IEC TR 63065:2017

(Main)Guidelines for operation and maintenance of line commutated converter (LCC) HVDC converter station

Guidelines for operation and maintenance of line commutated converter (LCC) HVDC converter station

IEC TR 63065:2017(E) provides general guidance on basic principles and general proposals for the safe and economic operation and maintenance of an LCC converter station.

These guidelines are based on the operation and maintenance practices that have been used successfully during the last decades at HVDC converter stations all over the world, and can be referred to by new HVDC users to optimize operation and maintenance policy and assist in performing the operation and maintenance work.

This document focuses only on the operation and maintenance of the equipment inside an LCC converter station, including back-to-back HVDC systems. The operation and maintenance of HVDC overhead transmission lines, HVDC cables and voltage sourced converter (VSC) are not covered by this document.

General Information

- Status

- Published

- Publication Date

- 14-Sep-2017

- Technical Committee

- TC 115 - High Voltage Direct Current (HVDC) transmission for DC voltages above 100 kV

- Drafting Committee

- WG 6 - TC 115/WG 6

- Current Stage

- PPUB - Publication issued

- Start Date

- 15-Sep-2017

- Completion Date

- 03-Oct-2017

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC TR 63065:2017 - "Guidelines for operation and maintenance of line commutated converter (LCC) HVDC converter station" - is a technical report from the IEC that gives practical, experience‑based guidance for the safe and economical operation and maintenance of LCC HVDC converter stations (including back‑to‑back systems). It focuses on equipment and procedures inside the converter station (not on HVDC overhead lines, cables or VSC technology) and is intended as a reference for new and existing HVDC users to optimize O&M policy.

Key Topics and Requirements

The report compiles decades of field practice and covers these core technical areas:

- Operation policy and objectives

- Target reliability and availability, operation cost trade‑offs, and considerations for manned vs unmanned operation.

- Operation conditions and system limits

- Typical HVDC operation configurations, control modes and operation procedures.

- Equipment‑level operation

- Converter valves, converter transformers and oil‑immersed smoothing reactors, AC/DC breakers and switchgear, AC/DC filters, control and protection systems, DC measurement instruments, valve cooling and auxiliary power.

- Maintenance strategies

- Corrective maintenance, time‑based maintenance (TBM), condition‑based maintenance (CBM), reliability‑centred maintenance (RCM) and preparation of maintenance programmes.

- Outage and in‑service maintenance

- Routine checks during operation and detailed maintenance actions under outage for valves, transformers, breakers, filters, DC measurements, cooling systems and arresters.

- Fault analysis, troubleshooting and training

- System disturbance analysis, station fault diagnosis, event interpretation, supplier engagement, and operator/maintenance training programs.

- Spare parts, tools and documentation

- Recommended spare parts policy, required tools and documentation responsibilities (supplier vs operator) and statistical analysis of station performance.

Note: IEC TR 63065 is a guidance document; specific contractual or supplier requirements may supersede its recommendations.

Practical Applications and Who Should Use It

This technical report is useful for:

- HVDC asset owners and transmission operators planning O&M policies or preparing operational procedures.

- Station operators and maintenance engineers needing structured checklists, maintenance philosophies (TBM/CBM/RCM) and troubleshooting guidance.

- Project managers and procurers drafting technical requirements for LCC converter stations and preparing handover documentation.

- Training coordinators designing operator and maintenance training curricula based on field‑proven practices.

- HVDC equipment suppliers as a reference for aligning documentation and service offers with industry practice.

Related Standards

- IEC 60633 - Terminology for high‑voltage direct current (HVDC) transmission.

- IEC 60919 - Performance of HVDC systems with line‑commutated converters.

Keywords: IEC TR 63065, LCC HVDC, operation and maintenance, HVDC converter station, line commutated converter, O&M guidelines, HVDC operation, maintenance strategies.

IEC TR 63065:2017 - Guidelines for operation and maintenance of line commutated converter (LCC) HVDC converter station

IEC TR 63065:2017+AMD1:2022 CSV - Guidelines for operation and maintenance of line commutated converter (LCC) HVDC converter station Released:6/3/2022

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

TL 9000 QuEST Forum

Telecommunications quality management system.

UL Solutions

Global safety science company with testing, inspection and certification.

Sponsored listings

Frequently Asked Questions

IEC TR 63065:2017 is a technical report published by the International Electrotechnical Commission (IEC). Its full title is "Guidelines for operation and maintenance of line commutated converter (LCC) HVDC converter station". This standard covers: IEC TR 63065:2017(E) provides general guidance on basic principles and general proposals for the safe and economic operation and maintenance of an LCC converter station. These guidelines are based on the operation and maintenance practices that have been used successfully during the last decades at HVDC converter stations all over the world, and can be referred to by new HVDC users to optimize operation and maintenance policy and assist in performing the operation and maintenance work. This document focuses only on the operation and maintenance of the equipment inside an LCC converter station, including back-to-back HVDC systems. The operation and maintenance of HVDC overhead transmission lines, HVDC cables and voltage sourced converter (VSC) are not covered by this document.

IEC TR 63065:2017(E) provides general guidance on basic principles and general proposals for the safe and economic operation and maintenance of an LCC converter station. These guidelines are based on the operation and maintenance practices that have been used successfully during the last decades at HVDC converter stations all over the world, and can be referred to by new HVDC users to optimize operation and maintenance policy and assist in performing the operation and maintenance work. This document focuses only on the operation and maintenance of the equipment inside an LCC converter station, including back-to-back HVDC systems. The operation and maintenance of HVDC overhead transmission lines, HVDC cables and voltage sourced converter (VSC) are not covered by this document.

IEC TR 63065:2017 is classified under the following ICS (International Classification for Standards) categories: 29.200 - Rectifiers. Convertors. Stabilized power supply; 29.240.01 - Power transmission and distribution networks in general; 33.160.20 - Radio receivers. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TR 63065:2017 has the following relationships with other standards: It is inter standard links to IEC TR 63065:2017/AMD1:2022. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC TR 63065:2017 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC TR 63065 ®

Edition 1.0 2017-09

TECHNICAL

REPORT

Guidelines for operation and maintenance of line commutated converter (LCC)

HVDC converter station

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 20 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 65 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

IEC TR 63065 ®

Edition 1.0 2017-09

TECHNICAL

REPORT

Guidelines for operation and maintenance of line commutated converter (LCC)

HVDC converter station

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 29.200; 29.240.01 ISBN 978-2-8322-4802-7

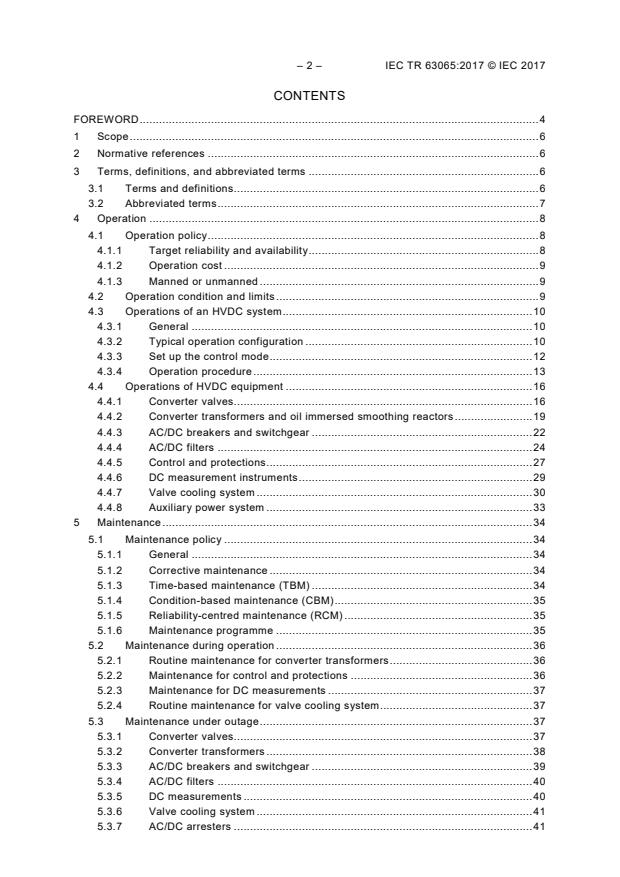

– 2 – IEC TR 63065:2017 © IEC 2017

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms, definitions, and abbreviated terms . 6

3.1 Terms and definitions . 6

3.2 Abbreviated terms . 7

4 Operation . 8

4.1 Operation policy . 8

4.1.1 Target reliability and availability . 8

4.1.2 Operation cost . 9

4.1.3 Manned or unmanned . 9

4.2 Operation condition and limits . 9

4.3 Operations of an HVDC system . 10

4.3.1 General . 10

4.3.2 Typical operation configuration . 10

4.3.3 Set up the control mode . 12

4.3.4 Operation procedure . 13

4.4 Operations of HVDC equipment . 16

4.4.1 Converter valves. 16

4.4.2 Converter transformers and oil immersed smoothing reactors . 19

4.4.3 AC/DC breakers and switchgear . 22

4.4.4 AC/DC filters . 24

4.4.5 Control and protections . 27

4.4.6 DC measurement instruments . 29

4.4.7 Valve cooling system . 30

4.4.8 Auxiliary power system . 33

5 Maintenance . 34

5.1 Maintenance policy . 34

5.1.1 General . 34

5.1.2 Corrective maintenance . 34

5.1.3 Time-based maintenance (TBM) . 34

5.1.4 Condition-based maintenance (CBM) . 35

5.1.5 Reliability-centred maintenance (RCM) . 35

5.1.6 Maintenance programme . 35

5.2 Maintenance during operation . 36

5.2.1 Routine maintenance for converter transformers . 36

5.2.2 Maintenance for control and protections . 36

5.2.3 Maintenance for DC measurements . 37

5.2.4 Routine maintenance for valve cooling system . 37

5.3 Maintenance under outage . 37

5.3.1 Converter valves. 37

5.3.2 Converter transformers . 38

5.3.3 AC/DC breakers and switchgear . 39

5.3.4 AC/DC filters . 40

5.3.5 DC measurements . 40

5.3.6 Valve cooling system . 41

5.3.7 AC/DC arresters . 41

6 Fault analysis and troubleshooting . 42

6.1 General . 42

6.2 System disturbances . 42

6.3 Station faults . 43

6.4 General information for fault analysis . 43

6.4.1 General . 43

6.4.2 Interpreting events and the TFR . 43

6.4.3 Checking plant circuit diagram and application software logics . 43

6.4.4 Analyzing the equipment status . 43

6.4.5 Simulation . 44

6.4.6 Site test . 44

6.4.7 Involving the HVDC supplier . 44

7 Training . 44

7.1 General . 44

7.2 Operator training program . 44

7.2.1 General . 44

7.2.2 Training courses . 44

7.2.3 Participation during installation and commissioning . 45

7.3 Maintenance training program . 45

7.3.1 General . 45

7.3.2 Training courses . 45

7.3.3 Training during equipment installation and testing . 46

7.3.4 Continuous transfer of knowledge . 46

8 Spare parts . 46

9 Tools . 47

10 Documentation . 48

10.1 General . 48

10.2 Documents to be provided by the supplier . 48

10.3 Documents to be prepared by the operators . 48

10.4 Statistics and analysis . 48

Bibliography . 50

Table 1 – Basic tools needed for operation and maintenance of an HVDC converter

station . 47

– 4 – IEC TR 63065:2017 © IEC 2017

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

GUIDELINES FOR OPERATION AND MAINTENANCE

OF LINE COMMUTATED CONVERTER (LCC)

HVDC CONVERTER STATION

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

The main task of IEC technical committees is to prepare International Standards. However, a

technical committee may propose the publication of a technical report when it has collected

data of a different kind from that which is normally published as an International Standard, for

example "state of the art".

IEC TR 63065, which is a technical report, has been prepared by IEC technical committee 115:

High Voltage Direct Current (HVDC) transmission for DC voltages above 100 kV.

The text of this technical report is based on the following documents:

Enquiry draft Report on voting

115/153/DTR 115/163/RVDTR

Full information on the voting for the approval of this technical report can be found in the

report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

– 6 – IEC TR 63065:2017 © IEC 2017

GUIDELINES FOR OPERATION AND MAINTENANCE

OF LINE COMMUTATED CONVERTER (LCC)

HVDC CONVERTER STATION

1 Scope

This Technical Report provides general guidance on basic principles and general proposals

for the safe and economic operation and maintenance of an LCC converter station.

These guidelines are based on the operation and maintenance practices that have been used

successfully during the last decades at HVDC converter stations all over the world, and can

be referred to by new HVDC users to optimize operation and maintenance policy and assist in

performing the operation and maintenance work.

This document focuses only on the operation and maintenance of the equipment inside an

LCC converter station, including back-to-back HVDC systems. The operation and

maintenance of HVDC overhead transmission lines, HVDC cables and voltage sourced

converter (VSC) are not covered by this document.

NOTE Usually the agreement between the purchaser and the suppliers of the HVDC converter station includes

specific requirements regarding contractual requirements of particular systems. Such specific requirements will

supersede the general/typical description mentioned in this document and all functions mentioned in this document

are not necessarily applicable for all systems.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60633, Terminology for high-voltage direct current (HVDC) transmission

IEC 60919 (all parts), Performance of high-voltage direct current (HVDC) systems with line-

commutated converters

IEC 61975, System tests for High-voltage direct current (HVDC) installations

IEC TS 62672-1, Reliability and availability evaluation of HVDC systems – Part 1: HVDC

systems with line commutated converters

3 Terms, definitions, and abbreviated terms

3.1 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60633 and the

following apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1.1

manned station

MS

HVDC converter station that is operated locally by several operators, 24 h a day

Note 1 to entry: In some systems the manned station controls and observes not only its own converter station but

also the opposite unmanned station.

3.1.2

unmanned station

US

HVDC converter station that is operated remotely with no operator on site

3.1.3

time based maintenance

TBM

maintenance carried out in accordance with a specified time schedule, in most cases annually

3.1.4

condition-based maintenance

CBM

necessary maintenance performed based on the equipment's condition, sometimes combined

with TBM

3.1.5

reliability centred maintenance

RCM

necessary maintenance performed after analyzing the performance of the equipment

3.1.6

operator

person operating the converter station

3.1.7

asset manager

person that manages the plant/asset for the overall planning, operation, maintenance and

performance in accordance with a set of criteria as assigned by the asset owner

3.2 Abbreviated terms

BOD break over diode

BPS by-pass switch

CBM condition-based maintenance

CT current transformer

DGA dissolved gas analysis

GIS gas insulated switchgear

GRTS ground return transfer switch

HMI human-machine interface

LCC line commuted converter

MCB micro circuit breaker

MRTB metallic return transfer breaker

MV medium voltage

NBS neutral bus switch

OEM original equipment manufacturer

– 8 – IEC TR 63065:2017 © IEC 2017

OLT open line test

OLTC on line tap changer

OTDR optical time domain reflectometer

RCM reliability-centred maintenance

RPC reactive power control

SCADA supervisory control and data acquisition

SER sequence of event records

TBM time-based maintenance

TFR transient fault record

4 Operation

4.1 Operation policy

4.1.1 Target reliability and availability

Generally, an availability of 97 % is requested as the minimum value in the design

specification of a new HVDC project. This is based on a forced unavailability of less than 1 %

and a scheduled unavailability of about 2 %. With good quality control applied in the design,

manufacture, installation and testing stages, as well as appropriate operating and careful

maintenance during operation, this requirement can be met in most modern HVDC systems.

According to the survey conducted by CIGRE B4 AG4 ([2] to [6] ) for the period 2003 to 2014,

typical target performance indicators for an HVDC system can be:

a) forced unavailability < 1 %;

b) availability > 97 %.

Scheduled unavailability varies from system to system depending on which operation and

maintenance policy is taken. This can be seen from the performance reports of CIGRE B4

AG4. For example, some systems perform maintenance using 24 h shifts, whereas others

work only 8 h a day and leave the system out of service for 16 h each day and on weekends.

In other systems, maintenance is performed when the generator is not available (thermal unit

out for maintenance or low water conditions, etc.). That is why the typical scheduled

unavailability and overall unavailability is not given above.

The number of forced outages, including sudden interruption of power transmission both by

protections and by manual emergency shutdown, is an important parameter for reliability.

Usually, for a bipolar LCC HVDC scheme, the number of monopole trips is designed to be

four times or fewer a year and the number of bipolar trips below once every ten years.

According to the operation practice of modern HVDC systems, the number of monopole trips

can be even limited to once a year. In systems with more than one converter in series per

pole, the converters' trips can be limited to two trips per converter per station.

Outage hours, a parameter that indicates not only the health of the equipment but also the

ability of maintenance, also affect the reliability and availability considerably. The outage

hours would be longer due to severe damage of the equipment, complex fault analyzing and

troubleshooting, or long waiting times for tools or spare parts. Every effort should be made to

put the HVDC system back into full operation as soon as possible.

Refer to IEC TS 62672-1 for the main performance indicators.

__________

Numbers in square brackets refer to the Bibliography.

4.1.2 Operation cost

The operation cost covers the following aspects:

a) human resources (salary for the operation and maintenance staff),

b) consumables,

c) maintenance and tests,

d) auxiliary power and cooling waters,

e) spare parts,

f) improvements and upgrade, and

g) other costs.

There are a number of variables that will impact the operational cost of an HVDC station. The

human resources cost for an unmanned station is much less than for a manned station. The

maintenance cost for an RCM station is much less than for a TBM station. The spare parts

cost for an old station is usually higher than for a new station.

Due to the above reasons, it is hard to give an average cost for running an HVDC converter

station for one year. The costs can be reduced if optimal operation, maintenance and spare

part policies are considered.

4.1.3 Manned or unmanned

Traditionally, an LCC HVDC converter station is a manned station, where several operators

monitor the status of the HVDC link and the equipment 24 h a day. Even for a manned station,

the power flow on the HVDC system may be dispatched remotely. As development in

automation increases, as well as the improvement of HVDC equipment, unmanned stations or

less-manned stations (e.g. manned only during office hours) are more common. Many stations

in Europe (like FennoSkan, SwePol) are unmanned. An unmanned converter station is

operated remotely from an operation centre or even a dispatch centre, and manned only when

something has failed.

Some important HVDC converter stations, such as Itaipu (Brazil), Nelson River (Canada) and

Fulong (China),which are responsible for transmitting 70 % of the power generated by nearby

hydro plants, are still manned stations. Equipment failure can be fixed faster at a manned

station. This in turn contributes to the reliability and availability of the HVDC link.

Whether a station is manned or unmanned can be evaluated technically and economically. If it

takes more than two hours to drive from a nearby city to the station, if the equipment failure

rate of the station is still high, or if the converter station is critical to the grid, it may be better

to man the station.

NOTE Some parts of the text in this document are applicable for manned stations only and are not applicable for

unmanned stations, as there is no operator in the station.

4.2 Operation condition and limits

Before entering commercial operation of an HVDC converter station, the following conditions

are normally required to be fulfilled:

a) the system test (IEC 61975) and the trial operation have been completed successfully;

b) the operating and maintenance staff is available and has been trained;

c) the communication between the dispatch centre and the converter station has been set up;

d) the standard operating procedure for operation and maintenance of the HVDC station has

been established; and

e) spare parts are available.

– 10 – IEC TR 63065:2017 © IEC 2017

Keeping and preserving the life of an HVDC converter station/link is the most important

aspect to manage. Generally, HVDC systems are planned, designed and expected to have a

lifetime of 30 years or more. To meet this requirement, operation limits should be clearly

defined and faithfully followed by the operating and maintenance staff. They at least include:

1) the current, voltage and temperature of the main equipment are within the limits defined

by HVDC suppliers;

2) the temperature, humidity and cleanliness of the valve hall, valve cooling system, relay

buildings and control rooms can meet the requirements of normal operation of related

equipment or devices;

3) the maximum acceptable current for electrodes and station grounds is such that it will not

affect nearby industry pipes or the environment;

4) environment (oil, water, PCB, etc.) management systems and procedures are in place and

the staff regularly reviews these procedures.

4.3 Operations of an HVDC system

4.3.1 General

Subclause 4.3 gives a generic guidance as to how to operate an HVDC system. Note that the

suppliers’ documentation for the given HVDC system shall always be consulted for the

particular HVDC system.

4.3.2 Typical operation configuration

4.3.2.1 General

Availability, reliability, and flexibility for operation and maintenance are closely related to the

operational configuration of HVDC systems. The general configuration and performance of

high voltage direct current (HVDC) system are given in IEC 60919.

4.3.2.2 Point-to-point HVDC system

A point-to-point HVDC system is mainly for bulk transmission. It usually consists of two

separate poles, which can be operated individually or together in a bipolar arrangement. This

kind of system can be operated in three operating configurations.

a) Bipolar ground return with bipolar power control

This is the normal operation mode for a bipolar HVDC system. Active power order is

shared between each pole and the current of both poles is balanced so that the earth

current is kept to a low value, typically less than 10 A. Furthermore, if one pole is tripped,

part of its power can be taken up by the healthy pole so that less power will be lost. The

above benefits make this the most commonly used operation modes in a bipolar HVDC

system.

During bipolar operation, the bipole neutral bus can be connected to either the electrode

or the station ground. This allows the electrode or electrode lines maintenance job to be

done without interruption of normal power transmission. However, it may be noted that

when the station ground is used, in the event of a trip of a pole, another pole will also be

tripped as a consequence of increased station ground current. Attention should also be

paid to a possible station ground potential change at pole ground fault.

Under contaminated conditions, which are often a combination of rain or fog in an HVDC

station or along the corridor of its DC lines, the affected pole can continue the power

transmission by running at reduced voltage, for instance 70 % or 80 % of rated DC

voltage.The current of each pole is balanced by the control system and the earth current is

still limited to a low value. The HVDC system can resume the rated voltage when the

weather conditions improve.

In the case where the DC equipment of one pole develops a fault such that the power or

current needs to be limited to a certain level, the defective pole can be set to pole power

control or pole current control.

b) Monopole metallic return

This is an optional operation mode for a bipolar system. If one pole for a bipolar HVDC

system is not available, and if long-term flow of high earth current is not allowable and the

DC line of the other pole is still available, the remaining pole can be connected to both DC

lines and earthed at one predefined station. The equipment belonging to the outage pole

can be checked or repaired and put into operation again. Compared to monopole ground

return, the power loss on the DC line will be doubled, so once the faulty pole is available

again, the operating pole can be transferred back first from metallic return to ground return

and then to bipolar ground return.

c) Monopole ground return

This is also an optional operation mode for a bipolar HVDC system. If one pole is not

available, for example when it is under construction, maintenance, or it is tripped by

protections, and if long-term flow of earth current is acceptable, the remaining pole is

connected to the electrode via the MRTB and can go on operating. The equipment

belonging to the faulty pole, as well as its DC line, can be checked or repaired and put into

operation again.

4.3.2.3 Back-to-back HVDC system

A back-to-back HVDC system is mainly used for asynchronous connections. In this

arrangement, there are no DC transmission lines or DC filters, and both converters are

located at one station. The valves for both the rectifier and the inverter are typically located in

one valve hall.

There is only one operating configuration for a back-to-back system. The 12-pulse converters

of both the rectifier and the inverter are connected directly through busbars. Some back-to-

back systems are comprised of several units so that the loss of a converter will not lead to a

total loss of power transmission or network islanding.

4.3.2.4 Two 12-pulse converters per pole

If the DC voltage or DC current of the converter reach their limits, two 12-pulse converters are

connected in series or in parallel for higher voltage or higher current. This configuration is

applied to Nelson River, Itaipu, and the UHVDC systems in China and India.

The operational configuration of 12-pulse converters per pole is the same as for bipolar

systems except that the system can still be operated in bipole mode when one converter is

out of service (forced or scheduled). In this case, the pole will operate at half the normal

voltage or half the DC current capability.

4.3.2.5 Set up the operation configuration

Operators should evaluate the state of main circuit equipment including:

a) AC configuration and minimum availability of AC filter;

b) availability of HVDC equipment of each pole;

c) allowed ground return current;

d) connectivity of DC lines;

e) ensuring all major or critical alarms have already been acknowledged and reset.

The operational configuration can then be set up by connecting both poles or a single pole, in

ground return or metallic return, and the DC lines of each pole or of both poles.

– 12 – IEC TR 63065:2017 © IEC 2017

4.3.3 Set up the control mode

4.3.3.1 General

A combination of different DC voltage settings, power direction, power control methods, power

control modes, reactive power control methods and reactive power control modes gives a

large combination of options.

Bipolar power control ensures that the total power of the DC bipolar transmission remains at

the ordered value and that the current is equally distributed between the two poles, thus

minimizing the earth current. This is the main mode of operation, and to fully synchronize the

two stations, telecommunication has to be in service.

Pole power control keeps the transmitted DC power equal to the power order given by the

operator. To keep the power constant, the DC voltage variation is compensated by adjusting

the DC current accordingly. The current order I is obtained by dividing the total power order

o

by the DC voltage of the converter.

Pole current control keeps DC current equal to the current order given by the operator.

4.3.3.2 Basic control mode

Before starting the power transmission of an HVDC system, the operators should set up the

following control modes:

a) reference DC voltage of each pole;

b) power transmission direction of each pole;

c) select control method and control mode of active power control;

d) enable joint control as long as telecommunication is available;

e) select control method and control mode of reactive power control;

f) enable or disable the supplementary control function such as frequency control, damping

control.

4.3.3.3 Additional control functions

The inherent high-speed power control capability of the HVDC transmission system may be

used for different objectives such as frequency control, power modulation, and power

oscillation damping.

Frequency control modifies the DC power transfer to assist the connected AC systems in

recovering from severe contingencies by limiting AC system frequency deviation above and

below the nominal frequency. The characteristics and dead bands of the frequency controls

are determined during the design studies.

Contingencies involving loss of generation in the inverter AC system and loss of load in the

rectifier AC system may require that the power on the DC system be rapidly increased to

improve the performance of the AC systems. Contingencies involving a loss of generation in

the rectifier AC system or a loss of load in the inverter AC system may require an automatic

reduction in DC power transfer. Power modulation functions are available both in bipolar and

monopolar operation.

Some HVDC systems of which both ends are connected to the same synchronized AC system

apply power modulation that can dampen the power oscillations that may be caused either by

a large disturbance or specific system conditions. The power flow of the HVDC system is

quickly controlled to repress power oscillation.

Therefore, before starting the power transmission of an HVDC system, operators should also

set up the following additional controls.

a) Enable or disable automatic frequency control and set up its parameters. Automatic

frequency control should be enabled if the HVDC link is connected to a weak AC system

or an islanded system.

b) Enable or disable power modulation and set up its parameters. Power modulation is

commonly used for network stability control. After loss of AC lines, DC transmission power

can be ramped down if needed. After tripping of DC link, the generators connected to the

rectifier and the loads connected to the inverter can be turned off.

c) Enable or disable oscillation damping and set up its parameters. Oscillation damping is

mainly used for the rectifier that is fed from thermal power generators and is weakly

connected to a power grid. To avoid subsynchronous oscillation, the power at special

frequencies is measured and modulated.

4.3.4 Operation procedure

4.3.4.1 Control position and control authority

Control orders to the HVDC system, either in digital or analogue, can be given from the

dispatch centre, SCADA, or from backup or local control locations. By default orders from

SCADA are accepted by the control system, unless the dispatch centre takes over the control

rights or when backup control is enabled.

Only the master station can control the power transmission of an HVDC link. If the slave

station needs to control the power, it needs to first take master control from the other station

first.

To increase the security of the HVDC system, only authorized operators should control the

equipment in corresponding areas such as the DC yard, AC yard, AC filters, and auxiliary

power system.

Operators shall log onto the human-machine interface (HMI) before performing any operation.

4.3.4.2 OLT

The open line test (OLT) is a test that is used by the operators to energize the pole DC side

with direct voltage for the purpose of testing the insulation on the DC side, as well as the

converter. The OLT can be performed either in manual or automatic mode.

The OLT is performed in one station at a time because the DC line will be energized up to the

pole disconnector of the other station. When one pole is in open line test the other pole may,

depending on the system design and operation permission, be operated independently.

The OLT is usually part of the commissioning of the HVDC scheme, in some cases it is also

carried out after annual maintenance or a DC line fault. But it is not necessary to carry out an

OLT every time before deblocking a pole. Some HVDC systems have never been subjected to

an OLT in the last thirty years, even after pole maintenance.

4.3.4.3 Deblock

Once the main circuit and the control mode are chosen, i.e. an operating mode is set up, the

HVDC system can be deblocked for power transmission. Before deblock, the status of the

main circuit equipment, control and protections and auxiliary systems should be confirmed to

ensure that the HVDC system is ready for operation. If any of the systems indicates a severe

alarm, maintenance staff should investigate its cause and should take steps to restore the

system to normal condition.

The inverter is always deblocked first to build up DC voltage, and then the rectifier is

deblocked to build up the DC current. The control of the two stations is synchronised via

telecommunication. In the event of a telecommunication failure, operators of the two stations

shall cooperate by telephone to manually deblock the HVDC link.

– 14 – IEC TR 63065:2017 © IEC 2017

4.3.4.4 Power ramp

During the change of power generation and load consumption, the power reference of an

HVDC link should also be adjusted dynamically. Operators receive the power orders or a daily

power curve from the dispatch centre and execute power ramps accordingly.

To ramp up or down the transmission power, the operator should:

a) set up the power ramp speed;

b) set up the power reference at the give time;

c) hold the existing ramp rate or set a new reference if needed.

Corresponding events will be generated after starting the power ramp and when the ramp

completes.

To simplify the above operations, an automatic bipolar power curve is used for some systems.

In this option, the bipolar power order is controlled automatically in response to a pre-

programmed power transfer curve, which will define the power transfer over the daily, weekly

or monthly load cycles.

4.3.4.5 Changing the operation mode

Even though it is safer and more economical to have a DC line running in bipolar ground

return mode with rated DC voltage, normal power direction and bipolar power control,

sometimes it is necessary to change to another operation mode due to the unavailability of

HVDC equipment, HVDC line or other reasons.

a) Change to monopole ground return or metallic return mode.

If one pole of a bipolar HVDC system is not available, for example when it is tripped by

protections, and if long-term flow of high earth current is acceptable, the remaining pole

can go into operation with the ground return until the other pole is available again and the

HVDC system can revert back to bipolar ground return mode. However, if long-term flow of

high earth current is undesirable while the DC line of the defective pole is still available,

the remaining pole can be transferred from ground return to metallic return by starting the

corresponding sequence. Once the other pole is available again, the operating pole can be

transferred back first from metallic return to ground return and then to bipolar ground

return mode.

b) Change to reduced voltage mode

If continuous electro-discharging is observed under contaminated conditions, often caused

by a combination with rain or fog in the converter station or along the corridor of DC lines,

the defective pole can continue the power transmission by running at reduced voltage, for

instance 80 % of rated DC voltage.

When operating in the reduced voltage mode, the taps of converter transformers are

lowered to the position resulting in minimum voltage, and the thyristor valve might operate

at a relatively higher firing angle so that the snubber circuits are subjected to additional

stresses. Additionally, more reactive power is consumed in this mode.

The HVDC system can be returned to rated voltage when the weather conditions improve.

c) Change to pole power/current control mode

When the DC equipment of one pole develops a problem so that its power or current

needs to be limited, this defective pole can be set to pole power control or pole current

control. In both cases, the pole in bipolar control mode will try to balance the current of

each pole so that the earth current can be still limited to a low value.

d) Overloaded

After one pole is blocked by protections, the remaining pole might be ov

...

IEC TR 63065 ®

Edition 1.1 2022-06

CONSOLIDATED VERSION

TECHNICAL

REPORT

colour

inside

Guidelines for operation and maintenance of line commutated converter (LCC)

HVDC converter station

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always

committee, …). It also gives information on projects, replaced have access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 300 terminological entries in English

details all new publications released. Available online and

and French, with equivalent terms in 19 additional languages.

once a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC TR 63065 ®

Edition 1.1 2022-06

CONSOLIDATED VERSION

TECHNICAL

REPORT

colour

inside

Guidelines for operation and maintenance of line commutated converter (LCC)

HVDC converter station

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 29.200; 29.240.01 ISBN 978-2-8322-3828-8

IEC TR 63065 ®

Edition 1.1 2022-06

CONSOLIDATED VERSION

REDLINE VERSION

colour

inside

Guidelines for operation and maintenance of line commutated converter (LCC)

HVDC converter station

– 2 – IEC TR 63065:2017+AMD1:2022 CSV

© IEC 2022

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms, definitions, and abbreviated terms . 6

3.1 Terms and definitions . 6

3.2 Abbreviated terms . 7

4 Operation . 8

4.1 Operation policy . 8

4.1.1 Target reliability and availability . 8

4.1.2 Operation cost . 9

4.1.3 Manned or unmanned . 9

4.2 Operation condition and limits . 9

4.3 Operations of an HVDC system . 10

4.3.1 General . 10

4.3.2 Typical operation configuration . 10

4.3.3 Set up the control mode . 12

4.3.4 Operation procedure . 13

4.4 Operations of HVDC equipment . 16

4.4.1 Converter valves. 16

4.4.2 Converter transformers and oil immersed smoothing reactors . 19

4.4.3 AC/DC breakers and switchgear . 22

4.4.4 AC/DC filters . 24

4.4.5 Control and protections . 27

4.4.6 DC measurement instruments . 29

4.4.7 Valve cooling system . 30

4.4.8 Auxiliary power system . 33

4.4.9 Fire protection system . 34

5 Maintenance . 35

5.1 Maintenance policy . 35

5.1.1 General . 35

5.1.2 Corrective maintenance . 36

5.1.3 Time-based maintenance (TBM) . 36

5.1.4 Condition-based maintenance (CBM) . 36

5.1.5 Reliability-centred maintenance (RCM) . 37

5.1.6 Maintenance programme . 37

5.2 Maintenance during operation . 37

5.2.1 Routine maintenance for converter transformers . 37

5.2.2 Maintenance for control and protections . 38

5.2.3 Maintenance for DC measurements . 38

5.2.4 Routine maintenance for valve cooling system . 38

5.2.5 Routine maintenance for Fire protection system . 39

5.3 Maintenance under outage . 39

5.3.1 Converter valves. 39

5.3.2 Converter transformers . 39

5.3.3 AC/DC breakers and switchgear . 41

5.3.4 AC/DC filters . 41

© IEC 2022

5.3.5 DC measurements . 42

5.3.6 Valve cooling system . 42

5.3.7 AC/DC arresters . 43

5.3.8 Fire protection system . 43

6 Fault analysis and troubleshooting . 44

6.1 General . 44

6.2 System disturbances . 44

6.3 Station faults . 44

6.4 General information for fault analysis . 45

6.4.1 General . 45

6.4.2 Interpreting events and the TFR . 45

6.4.3 Checking plant circuit diagram and application software logics . 45

6.4.4 Analyzing the equipment status . 45

6.4.5 Simulation . 45

6.4.6 Site test . 46

6.4.7 Involving the HVDC supplier . 46

7 Training . 46

7.1 General . 46

7.2 Operator training program . 46

7.2.1 General . 46

7.2.2 Training courses . 46

7.2.3 Participation during installation and commissioning . 46

7.3 Maintenance training program . 47

7.3.1 General . 47

7.3.2 Training courses . 47

7.3.3 Training during equipment installation and testing . 47

7.3.4 Continuous transfer of knowledge . 48

8 Spare parts . 48

9 Tools . 49

10 Documentation . 50

10.1 General . 50

10.2 Documents to be provided by the supplier . 50

10.3 Documents to be prepared by the operators . 50

10.4 Statistics and analysis . 50

Bibliography . 52

Table 1 – Basic tools needed for operation and maintenance of an HVDC converter

station . 49

– 4 – IEC TR 63065:2017+AMD1:2022 CSV

© IEC 2022

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

GUIDELINES FOR OPERATION AND MAINTENANCE

OF LINE COMMUTATED CONVERTER (LCC)

HVDC CONVERTER STATION

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This consolidated version of the official IEC Standard and its amendment has been

prepared for user convenience.

IEC TR 63065 edition 1.1 contains the first edition (2017-09) [documents 115/153/DTR

and 115/163/RVDTR] and its amendment 1 (2022-06) [documents 115/280/DTR and

115/294/RVDTR].

In this Redline version, a vertical line in the margin shows where the technical content

is modified by amendment 1. Additions are in green text, deletions are in strikethrough

red text. A separate Final version with all changes accepted is available in this

publication.

© IEC 2022

The main task of IEC technical committees is to prepare International Standards. However, a

technical committee may propose the publication of a technical report when it has collected

data of a different kind from that which is normally published as an International Standard, for

example "state of the art".

IEC TR 63065, which is a technical report, has been prepared by IEC technical committee 115:

High Voltage Direct Current (HVDC) transmission for DC voltages above 100 kV.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of the base publication and its amendments will

remain unchanged until the stability date indicated on the IEC web site under webstore.iec.ch

in the data related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 6 – IEC TR 63065:2017+AMD1:2022 CSV

© IEC 2022

GUIDELINES FOR OPERATION AND MAINTENANCE

OF LINE COMMUTATED CONVERTER (LCC)

HVDC CONVERTER STATION

1 Scope

This Technical Report provides general guidance on basic principles and general proposals

for the safe and economic operation and maintenance of an LCC converter station.

These guidelines are based on the operation and maintenance practices that have been used

successfully during the last decades at HVDC converter stations all over the world, and can

be referred to by new HVDC users to optimize operation and maintenance policy and assist in

performing the operation and maintenance work.

This document focuses only on the operation and maintenance of the equipment inside an

LCC converter station, including back-to-back HVDC systems. The operation and

maintenance of HVDC overhead transmission lines, HVDC cables and voltage sourced

converter (VSC) are not covered by this document.

NOTE Usually the agreement between the purchaser and the suppliers of the HVDC converter station includes

specific requirements regarding contractual requirements of particular systems. Such specific requirements will

supersede the general/typical description mentioned in this document and all functions mentioned in this document

are not necessarily applicable for all systems.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60633, Terminology for high-voltage direct current (HVDC) transmission

IEC 60919 (all parts), Performance of high-voltage direct current (HVDC) systems with line-

commutated converters

IEC 61975, System tests for High-voltage direct current (HVDC) installations

IEC TS 62672-1, Reliability and availability evaluation of HVDC systems – Part 1: HVDC

systems with line commutated converters

3 Terms, definitions, and abbreviated terms

3.1 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60633 and the

following apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

© IEC 2022

3.1.1

manned station

MS

HVDC converter station that is operated locally by several operators, 24 h a day

Note 1 to entry: In some systems the manned station controls and observes not only its own converter station but

also the opposite unmanned station.

3.1.2

unmanned station

US

HVDC converter station that is operated remotely with no operator on site

3.1.3

time based maintenance

TBM

maintenance carried out in accordance with a specified time schedule, in most cases annually

3.1.4

condition-based maintenance

CBM

necessary maintenance performed based on the equipment's condition, sometimes combined

with TBM

3.1.5

reliability centred maintenance

RCM

necessary maintenance performed after analyzing the performance of the equipment

3.1.6

operator

person operating the converter station

3.1.7

asset manager

person that manages the plant/asset for the overall planning, operation, maintenance and

performance in accordance with a set of criteria as assigned by the asset owner

3.2 Abbreviated terms

BOD break over diode

BPS by-pass switch

CBM condition-based maintenance

CT current transformer

DGA dissolved gas analysis

GIS gas insulated switchgear

GRTS ground return transfer switch

HMI human-machine interface

LCC line commuted converter

MCB micro circuit breaker

MRTB metallic return transfer breaker

MV medium voltage

NBS neutral bus switch

OEM original equipment manufacturer

– 8 – IEC TR 63065:2017+AMD1:2022 CSV

© IEC 2022

OLT open line test

OLTC on line tap changer

OTDR optical time domain reflectometer

RCM reliability-centred maintenance

RPC reactive power control

SCADA supervisory control and data acquisition

SER sequence of event records

TBM time-based maintenance

TFR transient fault record

4 Operation

4.1 Operation policy

4.1.1 Target reliability and availability

Generally, an availability of 97 % is requested as the minimum value in the design

specification of a new HVDC project. This is based on a forced unavailability of less than 1 %

and a scheduled unavailability of about 2 %. With good quality control applied in the design,

manufacture, installation and testing stages, as well as appropriate operating and careful

maintenance during operation, this requirement can be met in most modern HVDC systems.

According to the survey conducted by CIGRE B4 AG4 ([2] to [6] ) for the period 2003 to 2014,

typical target performance indicators for an HVDC system can be:

a) forced unavailability < 1 %;

b) availability > 97 %.

Scheduled unavailability varies from system to system depending on which operation and

maintenance policy is taken. This can be seen from the performance reports of CIGRE B4

AG4. For example, some systems perform maintenance using 24 h shifts, whereas others

work only 8 h a day and leave the system out of service for 16 h each day and on weekends.

In other systems, maintenance is performed when the generator is not available (thermal unit

out for maintenance or low water conditions, etc.). That is why the typical scheduled

unavailability and overall unavailability is not given above.

The number of forced outages, including sudden interruption of power transmission both by

protections and by manual emergency shutdown, is an important parameter for reliability.

Usually, for a bipolar LCC HVDC scheme, the number of monopole trips is designed to be

four times or fewer a year and the number of bipolar trips below once every ten years.

According to the operation practice of modern HVDC systems, the number of monopole trips

can be even limited to once a year. In systems with more than one converter in series per

pole, the converters' trips can be limited to two trips per converter per station.

Outage hours, a parameter that indicates not only the health of the equipment but also the

ability of maintenance, also affect the reliability and availability considerably. The outage

hours would be longer due to severe damage of the equipment, complex fault analyzing and

troubleshooting, or long waiting times for tools or spare parts. Every effort should be made to

put the HVDC system back into full operation as soon as possible.

Refer to IEC TS 62672-1 for the main performance indicators.

__________

Numbers in square brackets refer to the Bibliography.

© IEC 2022

4.1.2 Operation cost

The operation cost covers the following aspects:

a) human resources (salary for the operation and maintenance staff),

b) consumables,

c) maintenance and tests,

d) auxiliary power and cooling waters,

e) spare parts,

f) improvements and upgrade, and

g) other costs.

There are a number of variables that will impact the operational cost of an HVDC station. The

human resources cost for an unmanned station is much less than for a manned station. The

maintenance cost for an RCM station is much less than for a TBM station. The spare parts

cost for an old station is usually higher than for a new station.

Due to the above reasons, it is hard to give an average cost for running an HVDC converter

station for one year. The costs can be reduced if optimal operation, maintenance and spare

part policies are considered.

4.1.3 Manned or unmanned

Traditionally, an LCC HVDC converter station is a manned station, where several operators

monitor the status of the HVDC link and the equipment 24 h a day. Even for a manned station,

the power flow on the HVDC system may be dispatched remotely. As development in

automation increases, as well as the improvement of HVDC equipment, unmanned stations or

less-manned stations (e.g. manned only during office hours) are more common. Many stations

in Europe (like FennoSkan, SwePol) are unmanned. An unmanned converter station is

operated remotely from an operation centre or even a dispatch centre, and manned only when

something has failed.

Some important HVDC converter stations, such as Itaipu (Brazil), Nelson River (Canada) and

Fulong (China),which are responsible for transmitting 70 % of the power generated by nearby

hydro plants, are still manned stations. Equipment failure can be fixed faster at a manned

station. This in turn contributes to the reliability and availability of the HVDC link.

Whether a station is manned or unmanned can be evaluated technically and economically. If it

takes more than two hours to drive from a nearby city to the station, if the equipment failure

rate of the station is still high, or if the converter station is critical to the grid, it may be better

to man the station.

NOTE Some parts of the text in this document are applicable for manned stations only and are not applicable for

unmanned stations, as there is no operator in the station.

4.2 Operation condition and limits

Before entering commercial operation of an HVDC converter station, the following conditions

are normally required to be fulfilled:

a) the system test (IEC 61975) and the trial operation have been completed successfully;

b) the operating and maintenance staff is available and has been trained;

c) the communication between the dispatch centre and the converter station has been set up;

d) the standard operating procedure for operation and maintenance of the HVDC station has

been established; and

e) spare parts are available.

– 10 – IEC TR 63065:2017+AMD1:2022 CSV

© IEC 2022

Keeping and preserving the life of an HVDC converter station/link is the most important

aspect to manage. Generally, HVDC systems are planned, designed and expected to have a

lifetime of 30 years or more. To meet this requirement, operation limits should be clearly

defined and faithfully followed by the operating and maintenance staff. They at least include:

1) the current, voltage and temperature of the main equipment are within the limits defined

by HVDC suppliers;

2) the temperature, humidity and cleanliness of the valve hall, valve cooling system, relay

buildings and control rooms can meet the requirements of normal operation of related

equipment or devices;

3) the maximum acceptable current for electrodes and station grounds is such that it will not

affect nearby industry pipes or the environment;

4) environment (oil, water, PCB, etc.) management systems and procedures are in place and

the staff regularly reviews these procedures.

4.3 Operations of an HVDC system

4.3.1 General

Subclause 4.3 gives a generic guidance as to how to operate an HVDC system. Note that the

suppliers’ documentation for the given HVDC system shall always be consulted for the

particular HVDC system.

4.3.2 Typical operation configuration

4.3.2.1 General

Availability, reliability, and flexibility for operation and maintenance are closely related to the

operational configuration of HVDC systems. The general configuration and performance of

high voltage direct current (HVDC) system are given in IEC 60919.

4.3.2.2 Point-to-point HVDC system

A point-to-point HVDC system is mainly for bulk transmission. It usually consists of two

separate poles, which can be operated individually or together in a bipolar arrangement. This

kind of system can be operated in three operating configurations.

a) Bipolar ground return with bipolar power control

This is the normal operation mode for a bipolar HVDC system. Active power order is

shared between each pole and the current of both poles is balanced so that the earth

current is kept to a low value, typically less than 10 A. Furthermore, if one pole is tripped,

part of its power can be taken up by the healthy pole so that less power will be lost. The

above benefits make this the most commonly used operation modes in a bipolar HVDC

system.

During bipolar operation, the bipole neutral bus can be connected to either the electrode

or the station ground. This allows the electrode or electrode lines maintenance job to be

done without interruption of normal power transmission. However, it may be noted that

when the station ground is used, in the event of a trip of a pole, another pole will also be

tripped as a consequence of increased station ground current. Attention should also be

paid to a possible station ground potential change at pole ground fault.

Under contaminated conditions, which are often a combination of rain or fog in an HVDC

station or along the corridor of its DC lines, the affected pole can continue the power

transmission by running at reduced voltage, for instance 70 % or 80 % of rated DC

voltage.The current of each pole is balanced by the control system and the earth current is

still limited to a low value. The HVDC system can resume the rated voltage when the

weather conditions improve.

In the case where the DC equipment of one pole develops a fault such that the power or

current needs to be limited to a certain level, the defective pole can be set to pole power

control or pole current control.

© IEC 2022

b) Monopole metallic return

This is an optional operation mode for a bipolar system. If one pole for a bipolar HVDC

system is not available, and if long-term flow of high earth current is not allowable and the

DC line of the other pole is still available, the remaining pole can be connected to both DC

lines and earthed at one predefined station. The equipment belonging to the outage pole

can be checked or repaired and put into operation again. Compared to monopole ground

return, the power loss on the DC line will be doubled, so once the faulty pole is available

again, the operating pole can be transferred back first from metallic return to ground return

and then to bipolar ground return.

c) Monopole ground return

This is also an optional operation mode for a bipolar HVDC system. If one pole is not

available, for example when it is under construction, maintenance, or it is tripped by

protections, and if long-term flow of earth current is acceptable, the remaining pole is

connected to the electrode via the MRTB and can go on operating. The equipment

belonging to the faulty pole, as well as its DC line, can be checked or repaired and put into

operation again.

4.3.2.3 Back-to-back HVDC system

A back-to-back HVDC system is mainly used for asynchronous connections. In this

arrangement, there are no DC transmission lines or DC filters, and both converters are

located at one station. The valves for both the rectifier and the inverter are typically located in

one valve hall.

There is only one operating configuration for a back-to-back system. The 12-pulse converters

of both the rectifier and the inverter are connected directly through busbars. Some back-to-

back systems are comprised of several units so that the loss of a converter will not lead to a

total loss of power transmission or network islanding.

4.3.2.4 Two 12-pulse converters per pole

If the DC voltage or DC current of the converter reach their limits, two 12-pulse converters are

connected in series or in parallel for higher voltage or higher current. This configuration is

applied to Nelson River, Itaipu, and the UHVDC systems in China and India.

The operational configuration of 12-pulse converters per pole is the same as for bipolar

systems except that the system can still be operated in bipole mode when one converter is

out of service (forced or scheduled). In this case, the pole will operate at half the normal

voltage or half the DC current capability.

4.3.2.5 Set up the operation configuration

Operators should evaluate the state of main circuit equipment including:

a) AC configuration and minimum availability of AC filter;

b) availability of HVDC equipment of each pole;

c) allowed ground return current;

d) connectivity of DC lines;

e) ensuring all major or critical alarms have already been acknowledged and reset.

The operational configuration can then be set up by connecting both poles or a single pole, in

ground return or metallic return, and the DC lines of each pole or of both poles.

– 12 – IEC TR 63065:2017+AMD1:2022 CSV

© IEC 2022

4.3.3 Set up the control mode

4.3.3.1 General

A combination of different DC voltage settings, power direction, power control methods, power

control modes, reactive power control methods and reactive power control modes gives a

large combination of options.

Bipolar power control ensures that the total power of the DC bipolar transmission remains at

the ordered value and that the current is equally distributed between the two poles, thus

minimizing the earth current. This is the main mode of operation, and to fully synchronize the

two stations, telecommunication has to be in service.

Pole power control keeps the transmitted DC power equal to the power order given by the

operator. To keep the power constant, the DC voltage variation is compensated by adjusting

the DC current accordingly. The current order I is obtained by dividing the total power order

o

by the DC voltage of the converter.

Pole current control keeps DC current equal to the current order given by the operator.

4.3.3.2 Basic control mode

Before starting the power transmission of an HVDC system, the operators should set up the

following control modes:

a) reference DC voltage of each pole;

b) power transmission direction of each pole;

c) select control method and control mode of active power control;

d) enable joint control as long as telecommunication is available;

e) select control method and control mode of reactive power control;

f) enable or disable the supplementary control function such as frequency control, damping

control.

4.3.3.3 Additional control functions

The inherent high-speed power control capability of the HVDC transmission system may be

used for different objectives such as frequency control, power modulation, and power

oscillation damping.