IEC 60079-1:2007

(Main)Explosive atmospheres - Part 1: Equipment protection by flameproof enclosures "d"

Explosive atmospheres - Part 1: Equipment protection by flameproof enclosures "d"

Contains specific requirements for the construction and testing of electrical apparatus with the type of protection flameproof enclosure 'd', intended for use in explosive gas atmospheres. This edition contains significant technical changes with regard to the previous edition. The contents of the corrigendum of September 2008 have been included in this copy.

Atmosphères explosives - Partie 1: Protection du matériel par enveloppes antidéflagrantes "d"

Contient les exigences spécifiques de construction et d'essai du matériel électrique à enveloppe antidéflagrante, mode de protection «d», destiné à être utilisé dans les atmosphères explosives gazeuses. Cette édition inclut les modifications techniques majeures par rapport à l'édition précédente. Le contenu du corrigendum de septembre 2008 a été pris en considération dans cet exemplaire.

General Information

- Status

- Published

- Publication Date

- 26-Apr-2007

- Technical Committee

- TC 31 - Equipment for explosive atmospheres

- Drafting Committee

- MT 60079-1 - TC 31/MT 60079-1

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 27-Jun-2014

- Completion Date

- 14-Feb-2026

Relations

- Effective Date

- 20-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Revised

IEC 60079-1:2014 - Explosive atmospheres - Part 1: Equipment protection by flameproof enclosures "d" - Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 60079-1:2007 is an essential international standard published by the International Electrotechnical Commission (IEC) for ensuring the safety of electrical apparatus used in explosive gas atmospheres. This standard focuses on Equipment Protection by Flameproof Enclosures "d," providing detailed requirements for the design, construction, and testing of flameproof enclosures to prevent ignition of explosive gases. The 2007 edition (Edition 6.0) includes significant technical updates and integrates corrections from the 2008 corrigendum, reflecting the evolving safety landscape for equipment used in hazardous environments.

Key Topics

The IEC 60079-1:2007 standard covers a broad range of critical aspects related to flameproof enclosures, ensuring device reliability and operator safety in explosive atmospheres:

Scope and Definitions: Clarifies the types of electrical equipment and explosive gas atmospheres targeted by the flameproof enclosure protection method "d."

Design Requirements for Flameproof Joints: Specifications for joints, including threaded and non-threaded types, gaskets, and sealing to prevent flame transmission.

Materials and Mechanical Strength: Requirements focus on durable construction materials capable of withstanding explosive pressures and mechanical stresses.

Breathing and Draining Devices: Rules for safe venting and fluid drainage integrated into enclosures without compromising flameproof integrity.

Type and Routine Testing Procedures: Methods to validate enclosure performance, such as pressure tests and ignition prevention under operational conditions.

Supplementary Measures for Shafts, Bearings, and Operating Rods: Guidelines to maintain flameproof characteristics where moving parts penetrate the enclosure.

Marking and Documentation: Detailed instructions on proper labeling for clear identification of equipment ratings and safety warnings.

Additional Annexes: Include requirements for flameproof entry devices, batteries within enclosures, and alternative risk assessment methods concerning Equipment Protection Levels (EPLs).

This comprehensive scope ensures that electrical apparatus adhering to IEC 60079-1:2007 meets rigorous safety standards against explosive ignition hazards.

Applications

IEC 60079-1:2007 is widely applied in industries handling flammable gases, vapors, or dust where electrical equipment must not ignite explosive mixtures. Key industries and applications include:

Oil and Gas: Protection of electrical motors, switchgear, control panels, and lighting in refineries, offshore platforms, and pipelines.

Chemical and Petrochemical Plants: Ensures safe operation of instrumentation and electrical devices in areas with volatile substances.

Mining Operations: Safeguards electrical machinery operating in potentially explosive underground atmospheres.

Pharmaceutical Manufacturing: Provides safety for equipment handling combustible solvents or reactive chemical processes.

Food and Beverage Processing: For environments with dust or vapor hazards, ensuring equipment prevents ignition sources.

Flameproof enclosures designed and tested according to IEC 60079-1 standards provide peace of mind by mitigating ignition risks, thus protecting lives, assets, and the environment from industrial explosions.

Related Standards

IEC 60079-1:2007 is part of the broader IEC 60079 series, which collectively addresses equipment and protective systems for explosive atmospheres:

IEC 60079-0: General requirements for electrical apparatus in explosive atmospheres, providing foundational safety criteria.

IEC 60079-7: Protection by increased safety "e," covering alternative enclosure techniques without flameproof joints.

IEC 60079-11: Intrinsic safety "i," for instrument circuits designed to prevent ignition by limiting electrical energy.

IEC 60079-15: Protection by type of protection "n," for equipment in less hazardous zones with normal operation safety features.

IEC 60079-31: Protection of equipment in explosive dust atmospheres, complementing gaseous flameproof measures.

Together, these standards support a harmonized approach to electrical safety in hazardous locations globally.

Keywords: IEC 60079-1, flameproof enclosures, explosive atmospheres, equipment protection, electrical apparatus, hazardous locations, flameproof joints, gas atmospheres, IEC standards, explosion safety, electrical safety, hazardous area equipment, equipment protection level, ex equipment.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60079-1:2007 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Explosive atmospheres - Part 1: Equipment protection by flameproof enclosures "d"". This standard covers: Contains specific requirements for the construction and testing of electrical apparatus with the type of protection flameproof enclosure 'd', intended for use in explosive gas atmospheres. This edition contains significant technical changes with regard to the previous edition. The contents of the corrigendum of September 2008 have been included in this copy.

Contains specific requirements for the construction and testing of electrical apparatus with the type of protection flameproof enclosure 'd', intended for use in explosive gas atmospheres. This edition contains significant technical changes with regard to the previous edition. The contents of the corrigendum of September 2008 have been included in this copy.

IEC 60079-1:2007 is classified under the following ICS (International Classification for Standards) categories: 29.260.20 - Electrical apparatus for explosive atmospheres. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60079-1:2007 has the following relationships with other standards: It is inter standard links to EN 61800-2:2015, EN ISO 16852:2010, EN ISO 10438-1:2007, EN ISO 10440-1:2007, EN ISO 13705:2012, EN ISO 10437:2003, EN ISO 15970:2014, EN ISO 13631:2002, IEC 60079-1:2007/COR1:2008, IEC 60079-1:2003, IEC 60079-1:2014, IEC 60079-1:2003/ISH1:2007. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60079-1:2007 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60079-1

Edition 6.0 2007-04

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Explosive atmospheres –

Part 1: Equipment protection by flameproof enclosures “d”

Atmosphères explosives –

Partie 1: Protection du matériel par enveloppes antidéflagrantes «d»

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 60079-1

Edition 6.0 2007-04

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Explosive atmospheres –

Part 1: Equipment protection by flameproof enclosures “d”

Atmosphères explosives –

Partie 1: Protection du matériel par enveloppes antidéflagrantes «d»

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

XB

CODE PRIX

ICS 29.260.20 ISBN 2-8318-9116-7

– 2 – 60079-1 © IEC:2007

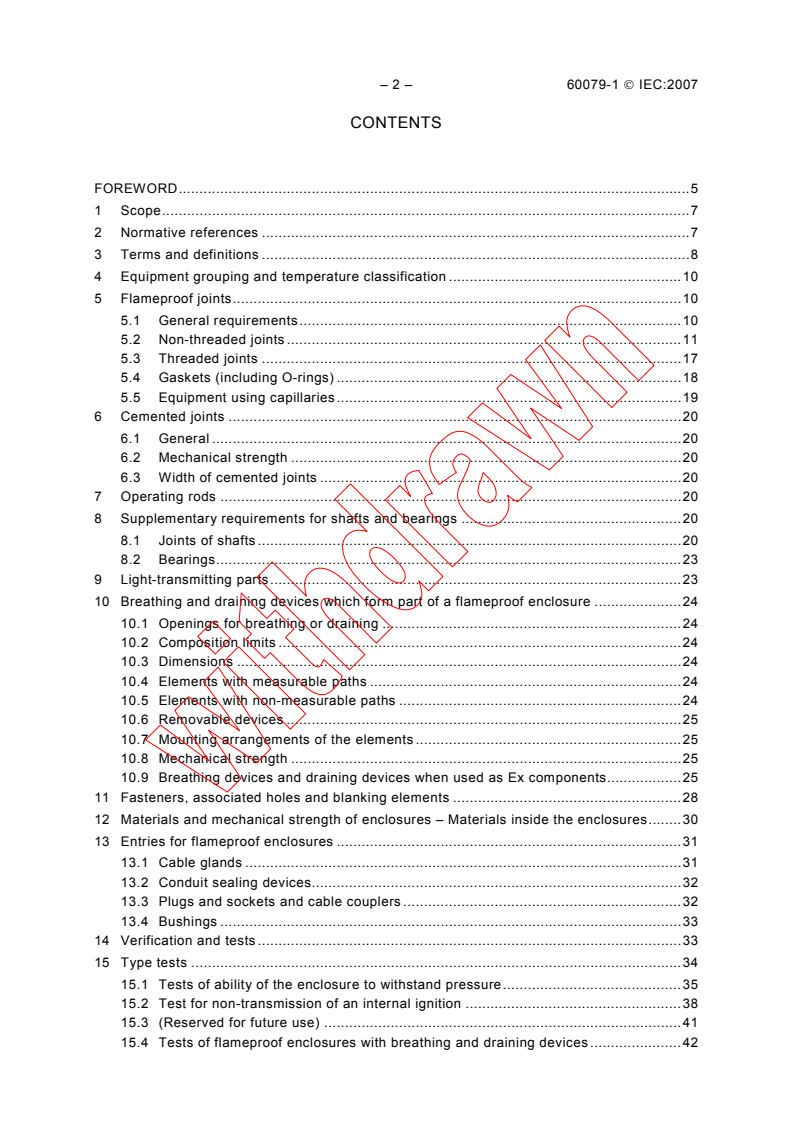

CONTENTS

FOREWORD.5

1 Scope.7

2 Normative references .7

3 Terms and definitions .8

4 Equipment grouping and temperature classification .10

5 Flameproof joints.10

5.1 General requirements.10

5.2 Non-threaded joints .11

5.3 Threaded joints .17

5.4 Gaskets (including O-rings) .18

5.5 Equipment using capillaries.19

6 Cemented joints .20

6.1 General .20

6.2 Mechanical strength .20

6.3 Width of cemented joints .20

7 Operating rods .20

8 Supplementary requirements for shafts and bearings .20

8.1 Joints of shafts .20

8.2 Bearings.23

9 Light-transmitting parts.23

10 Breathing and draining devices which form part of a flameproof enclosure .24

10.1 Openings for breathing or draining .24

10.2 Composition limits .24

10.3 Dimensions .24

10.4 Elements with measurable paths .24

10.5 Elements with non-measurable paths .24

10.6 Removable devices .25

10.7 Mounting arrangements of the elements .25

10.8 Mechanical strength .25

10.9 Breathing devices and draining devices when used as Ex components.25

11 Fasteners, associated holes and blanking elements .28

12 Materials and mechanical strength of enclosures – Materials inside the enclosures.30

13 Entries for flameproof enclosures .31

13.1 Cable glands .31

13.2 Conduit sealing devices.32

13.3 Plugs and sockets and cable couplers .32

13.4 Bushings .33

14 Verification and tests .33

15 Type tests .34

15.1 Tests of ability of the enclosure to withstand pressure.35

15.2 Test for non-transmission of an internal ignition .38

15.3 (Reserved for future use) .41

15.4 Tests of flameproof enclosures with breathing and draining devices .42

60079-1 © IEC:2007 – 3 –

16 Routine tests .44

17 Switchgear for group I .45

17.1 Means of isolation .45

17.2 Doors or covers.45

18 Lampholders and Iamp caps.46

18.1 Device preventing lamps working loose .46

18.2 Holders and caps for lamps with cylindrical caps .46

18.3 Holders for lamps with threaded caps.46

19 Non-metallic enclosures and non-metallic parts of enclosures .46

19.1 (Reserved for future use) .47

19.2 Special constructional requirements .47

19.3 Supplementary requirements for type tests.47

20 Marking .48

20.1 General .48

20.2 Caution and warning markings .48

20.3 Informative markings .48

Annex A (normative) Additional requirements for crimped ribbon elements and

multiple screen elements of breathing and draining devices .49

Annex B (normative) Additional requirements for elements, with non-measurable

paths, of breathing and draining devices .50

B.1 Sintered metal elements.50

B.2 Pressed metal wire elements.50

B.3 Metal foam elements .51

Annex C (normative) Additional requirements for flameproof entry devices .52

C.1 General .52

C.2 Constructional requirements.52

C.3 Type tests .54

Annex D (normative) Empty flameproof enclosures as Ex components.59

D.1 General .59

D.2 Introductory remarks .59

D.3 Ex component enclosure requirements .59

D.4 Utilization of an Ex component enclosure certificate to prepare an equipment

certificate .61

Annex E (normative) Cells and batteries used in flameproof “d” enclosures .62

E.1 Introductory remarks .62

E.2 Acceptable electrochemical systems .62

E.3 General requirements for cells (or batteries) inside flameproof enclosures .63

E.4 Arrangement of safety devices .63

E.5 Recharging of secondary cells inside flameproof enclosures .65

E.6 Rating of protection diodes and reliability of protection devices .66

Annex F (informative) Mechanical properties for screws and nuts .67

Annex G (informative) Introduction of an alternative risk assessment method

encompassing “equipment protection levels’ for Ex equipment .68

G.0 Introduction .68

G.1 Historical background.68

G.2 General .69

G.3 Risk of ignition protection afforded .70

G.4 Implementation.71

Bibliography.73

– 4 – 60079-1 © IEC:2007

Figure 1 – Example of construction for indirect checking of a flanged group I

flameproof joint.11

Figures 3, 4, 5 – Holes in surfaces of flanged joints .14

Figures 6, 7, 8 – Holes in surfaces of spigot joints .14

Figure 9a – Example of a joint with partial cylindrical surfaces.15

Figure 9b – Example of serrated joint.15

Figures 10 to 16 – Illustration of the requirements concerning gaskets .19

Figure 17 – Example of cylindrical joint for shaft of rotating electrical machine .21

Figure 18 – Example of labyrinth joint for shaft of rotating electrical machine.22

Figure 19 – Example of joint with floating gland for shaft of rotating electrical machine.22

Figure 20 – Joints of shaft glands of rotating electrical machines.23

Figure 21 – Component test rig for breathing and draining devices .27

Figure 22 – Examples of blanking elements for unused apertures .30

Figure C.1 – Device for the sealing tests for cable glands.55

Figure C.2 – Examples of Ex thread adapters .58

Figure E.1 – Fitting of diode arrangement for three cells in series.64

Figure E.2 – Fitting of blocking diodes to meet E.4.3 (third example) .65

Table 1 – Minimum width of joint and maximum gap for enclosures of groups I, IIA and IIB .16

Table 2 – Minimum width of joint and maximum gap for group IIC enclosures .17

Table 3 – Cylindrical threaded joints .17

a

Table 4 – Taper threaded joints .18

Table 5 – Conditions for the determination of maximum surface temperature.34

Table 6 – Reduction in length of a threaded joint for non-transmission test .39

Table 7 – Test factors to increase pressure or test gap (i ) .39

E

Table 9 − Text of caution or warning markings .48

Table 10 − Text of informative markings.48

Table C.1 – Tightening torque values.57

Table E.1 – Acceptable primary cells .62

Table E.2 – Acceptable secondary cells.63

Table F.1 – Mechanical properties for screws and nuts.67

Table G.1 – Traditional relationship of EPLs to zones (no additional risk assessment).70

Table G.2 – Description of risk of ignition protection provided.71

60079-1 © IEC:2007 – 5 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

EXPLOSIVE ATMOSPHERES –

Part 1: Equipment protection by flameproof enclosures “d”

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60079-1 has been prepared by IEC technical committee 31:

Equipment for explosive atmospheres.

This sixth edition cancels and replaces the fifth edition published in 2003 and constitutes a

technical revision.

This edition contains the following significant technical changes with regard to the previous

edition:

a) revisions to Clause 5 regarding markings and conditions of safe use when a dimension of

a flameproof joint is other than the relevant minimum or maximum;

b) revisions to Table 1 regarding maximum gap for flanged, cylindrical or spigot joints;

c) revisions to Table 4 regarding requirements for taper threaded joints;

d) revisions to Clause 10 regarding volume restrictions and test conditions associated with

breathing and draining devices;

e) revisions to Clause 11 regarding requirements for fasteners, associated holes and

blanking elements;

f) revisions to Clause 12 regarding material restrictions associated with zinc and zinc alloys;

– 6 – 60079-1 © IEC:2007

g) revisions to Table 5 regarding conditions for the determination of maximum surface

temperatures;

h) revisions to Clause 15 regarding the determination of explosion pressure (reference

pressure);

i) revisions to Table 6 regarding the reduction in length of a threaded joint for non-

transmission testing;

j) revisions to Table 7 regarding the test factors to increase pressure or test gap (i );

E

k) revisions to Table 8 regarding the minimum distance of obstructions from flange openings;

l) revisions to Clause 19 regarding tests for flameproofness;

m) revisions to Clause 20 regarding a tabulated collection of marking requirements;

n) revisions to Annex C regarding additional requirements for flameproof entry devices;

o) revisions to Annex D regarding empty flameproof enclosures as Ex components;

p) addition of a new Annex F regarding mechanical properties for screws and nuts; and

q) addition of a new Annex G regarding equipment protection levels for Ex equipment.

The text of this standard is based on the following documents:

FDIS Report on voting

31/680/FDIS 31/692/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This standard is to be read in conjunction with IEC 60079-0:2004, Electrical apparatus for

explosive gas atmospheres – Part 0: General requirements.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts of IEC 60079 series, under the general title Explosive atmospheres can be

found on the IEC website.

Future standards in this series will carry the new general title as cited above. Titles of existing

standards in this series will be updated at the time of the new edition.

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

The contents of the corrigendum of September 2008 have been included in this copy.

60079-1 © IEC:2007 – 7 –

EXPLOSIVE ATMOSPHERES –

Part 1: Equipment protection by flameproof enclosures “d”

1 Scope

This part of IEC 60079 contains specific requirements for the construction and testing of

electrical equipment with the type of protection flameproof enclosure “d”, intended for use in

explosive gas atmospheres.

This standard supplements and modifies the general requirements of IEC 60079-0. Where a

requirement of this standard conflicts with a requirement of IEC 60079-0, the requirement of

this standard will take precedence.

NOTE Equipment protection by flameproof enclosures “d” provides Equipment Protection Level (EPL) Gb. For further

information, see Annex G.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60061 (all parts), Lamp caps and holders together with gauges for the control of

interchangeability and safety

IEC 60079-0:2004, Electrical apparatus for explosive gas atmospheres – Part 0: General

requirements

IEC 60079-1-1, Electrical apparatus for explosive gas atmospheres – Part 1-1: Flameproof

enclosures “d” – Method of test for ascertainment of maximum experimental safe gap

IEC 60079-7, Explosive atmospheres – Part 7: Equipment protection by increased safety “e”

IEC 60079-11, Explosive atmospheres – Part 11: Equipment protection by intrinsic safety “i”

IEC 60079-14:2002, Electrical apparatus for explosive gas atmospheres – Part 14: Electrical

installations in hazardous areas (other than mines)

IEC 60086-1:2000, Primary batteries – Part 1: General

IEC 60112, Method for the determination of the proof and the comparative tracking indices of

solid insulating materials

IEC 60127 (all parts), Miniature fuses

IEC 60529:1989, Degrees of protection provided by enclosures (IP Code)

IEC 60623:2001, Secondary cells and batteries containing alkaline or other non-acid

electrolytes – Vented nickel-cadmium prismatic rechargeable single cells

IEC 60662:1980, High-pressure sodium vapour lamps

IEC 60695-11-10, Fire hazard testing – Part 11-10: Test flames – 50 W horizontal and vertical

flame test methods

– 8 – 60079-1 © IEC:2007

IEC 61951-1:2003, Secondary cells and batteries containing alkaline or other non-acid

electrolytes – Portable sealed rechargeable single cells – Part 1: Nickel-cadmium

IEC 61951-2:2003, Secondary cells and batteries containing alkaline or other non-acid

electrolytes – Portable sealed rechargeable single cells – Part 2:Nickel-metal hydride

ISO 185:1988, Grey cast iron – Classification

ISO 965-1:1998, ISO general-purpose metric screw threads – Tolerances – Part 1: Principles

and basic data

ISO 965-3:1998, ISO general-purpose metric screw threads – Tolerances – Part 3: Deviations

for constructional threads

ISO 2738:1999, Sintered metal materials, excluding hard metals – Permeable sintered metal

materials – Determination of density, oil content and open porosity

ISO 3864: 1984, Safety colours and safety signs

ISO 4003:1977, Permeable sintered metal materials – Determination of bubble test pore size

ISO 4022:1987, Permeable sintered metal materials – Determination of fluid permeability

ANSI/ASME B1.20.1-1983 (R2001), Pipe threads, general purpose (inch)

3 Terms and definitions

For the purposes of this document, the following terms and definitions, in addition to those

given in IEC 60079-0, apply.

NOTE Additional definitions applicable to explosive atmospheres can be found in IEC 60050-426.

3.1

flameproof enclosure “d”

enclosure in which the parts which can ignite an explosive gas atmosphere are placed and

which can withstand the pressure developed during an internal explosion of an explosive

mixture, and which prevents the transmission of the explosion to the explosive gas

atmosphere surrounding the enclosure

3.2

volume

total internal volume of the enclosure. However, for enclosures in which the contents are

essential in service, the volume to be considered is the remaining free volume

NOTE For luminaries, the volume is determined without lamps fitted.

3.3

flameproof joint or flamepath

place where the corresponding surfaces of two parts of an enclosure, or the conjunction of

enclosures, come together and which prevents the transmission of an internal explosion to

the explosive gas atmosphere surrounding the enclosure

3.4

width of flameproof joint

L

shortest path through a flameproof joint from the inside to the outside of an enclosure

NOTE This definition does not apply to threaded joints.

60079-1 © IEC:2007 – 9 –

3.5

distance

l

shortest path through a flameproof joint, when the width of the flameproof joint L is interrupted

by holes intended for the passage of fasteners for assembling the parts of the flameproof

enclosure

3.6

gap of flameproof joint

i

distance between the corresponding surfaces of a flameproof joint when the electrical

apparatus enclosure has been assembled

NOTE For cylindrical surfaces, forming cylindrical joints, the gap is the difference between the diameters of the

bore and the cylindrical component.

3.7

maximum experimental safe gap (for an explosive mixture)

MESG

maximum gap of a joint of 25 mm in width which prevents any transmission of an explosion

during 10 tests made under the conditions specified in IEC 60079-1-1

3.8

shaft

part of circular cross-section used for the transmission of rotary movement

3.9

operating rod

part used for the transmission of control movements which may be rotary or linear or a

combination of the two

3.10

pressure-piling

results of an ignition, in a compartment or subdivision of an enclosure, of a gas mixture pre-

compressed, for example, due to a primary ignition in another compartment or subdivision

3.11

quick-acting door or cover

door or cover provided with a device which permits opening or closing by a simple operation,

such as the movement of a lever or the rotation of a wheel. The device is arranged so that the

operation has two stages:

– one for locking or unlocking,

– another for opening or closing

3.12

door or cover fixed by threaded fasteners

door or cover, the opening or closing of which requires the manipulation of one or more

threaded fasteners (screws, studs, bolts or nuts)

3.13

threaded door or cover

door or cover which is assembled to a flameproof enclosure by a threaded flameproof joint

3.14

breathing device

device which permits an exchange between the atmosphere within an enclosure and the

surrounding atmosphere and which maintains the integrity of the type of protection

– 10 – 60079-1 © IEC:2007

3.15

draining device

device which permits liquids to flow out from an enclosure and which maintains the integrity of

the type of protection

3.16

Ex blanking element

threaded blanking element tested separately from the equipment enclosure but having an

equipment certificate and which is intended to be fitted to the equipment enclosure without

further consideration

NOTE 1 This does not preclude a component certificate for blanking elements in accordance with IEC 60079-0.

Examples of blanking elements are shown in Figure 22.

NOTE 2 Non-threaded blanking elements are not equipment.

3.17

Ex thread adapter

thread adapter tested separately from the enclosure but having an equipment certificate and

which is intended to be fitted to the equipment enclosure without further consideration

NOTE This does not preclude a component certificate for thread adapters in accordance with IEC 60079-0.

Examples of thread adapters are shown in Figure C.2.

3.18

Ex component enclosure

empty flameproof enclosure provided with an Ex component certificate, without the internal

equipment being defined, so as to enable the empty enclosure to be made available for

incorporation into an equipment certificate without the need for repetition of type testing

4 Equipment grouping and temperature classification

The equipment grouping and temperature classification defined in IEC 60079-0 for the use of

electrical equipment in explosive gas atmospheres apply to flameproof enclosures. The

subdivisions A, B and C for electrical equipment of Group II also apply.

5 Flameproof joints

5.1 General requirements

All flameproof joints, whether permanently closed or designed to be opened from time to time,

shall comply, in the absence of pressure, with the appropriate requirements of Clause 5.

The design of joints shall be appropriate to the mechanical constraints applied to them.

The dimensions given in 5.2 to 5.5 inclusive specify the minimum or maximum values that

may be applied to the essential parameters of flamepaths. In instances where a dimension of

a flameproof joint is other than the relevant minimum or maximum (for example, in order to

comply with the test for non-transmission of an internal ignition), the equipment shall be

marked “X” according to 29.2 item i) of IEC 60079-0 and the specific conditions of use on the

certificate shall be in accordance with one of the following:

a) dimensions of the flameproof joints shall be detailed; or

b) specific drawing referenced that details the dimensions of the flameproof joints; or

c) specific guidance noted to contact the original manufacturer for information on the

dimensions of the flameproof joints.

The surface of joints may be protected against corrosion.

60079-1 © IEC:2007 – 11 –

Coating with paint or powder-coat finish is not permitted. Other coating material may be used

if the material and application procedure have been shown not to adversely affect the

flameproof properties of the joint.

A corrosion inhibiting grease may be applied to joint surfaces before assembly. The grease, if

applied, shall be of a type that does not harden because of ageing, does not contain an

evaporating solvent, and does not cause corrosion of the joint surfaces. Verification of

suitability shall be in accordance with the grease manufacturer's specifications.

Joint surfaces may be electroplated. The metal plating, if applied, shall not be more than

0,008 mm thick.

5.2 Non-threaded joints

5.2.1 Width of joints (L)

The width of joints shall not be less than the minimum values given in Tables 1 and 2. The

width of joints for cylindrical metallic parts press-fitted into the walls of a metallic flameproof

enclosure of a volume not greater than 2 000 cm may be reduced to 5 mm, if

– the design does not rely only on an interference fit to prevent the part being displaced

during the type tests of Clause 15, and

– the assembly meets the impact test requirements of IEC 60079-0, taking the worst-case

interference fit tolerances into account, and

– the external diameter of the press-fitted part, where the width of the joint is measured,

does not exceed 60 mm.

5.2.2 Gap (i)

The gap, if one exists, between the surfaces of a joint shall nowhere exceed the maximum

values given in Tables 1 and 2.

The surfaces of joints shall be such that their average roughness R (derived from ISO 468)

a

does not exceed 6,3 μm.

For flanged joints, there shall be no intentional gap between the surfaces, except for quick-

acting doors or covers.

For electrical equipment of group I, it shall be possible to check, directly or indirectly, the

gaps of flanged joints of covers and doors designed to be opened from time to time. Figure 1

shows an example of construction for indirect checking of a flameproof joint.

Flame proof

enclosure

Cylindrical dowel

driven into hole

Cover L

Width of joint Surface of cover

and dowel shall be

in the same plane

IEC 541/07

Figure 1 – Example of construction for indirect checking of a flanged

group I flameproof joint

– 12 – 60079-1 © IEC:2007

5.2.3 Spigot joints

For the determination of the width L of spigot joints, one of the following shall be taken into

account:

– the cylindrical part and the plane part (see Figure 2a). In this case, the gap shall nowhere

exceed the maximum values given in Tables 1 and 2;

– the cylindrical part only (see Figure 2b). In this case, the plane part need not comply with

the requirements of Tables 1 and 2.

NOTE For gaskets, see also 5.4.

c f

IEC 062/01 IEC 063/01

Figure 2a – Cylindrical part and plane part Figure 2b – Cylindrical part only

Key

L = c + d (I, IIA, IIB, IIC)

c ≥ 6,0 mm (IIC)

≥ 3,0 mm (I, IIA, IIB)

d ≥ 0,50 L (IIC)

f ≤ 1,0 mm (I, IIA, IIB, IIC)

1 interior of enclosure

Figure 2 – Spigot joints

5.2.4 Holes in joint surfaces

Where a plane joint or the plane part or partial cylindrical surface (see 5.2.6) of a joint is

interrupted by holes intended for the passage of threaded fasteners for assembling the parts

of a flameproof enclosure, the distance l to the edge of the hole shall be equal to or greater

than

– 6 mm when the width of joint L is less than 12,5 mm,

– 8 mm when the width of joint L is equal to or greater than 12,5 mm but less than 25 mm,

– 9 mm when the width of joint L is equal to or greater than 25 mm.

NOTE The requirements for clearance holes of fasteners are specified in IEC 60079-0.

The distance I is determined as follows.

5.2.4.1 Flanged joints with holes outside the enclosure (see Figures 3 and 5)

The distance l is measured between each hole and the inside of the enclosure.

5.2.4.2 Flanged joints with holes inside the enclosure (see Figure 4)

The distance I is measured between each hole and the outside of the enclosure.

d f

L

60079-1 © IEC:2007 – 13 –

5.2.4.3 Spigot joints where, to the edges of the holes, the joint consists of a cylindrical

part and a plane part (see Figure 6)

The distance I is defined as follows:

– the sum of the width a of the cylindrical part and the width b of the plane part, if f is less

than or equal to 1 mm and if the gap of the cylindrical part is less than or equal to 0,2 mm

for electrical equipment of groups I and IIA, 0,15 mm for electrical equipment of group IIB,

or 0,1 mm for electrical equipment of group IIC (reduced gap); or

– the width b of the plane part alone, if either of the above-mentioned conditions is not met.

l

l

L

L

IEC 065/01

IEC 064/01

Figure 3 Figure 4

b f

L

l

i ≤ 0,20 mm (I,IIA)

l

i ≤ 0,15 mm (IIB)

i ≤ 0,10 mm (IIC)

L

IEC 066/01

i

IEC 1939/03

Figure 5 Figure 6

f

a

– 14 – 60079-1 © IEC:2007

L

L

l

IEC 069/01

l

IEC 068/01

Figure 7 Figure 8

Key

1 interior of enclosure

Figures 3, 4, 5 – Holes in surfaces of flanged joints

Figures 6, 7, 8 – Holes in surfaces of spigot joints

5.2.4.4 Spigot joints where, to the edges of the holes, the joint consists only of the plane

part (see Figures 7 and 8), in so far as plane joints are permitted (see 5.2.7)

The distance l is the width of the plane part between the inside of the enclosure and a hole,

where the hole is outside the enclosure (see Figure 7), or between a hole and the outside of

the enclosure where the hole is inside the enclosure (see Figure 8).

5.2.5 Conical joints

Where joints include conical surfaces, the width of the joint and the gap normal to the joint

surfaces shall comply with the relevant values in Tables 1 and 2. The gap shall be uniform

through the conical part. For electrical equipment of Group IIC, the cone angle shall not

exceed 5°.

NOTE The cone angle is taken to be the angle between the major axis of the cone and the surface of the cone.

5.2.6 Joints with partial cylindrical surfaces (not permitted for group IIC)

There shall be no intentional gap between the two parts (see Figure 9a).

The width of the joint shall comply with the requirements of Table 1.

The diameters of the cylindrical surfaces of the two parts forming the flameproof joint, and

their tolerances, shall ensure compliance with the relevant requirements for the gap of a

cylindrical joint as given in Table 1.

60079-1 © IEC:2007 – 15 –

IEC 070/01

Figure 9a – Example of a joint with partial cylindrical surfaces

5.2.7 Flanged joints for acetylene atmospheres

Flanged joints are only permitted for electrical equipment of group IIC intended for use in

explosive gas atmospheres containing acetylene provided all of the following conditions are met:

a) gap i ≤0,04 mm;

b) width L ≥ 9,5 mm; and

c) volume ≤ 500 cm .

5.2.8 Serrated joints

Serrated joints need not comply with the requirements of Tables 1 and 2 but shall have

a) at least five fully engaged serrations,

b) a pitch greater than or equal to 1,25 mm, and

c) an included angle of 60° (±5°).

Serrated joints shall not be used for moving parts.

, between the mating

Serrated joints shall satisfy the test requirements of 15.2, with the test gap, i

E

serrations as specified in 15.2, based on the manufacturer’s maximum constructional gap, i .

C

If the manufacturer’s maximum constructional gap is different to that shown in Tables 1 or 2

for a flanged joint of the same length (determined by multiplying the pitch by the number of

serrations), the “conditions of use” requirements of 5.1 apply.

See Figure 9b.

X

Y

Y ≥ 5T

T

α Y

Test length =

1,5

X

T ≥ 1,25 mm

α = 60° (±5°)

IEC 1940/03

Figure 9b – Example of serrated joint

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...