devices . 38

10.7.1 General . 38

10.7.2 Mounting arrangements of the elements . 38

10.8 Mechanical strength . 38

10.9 Breathing devices and draining devices when used as Ex components . 38

10.9.1 General . 38

10.9.2 Mounting arrangements of the elements and components . 38

10.9.3 Type tests for breathing and draining devices used as Ex components . 38

10.9.4 Ex component certificate . 41

11 Fasteners and openings . 42

12 Materials . 43

13 Entries for flameproof enclosures . 44

13.1 General . 44

13.2 Threaded holes . 44

13.3 Non-threaded holes (for Group I only) . 44

13.4 Cable glands . 45

13.5 Conduit sealing devices . 45

13.6 Plugs and sockets and cable couplers . 46

13.7 Bushings . 47

13.8 Blanking elements. 47

14 Verification and tests . 47

15 Type tests . 48

15.1 General . 48

15.2 Tests of ability of the enclosure to withstand pressure . 49

15.2.1 General . 49

15.2.2 Determination of explosion pressure (reference pressure) . 49

15.2.3 Overpressure test . 52

15.3 Test for non-transmission of an internal ignition . 53

15.3.1 General . 53

15.3.2 Electrical equipment of Groups I, IIA and IIB. 55

15.3.3 Electrical equipment of Group lIC . 56

15.4 Tests of flameproof enclosures with breathing and draining devices . 57

15.4.1 General . 57

15.4.2 Tests of ability of the enclosure to withstand pressure . 57

15.4.3 Thermal tests . 58

15.4.4 Test for non-transmission of an internal ignition . 58

15.5 Tests for “dc” devices . 59

15.5.1 General . 59

15.5.2 Preparation of “dc” samples . 59

15.5.3 Test conditions for “dc” devices . 59

– 4 – IEC 60079-1:2014 © IEC 2014

16 Routine tests . 60

16.1 General . 60

16.2 Enclosures not incorporating a welded construction . 61

16.3 Enclosures incorporating a welded construction . 61

16.4 Bushings not specific to one flameproof enclosure . 61

16.5 Acceptance criteria . 61

16.6 Batch testing . 61

17 Switchgear for Group I . 62

17.1 General . 62

17.2 Means of isolation . 62

17.2.1 General . 62

17.3 Doors or covers . 62

17.3.1 Quick-acting doors or covers . 62

17.3.2 Doors or covers fixed by screws . 62

17.3.3 Threaded doors or covers . 63

18 Lampholders and Iamp caps . 63

18.1 General . 63

18.2 Device preventing lamps working loose . 63

18.3 Holders and caps for lamps with cylindrical caps. 63

18.4 Holders for lamps with threaded caps . 63

19 Non-metallic enclosures and non-metallic parts of enclosures . 63

19.1 General . 63

19.2 Resistance to tracking and creepage distances on internal surfaces of the

enclosure walls . 64

19.3 Requirements for type tests . 64

19.4 Test of erosion by flame . 64

20 Marking . 64

20.1 General . 64

20.2 Caution and warning markings . 65

20.3 Informative markings . 65

21 Instructions . 65

Annex A (normative) Additional requirements for crimped ribbon elements and

multiple screen elements of breathing and draining devices . 66

Annex B (normative) Additional requirements for elements, with non-measurable

paths of breathing and draining devices . 67

B.1 Sintered metal elements . 67

B.2 Pressed metal wire elements . 67

B.3 Metal foam elements . 68

Annex C (normative) Additional requirements for flameproof entry devices . 69

C.1 General . 69

C.2 Constructional requirements . 69

C.2.1 Sealing methods . 69

C.2.2 Flameproof joints . 70

C.2.3 Constructional requirements for Ex blanking elements . 71

C.2.4 Constructional requirements for Ex thread adapters. 73

C.3 Type tests . 73

C.3.1 Sealing test . 73

C.3.2 Test of mechanical strength . 74

C.3.3 Type tests for Ex blanking elements . 75

C.3.4 Type tests for Ex thread adapters . 76

Annex D (normative) Empty flameproof enclosures as Ex components . 78

D.1 General . 78

D.2 Introductory remarks . 78

D.3 Ex component enclosure requirements . 78

D.4 Utilization of an Ex component enclosure certificate to prepare an equipment

certificate . 80

D.4.1 Procedure . 80

D.4.2 Application of the schedule of limitations . 80

Annex E (normative) Cells and batteries used in flameproof “d” enclosures . 81

E.1 Introductory remarks . 81

E.2 Acceptable electrochemical systems . 81

E.3 General requirements for cells (or batteries) inside flameproof enclosures . 82

E.4 Arrangement of safety devices . 82

E.4.1 Prevention of excessive temperature and cell damage . 82

E.4.2 Prevention of cell polarity reversal or reverse charging by another cell

in the same battery . 83

E.4.3 Prevention of inadvertent charging of a battery by other voltage sources

in the enclosure . 83

E.5 Recharging of secondary cells inside flameproof enclosures . 84

E.6 Rating of protection diodes and reliability of protection devices . 85

Annex F (informative) Mechanical properties for screws and nuts . 86

Annex G (normative) Additional requirements for flameproof enclosures with an

internal source of release (containment system) . 87

G.1 General . 87

G.2 Release conditions. 87

G.2.1 No release . 87

G.2.2 Limited release of a gas or vapour . 88

G.2.3 Limited release of a liquid . 88

G.3 Design requirements for the containment system . 88

G.3.1 General design requirements . 88

G.3.2 Infallible containment system . 88

G.3.3 Containment system with a limited release . 89

G.4 Type tests for the containment system . 89

G.4.1 Overpressure test . 89

G.4.2 Leakage test for an infallible containment system . 89

G.4.3 Leakage test for a containment system with a limited release . 90

Annex H (normative) Requirements for machines with flameproof “d” enclosures fed

from converters . 91

H.1 General . 91

H.2 Construction requirements for bearings . 91

H.3 Temperature requirements . 91

Bibliography . 92

Figure 1 – Example of construction for indirect checking of a flanged Group I

flameproof joint . 22

Figure 2 – Spigot joints . 23

Figure 3 – Holes in surfaces of flanged joints, example 1 . 24

– 6 – IEC 60079-1:2014 © IEC 2014

Figure 4 – Holes in surfaces of flanged joints, example 2 . 24

Figure 5 – Holes in surfaces of flanged joints, example 3 . 24

Figure 6 – Holes in surfaces of spigot joints, example 1 . 24

Figure 7 – Holes in surfaces of spigot joints, example 2 . 25

Figure 8 – Holes in surfaces of spigot joints, example 3 . 25

Figure 9 – Examples of joint constructions . 26

Figure 10 – Illustration of the requirements concerning gaskets – Example 1 . 31

Figure 11 – Illustration of the requirements concerning gaskets – Example 2 . 31

Figure 12 – Illustration of the requirements concerning gaskets – Example 3 . 31

Figure 13 – Illustration of the requirements concerning gaskets – Example 4 . 31

Figure 14 – Illustration of the requirements concerning gaskets – Example 5 . 31

Figure 15 – Illustration of the requirements concerning gaskets – Example 6 . 31

Figure 16 – Illustration of the requirements concerning gaskets – Example 7 . 32

Figure 17 – Example of cylindrical joint for shaft of rotating electrical machine . 35

Figure 18 – Example of labyrinth joint for shaft of rotating electrical machine . 35

Figure 19 – Example of joint with floating gland for shaft of rotating electrical machine . 35

Figure 20 – Joints of shaft glands of rotating electrical machines . 36

Figure 21 – Component test rig for breathing and draining devices . 39

Figure 22 – Example of possible documentation . 45

Figure 23 – Example of a regular shaped waveform . 51

Figure 24 – Example of an irregular shaped waveform . 51

Figure C.1 – Examples of blanking elements for unused entries . 72

Figure C.2 – Device for the sealing tests for cable glands . 74

Figure C.3 – Examples of Ex thread adapters . 77

Figure E.1 – Fitting of diode arrangement for three cells in series . 83

Figure E.2 – Fitting of blocking diodes to meet E.4.3 (third example) . 84

Figure G.1 – Flameproof enclosure with containment system . 87

Table 1 – Number of non-transmission tests for level of protection “da” . 20

Table 2 – Minimum width of joint and maximum gap for enclosures of Groups I, IIA

and IIB . 28

Table 3 – Minimum width of joint and maximum gap for Group IIC enclosures . 29

Table 4 – Cylindrical threaded joints . 30

a, c

Table 5 – Taper threaded joints . 30

Table 6 – Conditions for the determination of maximum surface temperature . 48

Table 7 – Test factors for reduced ambient conditions . 50

Table 8 – Relative pressures for small equipment . 52

Table 9 – Reduction in length of a threaded joint for non-transmission test . 54

Table 10 – Test factors to increase pressure or test gap (i ) . 54

E

Table 11 – Minimum distance of obstructions from flameproof “d” flange openings . 54

Table 12 – Gas/air mixtures . 55

Table 13 – Static pressures . 60

Table 14 – Text of caution or warning markings . 65

Table 15 – Text of informative markings. 65

Table C.1 – Tightening torque values, metric . 76

Table C.2 – Tightening torque values, NPT . 77

Table E.1 – Acceptable primary cells . 81

Table E.2 – Acceptable secondary cells . 82

Table F.1 – Mechanical properties for screws and nuts . 86

– 8 – IEC 60079-1:2014 © IEC 2014

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

EXPLOSIVE ATMOSPHERES –

Part 1: Equipment protection by flameproof enclosures “d”

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60079-1 has been prepared by IEC technical committee 31:

Equipment for explosive atmospheres.

This seventh edition cancels and replaces the sixth edition, published in 2007, and constitutes

a technical revision.

The significance of the changes between IEC 60079-1, Edition 7.0 (2014) and IEC 60079-1

Edition 6.0 (2007) (including Corrigendum 1 (2008)), is as listed below:

Type

Explanation of the significance of the changes Clause Minor and Extension Major

editorial technical

changes changes

Normative references

2 X

(Removal of the edition date from the reference for

IEC 60079-0)

Requirements for level of protection “da”

4.2 X

(Catalytic sensors of portable combustible gas detectors)

Requirements for level of protection “dc”

4.4, 15.5 X

(“Enclosed break” devices from IEC 60079-15)

Flameproof joints, General requirements

5.1 X

(Documentation clarification and examples of corrosion

inhibiting grease)

Flameproof joints, General requirements

5.1 X

(Specific Conditions of Use that joints are not intended to

be repaired)

Flameproof joints, General requirements

5.1 X

(Electroplating more than 0,008 mm thick)

Non-threaded joints, Gap (i)

5.2.2 X

(Intentional gaps between surface for flanged joints)

Serrated joints

5.2.8 X

(Use and test requirements)

Multi-step joints

5.2.9 X

(Not less than 3 adjacent segments and two path changes)

Minimum width of joint and maximum gap for enclosures of

Table 2 X

groups IIA and IIB

(Maximum gaps for flanged, cylindrical or spigot joints of

9,5 mm minimum width and volume greater than 2 000 cm3)

Minimum width of joint and maximum gap for enclosures of

Table 2, X

groups I, IIA, IIB and IIC

Table 3

(ISO 80000-1 for constructional value rounding)

Cylindrical threaded joints

Table 4 X

(ISO 965-1 standard in respect of thread form or quality of fit)

Taper threaded joints

Table 5 X

(External and internal thread construction)

Cemented joints 6.1.2

C1

(Supplemental mechanical means of securement)

Cemented joints

6.1.2 X

(Evaluation criteria if there is leakage)

Fused glass joints

6.2 X

(Glass-to-metal joints)

Thermal tests of breathing and draining devices

10.9.3.2 X

(Temperature class based on external surface temperature

after the 10 min test period)

Test of the ability of the breathing and draining device to

10.9.3.4 X

withstand pressure

(Relocated from before thermal tests to after the non-

transmission test)

– 10 – IEC 60079-1:2014 © IEC 2014

Type

Explanation of the significance of the changes Clause Minor and Extension Major

editorial technical

changes changes

Ex component certificate

10.9.4 X

(Service temperature range for non-metallic enclosures per

IEC 60079-0)

Fasteners and openings

11 X

(Relocation of blanking element content to 13.8 and C.2.3)

Fasteners and openings, Property class or yield stress

11.3 X

(Certificate specific condition of use)

Fasteners and openings

11.8 X

(Openings in the wall of the enclosure)

Materials

12.8 C2

(Material limitation in acetylene atmospheres)

Entries for flameproof enclosures, General

13.1 X

(Metric and NPT threaded entries)

Entries for flameproof enclosures, General

13.1 X

(Group I non-threaded joints)

Entries for flameproof enclosures, Non-threaded holes

13.3 X

(Group I application)

Entries for flameproof enclosures, Cable glands

13.4 X

(Group I application)

Cable glands, Conduit sealing devices

13.4,13.5 X

(Documentation to facilitate mounting)

Plugs and sockets and cable couplers

13.6.4 C3

(Load requirement for arc-quenching test)

Bushings

13.7 X

(Documentation to facilitate mounting)

Blanking elements

13.8 X

(Relocated from Clause 11)

Verification and tests

Table 6 X

(Maximum surface temperature conditions)

Type tests

15 X

(Sequence and number of samples for tests)

Determination of explosion pressure, General

15.2.2.2 X

(Devices that can cause turbulence)

Determination of explosion pressure, General

15.2.2.2 X

(Number of tests for Group IIC)

Determination of explosion pressure, General

15.2.2.4 X

(Pressure pilling for Group IIB)

Determination of explosion pressure, General

15.2.2.5 X

(Equipment marked for a single gas)

Overpressure test, General

15.2.3 X

(Low ambient overpressure tests not required)

Overpressure test – First method (static)

15.2.3.2 X

(3 times option when routine batch testing)

Type

Explanation of the significance of the changes Clause Minor and Extension Major

editorial technical

changes changes

Overpressure test – First method (static)

15.2.3.2 X

(Adjustment for low ambient due to small size of equipment)

Overpressure test – Second method (dynamic)

15.2.3.3 X

(Number of tests to be made)

Test for non-transmission of an internal ignition

15.3 X

(Clarification regarding grease)

Reduction in length of a threaded joint for non-transmission

Table 9 X

test

(ISO 965-1 and 965-3 standards in respect of thread form

and quality of fit)

Test factors to increase pressure or test gap

Table 10 X

(Group IIC adjustments for elevated ambients)

Test for non-transmission of an internal ignition, Groups I,

15.3.2.3 X

IIA and IIB

(Number of tests to be made)

Test for non-transmission of an internal ignition, Group IIC

15.3.3.2 X

testing by increased gap

(Number of tests to be made)

Test for non-transmission of an internal ignition, Group IIC

15.3.3.4 X

(Oxygen enrichment of test gases)

Thermal tests of enclosures with breathing and draining

15.4.3.1 X

devices

(Temperature class based on external surface temperature

after the 10 min test period)

Tests for “dc” devices

15.5 X

(“Enclosed break” devices from IEC 60079-15)

Routine tests, General

16.1.2 X

(Adjustment for low ambient due to small size of equipment)

Routine tests, General

16.1.3 X

(Options when second method is chosen)

Routine tests, General

16.3 X

(Welded joint inspection options)

Routine tests, General

16.6 X

(Allowance for batch testing)

Switchgear for Group I

17.2.2, X

17.2.3

(Clarifying need for compliance with EPL Mb types of

protection)

Non-metallic enclosures and non-metallic parts of

19.1 X

enclosures, General

(Exception for cemented joints)

Non-metall

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...