IEC 60204-31:2013

(Main)Safety of machinery - Electrical equipment of machines - Part 31: Particular safety and EMC requirements for sewing machines, units and systems

Safety of machinery - Electrical equipment of machines - Part 31: Particular safety and EMC requirements for sewing machines, units and systems

IEC 60204-31:2013 applies to electrical and electronic equipment, sewing machines, units and systems, designed specifically for professional use in the sewing industry. It is applicable to the electrical equipment or parts of the electrical equipment which operate with nominal supply voltages not exceeding 1 000 V for alternating current and not exceeding 1 500 V for direct current, and with nominal frequencies not exceeding 200 Hz. This fourth edition cancels and replaces the third edition, published in 2001 and constitutes a technical revision. It includes the following changes:

- Alignment of the normative references;

- Alignment of titles and subtitles to the IEC 60204-1;

- Revision of Annex AA to align this annex with the relevant IEC standards.

This publication is to be read in conjunction with IEC 60204-1:2009.

Sécurité des machines - Equipement électrique des machines - Partie 31: Exigences particulières de sécurité et de CEM pour machines à coudre, unités et systèmes de couture

La CEI 60204-31:2013 est applicable à l'équipement aussi bien électrique qu'électronique des machines à coudre, des unités et systèmes de couture conçus spécialement pour un usage professionnel dans l'industrie de la couture. Elle est applicable à l'équipement électrique ou à des parties de l'équipement électrique fonctionnant sous une tension nominale ne dépassant pas 1 000 V en courant alternatif ou 1 500 V en courant continu, et pour des fréquences nominales ne dépassant pas 200 Hz. Cette quatrième édition annule et remplace la troisième édition, parue en 2001 dont elle constitue une révision technique. Cette édition inclut les modifications techniques suivantes:

- Alignement des références normatives;

- Alignement des titres et sous-titres à la CEI 60204-1;

- La révision de l'Annexe AA pour aligner cette annexe avec les normes CEI correspondantes.

Cette publication doit être lue conjointement avec la CEI 60204-1:2009.

General Information

- Status

- Published

- Publication Date

- 22-Apr-2013

- Technical Committee

- TC 44 - Safety of machinery - Electrotechnical aspects

- Drafting Committee

- MT 60204-31 - TC 44/MT 60204-31

- Current Stage

- PPUB - Publication issued

- Start Date

- 23-Apr-2013

- Completion Date

- 30-Apr-2013

Relations

- Effective Date

- 05-Sep-2023

Overview

The IEC 60204-31:2013 standard, issued by the International Electrotechnical Commission (IEC), addresses the safety and electromagnetic compatibility (EMC) requirements specific to the electrical and electronic equipment of sewing machines, units, and systems designed for professional use in the sewing industry. This part 31 of IEC 60204 series ensures safe operation and electrical compliance for professional-grade sewing machines operating at nominal voltages up to 1,000 V AC and 1,500 V DC, with frequencies not exceeding 200 Hz.

This fourth edition revises and replaces the previous 2001 edition, aligning references and terminology with IEC 60204-1 and updating Annex AA in line with relevant IEC standards. It complements IEC 60204-1 and focuses on electrical hazards while considering EMC to avoid interference with other equipment.

Key Topics

Scope and Applicability

Applicable to professional sewing machines, units, and systems used in dry, clean industrial environments. It excludes household sewing machines and non-electrical hazards such as mechanical guarding and noise emission.Electrical Safety Requirements

Ensures protection against electric shock, proper wiring, equipotential bonding, and secure termination of supply conductors with disconnecting devices for safe maintenance and operation.Control and Operator Interfaces

Specifies requirements for control circuits, machine-mounted control devices, and operator interfaces for safe and reliable operation.Electromagnetic Compatibility (EMC)

Includes comprehensive EMC requirements (Annex AA) covering emission limits and immunity tests for radiated disturbances, conducted disturbances, surges, electrostatic discharge, and voltage variations, ensuring machines operate reliably without causing or suffering interference.Marking and Documentation

Emphasizes the need for clear marking, warning signs, and technical documentation to support safe installation, operation, and maintenance.Technical Revisions

Updates normative references, harmonizes chapter titles and subtitles with IEC 60204-1, and revises Annex AA to align with industry EMC standards.

Applications

IEC 60204-31:2013 is essential for manufacturers, designers, and safety engineers involved with:

Professional Sewing Machinery

Industrial sewing machines and sewing units tailored for textile manufacturing, garment production, and related sectors.Sewing Systems Integration

Multi-unit sewing systems where electrical equipment must comply with both safety and EMC requirements to form a safe production line.Electrical Safety Compliance

Ensuring that sewing machines meet international safety standards by addressing shock hazards, proper wiring, and control safety functions.Regulatory and Compliance Testing

Assists in preparing machines for certification and legal compliance in global markets, focusing on electrical safety and EMC performance.Maintenance and Inspection Protocols

Guides the verification and inspection of electrical equipment on sewing machines to maintain ongoing safety and performance.

Related Standards

IEC 60204-1:2005 / Amend.1:2008 – General requirements for electrical equipment of machines, harmonized with this standard.

IEC 60335-2-28 – Safety requirements for household and similar electrical sewing machines.

IEC 61000 Series – Comprehensive EMC standards covering emission and immunity testing (Parts 3 and 4).

IEC 60947-1 – Low-voltage switchgear and controlgear general rules.

IEC 60364-4-41 – Protection against electric shock in low-voltage electrical installations.

CISPR 11:2009 – Limits and measurement methods for radio-frequency disturbances from industrial equipment.

Together, these related standards form a comprehensive framework to ensure the electrical safety, functional reliability, and electromagnetic compatibility of sewing machines and related equipment across the professional textile manufacturing industry.

Keywords: IEC 60204-31, safety of machinery, electrical equipment, professional sewing machines, sewing units, electrical safety, EMC requirements, electromagnetic compatibility, industrial sewing machines, electrical hazards, control circuits, equipment marking, technical documentation, low-voltage machinery, machine safety standards.

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

IEC 60204-31:2013 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Safety of machinery - Electrical equipment of machines - Part 31: Particular safety and EMC requirements for sewing machines, units and systems". This standard covers: IEC 60204-31:2013 applies to electrical and electronic equipment, sewing machines, units and systems, designed specifically for professional use in the sewing industry. It is applicable to the electrical equipment or parts of the electrical equipment which operate with nominal supply voltages not exceeding 1 000 V for alternating current and not exceeding 1 500 V for direct current, and with nominal frequencies not exceeding 200 Hz. This fourth edition cancels and replaces the third edition, published in 2001 and constitutes a technical revision. It includes the following changes: - Alignment of the normative references; - Alignment of titles and subtitles to the IEC 60204-1; - Revision of Annex AA to align this annex with the relevant IEC standards. This publication is to be read in conjunction with IEC 60204-1:2009.

IEC 60204-31:2013 applies to electrical and electronic equipment, sewing machines, units and systems, designed specifically for professional use in the sewing industry. It is applicable to the electrical equipment or parts of the electrical equipment which operate with nominal supply voltages not exceeding 1 000 V for alternating current and not exceeding 1 500 V for direct current, and with nominal frequencies not exceeding 200 Hz. This fourth edition cancels and replaces the third edition, published in 2001 and constitutes a technical revision. It includes the following changes: - Alignment of the normative references; - Alignment of titles and subtitles to the IEC 60204-1; - Revision of Annex AA to align this annex with the relevant IEC standards. This publication is to be read in conjunction with IEC 60204-1:2009.

IEC 60204-31:2013 is classified under the following ICS (International Classification for Standards) categories: 01 - GENERALITIES. TERMINOLOGY. STANDARDIZATION. DOCUMENTATION; 13.110 - Safety of machinery; 61.080 - Sewing machines and other equipment for the clothing industry. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60204-31:2013 has the following relationships with other standards: It is inter standard links to IEC 60204-31:2001. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60204-31:2013 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60204-31 ®

Edition 4.0 2013-04

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Safety of machinery – Electrical equipment of machines –

Part 31: Particular safety and EMC requirements for sewing machines, units and

systems

Sécurité des machines – Équipement électrique des machines –

Partie 31: Exigences particulières de sécurité et de CEM pour machines à

coudre, unités et systèmes de couture

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et les

microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Useful links:

IEC publications search - www.iec.ch/searchpub Electropedia - www.electropedia.org

The advanced search enables you to find IEC publications The world's leading online dictionary of electronic and

by a variety of criteria (reference number, text, technical electrical terms containing more than 30 000 terms and

committee,…). definitions in English and French, with equivalent terms in

It also gives information on projects, replaced and additional languages. Also known as the International

withdrawn publications. Electrotechnical Vocabulary (IEV) on-line.

IEC Just Published - webstore.iec.ch/justpublished Customer Service Centre - webstore.iec.ch/csc

Stay up to date on all new IEC publications. Just Published If you wish to give us your feedback on this publication

details all new publications released. Available on-line and or need further assistance, please contact the

also once a month by email. Customer Service Centre: csc@iec.ch.

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Liens utiles:

Recherche de publications CEI - www.iec.ch/searchpub Electropedia - www.electropedia.org

La recherche avancée vous permet de trouver des Le premier dictionnaire en ligne au monde de termes

publications CEI en utilisant différents critères (numéro de électroniques et électriques. Il contient plus de 30 000

référence, texte, comité d’études,…). termes et définitions en anglais et en français, ainsi que

Elle donne aussi des informations sur les projets et les les termes équivalents dans les langues additionnelles.

publications remplacées ou retirées. Egalement appelé Vocabulaire Electrotechnique

International (VEI) en ligne.

Just Published CEI - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications de la CEI.

Just Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur

Disponible en ligne et aussi une fois par mois par email. cette publication ou si vous avez des questions

contactez-nous: csc@iec.ch.

IEC 60204-31 ®

Edition 4.0 2013-04

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Safety of machinery – Electrical equipment of machines –

Part 31: Particular safety and EMC requirements for sewing machines, units and

systems

Sécurité des machines – Équipement électrique des machines –

Partie 31: Exigences particulières de sécurité et de CEM pour machines à

coudre, unités et systèmes de couture

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX T

ICS 13.110; 61.080 ISBN 978-2-83220-749-9

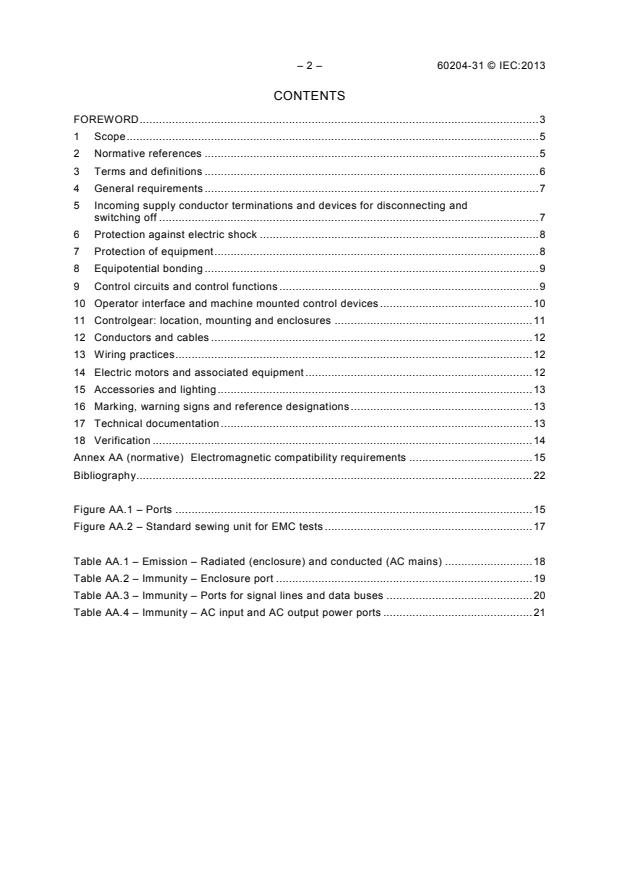

– 2 – 60204-31 © IEC:2013

CONTENTS

FOREWORD . 3

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 6

4 General requirements . 7

5 Incoming supply conductor terminations and devices for disconnecting and

switching off . 7

6 Protection against electric shock . 8

7 Protection of equipment . 8

8 Equipotential bonding . 9

9 Control circuits and control functions . 9

10 Operator interface and machine mounted control devices . 10

11 Controlgear: location, mounting and enclosures . 11

12 Conductors and cables . 12

13 Wiring practices . 12

14 Electric motors and associated equipment . 12

15 Accessories and lighting . 13

16 Marking, warning signs and reference designations . 13

17 Technical documentation . 13

18 Verification . 14

Annex AA (normative) Electromagnetic compatibility requirements . 15

Bibliography . 22

Figure AA.1 – Ports . 15

Figure AA.2 – Standard sewing unit for EMC tests . 17

Table AA.1 – Emission – Radiated (enclosure) and conducted (AC mains) . 18

Table AA.2 – Immunity – Enclosure port . 19

Table AA.3 – Immunity – Ports for signal lines and data buses . 20

Table AA.4 – Immunity – AC input and AC output power ports . 21

60204-31 © IEC:2013 – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

SAFETY OF MACHINERY –

ELECTRICAL EQUIPMENT OF MACHINES –

Part 31: Particular safety and EMC requirements

for sewing machines, units and systems

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60204-31 has been prepared by IEC technical committee 44:

Safety of machinery – Electrotechnical aspects.

This fourth edition cancels and replaces the third edition, published in 2001. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) Alignment of the normative references;

b) Alignment of titles and subtitles to the IEC 60204-1;

c) Revision of Annex AA to align this annex with the relevant IEC standards.

– 4 – 60204-31 © IEC:2013

The text of this standard is based on the following documents:

FDIS Report on voting

44/685/FDIS 44/687/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

This International Standard is to be used in conjunction with IEC 60204-1:2005 and its

Amendment 1:2008.

This part supplements or modifies the corresponding clauses in IEC 60204-1 so as to convert

that publication into the IEC standard dealing with requirements for the electrical equipment of

sewing machines, units and systems.

Where a particular subclause of Part 1 is not mentioned in this part, that subclause applies as

far as is reasonable. Where this part states "addition", "modification" or "replacement" the

relevant text in Part 1 is adapted accordingly.

The Annex which is additional to those in Part 1 is lettered AA.

A list of all the parts in the IEC 60204 series, published under the general title Safety of

machinery – Electrical equipment of machines, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

60204-31 © IEC:2013 – 5 –

SAFETY OF MACHINERY –

ELECTRICAL EQUIPMENT OF MACHINES –

Part 31: Particular safety and EMC requirements

for sewing machines, units and systems

1 Scope

This clause of Part 1 is replaced by:

This part of IEC 60204 applies to the application of electrical and electronic equipment to

sewing machines, units and systems, designed specifically for professional use in the sewing

industry.

NOTE The requirements for sewing machines for household and similar use can be found in IEC 60335-2-28.

The equipment covered by this part commences at the point of connection of the supply to the

electrical equipment of the machine (see 5.1). This part is applicable to the electrical

equipment or parts of the electrical equipment which operate with nominal supply voltages not

exceeding 1 000 V for alternating current and not exceeding 1 500 V for direct current, and

with nominal frequencies not exceeding 200 Hz.

It does not cover all the requirements (e.g. guarding, interlocking, control) that are necessary

to safeguard persons from hazards other than electrical hazards and which are specified in

other standards.

This part applies to sewing units and systems which are installed in dry and well-kept clean

locations and which process dry sewing material, as in the clothing industry. Where sewing

units and systems are used in other than dry and well-kept clean locations, more stringent

measures can be necessary, which need to be agreed between manufacturer and customer.

The noise emission of electrical and electronic equipment for sewing machines is not

considered to be a relevant hazard. Therefore this standard does not contain any specific

requirements on noise.

2 Normative references

This clause of Part 1 is applicable except as follows:

Additional references:

IEC 60204-1:2005, Safety of machinery – Electrical equipment of machines – Part 1: General

requirements

Amendment 1:2008

IEC 60364-4-41, Low-voltage electrical installations – Part 4-41: Protection for safety –

Protection against electric shock

IEC 60664-1:2007, Insulation coordination for equipment within low-voltage systems – Part 1:

Principles, requirements and tests

– 6 – 60204-31 © IEC:2013

IEC 60721-3-3, Classification of environmental conditions – Part 3: Classification of groups of

environmental parameters and their severities – Section 3: Stationary use at

weatherprotected locations

IEC 60947-1:2007, Low-voltage switchgear and controlgear – Part 1: General rules

Amendment 1:2010

IEC 61000-3-2, Electromagnetic compatibility (EMC) – Part 3-2: Limits – Limits for harmonic

current emissions (equipment input current ≤ 16 A per phase)

IEC 61000-3-3, Electromagnetic compatibility (EMC) – Part 3-3: Limits – Limitation of voltage

changes, voltage fluctuations and flicker in public low-voltage supply systems, for equipment

with rated current ≤ 16 A per phase and not subject to conditional connection

IEC 61000-4-2, Electromagnetic compatibility (EMC) – Part 4-2: Testing and measurement

techniques – Electrostatic discharge immunity test

IEC 61000-4-3, Electromagnetic compatibility (EMC) – Part 4-3: Testing and measurement

techniques – Radiated, radio-frequency, electromagnetic field immunity test

IEC 61000-4-4, Electromagnetic compatibility (EMC) – Part 4-4: Testing and measurement

techniques – Electrical fast transient/burst immunity test

IEC 61000-4-5:2005, Electromagnetic compatibility (EMC) – Part 4-5: Testing and

measurement techniques – Surge immunity test

IEC 61000-4-6, Electromagnetic compatibility (EMC) – Part 4-6: Testing and measurement

techniques – Immunity to conducted disturbances, induced by radio-frequency fields

IEC 61000-4-11, Electromagnetic compatibility (EMC) – Part 4-11: Testing and measurement

techniques – Voltage dips, short interruptions and voltage variations immunity tests

IEC 61058-1, Switches for appliances – Part 1: General requirements

IEC 61558-1, Safety of power transformers, power supplies, reactors and similar products –

Part 1: General requirements and tests

CISPR 11:2009, Industrial, scientific and medical equipment – Radio-frequency disturbance

characteristics – Limits and methods of measurement

Amendment 1:2010

ENV 50204, Radiated electromagnetic field from digital radio telephones – Immunity test

3 Terms and definitions

This clause of Part 1 is applicable except as follows:

Additional definitions:

3.101

sewing machine

machine designed to produce one or more stitch types with one or more sewing threads

Note 1 to entry: Previously, the term “sewing machine head” was used instead of “sewing machine”.

Note 2 to entry: Stitch types are defined in ISO 4915.

60204-31 © IEC:2013 – 7 –

Note 3 to entry: Seam types are defined in ISO 4916.

Note 4 to entry: In producing a seam, the machine can perform one or more sewing functions.

3.102

sewing machine stand

item, for example designed as a table, on which the sewing machine is arranged to enable

optimum operation

3.103

sewing machine drive

equipment that drives a sewing machine, such as an electric motor, which is speed-controlled

by electrical and/or mechanical means with or without a positioning device and with or without

control of machine functions

3.104

sewing unit

equipment consisting of at least a sewing machine, a sewing machine stand and a sewing

machine drive

Note 1 to entry: One or several devices incorporated in and/or attached to the sewing machine or sewing unit, for

example for sewing, cutting, feeding, etc. the sewing material, as well as the sewing machine itself, are controlled

by the operator or automatically.

3.105

sewing system

equipment consisting of at least two sewing units or parts of them, which are functionally

interlinked

4 General requirements

This clause of Part 1 is applicable except as follows:

4.4.2 Electromagnetic compatibility (EMC)

Replacement:

Replace this subclause with Annex AA.

4.4.4 Humidity

Modification:

Instead of the first paragraph, the following applies:

The electrical equipment shall be capable of operating in the intended manner in the humidity

conditions covered by class 3K3 as specified in IEC 60721-3-3.

5 Incoming supply conductor terminations and devices for disconnecting

and switching off

This clause of Part 1 is applicable except as follows:

5.1 Incoming supply conductor terminations

Modification:

– 8 – 60204-31 © IEC:2013

Add after the first sentence of the first paragraph:

Each sewing unit shall have only one incoming supply connection.

Each sewing system consisting of at least two sewing units that are not interlinked by means

of control systems may have its own incoming supply connection for each sewing unit;

however, if a failure of one sewing unit can cause a hazard, the sewing system shall have

only one incoming supply connection.

5.3 Supply disconnecting (isolating) device

5.3.1 General

Addition:

When sewing units are interconnected by means of control systems to form a sewing system,

only one supply disconnecting device shall be provided.

5.3.2 Type

Addition to item d):

On sewing units and systems which are started and stopped by actuating a hold-to-run control

device (e.g. pedal), an isolating switch according to IEC 60947-3 for utilization categories

AC-3 or DC-3, or a incorporated switch according to IEC 61058-1, shall be used.

5.3.4 Operating means

Addition:

For seated positions the operating handle of the ON/OFF switch shall be mounted between

0,5 m and 1,5 m above the servicing level.

6 Protection against electric shock

This clause of Part 1 is applicable except as follows:

6.1 General

Addition:

This can also be achieved by the application of SELV according to IEC 60364-4-41.

7 Protection of equipment

This clause of Part 1 is applicable except as follows:

7.5 Protection against supply interruption or voltage reduction and subsequent

restoration

Addition:

On sewing units and systems, which are started by actuating a hold-to-run control device

(such as a pedal), and stopped by releasing it, the provision of a device for avoiding an

unintentional restart after a supply interruption or voltage reduction and subsequent

restoration is not necessary.

60204-31 © IEC:2013 – 9 –

8 Equipotential bonding

This clause of Part 1 is applicable except as follows:

8.2.5 Parts that need not be connected to the protective bonding circuit

Addition:

It is not necessary to connect sewing machine stands or their accessible conducting parts

when:

– they do not carry electrical equipment; or

– they carry electrical equipment operated at SELV and/or PELV only (see IEC 60364-4-41).

9 Control circuits and control functions

This clause of Part 1 is applicable except as follows:

9.1.1 Control circuit supply

Replacement:

Control circuits of sewing units and systems shall meet requirements for PELV (see 6.4) or

SELV (see IEC 60364-4-41). The transformers supplying these circuits shall meet the

requirements of IEC 61558-1.

9.2.5.2 Start

Addition:

The requirements of 9.2.5.2 do not apply to:

– sewing units and systems, which are started by actuating a hold-to-run control device

(such as a pedal).

9.2.5.3 Stop

Addition:

The stop function required for sewing units and systems is met by a hold-to-run control

devices (such as a pedal). On sewing units and systems for automatic bar tacking, sewing of

buttonholes, fastening of buttons, etc., which have a short sewing cycle, the required function

is met by an ON/OFF switch according to IEC 60947-3 or IEC 61058-1.

9.4 Control functions in the event of failure

9.4.1 General requirements

Addition:

NOTE On sewing units and systems on which the hazardous movement of parts is protected by fixed guards,

interlocking of the guard with the electrical circuit is not necessary.

9.4.2.2 Provisions of partial or complete redundancy

Addition:

NOTE On sewing units and systems on which the hazardous movement of parts is limited to parts of the sewing

machine itself, for example stitch forming elements, feed, etc., use of redundancy is not necessary.

– 10 – 60204-31 © IEC:2013

9.4.2.3 Provision of diversity

Addition:

NOTE On sewing units and systems on which the hazardous movement of parts is limited to parts of the sewing

machine itself, for example stitch forming elements, feed, etc., use of diversity is not necessary.

9.4.3.1 Earth faults

Addition:

On sewing units and systems, a particularly safe installation of those conductors that in the

case of an earth fault could cause unintended starting, or hazardous movement of a machine,

or could prevent its stopping, may be used instead of connecting the control circuits to the

protective bonding circuit or providing an insulation monitoring device.

A particularly safe installation can be achieved, for example, by:

– enclosure of insulated conductors in ducts of insulating material;

– use of double insulation techniques; or

– encapsulation of components and devices.

10 Operator interface and machine mounted control devices

This clause of Part 1 is applicable except as follows:

10.1.2 Location and mounting

Modification:

Replace the first dashed indent of the second paragraph by the following:

– those used for normal operation are not less than 0,5 m above the servicing level and are

within easy reach from the normal working position of the operator (but see also 5.3.4 of

this part);

– those used for adjustment and maintenance are not less than 0,3 m above the servicing

level and so installed that they cannot be actuated during normal operation for example by

position, locking, etc.

10.1.3 Protection

Replacement:

Where mounted as intended, operator interface and machine mounted control devices shall

withstand the stresses of the expected use and shall have a minimum degree of protection of

at least IP40 (see IEC 60529). IP40 is considered to be sufficient when sewing units and

sewing systems are operated in an environment in which the effects of aggressive fluids,

vapours and contamination by coarse dust and chips are not to be expected.

10.2 Push-buttons

10.2.1 Colours

Modification:

Instead of the first paragraph, the following applies:

60204-31 © IEC:2013 – 11 –

As far as is practicable, push-button actuators shall be colour-coded in accordance with

Table 2; limitations of the practicability are sizes of actuators, built-in casing and design of

actuators.

10.3 Indicator lights and displays

10.3.2 Colours

Modification:

Instead of the first sentence, the following applies:

As far as is practicable, indicator light lenses shall be colour-coded, with respect to the

condition (status) of the machine in accordance with Table 4; limitations of the practicability

are sizes of actuators, built-in casing and design of actuators.

10.4 Illuminated push-buttons

Modification:

Instead of the first sentence, the following applies:

As far as is practicable, illuminated push-buttons shall be colour-coded in accordance with

Tables 2 and 4; limitations of the practicability are sizes of actuators, built-in casing and

design of actuators.

10.7.4 Local operation of the supply disconnecting device to effect emergency stop

Addition:

On automatically controlled sewing units and systems for which emergency stop devices

according to 10.7.2 are considered to be unnecessary, the supply disconnecting device shall

fulfil the function of the emergency stop device.

On sewing units and systems which are started by actuating a hold-to-run control device

(such as a pedal), an emergency stop device is not required. Moreover, an emergency stop

device is not necessary on automatically controlled sewing units and systems for automatic

bar tacking, sewing of buttonholes, fastening of buttons, etc., which have only a short

automatic sewing process.

These sewing units and systems may be equipped with a device according to IEC 60947-3 or

IEC 61058-1 for switching ON and OFF.

11 Controlgear: location, mounting and enclosures

This clause of Part 1 is applicable except as follows:

11.2 Location and mounting

11.2.1 Accessibility and maintenance

Modification:

Instead of the second paragraph, the following applies:

Where access is required for regular maintenance or adjustment, the relevant devices shall be

arranged between 0,3 m and 2,0 m above the servicing level.

– 12 – 60204-31 © IEC:2013

11.2.2 Physical separation or grouping

Addition:

In enclosures according to 6.2.1, the distances between the protective enclosure and live

parts shall be not less than the clearance and creepage distances given in Table 13 Case A

and Table 15 of IEC 60947-1:2007, Amendment 1:2010, pollution degree 2 shall apply.

For printed circuit assemblies and all other electrical equipment and devices (such as

switches, motors), IEC 60664-1:2007, Table F.4, pollution degree 2 shall apply.

11.3 Degrees of protection

Replacement:

The minimum degree of protection shall be IP40 for enclosures of switching devices of sewing

units and systems. Exception: if all the circuits used in and with the devices meet the

requirements of 6.1 of this part of IEC 60204, IP20 is permitted as the minimum degree of

protection.

12 Conductors and cables

This clause of Part 1 is applicable.

13 Wiring practices

This clause of Part 1 is applicable except as follows:

13.2.4 Identification by colour

Addition:

Conductors used for functional earthing shall be identified by the colour GREY.

Common conductors, for example for eliminating static charges, shall be identified by the

colour GREY.

13.5.8 Connection boxes and other boxes

Modification:

Instead of the second sentence of the first paragraph, the following applies:

IP40 (see IEC 60529) shall be the minimum degree of protection for connection and through

boxes of sewing units and systems. Exception: if all the circuits used in and with the devices

meet the requirements of 6.1 of this part of IEC 60204, IP20 is permitted as the minimum

degree of protection.

14 Electric motors and associated equipment

This clause of Part 1 is applicable except as follows:

14.1 General requirements

Addition:

60204-31 © IEC:2013 – 13 –

Voltage transformation for the purpose of feeding external consumers (loads) by tapping the

stator winding of motors is not permitted.

14.2 Motor enclosures

Addition:

The minimum degree of protection of the sewing machine drive (including the control device

possibly attached to it) shall be IP40.

14.3 Motor dimensions

Addition:

The dimensions of sewing machine drives need not correspond to IEC 60072-1 and

IEC 60072-2.

15 Accessories and lighting

This clause of Part 1 is applicable except as follows:

15.2 Local lighting of the machine and equipment

15.2.1 General

Addition:

For local lighting (sewing lamps) of sewing units and systems up to a rated voltage of 50 V

a.c., the ON/OFF switch may be incorporated in the flexible connecting cords.

15.2.2 Supply

Addition:

Low-voltage sewing lamps shall be supplied either by built-in transformers or by external

extra-low voltage transformers according to IEC 61558-1.

Circuits for local lighting (sewing lamps) intended for use, for example threading, replacing

sewing implements, maintenance work, shall be connected to the incoming supply side of the

device for switching ON and OFF the sewing unit or system.

16 Marking, warning signs and reference designations

This clause of Part 1 is applicable.

17 Technical documentation

This clause of Part 1 is applicable except as follows:

17.7 Operating manual

Addition:

– 14 – 60204-31 © IEC:2013

The instructions shall draw attention to the need always to switch off the sewing unit or

system, for example by actuating the ON/OFF switch or by disconnecting the plug from the

incoming supply, when:

– sewing implements (such as sewing machine needle, presser foot, bobbin or needle plate)

have to be replaced;

– threading a needle, looper, spreader, etc. is required;

– the workplace is left unattended;

– maintenance work has to be performed.

18 Verification

This clause of Part 1 is applicable except as follows:

18.1 General

Addition:

The tests of 18.2, 18.3, 18.4 and 18.7 are routine tests.

The tests of 18.5 and 18.6 are type tests.

18.3 Insulation resistance tests

Addition:

Control and signal circuits containing electronic devices shall be connected to the protective

conductor while the other circuits are tested. After disconnecting the protective conductor

connection mentioned above, the insulation resistance to earth shall be measured in a second

test with at least 100 V d.c. The test voltage shall not be applied suddenly in order to avoid

any damage to the electronic circuit.

18.4 Voltage tests

Addition:

Such disconnected components include rectifiers, capacitors, electronic devices and motors

up to a rated power of 1 kW.

Motors shall be tested according to IEC 60034-1. Electronic circuits of below 50 V rated

voltage shall not be subjected to a voltage test.

If the electrical equipment of the machine contains surge protection devices which are likely

to operate during the test, it is permitted to either:

– disconnect these devices, or

– reduce the test voltage to a value lower than the voltage protection level of the search

protection devices, but not lower than the peak value of the upper limit of the supply

(phase to neutral) voltage.

Annexes

The annexes of Part 1 are applicable except as follows:

Addition:

60204-31 © IEC:2013 – 15 –

Annex AA

(normative)

Electromagnetic compatibility requirements

AA.1 General

The objective of this annex is to define limits for sewing units, sewing systems and their

equipment, e.g. sewing machine drives, controls, etc., in relation to electromagnetic

emissions which may cause interference in other equipment, and in relation to continuous and

transient, conducted and radiated disturbances, including electrostatic discharges.

AA.2 Electromagnetic compatibility test levels

The ports which can be influenced by electromagnetic phenomena are:

Encolusre port

AC power port

Signal port

DC power port

Machine,

equipment

Process measurement

and control port

IEC 692/13

Figure AA.1 – Ports

The limits of electromagnetic compatibility specified in Tables AA.1 to AA.4 are effective:

a) in the case of emission limits, for foreseeable use in a residential environment; and

b) in the case of immunity, for use in the industrial environment characteristic of the sewing

industry;

and therefore covers foreseeable use in all environments of the sewing industry.

AA.3 Emission

The electrical disturbances generated by the machine or by the equipment shall not exceed

the levels specified in Table AA.1.

Measurement of interference voltages is not required on shielded lines which connect

shielded parts of equipment. The shields shall be connected together.

Measurement of the interference voltages is not required on lines connecting parts of

equipment which are less than 2 m in length and which cannot be extended.

AA.4 Immunity

Where electronic equipment is used, it shall be designed to withstand at least the test values

specified in Tables AA.2 to AA.4.

The immunity test requirements for machines and equipment covered by this part of

IEC 60204 are on a port to port basis.

– 16 – 60204-31 © IEC:2013

AA.5 Performance criteria

Machines and equipment shall not become hazardous as a result of the application of the

tests defined in this part of IEC 60204.

A functional description and a definition of performance criteria, during or as a consequence

of the EMC testing, shall be noted in the test report, based on the following:

– performance criterion A: the machines and equipment shall continue to operate in the

intended manner. No degradation of performance or loss of function is allowed below a

performance level specified by the manufacturer, when the machines and equipment are

used as intended. In some cases, the performance level may be replaced by a permissible

loss of performance;

– performance criterion B: the machines and equipment shall continue to operate in the

intended manner after the test. No degradation of performance or loss of function is

allowed below a performance level specified by the manufacturer, when the machines and

equipment are used as intended. In some cases, the performance level may be replaced

by a permissible loss of performance. During the test, degradation of performance is

however allowed. No change of actual operating state or stored data is allowed.

– performance criterion C: a temporary malfunction is permissible, if the function is self-

recovering or recoverable by activation of the operating and/or setting elements.

If either the minimum performance level or the permissible performance loss is not specified

by the supplier, then either of these may be derived from the product description and

documentation and what the user may reasonably expect from the machines and equipment

when used in the intended manner.

AA.6 Electromagnetic compatibility tests

AA.6.1 General electromagnetic compatibility (EMC) test conditions

The EMC tests shall be carried out:

– within the specified operating conditions for sewing units and systems or equipment and

its nominal supply voltage;

– on completely equipped and ready-for-use sewing units and systems or, for sewing

systems, on the individual machines in working order which build the entirety of the

system;

– on sewing units and systems or equipment arranged in their maximum extension (for

example controls with the maximum number of inputs/outputs and functions, all machines

and equipment with minor configurations being considered to be in accordance with this

part of IEC 60204);

– as single tests in sequence, the sequence of the test being optional.

The configuration and mode of operation during the test shall be precisely noted in the test

report.

It is not always possible to test every function of the machine, and in such cases the most

critical mode of operation shall be selected.

It may be determined, from consideration of the electrical characteristics and usage of

particular machines and equipment, that some of the tests are inappropriate and are therefore

unnecessary. In such a case, the decision not to test shall be recorded in the test report.

The sewing machine drive and additional equipment shall be tested on a standard sewing unit

equipped as shown in Figure AA.1.

60204-31 © IEC:2013 – 17 –

The sewing machine drives and equipment thus tested will be regarded as EMC-prepared.

Specific test measures shall be agreed upon with the suppliers involved.

NOTE EMC-prepared equipment cannot guarantee solely the EMC-compatibility of the sewing unit or sewing

system.

Measurements shall be performed under well-defined and reproducible conditions for each

type of EMC phenomenon.

AA.6.2 EMC test conditions for emission

The description of the test and the test equipment shall be as given in Clauses 7 and 8 of

CISPR 11:2009, Amendment 1:2010.

The test shall be carried out using the test set-up shown in Figure AA.2, except that the

requirements for the ground plane shall be according to Clause 8 of CISPR 11:2009,

Amendment 1:2010.

AA.6.3 EMC test conditions for immunity

The description of the test, the test methods and test equipment are given in the standards

listed in Tables AA.2 to AA.4.

The test shall be carried out using the test set-up shown in Figure AA.2.

The test for sewing systems may differ from this test set-up.

Additional

equipment

Sewing machine

drive

≥0,1 m

≥0,1 m

≥0,1 m

≥0,1 m

Insulating

0,1 m

Ground plane

Ground

IEIECC 693 398//1963

Figure AA.2 – Standard sewing unit for EMC tests

– 18 – 60204-31 © IEC:2013

Table AA.1 – Emission – Radiated (enclosure) and conducted (AC mains)

Port Frequency range Limits Basic standard Applicability Note

30 MHz – 230 MHz 30 dB(µV/m) quasi-peak, measured at 10 m distance

Enclosure See Note 1

230 MHz – 1 000 MHz 37 dB(µV/m) quasi-peak, measured at 10 m distance

150 kHz – 0,5 MHz

66 dB(µV) to 56 dB(µV) quasi-peak

See Notes 2, 3 and 4

56 dB(µV) to 46 dB(µV) average decreasing

linearly with the logarithm of the frequency CISPR 11

AC mains 0,5 MHz – 5 MHz 56 dB(µV) quasi-peak

See Notes 2, 3 and 4

46 dB(µV) average

5 MHz – 30 MHz

60 dB(µV) quasi-peak

See Notes 2, 3 and 4

50 dB(µV) average

NOTE 1 In situ measurements are excluded from this standard.

NOTE 2 Impulse noise (clicks) which occurs less than five times per minute is not considered. For clicks appearing more often than 30 times per minute, the limits of

Table AA.1 apply. For clicks appearing between five and 30 times per minute, a relaxation of 20 log 30/N dB of the limits of Table AA.1 is allowed (where N is the number of

clicks per minute).

NOTE 3 Applies only to machine and equipment operating at less than 1 000 V RMS (Root Mean Square).

NOTE 4 These values are part of CISPR 11.

The requirements of IEC 61000-3-2 and IEC 61000-3-3 shall apply.

60204-31 © IEC:2013 – 19 –

Table AA.2 – Immunity – Enclosure port

Environmental Test Units Basic Remarks Performance

phenomena specification standard criteria

1.1 The test is to be executed according

to the power supply frequency.

Equipment (company equipment,

50, 60 Hz

b

Magnetic field at power frequency IEC 61000-4-8 devices) that is intended to be used A

30 A/m

in regions that are only supplied by

one of these frequencies have to be

a

tested at this frequency only .

1.2 electromagnetic 80 – 1 000 MHz

The specified test level

HF-field, amplitude 10 V/m IEC 61000-4-3

A

c

is the RMS prior to modulation

modulated 80 % AM (1 kHz)

1.3 electromagnetic 1.4 to 2.0 GHz

The specified test level

HF-field, amplitude 3 V/m IEC 61000-4-3 A

d

is the RMS prior to modulation

modulated 80 % AM (1 kHz)

1.4 electromagnetic 1.4 to 2.7 GHz

The specified test level

HF-field, amplitude 1 V/m IEC 61000-4-3 A

d

is the RMS prior to modulation

modulated 80 % AM (1 kHz)

Contact ±4 (charge

kV B

Discharging

discharge voltage)

See basic standard for applicability of

1.5 static IEC 61000-4-2

contact and/or air discharge test

electricity ±8 (charge

Air discharge kV B

voltage)

a

Only for company equipment (devices) which contain devices (components) that are sensitive to magnetic fields.

b

For monitors with cathode ray tubes the acceptable jitter depends on the font size and is calculated for a test level of 1 A/m according to: J ≤ (3C + 1)/40. The jitter J and the

font size C is in mm. As the jitter is linearly proportional to the magnetic field strength, tests may be carried out with other test levels, whereas the maximum jitter has to be

extrapolated.

c Except for the ITU broadcast frequency bands: 87 MHz – 108 MHz, 174 MHz – 230 MHz and 470 MHz – 790 MHz, where the level is 3 V/m.

d

The frequency ranges have been selected so that frequencies with the hig

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...