IEC 61190-1-2:2014

(Main)Attachment materials for electronic assembly - Part 1-2: Requirements for soldering pastes for high-quality interconnects in electronics assembly

Attachment materials for electronic assembly - Part 1-2: Requirements for soldering pastes for high-quality interconnects in electronics assembly

IEC 61190-1-2:2014-02(en-fr) specifies general requirements for the characterization and testing of solder pastes used to make high-quality electronic interconnections in electronics assembly. This standard serves as a quality control document and is not intended to relate directly to the material's performance in the manufacturing process. This edition includes the following significant technical changes with respect to the previous edition:

a) modification of the solder powder size in Table 2;

b) addition of the information of "Reflow condition and profile" in Annex B;

c) addition of a new Annex C.

Matériaux de fixation pour les assemblages électroniques - Partie 1-2: Exigences relatives aux pâtes à braser pour les interconnexions de haute qualité dans les assemblages de composants électroniques

IEC 61190-1-2:2014-02(en-fr) spécifie les exigences d'ordre général relatives à la caractérisation et à l'essai des pâtes à braser utilisées pour obtenir des interconnexions électroniques de haute qualité dans l'assemblage de composants électroniques. La présente norme sert de document de contrôle de la qualité et n'a pas pour objet de s'intéresser directement à la performance du matériau au cours du procédé de fabrication. Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

a) modification des dimensions granulométriques de la poudre à braser dans le Tableau 2;

b) ajout d'informations relatives à la "Condition et profil de refusion" en Annexe B;

c) ajout d'une nouvelle Annexe C.

General Information

- Status

- Published

- Publication Date

- 18-Feb-2014

- Technical Committee

- TC 91 - Electronics assembly technology

- Drafting Committee

- WG 2 - TC 91/WG 2

- Current Stage

- PPUB - Publication issued

- Start Date

- 19-Feb-2014

- Completion Date

- 15-Mar-2014

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 61190-1-2:2014 is an international standard developed by the International Electrotechnical Commission (IEC), focusing on the requirements for soldering pastes used in electronics assembly. Specifically, this standard sets general requirements for characterization and testing of solder pastes intended for creating high-quality electronic interconnections. It serves as a quality control guideline, ensuring consistent material specifications, but does not directly address manufacturing process performance.

The 2014 edition (Edition 3.0) introduces key updates such as revised solder powder size classifications, detailed guidance on reflow conditions and profiles, and additional annexes comparing particle size measurement methods. This standard applies globally and assists manufacturers, suppliers, and quality engineers in maintaining reliable and trusted solder paste quality for electronic assemblies.

Key Topics

Solder Paste Characterization: Defines measurement methods and test procedures for:

- Alloy composition

- Flux properties and shelf life

- Solder powder particle size and shape

- Viscosity and slump tests

- Tackiness and wetting ability

- Solder ball formation as a defect indicator

Standardized Product Description: Provides structured terminology and classification for solder paste types to facilitate clearer communication among manufacturers and users.

Quality Assurance: Outlines responsibilities for inspection, sampling plans for qualification and acceptance, and requirements for test equipment and reporting to ensure consistent product quality.

Technical Updates:

- Revised solder powder size specifications (see Table 2 in the standard)

- Inclusion of Annex B covering recommended reflow conditions and thermal profiles to optimize soldering outcomes

- Addition of Annex C that compares laser diffraction and screen methods for particle size measurement

Applications

IEC 61190-1-2:2014 is essential for industries involved in manufacturing and assembly of electronic devices where reliability of interconnects is critical. Practical applications include:

Electronics Manufacturing: Ensuring solder pastes meet stringent quality requirements for producing PCB assemblies with high interconnect integrity.

Component Assembly: Aiding process engineers in selecting and verifying solder paste materials that comply with international norms for flux activity, particle size, and viscosity.

Quality Control Laboratories: Providing comprehensive test methodologies to assess solder paste characteristics for acceptance or rejection before use.

Supplier Certification: Assisting solder paste suppliers to certify their products against recognized benchmarks, facilitating global market acceptance.

R&D and Process Optimization: Supplying foundational data for developing new solder paste formulations or adjusting reflow profiles to enhance assembly reliability.

Related Standards

IEC 61190-1-2:2014 is part of the broader IEC 61190 series on attachment materials for electronic assembly. Related standards in this series cover other types of soldering materials and attachment technologies, including:

- IEC 61190-1-1 – Requirements for soldering fluxes

- IEC 61190-1-3 – Specifications for solid solder alloys in electronics

- IEC 61190-2 – Assembly techniques and soldering processes

Additionally, this standard references companion documents and normative publications on test methods, safety, and environmental considerations relevant to electronics assembly materials.

By adhering to IEC 61190-1-2:2014, manufacturers, assemblers, and quality assurance teams can ensure the use of high-quality soldering pastes that meet international requirements, resulting in better reliability, performance, and longevity of electronic assemblies worldwide.

Frequently Asked Questions

IEC 61190-1-2:2014 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Attachment materials for electronic assembly - Part 1-2: Requirements for soldering pastes for high-quality interconnects in electronics assembly". This standard covers: IEC 61190-1-2:2014-02(en-fr) specifies general requirements for the characterization and testing of solder pastes used to make high-quality electronic interconnections in electronics assembly. This standard serves as a quality control document and is not intended to relate directly to the material's performance in the manufacturing process. This edition includes the following significant technical changes with respect to the previous edition: a) modification of the solder powder size in Table 2; b) addition of the information of "Reflow condition and profile" in Annex B; c) addition of a new Annex C.

IEC 61190-1-2:2014-02(en-fr) specifies general requirements for the characterization and testing of solder pastes used to make high-quality electronic interconnections in electronics assembly. This standard serves as a quality control document and is not intended to relate directly to the material's performance in the manufacturing process. This edition includes the following significant technical changes with respect to the previous edition: a) modification of the solder powder size in Table 2; b) addition of the information of "Reflow condition and profile" in Annex B; c) addition of a new Annex C.

IEC 61190-1-2:2014 is classified under the following ICS (International Classification for Standards) categories: 01 - GENERALITIES. TERMINOLOGY. STANDARDIZATION. DOCUMENTATION; 31.190 - Electronic component assemblies. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61190-1-2:2014 has the following relationships with other standards: It is inter standard links to IEC 61190-1-2:2007. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61190-1-2:2014 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61190-1-2 ®

Edition 3.0 2014-02

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Attachment materials for electronic assembly –

Part 1-2: Requirements for soldering pastes for high-quality interconnects in

electronics assembly

Matériaux de fixation pour les assemblages électroniques –

Partie 1-2: Exigences relatives aux pâtes à braser pour les interconnexions de

haute qualité dans les assemblages de composants électroniques

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing more than 30 000 terms and

Technical Specifications, Technical Reports and other definitions in English and French, with equivalent terms in 14

documents. Available for PC, Mac OS, Android Tablets and additional languages. Also known as the International

iPad. Electrotechnical Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a More than 55 000 electrotechnical terminology entries in

variety of criteria (reference number, text, technical English and French extracted from the Terms and Definitions

committee,…). It also gives information on projects, replaced clause of IEC publications issued since 2002. Some entries

and withdrawn publications. have been collected from earlier publications of IEC TC 37,

77, 86 and CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient plus de 30 000 termes et définitions en

Spécifications techniques, Rapports techniques et autres

anglais et en français, ainsi que les termes équivalents dans

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

14 langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

Plus de 55 000 entrées terminologiques électrotechniques, en

La recherche avancée permet de trouver des publications IEC

en utilisant différents critères (numéro de référence, texte, anglais et en français, extraites des articles Termes et

comité d’études,…). Elle donne aussi des informations sur les Définitions des publications IEC parues depuis 2002. Plus

projets et les publications remplacées ou retirées. certaines entrées antérieures extraites des publications des

CE 37, 77, 86 et CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 61190-1-2 ®

Edition 3.0 2014-02

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Attachment materials for electronic assembly –

Part 1-2: Requirements for soldering pastes for high-quality interconnects in

electronics assembly

Matériaux de fixation pour les assemblages électroniques –

Partie 1-2: Exigences relatives aux pâtes à braser pour les interconnexions de

haute qualité dans les assemblages de composants électroniques

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX T

ICS 31.190 ISBN 978-2-83221-423-7

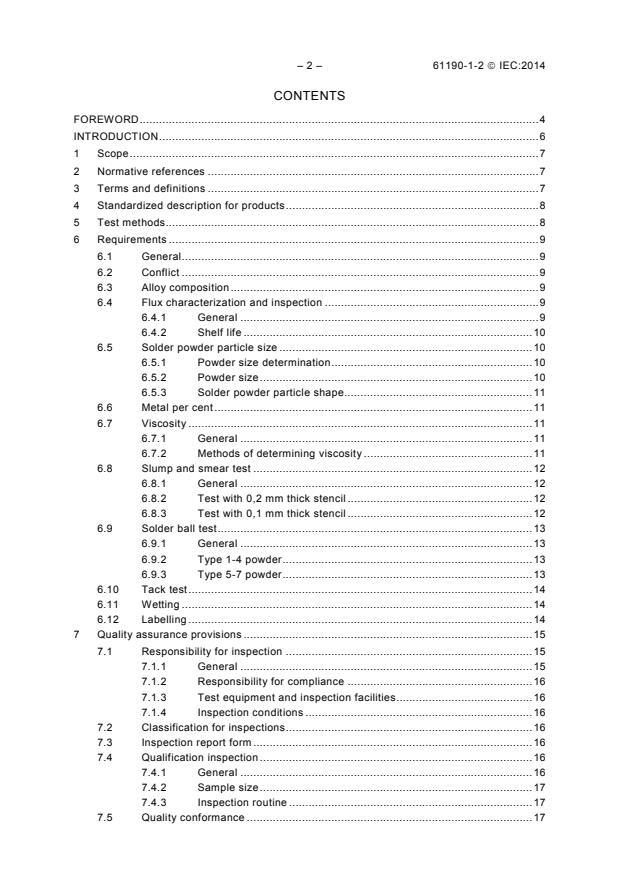

– 2 – 61190-1-2 IEC:2014

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 7

4 Standardized description for products . 8

5 Test methods . 8

6 Requirements . 9

6.1 General . 9

6.2 Conflict . 9

6.3 Alloy composition . 9

6.4 Flux characterization and inspection . 9

6.4.1 General . 9

6.4.2 Shelf life . 10

6.5 Solder powder particle size . 10

6.5.1 Powder size determination . 10

6.5.2 Powder size . 10

6.5.3 Solder powder particle shape. 11

Metal per cent . 11

6.6

6.7 Viscosity . 11

6.7.1 General . 11

6.7.2 Methods of determining viscosity . 11

6.8 Slump and smear test . 12

6.8.1 General . 12

6.8.2 Test with 0,2 mm thick stencil . 12

6.8.3 Test with 0,1 mm thick stencil . 12

6.9 Solder ball test . 13

6.9.1 General . 13

6.9.2 Type 1-4 powder . 13

6.9.3 Type 5-7 powder . 13

Tack test . 14

6.10

6.11 Wetting . 14

6.12 Labelling . 14

7 Quality assurance provisions . 15

7.1 Responsibility for inspection . 15

7.1.1 General . 15

7.1.2 Responsibility for compliance . 16

7.1.3 Test equipment and inspection facilities . 16

7.1.4 Inspection conditions . 16

7.2 Classification for inspections . 16

7.3 Inspection report form . 16

7.4 Qualification inspection . 16

7.4.1 General . 16

7.4.2 Sample size . 17

7.4.3 Inspection routine . 17

7.5 Quality conformance . 17

61190-1-2 IEC:2014 – 3 –

7.5.1 General . 17

7.5.2 Sampling plan . 17

7.5.3 Rejected lots . 17

8 Preparation for delivery . 17

9 Additional information – Performance and shelf life extension inspections . 18

Annex A (normative) Test report on solder paste . 19

Annex B (informative) Reflow condition and profile . 20

Annex C (informative) Typical comparison of particle size distributions between laser

diffraction method and screen method . 21

Bibliography . 22

Figure 1 – Slump test stencil thickness, 0,20 mm . 12

Figure 2 – Slump test stencil thickness, 0,10 mm . 13

Figure 3 – Solder ball test standards . 15

Figure C.1 – Typical comparison between laser diffraction and sieving . 21

Table 1 – Standardized solder paste description . 8

Table 2 – Standard solder powders . 10

Table 3 – Test methods for particle size distribution . 11

Table 4 – Solder paste qualification inspection . 17

Table 5 – User inspection for solder paste prior to use . 18

Table A.1 – Solder paste inspection report form . 19

– 4 – 61190-1-2 IEC:2014

INTERNATIONAL ELECTROTECHNICAL COMMISSION

______________

ATTACHMENT MATERIALS FOR ELECTRONIC ASSEMBLY –

Part 1-2: Requirements for soldering pastes

for high-quality interconnects in electronics assembly

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61190-1-2 has been prepared by IEC technical committee 91:

Electronics assembly technology.

This third edition cancels and replaces the second edition published in 2007. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) modification of the solder powder size in Table 2;

b) addition of the information of “Reflow condition and profile” in Annex B;

c) addition of a new Annex C.

61190-1-2 IEC:2014 – 5 –

The text of this standard is based on the following documents:

CDV Report on voting

91/1154A/FDIS 91/1166/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 61190 series, published under the general title Attachment

materials for electronic assembly, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 6 – 61190-1-2 IEC:2014

INTRODUCTION

This part of IEC 61190 defines the characteristics of solder paste through the definitions of

properties and specification of test methods and inspection criteria. Materials include solder

powder and solder paste flux blended to produce solder paste. Solder powders are classified

according to both shape and size distribution of the particles. It is not the intention of this

standard to exclude those particle sizes or distributions not specifically listed. For flux

properties of solder paste, including classification and testing, see IEC 61190-1-1.

The requirements for solder paste are defined in general terms. In practice, where more

stringent requirements are necessary, additional requirements may be defined by mutual

agreement between the user and supplier. Users are cautioned to perform tests (beyond the

scope of this specification) to determine the acceptability of the solder paste for specific

processes.

This standard is intended to be applicable to all types of solder paste used for soldering in

general, as well as for soldering in electronics assembly. The solder pastes involved relate to

all aspects of application. Generic specifications for soldering pastes are given in ISO 9454-2.

61190-1-2 IEC:2014 – 7 –

ATTACHMENT MATERIALS FOR ELECTRONIC ASSEMBLY –

Part 1-2: Requirements for soldering pastes

for high-quality interconnects in electronics assembly

1 Scope

This part of IEC 61190 specifies general requirements for the characterization and testing of

solder pastes used to make high-quality electronic interconnections in electronics assembly.

This standard serves as a quality control document and is not intended to relate directly to the

material's performance in the manufacturing process.

Related information on flux characterization, quality control and procurement documentation

for solder flux and flux containing material may be found in IEC 61190-1-1.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60194, Printed board design, manufacture and assembly – Terms and definitions

IEC 61189-5-3 , Test methods for electrical materials, interconnection structures and

assemblies – Part 5-3: Test methods for printed board assemblies: Soldering paste

IEC 61190-1-1, Attachment materials for electronic assembly – Part 1-1: Requirements for

soldering fluxes for high quality interconnections in electronics assembly

IEC 61190-1-3, Attachment materials for electronic assembly – Part 1-3: Requirements for

electronic grade solder alloys and fluxed and non-fluxed solid solders for electronic soldering

applications

ISO 9454-2, Soft soldering fluxes – classification and requirements – Part 2: Performance

requirements

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60194, as well as

the following apply.

3.1

drying

ambient or heating process to evaporate volatile components from solder paste which may, or

may not, result in melting of rosin/resin

3.2

rheology

___________

To be published.

– 8 – 61190-1-2 IEC:2014

study of the change in form and the flow of matter, generally characterized by elasticity,

viscosity, and plasticity

3.3

lead free solder

solder alloy which lead content is equal to, or less than 0,10 % by mass

3.4

thinner

thinner paste

solvent or paste system with, or without, activator which is added to solder paste to replace

evaporated solvents, adjust viscosity, or reduce solids content

3.5

viscosity

internal friction of a fluid, caused by molecular attraction, which makes it resist a tendency to

flow, expressed in pascal-seconds (Pa·s)

4 Standardized description for products

The solder paste product shall be described as outlined in Table 1.

Table 1 – Standardized solder paste description

Alloy Flux Powder size Nominal metal Viscosity

a

designation classification type content

b

Designation from Classification from Type no. Weight per cent Pa·s

IEC 61190-1-3 IEC 61190-1-1

or ISO 9454-2

a

As defined and determined in IEC 61190-1-1 for low (L), moderate (M), and high (H) activity of the flux residues.

b

See Table 2.

5 Test methods

The test methods used in this standard are taken from IEC 61189-5-3:

Test methods for electrical materials, interconnection structures and assemblies –

Part 5-3:Test methods for printed board assemblies: Soldering paste:

5-3X01 Paste flux viscosity – T-Bar spindle method (5X02)

5-3X02 Spread test, liquid or extracted solder flux and solder paste (5X03)

5-3X03 Solder paste viscosity – t-bar spin spindle method (applicable for 300 Pa-s to

1 600 Pa-s) (5X04)

5-3X04 Solder paste viscosity – t-bar spindle method (applicable at less than 300 Pa-s)

(5X05)

5-3X05 Solder paste viscosity – spiral pump method (for 300 Pa-s to 1 600 Pa-s) (5X06)

5-3X06 Solder paste viscosity – spiral pump method (applicable at less than 300 Pa-s)

(5X07)

5-3X07 Solder paste – slump test (5X08)

___________

(5X0x ) ; Test number in IEC 61189-5:2006, see Bibliography.

61190-1-2 IEC:2014 – 9 –

5-3X08 Solder paste – solder ball test (5X09)

5-3X09 Solder paste – tack test (5X10)

5-3X10 Solder paste – wetting test (5X11)

5-3X11 Solder powder particle size distribution – screen method (6X01)

5-3X12 Solder powder particle size distribution – measuring microscope method (6X02)

5-3X13 Solder powder particle size distribution – optical image analyzer method (6X03)

5-3X14 Solder powder particle size distribution – Measuring laser diffraction method (6X04)

5-3X15 Determination of maximum solder powder particle size ( 6X05)

5-3X16 Solder paste metal content by weight (6X06)

6 Requirements

6.1 General

Except when otherwise specified in the design or assembly drawings, or instructions by the

user, the soldering pastes covered by this standard shall conform with 6.2 to 6.12.

6.2 Conflict

In the event of conflict between the requirements of this standard and other requirements of

the applicable acquisition documents, the precedence in which documents shall govern in

descending order is as follows:

a) the applicable acquisition document;

b) the applicable specification sheet/drawing;

c) this standard;

d) applicable normative references.

6.3 Alloy composition

The alloy composition of the solder pastes shall be characterized by the supplier in

accordance with the alloy characterization requirements specified in IEC 61190-1-3 and shall

be inspected in accordance with the alloy inspection requirements of IEC 61190-1-3. The

results of these inspections should be recorded on the report form included in IEC 61190-1-3

and the alloy type shall be recorded on the solder paste report form (see Table A.1).

The percentage of each element in an alloy shall be determined by any standard analytical

procedure. Wet chemistry shall be used as the reference procedure.

6.4 Flux characterization and inspection

6.4.1 General

The fluxes in solder pastes shall be characterized by the supplier in accordance with the flux

characterization requirements specified in IEC 61190-1-1 and shall be inspected in

accordance with the flux inspection requirements of IEC 61190-1-1. The results of these

inspections should be recorded on the report form included in IEC 61190-1-1 and the flux type

shall be recorded on the solder paste report form (see Table A.1). If the reflow temperature is

unsuitable for inspection, a different reflow temperature should be agreed upon by user and

supplier.

___________

(6X0x ) ; Test number in IEC 61189-6:2006, see Bibliography.

– 10 – 61190-1-2 IEC:2014

6.4.2 Shelf life

If the shelf life of the solder paste has expired, but the paste still meets performance testing,

then it may be used. Paste which has been re-qualified can only be used directly after re-

qualification.

6.5 Solder powder particle size

6.5.1 Powder size determination

Powder size determination shall be made using this standard. Alternate test procedures may

be agreed upon by user and supplier.

6.5.2 Powder size

6.5.2.1 General

When tested in accordance with 6.5.2.2, the powder size shall be classified by type as per a

standard sieve size or the nearest sieve size shown which matches the values of Table 2.

Table 2 – Standard solder powders

a

Less than 0,5 % 10 % Maximum 80 % Minimum 10 % Maximum

Type

larger than between between less Than

µm µm µm µm

1 160 150 to 160 75 to 150 75

2 80 75 to 80 45 to 75 45

3 60 45 to 60 25 to 45 25

4 50 38 to 50 20 to 38 20

5 40 25 to 40 15 to 25 15

6 25 15 to 25 5 to 15 5

7 15 11 to 15 2 to 11 2

a

Basic powder size symbol for each powder size type.

6.5.2.2 Maximum powder size (fineness of grind)

The maximum powder size shall be determined in accordance with IEC 61189-5-3, Test

method 5-3X15 (6X05) .

6.5.2.3 Solder powder

Powder particle size distribution shall be determined by a suitable test method using

2 2 2

IEC 61189-5-3, Test methods 5-3X11 (6X01) , 5-3X12 (6X02) , 5-3X13 (6X03) or 5-

3X14(6X04) for minimum particle size, as shown in Table 3.

61190-1-2 IEC:2014 – 11 –

Table 3 – Test methods for particle size distribution

Type of weight per cent Test methods

nominal size

1, 2 1, 2, 3, 4

3, 4 2, 3, 4

5, 6, 7 3, 4

Sieve method

Microscopic method

Optical image analyzer

4 4

Laser scattering reflectometry

6.5.3 Solder powder particle shape

6.5.3.1 Powder shape

Solder powder shape shall be spherical with maximum length-to-width ratio of 1,2 when tested

in accordance with 6.5.3.2. Other shapes shall be acceptable if agreed upon by user and

supplier.

6.5.3.2 Determination of solder powder particle shape

Solder powder particle shape shall be determined by visual observation of the powder with a

binocular microscope at a magnification sufficient to determine the percentage that are

spherical or elliptical (length-to-width ratio of less than 2). Alternatively determine the

percentage of particles with aspect ratio of 1,2 or less using image analysis. Powder with 90 %

of the particles that are spherical shall be classified as spherical; all other powders shall be

classified as non-spherical.

Solder powder roundness is determined with a light beam scatter and shall be classified as

spherical if the deviation is 1:0 (perfectly spherical) to 1:07. Powders with values above 1:07

shall be classified as non-spherical.

6.6 Metal per cent

The metal content should be range from 65 % (by weight) to 96 % (by weight) when tested in

accordance with IEC 61189-5-3, test method 5-3X16(6X06) . The metal per cent shall be

within ± 1 % of the nominal value specified on the user's purchase order.

6.7 Viscosity

6.7.1 General

If a measure of viscosity is required it shall be as agreed between user and supplier. The

measurement and test conditions shall be in accordance with 6.7.2.

6.7.2 Methods of determining viscosity

The methods for determining the viscosity of solder paste in the range of 300 Pa·s to

1 600 Pa·s shall be in accordance with IEC-61189-5-3, test method 5-3X03, or test method 5-

3X05. The method for determining viscosity of solder paste in the range of 50 Pa·s to

300 Pa·s shall be in accordance with IEC 61189-5-3, test method 5-3X04 or test method 5-

3X06.

___________

See Annex C (informative): Typical comparison of particle size distributions between laser diffraction method

and screen method.

– 12 – 61190-1-2 IEC:2014

6.8 Slump and smear test

6.8.1 General

Unless otherwise specified in the contract or purchase order, slump is assessed using two

stencil thicknesses and three land (deposit) sizes in accordance with 6.7.2 and 6.8.3.

6.8.2 Test with 0,2 mm thick stencil

The 0,63 mm × 2,03 mm lands of the stencil shown in Figure 1 when tested in accordance

IEC-61189-5-3, test method 5-3X07 at ambient, should show no evidence of bridging between

lands when spacing is 0,56 mm or greater. When tested in accordance with IEC-61189-5-3,

test method 5-3X07 at elevated temperature, the specimen shall show no evidence of bridging

between pads when the spacing is 0,63 mm or greater. The 0,33 mm × 2,03 mm lands of the

stencil shown in the Figure 1 pattern, when tested in IEC-61189-5-3, test method 5-3X07 at

ambient, shall show no evidence of bridging at spacing of 0,25 mm or greater; and when

tested as per IEC-61189-5-3, test method 5-3X07 at elevated temperature, they shall show no

evidence of bridging at spacing of 0,30 mm or greater.

Spacing 0,33 0,41 0,48 0,56 0,63 0,71 0,79 0,71 0,63 0,56 0,48 0,41 0,33 Spacing

mm mm

Spacing 0,06

0,10

mm Pad size: 0,63 mm × 2,03 mm

0,15

– 14 identical pads per row

0,20

– Same spacings each row

0,25

0,30

0,35

0,40

Vertical

0,45 row

0,40

0,35

0,30

0,25

0,20

0,15

0,10

Spacing

0,06

mm

Pad size: 0,33 mm × 2,03 mm

– 18 identical pads per row

– Same spacings each row

IEC 0613/14

Figure 1 – Slump test stencil thickness, 0,20 mm

6.8.3 Test with 0,1 mm thick stencil

The 0,33 mm × 2,03 mm lands of the stencil shown in Figure 2, when tested in accordance

IEC-61189-5-3, test method 5-3X07 at ambient, should show no evidence of bridging at

spacing of 0,25 mm or greater. When tested as per IEC-61189-5-3, test method 5-3X07 at

elevated temperature, the lands shall show no evidence of bridging at spacing of 0,30 mm or

greater.

61190-1-2 IEC:2014 – 13 –

The 0,2 mm × 2,03 mm lands of the stencil shown in Figure 2, when tested in accordance with

IEC-61189-5-3, test method 5-3X07 at ambient, shall show no bridging at spacing of

0,175 mm or greater. When tested in accordance with IEC-61189-5-3, test method 5-3X07 at

elevated temperature, the lands shall show no evidence of bridging at spacing of 0,20 mm or

greater.

Pad size: 0,20 mm × 2,03 mm

– 16 identical pads per row

– Same spacings each row

Spacing 0,06

0,10

mm

0,15

0,20

0,25

0,30

0,35

0,40

0,075 Spacing

0,100

0,45

mm

0,125

0,150

0,40

0,175

Vertical

0,200

0,35

0,250

row

0,30

0,300

0,25 0,250

0,20 0,200

0,175

0,15

0,150

0,10

Spacing 0,125

Spacing

0,100

0,06

mm

0,075 mm

Pad size: 0,33 mm × 2,03 mm

– 18 identical pads per row

– Same spacings each row

IEC 0614/14

Figure 2 – Slump test stencil thickness, 0,10 mm

6.9 Solder ball test

6.9.1 General

The solder paste, when tested in accordance with the applicable method listed below, shall

meet the requirements for random solder particles (solder balls) as specified. If the solder

paste is required to reflow in a nitrogen atmosphere, for example in the case of indium (In)

containing solder paste, a solder ball test under controlled nitrogen atmosphere should be

allowable.

6.9.2 Type 1-4 powder

The solder paste with type 1 through 4 type powder, as defined in IEC-61189-5-3, test method

5-3X08, shall meet the acceptance criteria presented in Figure 3. In addition, individual solder

balls of greater than 75 µm shall not form on more than one of the three test patterns used in

the evaluation.

6.9.3 Type 5-7 powder

The solder paste with type 5 through 7 type powder as defined in IEC-61189-5-3, test method

5-3X08, shall meet the acceptance criteria presented in Figure 3. If necessary, it is

recommended to test in a controlled nitrogen atmosphere. In addition, individual solder balls

of greater than 50 µm shall not form on more than one of the three test patterns used in the

evaluation. Tests shall be performed while specimen is in a controlled nitrogen atmosphere.

– 14 – 61190-1-2 IEC:2014

6.10 Tack test

The solder paste shall be tested in accordance with IEC-61189-5-3, test method 5-3X09.

Minimum holding force and time shall be agreed upon by user and supplier.

6.11 Wetting

When tested in accordance with IEC-61189-5-3, test method 5-3X10, the solder paste shall

uniformly wet the copper lands of the coupon without evidence of dewetting or non-wetting. If

the solder paste is required to reflow under a nitrogen atmosphere, for example in case of

indium (In) containing solder paste, wetting test under a controlled nitrogen atmosphere

should be allowable.

6.12 Labelling

The supplier shall label each container of solder paste with the following:

a) the supplier's name and address;

b) the paste classification/designation, for example, designation of alloy name, designation of

powder size , flux classification, and supplier's designation of the solder paste, if different;

c) the net mass of solder paste;

d) the batch number;

e) the date of manufacture;

f) expiration date (see Clause 9);

g) all required environment, health and safety warnings;

h) percent metal;

i) information about lead free soldering process if necessary.

61190-1-2 IEC:2014 – 15 –

IEC 0615/14 IEC 0616/14

The solder paste has melted into a big single solder The solder paste has melted into a big solder ball,

ball. which must not be surrounded by clustered small

solder balls.

a) Category 1 – Preferred (pass) b) Category 2 – Acceptable (pass)

IEC 0617/14 IEC 0618/14

The solder paste has melted into a big solder ball, The molten solder paste has not melted completely or

which is surrounded by clustered solder balls. has formed many individual solder balls.

c) Category 3 – Unacceptable, clusters d) Category 4 – Unacceptable (reject)

(reject)

Figure 3 – Solder ball test standards

7 Quality assurance provisions

7.1 Responsibility for inspection

7.1.1 General

The solder paste supplier is responsible for the performance of all inspection specified herein

except the performance inspections which are the responsibility of the user. The solder paste

– 16 – 61190-1-2 IEC:2014

supplier may use its own or any other facilities suitable for the performance of the inspections

specified herein, unless disapproved by the user. The user reserves the right to perform any

of the inspections set forth in the specification where such inspections are deemed necessary

to ensure that supplies and services conform to prescribed requirements.

7.1.2 Responsibility for compliance

7.1.2.1 General

Materials covered by this specification shall meet all requirements of Clause 6. The

inspection(s) excluding the performance inspections defined in this specification shall become

a part of the supplier's overall inspection system or quality program. The supplier has

responsibility of ensuring that all products or supplies submitted to the user for acceptance

comply with all requirements of the purchase order contract.

7.1.2.2 Quality assurance program

When required by the user, a quality assurance program for material furnished under this

specification shall be established and maintained in accordance with a quality assurance

system, or as otherwise agreed on between user and supplier, and shall be monitored by the

qualifying activity.

7.1.3 Test equipment and inspection facilities

Test/measuring equipment and inspection facilities, of sufficient accuracy, quality, and

quantity to permit performance of the required inspection(s), shall be established and

maintained or designated by the supplier. Establishment and maintenance of a calibration

system to control the accuracy of the measuring and test equipment shall be in accordance

with an agreed-upon quality assurance system.

7.1.4 Inspection conditions

Unless otherwise specified herein, all inspections shall be performed in accordance with the

test conditions specified in Clause 6.

7.2 Classification for inspections

The inspections specified herein are classified as follows:

a) qualification inspection (7.4);

b) quality conformance (7.5);

c) performance inspection (9).

7.3 Inspection report form

Table A.1 is a report form suitable, and recommended, for recording the results of solder

paste inspections. Where definitive test results are not required or appropriate, successful

completion of inspections should be indicated by checkmarks on the solder paste report form.

7.4 Qualification inspection

7.4.1 General

Qualification inspection may be performed at accredited laboratory or a laboratory acceptable

to the user on samples produced with equipment and procedures normally used in production.

61190-1-2 IEC:2014 – 17 –

7.4.2 Sample size

Sample sizes shall be appropriate to the solder paste being inspected and the inspection

being performed.

7.4.3 Inspection routine

The sample shall be subjected to the inspections specified in Table 4.

Table 4 – Solder paste qualification inspection

Inspection IEC 61189-5-3 test method Qualification

Metal content (6.6) 5-3X16(6X05) X

Viscosity (6.7.2) 5-3X03, 5-3X04, 5-3X05, 5-3X06 X

Solder ball (6.9.2, 6.9.3) 5-3X08 X

Slump (6.8.2, 6.8.3) 5-3X07 X

Alloy composition (6.3) Standard analytical procedure X

Flux characterization (6.4) IEC 61190-1-1 X

Flux characteristics (6.4) IEC 61190-1-1 X

2 2 2

Powder size (6.5.2.3) 5-3X11(6X01) , 5-3X12(6X02) , 5-3X13(6X03) , X

5-3X14(6X04)

Maximum powder size (6.5.2.2) 5-3X15(6X04) X

Powder shape (6.5.3.2) Binocular microscope, sufficient magnification X

Tack (6.10) 5-3X09 X

Wetting (6.11) 5-3X10 X

7.5 Quality conformance

7.5.1 General

The material supplier shall perform those inspections necessary to insure that the process is

in control and to insure that the product is within specification limit.

7.5.2 Sampling plan

Statistical sampling and inspection shall be in accordance with an approved quality program.

(See 7.1.2).

7.5.3 Rejected lots

If an inspection lot is rejected, the supplier may modify it to correct the defects, or screen out

the defective units and resubmit for reinspection. Resubmitted lots shall be subject to

tightened inspection. Such lots shall be separate from new lots, and shall be clearly identified

as reinspected lots.

8 Preparation for delivery

Preservation packaging, packing and marking for shipment, and identification shall be as

specified in the contract or purchase order.

– 18 – 61190-1-2 IEC:2014

9 Additional information – Performance and shelf life extension inspections

Performance inspections are useful in assessing how well the solder products will perform in

a particular application. Table 5 indicates the methodology that the user should employ to

verify performance and shelf life extension of solder paste.

Table 5 – User inspection for solder paste prior to use

Inspections IEC 61189-5-3 Performance Shelf life

test method extension

Visual X X

Viscosity (6.7.2) 5-3X03, 5-3X04, X X

5-3X05, 5-3X06

Solder ball (6.9.2, 6.9.3) 5-3X08 X

Slump (6.8.2, 6.8.3) 5-3X07 X

Tack (6.10) 5-3X09 X

Wetting (6.11) 5-3X10 X

61190-1-2 IEC:2014 – 19 –

Annex A

(normative)

Test report on solder paste

Table A.1 – Solder paste inspection report form

Enter appropriate/information in top portion of report and complete report by entering the test

results or checkmarks in the appropriate spaces. Add the measurements, values, pictures, et

al. as an attachment to this report.

Inspection purpose:

_____Qualification Supplier’s identification________________

_____Shelf life extension Supplier’s batch number________________

_____Performance Date of manufacture ___________________

Original USE-by date___________________

Revised USE-by date___________________

Date inspection completed: ________________________ Overall results: ______Pass_____Fail

Inspection performed by: Witnessed by:

________________________ ____________________________

Inspections Requirement Test method User’s actual Test P/F * Tested by and date

clause requirement result

Material

Visual

Metal content

Viscosity

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...