IEC 62337:2012

(Main)Commissioning of electrical, instrumentation and control systems in the process industry - Specific phases and milestones

Commissioning of electrical, instrumentation and control systems in the process industry - Specific phases and milestones

IEC 62337:2012 defines specific phases and milestones in the commissioning of electrical, instrumentation and control systems in the process industry. By way of example, it describes activities following the "completion-of-erection" milestone of the project and prior to the "acceptance-of-the-plant" phase by the owner. Such activities need to be adapted for each type of process/plant concerned. This second edition cancels and replaces the first edition published in 2006. This edition constitutes a technical revision. The main changes with respect to the previous edition is: the definition of the documents mentioned in this standard is in accordance with future IEC 62708. The contents of the corrigendum of December 2012 have been included in this copy.

Mise en service des systèmes électriques, de mesure et de commande dans l'industrie de transformation - Phases et jalons spécifiques

La CEI 62337:2012 définit des phases et des jalons spécifiques (voir Figure 1) pour la mise en service des systèmes électriques, de mesure et de commande, utilisés dans l'industrie de transformation. Elle décrit, à titre d'exemple, les activités qui suivent le jalon "achèvement du montage" du projet mais préalables à la phase "de réception de l'ensemble industriel" par le maître d'ouvrage. Il est nécessaire d'adapter ces activités à chaque type de processus/ensemble industriel concerné. Cette deuxième édition annule et remplace la première édition parue en 2006. Cette édition constitue une révision technique. Les modifications principales par rapport à l'édition précédente: La définition des documents mentionnés dans la présente norme est conforme à la future CEI 62708. Le contenu du corrigendum de décembre 2012 a été pris en considération dans cet exemplaire.

General Information

- Status

- Published

- Publication Date

- 21-Feb-2012

- Technical Committee

- SC 65E - Devices and integration in enterprise systems

- Drafting Committee

- WG 3 - TC 65/SC 65E/WG 3

- Current Stage

- PPUB - Publication issued

- Start Date

- 22-Feb-2012

- Completion Date

- 15-Feb-2012

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 62337:2012 is an international standard published by the International Electrotechnical Commission (IEC) that defines specific phases and milestones involved in the commissioning of electrical, instrumentation, and control systems within the process industry. This standard addresses the key activities that take place after the "completion-of-erection" milestone and before the "acceptance-of-the-plant" by the owner. It ensures clarity and mutual understanding between contractors and plant owners on scope, responsibilities, and timelines, helping to accelerate project negotiations and improve overall commissioning efficiency.

The 2012 edition is a technical revision of the original 2006 version and includes updates aligning document definitions with the forthcoming IEC 62708 standard. It integrates the December 2012 corrigendum and reflects up-to-date industry best practices for commissioning complex systems in process plants.

Key Topics

Phases of Commissioning:

- Completion of Erection: Mechanical and electrical erection completed in accordance with project specifications.

- Precommissioning (Mechanical Completion): Activities such as mechanical checks, cold alignment, cleaning, and cold testing of machinery.

- Commissioning:

- Cold Commissioning: Testing and operation using inert test media before actual chemical introduction.

- Hot Commissioning: Testing with actual process chemicals prior to production start.

- Performance Test: Runs designed to demonstrate plant operation at design capacity and contractual performance guarantees.

- Acceptance of Plant: Formal handover of the plant from the contractor to the owner.

Milestones Defined:

- Mechanical Completion: Confirms readiness for cold commissioning after erection and testing.

- Start-Up: Marks transition from cold to hot commissioning, with instrumentation adjusted for operational parameters.

- Start of Production: Indicates the plant is ready for full-scale, continuous operation.

Document and Process Standardization:

- Aligns documentation requirements with future IEC 62708.

- Provides standardized terminology, definitions, and procedures to harmonize commissioning across various types of process plants.

- Emphasizes adaptation to specific industry requirements such as pharmaceuticals, aligning with GMP compliance standards and guidelines like GAMP and FDA 21 CFR.

Applications

IEC 62337:2012 is essential for stakeholders involved in:

- Engineering, procurement, and construction (EPC) contractors managing process industry plants.

- Process plant owners overseeing commissioning and plant acceptance.

- Project managers and commissioning engineers ensuring alignment of activities, responsibilities, and documentation.

- Quality assurance teams verifying proper progression through defined commissioning phases.

- Regulatory and compliance auditors verifying conformance with international and industry-specific standards.

This standard supports various process industries, including chemical, petrochemical, pharmaceutical, and manufacturing sectors, by providing a clear framework to:

- Streamline commissioning workflows.

- Reduce disputes over project scope or milestones.

- Achieve timely and controlled plant startup.

- Ensure all systems are thoroughly tested and validated before production start.

- Facilitate documentation and certification during commissioning stages.

Related Standards

To ensure comprehensive commissioning management and compliance, IEC 62337 references and complements several other key standards, including:

- IEC 62708 (forthcoming): Defines documentation requirements for commissioning and project management in the process industry, which IEC 62337 aligns with.

- IEC 62079: Guidance on preparing user instructions to support commissioning activities.

- IEC 62424: Standards on process control engineering representation supporting interface tools used during commissioning.

- ISO 10628-2: Graphical symbols for diagrams in chemical and petrochemical plants.

- ISA-S7.0.01: Quality standards for instrument air used in process instrumentation.

- Pharmaceutical compliance standards: Such as FDA 21 CFR, GAMP guidelines, and SOP/INSP/2003 by the European Medicines Agency, relevant for plants requiring validated commissioning procedures.

By leveraging IEC 62337:2012, organizations in the process industry gain a well-structured, standardized approach to commissioning electrical, instrumentation, and control systems-helping to minimize risk, ensure operational readiness, and facilitate successful plant handover.

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

IEC 62337:2012 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Commissioning of electrical, instrumentation and control systems in the process industry - Specific phases and milestones". This standard covers: IEC 62337:2012 defines specific phases and milestones in the commissioning of electrical, instrumentation and control systems in the process industry. By way of example, it describes activities following the "completion-of-erection" milestone of the project and prior to the "acceptance-of-the-plant" phase by the owner. Such activities need to be adapted for each type of process/plant concerned. This second edition cancels and replaces the first edition published in 2006. This edition constitutes a technical revision. The main changes with respect to the previous edition is: the definition of the documents mentioned in this standard is in accordance with future IEC 62708. The contents of the corrigendum of December 2012 have been included in this copy.

IEC 62337:2012 defines specific phases and milestones in the commissioning of electrical, instrumentation and control systems in the process industry. By way of example, it describes activities following the "completion-of-erection" milestone of the project and prior to the "acceptance-of-the-plant" phase by the owner. Such activities need to be adapted for each type of process/plant concerned. This second edition cancels and replaces the first edition published in 2006. This edition constitutes a technical revision. The main changes with respect to the previous edition is: the definition of the documents mentioned in this standard is in accordance with future IEC 62708. The contents of the corrigendum of December 2012 have been included in this copy.

IEC 62337:2012 is classified under the following ICS (International Classification for Standards) categories: 91.010.20 - Contractual aspects; 91.040.20 - Buildings for commerce and industry. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62337:2012 has the following relationships with other standards: It is inter standard links to IEC 62337:2012/COR1:2012, IEC 62337:2006. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 62337:2012 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62337 ®

Edition 2.0 2012-02

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Commissioning of electrical, instrumentation and control systems in the

process industry – Specific phases and milestones

Mise en service des systèmes électriques, de mesure et de commande dans

l'industrie de transformation – Phases et jalons spécifiques

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et les

microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Useful links:

IEC publications search - www.iec.ch/searchpub Electropedia - www.electropedia.org

The advanced search enables you to find IEC publications The world's leading online dictionary of electronic and

by a variety of criteria (reference number, text, technical electrical terms containing more than 30 000 terms and

committee,…). definitions in English and French, with equivalent terms in

It also gives information on projects, replaced and additional languages. Also known as the International

withdrawn publications. Electrotechnical Vocabulary (IEV) on-line.

IEC Just Published - webstore.iec.ch/justpublished Customer Service Centre - webstore.iec.ch/csc

Stay up to date on all new IEC publications. Just Published If you wish to give us your feedback on this publication

details all new publications released. Available on-line and or need further assistance, please contact the

also once a month by email. Customer Service Centre: csc@iec.ch.

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Liens utiles:

Recherche de publications CEI - www.iec.ch/searchpub Electropedia - www.electropedia.org

La recherche avancée vous permet de trouver des Le premier dictionnaire en ligne au monde de termes

publications CEI en utilisant différents critères (numéro de électroniques et électriques. Il contient plus de 30 000

référence, texte, comité d’études,…). termes et définitions en anglais et en français, ainsi que

Elle donne aussi des informations sur les projets et les les termes équivalents dans les langues additionnelles.

publications remplacées ou retirées. Egalement appelé Vocabulaire Electrotechnique

International (VEI) en ligne.

Just Published CEI - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications de la CEI.

Just Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur

Disponible en ligne et aussi une fois par mois par email. cette publication ou si vous avez des questions

contactez-nous: csc@iec.ch.

IEC 62337 ®

Edition 2.0 2012-02

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Commissioning of electrical, instrumentation and control systems in the

process industry – Specific phases and milestones

Mise en service des systèmes électriques, de mesure et de commande dans

l'industrie de transformation – Phases et jalons spécifiques

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX V

ICS 25.040.40; 91.010; 91.040; 91.140 ISBN 978-2-88912-913-3

– 2 – 62337 © IEC:2012

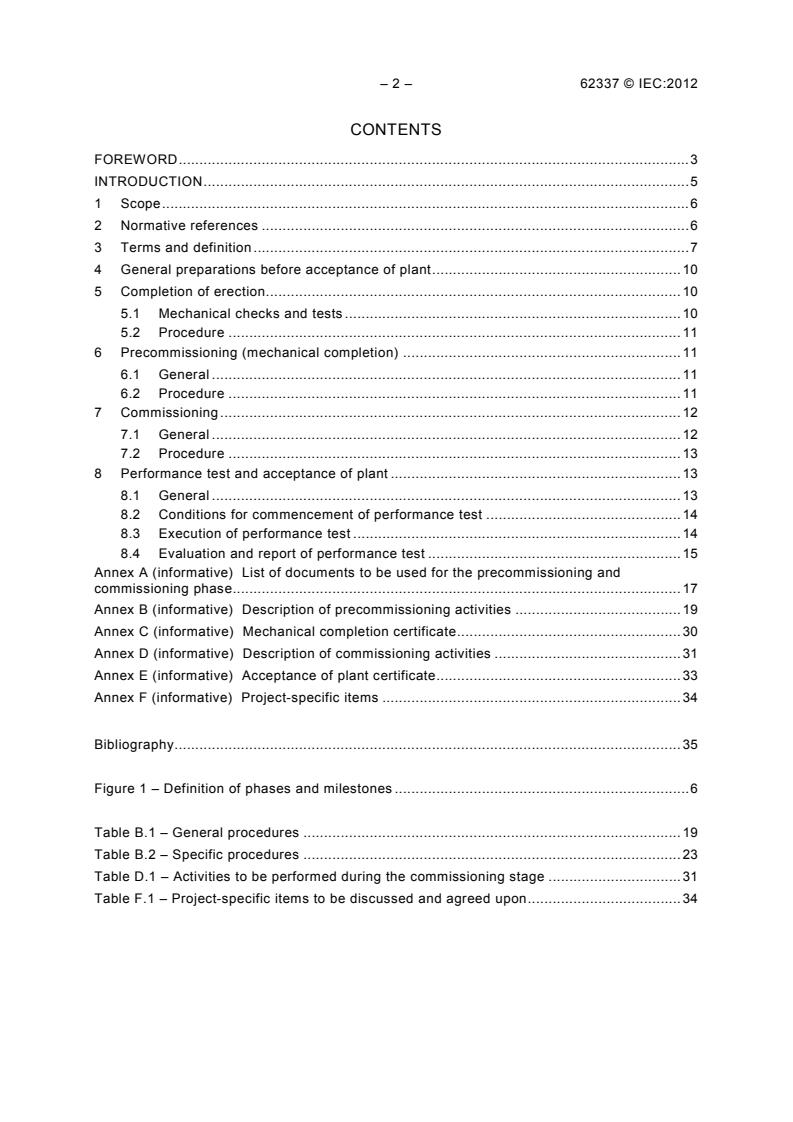

CONTENTS

FOREWORD . 3

INTRODUCTION . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definition . 7

4 General preparations before acceptance of plant . 10

5 Completion of erection . 10

5.1 Mechanical checks and tests . 10

5.2 Procedure . 11

6 Precommissioning (mechanical completion) . 11

6.1 General . 11

6.2 Procedure . 11

7 Commissioning . 12

7.1 General . 12

7.2 Procedure . 13

8 Performance test and acceptance of plant . 13

8.1 General . 13

8.2 Conditions for commencement of performance test . 14

8.3 Execution of performance test . 14

8.4 Evaluation and report of performance test . 15

Annex A (informative) List of documents to be used for the precommissioning and

commissioning phase. 17

Annex B (informative) Description of precommissioning activities . 19

Annex C (informative) Mechanical completion certificate . 30

Annex D (informative) Description of commissioning activities . 31

Annex E (informative) Acceptance of plant certificate. 33

Annex F (informative) Project-specific items . 34

Bibliography . 35

Figure 1 – Definition of phases and milestones . 6

Table B.1 – General procedures . 19

Table B.2 – Specific procedures . 23

Table D.1 – Activities to be performed during the commissioning stage . 31

Table F.1 – Project-specific items to be discussed and agreed upon . 34

62337 © IEC:2012 – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

COMMISSIONING OF ELECTRICAL, INSTRUMENTATION

AND CONTROL SYSTEMS IN THE PROCESS INDUSTRY –

SPECIFIC PHASES AND MILESTONES

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62337 has been prepared by subcommittee 65E: Devices and

integration in enterprise systems of IEC technical committee 65: Industrial-process

measurement, control and automation.

This second edition cancels and replaces the first edition published in 2006. This edition

constitutes a technical revision.

The main changes with respect to the previous edition are listed below:

– The definition of the documents mentioned in this standard is in accordance with future

IEC 62708 .

___________

To be published.

– 4 – 62337 © IEC:2012

The text of this standard is based on the following documents:

FDIS Report on voting

65E/221/FDIS 65E/226/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

The contents of the corrigendum of December 2012 have been included in this copy.

62337 © IEC:2012 – 5 –

INTRODUCTION

There is an increasing trend in the process industry to award the construction of whole plants

to contractors on a lump-sum turnkey or similar commercial basis. Experience has shown that

both the process industry (hereinafter called “the owner”) and the contractor have long and

expensive discussions to lay down unambiguously the scope of activities to be taken by the

contractor and the owner and their responsibilities to achieve the handover of the plant.

This standard is intended to lead to an improvement and acceleration of the negotiation phase

and to a mutual understanding about the scope of the activities of each party.

– 6 – 62337 © IEC:2012

COMMISSIONING OF ELECTRICAL, INSTRUMENTATION

AND CONTROL SYSTEMS IN THE PROCESS INDUSTRY –

SPECIFIC PHASES AND MILESTONES

1 Scope

This International Standard defines specific phases and milestones (see Figure 1) in the

commissioning of electrical, instrumentation and control systems in the process industry. By

way of example, it describes activities following the “completion-of-erection” milestone of the

project and prior to the “acceptance-of-the-plant” phase by the owner. Such activities need to

be adapted for each type of process/plant concerned.

NOTE This standard assumes that the “acceptance-of-the-plant” milestone will occur after the performance test. If

there is a reduced scope, this document should be adapted accordingly.

Acceptance

of plant

Construction Precommissioning Commissioning Production

PHASES

Cold Hot

Completion Mechanical St a rt- up Start of

MILESTONES

of erection completion production Performance

test

IEC 135/12

NOTE Construction and precommissioning activities could be overlapping.

Figure 1 – Definition of phases and milestones

For application in the pharmaceutical or other highly specialized industries, additional

guidelines (for example, Good Automated Manufacturing Practice (GAMP)), definitions and

stipulations should apply in accordance with existing standards, for example, for GMP

Compliance 21 CFR (FDA) and the Standard Operating Procedure of the European Medicines

Agency (SOP/INSP/2003).

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 62079, Preparation of instruction – Structuring, content and presentation

IEC 62424, Representation of process control engineering – Requests in P&I diagrams and

data exchange between P&ID tools and PCE-CAE tools

ISO 10628-2, Diagrams for chemical and petrochemical industry – Part 2: Graphical symbols

ISA-S7.0.01, Quality standard for instrument air

62337 © IEC:2012 – 7 –

3 Terms and definition

For the purposes of this document, the following terms and definitions apply .

3.1

precommissioning

phase during which the activities of non-operating adjustments, cold alignment checks,

cleaning, and testing of machinery take place

NOTE Refer to Annex B for the detailed activities.

3.2

mechanical completion

milestone which is achieved when the plant, or any part thereof, has been erected and tested

in accordance with drawings, specifications, instructions, and applicable codes and

regulations to the extent necessary to permit cold commissioning

NOTE This includes completion of all necessary electrical and instrumentation work. This is a milestone marking

the end of the precommissioning activities.

3.3

cold commissioning

phase during which the activities associated with the testing and operation of equipment or

facilities using test media such as water or inert substances, prior to introducing any chemical

in the system, take place

3.4

start-up

milestone marking the end of cold commissioning

NOTE At this stage, the operating range of every instrument loop should already be adjusted to reflect the actual

working condition.

3.5

hot commissioning

phase during which the activities associated with the testing and operation of equipment or

facilities using the actual process chemical, prior to making an actual production run, take

place

3.6

start of production

milestone marking the end of hot commissioning

NOTE At this stage, the plant is ready for full and continuous operation.

3.7

performance test

milestone at which time the production plant runs to its design capacity

NOTE This test, carried out by the owner’s personnel with the help and supervision of the contractor, serves to

demonstrate the contractor’s process performance and consumption guarantees as specified in the contract.

3.8

acceptance of plant

milestone in which the formal turnover of the plant from the contractor to the owner is carried

out

___________

Future standard IEC 62708 will provide additional information on the terms used in this document.

– 8 – 62337 © IEC:2012

NOTE At this stage, the contractor is relieved from any obligation, with the exception of defect liability and any

other outstanding obligations which are part of the contract. The owner resumes full responsibility for running and

maintaining the plant.

3.9

owner

company that hired a contractor to build a plant

3.10

contractor

company which is hired by the owner to design and build a plant

NOTE This company is responsible for all activities as described in a separate contract including, for example,

the engineering design, procurement, erection of the plant as well as the implementation of all tests and

acceptances that are necessary to deliver a serviceable plant. This company may also be responsible for training

the owner’s production as well as maintenance personnel on plant operation.

3.11

licenser

company or individual that has a process know-how which willingly provides the owner with

the technology to be used in the construction, operation and maintenance of a plant, or part of

the process in such a plant

3.12

vendor

manufacturer or distributor of a piece of equipment/instrument/package unit

NOTE The vendor is the expert for proper installation as well as operation of the equipment/ instrument/ package

unit.

3.13

process industry

industry that uses chemical reactions, separations, or mixing techniques in order to create

new products, modify existing products or treat waste and includes the following types of

industries: chemical, petrochemical, waste treatment, paper, cement, etc. It does not include

such industries as equipment/machine manufacturing or other similar industries. Industries

which are subject to special requirements and or validation, etc. are also not included.

3.14

manpower mobilization plan

bar chart schedule with associated resources and qualifications

3.15

vendor documentation

product describing documents

Example Datasheets, handbooks, operating manuals and spare part lists of supplied devices or systems are parts

of a vendor documentation.

3.16

piping and instrumentation diagram

P&ID

diagram according to DIN EN ISO 10628 including plant process equipment and connecting

piping. E&I equipment shown according project specific requirements

3.17

general design requirements

design guideline adapted from project specific requirements as well as from relevant legal

requirements and regulations

62337 © IEC:2012 – 9 –

3.18

test report

documentation of test sequence and result

3.19

test plan

overview of tests as provided in the contract

3.20

punch list

list of all open tasks

3.21

check list

list of all tests

3.22

operating manual

manufacturer’s instruction for the intended handling and using of a device or system

according to IEC 62079

3.23

process flow diagram

diagram according to DIN EN ISO 10628 including plant process equipment and important

connecting piping. Important E&I equipment shown according project specific requirements

3.24

loop list

tabulated list of all E&I tags with tagging, function and PID reference

3.25

instrument index

tabulated list of all instruments per tag including tagging, instrument type and labelling

3.26

loop diagram

representation of hardware and/or software functions of a control loop with graphical symbols

e.g. according to IEC 62424. It shows equipment in its topological order and wiring including

the terminals

3.27

loop sheet

data sheet with all essential E&I data concerning tagging, function, description, measuring

range, location, process data, instrument data, etc.

3.28

hazardous area classification drawing

plan showing the hazardous areas and temperature classes. The area classification shall be

clearly indicated by class and division

3.29

plot plan E&I

presentation of the locations of E&I equipment in layout and building drawings

3.30

cabinet layout drawing

drawing to scale of equipment, terminal strips, cable trays etc. in cabinets, consoles and

similar

– 10 – 62337 © IEC:2012

3.31

function diagram or logic diagram

description of the E&I functions according to IEC 61131 Use of such a diagram is limited to

digital signal processing only

3.32

functional description

verbal description of task, function and operation of E&I logic like sequence-, batch control

and interlocks

4 General preparations before acceptance of plant

The following items shall be completed in accordance with the responsibilities as defined

within the contract.

a) Documents

The documents agreed upon according to A.1 shall be issued by the contractor to the

owner.

b) Manpower mobilization plan

The agreed amount of manpower required both from the owner and from the contractor,

including their qualification and their availability, shall be available. The organization of

personnel during precommissioning, commissioning and performance testing shall be

established.

c) Equipment and tools

The agreed required tools and equipment to be supplied by the owner or the contractor

shall be available.

d) Raw materials and utilities

For the agreed supply of raw materials and utilities, the contractor and the owner shall

agree upon a detailed time schedule and the conditions for supply within a reasonable

time before the completion of erection.

e) Catalysts and consumables

For the agreed supply of required catalysts, lubricants, chemicals and other consumables,

the contractor and the owner shall agree upon a detailed time schedule and conditions

within a reasonable time before the completion of erection.

5 Completion of erection

5.1 Mechanical checks and tests

After erection of the plant, of each piece of equipment, facility or discrete part of the plant,

mechanical checks and tests shall be carried out by the contractor.

The mechanical checks and tests shall verify that:

a) the plant is erected in accordance with the piping and instrument diagram (P&I), plot plan

and the vendor’s documentation;

b) the equipment is installed and mechanically functions in accordance with the general

design requirements;

c) applicable codes, as listed in the general design requirements, are followed for materials

and workmanship.

Items such as painting, thermal insulation and final clean-up which would not affect the

operation or safety of the plant could be excluded. All these items shall be listed and

62337 © IEC:2012 – 11 –

completed after precommissioning or commissioning within a mutually agreed schedule

between the contractor and the owner but before the acceptance of the plant.

5.2 Procedure

The following shall apply:

a) The contractor shall prepare and maintain on-site test reports and records which shall

include the following information:

– description of the type of test or check;

– date and time of test or check;

– identification of equipment and facilities;

– test pressure if applicable, test data and results, including remarks, if any;

– signature of the owner’s personnel witnessing the data recorded, if required.

b) Check, test and records thereof shall be carried out by the contractor’s personnel.

Wherever the owner’s witness or attesting for the check or test is required, the owner’s

personnel shall attend such check and test. For this purpose, the contractor shall keep the

owner informed of the day-to-day test-plan schedule. The test-plan schedule should be

constantly revised to reflect the actual progress of the work and test.

c) Any items found incomplete or requiring repair or adjustment shall be marked as such on a

separate punch list and reported by the contractor to the owner’s and the contractor’s

personnel in charge of the relevant construction area. The check list for items in the punch

list will be left blank until the problem has been corrected.

d) The contractor shall expedite and follow up the termination of all incomplete, repaired or

adjusted work items in the punch list and shall keep these expediting records up to date.

e) Checking procedures shall be repeated until all the items on the check list are cleared.

f) At the completion of each test, the owner shall certify on the test reports that the test has

been satisfactory; otherwise, the contractor shall repeat the tests. Upon satisfactory

completion of the re-test, re-certification by the owner shall be made accordingly.

g) A complete set of test reports shall be handed over to the owner on completion and, at

this date, the completion of the erection shall be considered as achieved.

6 Precommissioning (mechanical completion)

6.1 General

After completion of the erection, the precommissioning activities listed in the procedure

defined in Annex B and the final steps listed in 6.2 shall be carried out in accordance with the

contract to make the plant mechanically complete and ready for commissioning.

The documents to be utilized are listed in Annex A.

6.2 Procedure

a) The contractor’s personnel responsible for the checks, tests and recording of results on

the completion of erection shall be responsible for the completion of any remaining work,

adjustments and repairs of the equipment marked on the check list during

precommissioning and for the maintenance of appropriate records.

b) The contractor’s personnel appointed for commissioning should also participate in the

precommissioning work to verify the satisfactory performance of the plant.

c) During the checks and tests, the contractor’s personnel is responsible for training the

owner’s personnel on the operation of the plant, as defined within the contract.

– 12 – 62337 © IEC:2012

d) The owner or the contractor shall furnish operating and maintenance personnel, according

to the manpower mobilization plan, to perform those parts of the precommissioning work,

which are agreed to be the owner’s responsibility in accordance with Annex B.

e) The contractor shall ensure that his personnel work in close conjunction with the owner’s

personnel by providing supervision and advice where necessary.

f) The contractor shall prepare detailed procedures for each precommissioning activity listed

in Annex B. Procedures shall be updated or added by the contractor as necessary to

support any additional work.

g) Mechanical completion shall be confirmed on each part/section/unit/facility of the plant

individually.

h) A detailed schedule for the precommissioning of each part/section/unit/facility shall be

submitted by the contractor to the owner before completion of the erection.

i) Upon completion of the precommissioning activities of each part/section/unit/facility of the

plant, the contractor shall submit to the owner a written notice of mechanical completion,

which shall include:

– identity of a part/section/unit/facility of the plant considered mechanically complete;

– a copy of all relevant completed test reports;

– the date on which the completion of the tests was achieved;

– a check list;

– a request for acceptance of a mechanical completion certificate in respect of that

part/section/unit/facility.

j) Within an agreed period from the date of receipt of the contractor’s written notice, the

owner shall:

– in the case of acceptance:

sign the issued mechanical completion certificate similar to the form given in Annex C;

or

– in the case of objection:

submit a rejection statement listing the remaining items to be completed or defects or

deficiencies to be corrected before the mechanical completion status can be accepted.

k) When the owner rejects the contractor’s notice, the contractor shall take any necessary

action to complete or correct the items marked and give the owner a subsequent notice of

mechanical completion.

l) The owner shall sign either a completion certificate or shall issue a rejection statement

within an agreed period after the date of any subsequent notice of mechanical completion.

m) Upon acceptance of the mechanical completion certificate of the last part/section/

unit/facility of the plant by the owner, the owner shall, within an agreed period, accept the

relevant issued mechanical completion certificate for the plant similar to the form given in

Annex C.

7 Commissioning

7.1 General

After the owner has issued a mechanical completion certificate for a part/section/unit/facility

of the plant, the commissioning activities listed in 7.2 shall be carried out as far as possible to

enable the start-up and/or start of production.

The documents to be used are listed in Annex A.

62337 © IEC:2012 – 13 –

7.2 Procedure

a) Commissioning shall be carried out in the following sequence:

– warming up or cooling down;

– initial running using test media such as water or other inert substances;

– operability adjustment;

– feeding in;

– stable operation;

– loading up to the design capacity;

– final adjustment.

b) At all stages of the commissioning sequence, the plant shall be operated at optimum and

in safe plant conditions. To ensure this, the contractor may make adjustments to the

condition indicated in the operating manual and process flow diagrams as necessary.

c) The contractor shall specify for each discrete part of the plant the operational data to be

recorded and the manner in which the data is to be taken.

d) All the operating data shall be recorded by the owner on the predefined forms to be

mutually agreed upon. A copy of the operating log and analytical data from the initial

operation through to the completion of the performance test shall be made available by the

owner to the contractor for evaluation.

e) When any part of the plant is pressurized or placed in hot alignment, regular checking on

thermal expansion, vibration, noise and the like shall be performed by the contractor.

f) The detailed methods and procedures for each of the commissioning tests and operations

shall be specified by the contractor in the operating manual or issued to the owner as

additional work procedures.

g) The contractor shall arrange for the presence of the vendor's and the licenser’s rep-

resentatives at the site to assist the contractor’s personnel, wherever necessary.

h) The contractor’s construction personnel appointed for precommissioning should remain on

site to carry out any necessary adjustment and remedial work.

i) All changes and modifications applied during commissioning shall be documented.

8 Performance test and acceptance of plant

8.1 General

After the initial operation of the plant, a performance test shall be carried out to demonstrate

the contractor’s process performance and consumption guarantees specified in the contract.

a) Detailed test procedure

The contractor shall propose detailed performance test procedures within an agreed

period of time and the contractor and the owner shall agree upon the test procedures prior

to starting the performance test based on the test procedure specified in the contract.

b) Type of operation

Unless otherwise specified in the contract, the performance test will be limited to one type

of operation, raw material and one operation mode.

c) Measurement

The instrument, apparatus and method of measuring of the quantity and quality of

individual media, consumption, etc. should be specified and used to measure such

streams in relation to the process performance and consumption guarantees based on the

measurement specifications described in the contract.

The measurement tolerances, loss corrections, performance for sampling methods and

analytical procedures shall be specified on a project-related basis.

– 14 – 62337 © IEC:2012

d) Performance test schedule

The performance test schedule shall be determined with due regard to the actual progress

of the work and the condition of the plant.

8.2 Conditions for commencement of performance test

The performance test will be commenced when the following conditions are satisfied from the

viewpoint of the process design requirements.

a) Plant operation

The plant shall be operated at the normal operating conditions shown on the applicable

flow diagrams and in the operating manual.

Minor variations from the conditions indicated on the flow diagrams and in the operating

manual to obtain optimum process performance shall be agreed upon by the owner.

b) Instruments

Verify that all plant instruments and analytical apparatus perform as expected.

c) Supply of raw materials and utilities by the owner or the contractor

The plant is supplied with adequate and uninterrupted supplies of raw materials and

utilities by the owner as required at the battery limit conditions to permit a successful

performance test to be completed.

d) Supply of catalysts, lubricants and chemicals by the contractor or the owner

The plant is supplied with adequate and timely supplies of catalysts, lubricants, chemicals

and other consumables to permit a successful performance test to be completed.

e) Transfer of products and waste

The owner shall be responsible for the safe transfer of the plant products and waste from

the battery limit of the plant.

h) Other conditions

Any other conditions necessary for the commencement of the performance test as agreed

between the owner and the contractor shall be satisfied.

8.3 Execution of performance test

a) Notice of readiness to carry out performance test

When the contractor considers that the plant is ready for the performance test and that all

of the conditions stated in 8.2 have been fulfilled, he shall then give the owner a notice of

readiness to carry out the performance test.

Within a predefined period of the receipt of such notice, the owner shall

– acknowledge that the plant is ready for the performance test to be conducted;

or

– submit to the contractor a written statement setting forth in which respects the plant is

not ready for such a test.

If the owner considers that the plant is not ready, then he shall specify in writing the

conditions preventing the start of the performance test. The party responsible for such

conditions shall rectify the problem.

The performance test shall be commenced as soon as the above conditions are corrected.

b) Performance test run

The performance test shall extend continuously over a period specified in the contract.

62337 © IEC:2012 – 15 –

c) Two or more units

Where the plant includes two or more individual process units for which separate process

performance and consumption guarantees are to be demonstrated, a performance test or

tests may be carried out individually on each of the units or simultaneously with any other

unit or units.

d) Operating data

Operating and analytical data recorded during the performance test shall be documented

by the owner and made available to the contractor for evaluation as stated in 8.4.

e) Sampling and analysis

During the performance test, samples necessary for the evaluation of the performance of

the plant shall be taken as often as the contractor and the owner mutually agree or have

agreed.

The samples shall include all streams which may be necessary to check the data from

which the degree of compliance with the process performance and consumption

guarantees can be determined.

The locations and methods of sampling the streams shall be in accordance with those

agreed between the parties under 8.1.

f) Testing

Testing of all samples shall be carried out by the owner’s laboratory. The contractor’s and

the owner’s personnel may have access to the laboratory when the samples are tested

and may check the results. However, by agreement, the contractor may also carry out

testing of samples.

8.4 Evaluation and report of performance test

a) Evaluation of performance test data

Evaluations of performance test data including operating and laboratory data accumulated

during, or as a part of, the performance test shall be carried out by the contractor within a

predefined period after the completion of the performance test.

b) Abnormal test data

Any abnormal test data, which is not compatible with other significant data, shall be taken

again from the plant operating conditions.

c) Tolerances

The performance of the plant shall be evaluated on the basis of the average performance

over the entire period of the performance test and after adjustment with due regard to

tolerances in instrument readings according to the agreed performance test procedures.

d) Report of test results

The contractor shall submit to the owner a report on the performance test in writing,

indicating whether the process performance and consumption guarantees have been met.

The report shall include:

– test results;

– analysis;

– the contractor’s evaluation;

– reference information supporting the evaluation (the necessary signatures, where

required).

e) Reasons for failure

If the performance test results show that a test was unsuccessful, the contractor shall

state probable reasons for such failure.

– 16 – 62337 © IEC:2012

f) Owner’s response to the report

Within a predefined time period after receipt of the performance test report, the owner

shall signify in writing agreement or comments.

g) Contractor’s action in the case of performance test failure

If the evaluation of performance test results shows that the failure of the performance test

is the contractor’s fault, then the contractor shall act in accordance with the contract

conditions.

62337 © IEC:2012 – 17 –

Annex A

(informative)

List of documents to be used for

the precommissioning and commissioning phase

A.1 Technical documents

a) Operating manual/analytical manual

b) Design document including, but not limited to, the following information:

– piping and instrumentation diagram (P&ID);

– equipment index;

– equipment specification;

– vendor documentation;

– loop list;

– instrument index;

– loop diagram;

– loop sheet;

– technical drawings (hazards area classification drawing, plot plan E&I, cabinet lay out

drawing), etc.);

– functional description;

– function diagram or logic diagram;

– operating manuals for equipment;

– fulfilment of the relevant regulations;

– fulfilment of additional regulations demanded by authorities of the government.

c) Others

– special tools and equipment list;

– spare-parts list;

– lubricants/chemicals/catalyst list.

A.2 Procedures

a) Mechanical testing procedure;

b) Detailed precommissioning and commissioning procedure and operating manual;

c) Detailed performance test procedure.

A.3 General and coordination documents

a) Detailed organization charts for precommissioning and commissioning showing:

1) lines of authorities and responsibilities;

2) functions of all key personnel.

b) The job description of the members of this team;

c) The scheduled dates of assignment of each member to precommissioning and

commissioning organizations;

d) A detailed schedule showing the time sequence which the contractor anticipates to follow

for the various steps in completion of erection, precommissioning and commissioning of

each unit and equipment;

– 18 – 62337 © IEC:2012

e) The owner’s regulations for health, environment and safety;

f) The practical organization of the relationship (meetings, reports, etc.) between the

contractor and the owner at the phases of precommissioning and commissioning;

g) Owner’s emergency communication route.

62337 © IEC:2012 – 19 –

Annex B

(informative)

Description of precommissioning activities

This check list defines the activities and responsibilities of the contractor and the owner and

the achievement of the mechanical completion. The allocation of responsibility, i.e. whether

the cross is in the left or the right column is a recommendation which is based on practical

experience, but no enforcement in a given situation is required. The work responsibility should

be defined in accordance with actual project requirements. Some of the activities below might

not occur during erection but are nevertheless included in this list for the sake of

completeness.

Table B.1 lists the general procedure and also outlines the work to be performed by the

contractor and by the owner.

Table B.2 lists the procedure applicable to specific systems or equipment including outline of

the work to be performed by t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...