IEC 60747-18-1:2019

(Main)Semiconductor devices - Part 18-1: Semiconductor bio sensors - Test method and data analysis for calibration of lens-free CMOS photonic array sensors

Semiconductor devices - Part 18-1: Semiconductor bio sensors - Test method and data analysis for calibration of lens-free CMOS photonic array sensors

IEC 60747-18-1:2019 (E) specifies the test methods and data analysis for the calibration of lens-free CMOS photonic array sensors. This document includes the test conditions of each process, configuration of lens-free CMOS photonic array sensors, statistical analysis of test data, calibration for planarization and linearity, and test reports.

General Information

- Status

- Published

- Publication Date

- 19-May-2019

- Technical Committee

- SC 47E - Discrete semiconductor devices

- Drafting Committee

- WG 1 - TC 47/SC 47E/WG 1

- Current Stage

- PPUB - Publication issued

- Start Date

- 20-May-2019

- Completion Date

- 07-Jun-2019

Overview

IEC 60747-18-1:2019 is an IEC international standard that defines test methods and data analysis for the calibration of lens-free CMOS photonic array sensors used as semiconductor bio sensors. The standard specifies measurement setups, test conditions, statistical analysis procedures, calibration for planarization and linearity, and the content required in test reports. It is part of the IEC 60747 series on semiconductor devices and supports consistent, reproducible calibration of lens-free photonic sensor arrays for bio-detection applications.

Key Topics and Technical Requirements

- Measurement setup and system configuration

- Overall system architecture (examples include integrating sphere and parallel incident light setups)

- Controlled environments such as dark box and specified light sources

- Sensor board configuration and capture parameters

- Measurement procedures

- Case 1: Fixed wavelength (λ) - tests for planarization (pixel-to-pixel uniformity) and linearity (response vs. incident intensity)

- Case 2: Multiple wavelengths - spectral response and calibration across λ

- Data analysis and statistical methods

- Data plotting, sensor screening and noise characterization (e.g., box plots, dark-frame subtraction)

- Determination of a reference pixel and representative values for per-pixel calibration

- Criteria for defining the linear region and the effective area of light intensity for each pixel

- Construction of lookup tables for planarization and linearity calibration

- Calibration and test reporting

- Methods to build and apply calibration lookup tables

- Required test report elements (test environment specifications, sensor specification, calibration tables)

- Informative Annex A provides sample report formats and representative value tables

Practical Applications and Who Uses This Standard

- CMOS photonic sensor manufacturers: to standardize pixel-level calibration and improve sensor uniformity and linearity.

- Biosensor developers and integrators: ensuring reliable, repeatable optical readout for lens-free bio-detection platforms (e.g., point-of-care diagnostics, lab-on-chip assays).

- Test laboratories and OEM quality teams: for reproducible measurement setups, statistical validation and regulatory submission data.

- R&D engineers and system designers: to benchmark sensor modules and develop firmware/software that applies calibration lookup tables.

- Medical device developers and regulators: to assess calibration traceability and test-report completeness.

Related Standards

- IEC 60747 series (Semiconductor devices) - broader device testing and device family standards.

- Other planned parts in the series: IEC 60747-18-2 (sensor package module evaluation) and IEC 60747-18-3 (fluidic/flow characteristics for sensor modules).

Keywords: IEC 60747-18-1, lens-free CMOS photonic array sensors, calibration, planarization, linearity, test methods, data analysis, semiconductor bio sensors, calibration lookup table.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60747-18-1:2019 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Semiconductor devices - Part 18-1: Semiconductor bio sensors - Test method and data analysis for calibration of lens-free CMOS photonic array sensors". This standard covers: IEC 60747-18-1:2019 (E) specifies the test methods and data analysis for the calibration of lens-free CMOS photonic array sensors. This document includes the test conditions of each process, configuration of lens-free CMOS photonic array sensors, statistical analysis of test data, calibration for planarization and linearity, and test reports.

IEC 60747-18-1:2019 (E) specifies the test methods and data analysis for the calibration of lens-free CMOS photonic array sensors. This document includes the test conditions of each process, configuration of lens-free CMOS photonic array sensors, statistical analysis of test data, calibration for planarization and linearity, and test reports.

IEC 60747-18-1:2019 is classified under the following ICS (International Classification for Standards) categories: 17.220.20 - Measurement of electrical and magnetic quantities; 29.030 - Magnetic materials; 31.080.99 - Other semiconductor devices. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60747-18-1:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60747-18-1 ®

Edition 1.0 2019-05

INTERNATIONAL

STANDARD

colour

inside

Semiconductor devices –

Part 18-1: Semiconductor bio sensors – Test method and data analysis for

calibration of lens-free CMOS photonic array sensors

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 60747-18-1 ®

Edition 1.0 2019-05

INTERNATIONAL

STANDARD

colour

inside

Semiconductor devices –

Part 18-1: Semiconductor bio sensors – Test method and data analysis for

calibration of lens-free CMOS photonic array sensors

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 31.080.99 ISBN 978-2-8322-6909-1

– 2 – IEC 60747-18-1:2019 © IEC 2019

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 8

2 Normative references . 8

3 Terms and definitions . 8

4 Measurement setup . 9

4.1 General . 9

4.2 Measurement system . 9

4.2.1 Overall system . 9

4.2.2 Dark box . 11

4.2.3 Light source . 11

4.2.4 Sensor board . 11

4.2.5 Configuration parameters . 12

5 Measurement . 12

5.1 General . 12

5.2 Case 1: Fixed wavelength (λ) of light . 12

5.2.1 Planarization: At fixed λ and incident light intensity . 12

5.2.2 Linearity: Varying the incident light intensity with a fixed wavelength . 14

5.3 Case 2: Various wavelength (λ) of light . 14

6 Data analysis . 14

6.1 Data plot . 14

6.1.1 General . 14

6.1.2 Sensor screening . 16

6.2 Planarization characteristics . 16

6.2.1 Criterion of determining the reference pixel . 16

6.2.2 Lookup table of representative value for planarization calibration of

each pixel . 17

6.3 Linearity . 17

6.3.1 Criterion of linear region of each pixel . 17

6.3.2 Criterion of light intensity effective area for linearity. 18

6.3.3 Lookup table of the representative value for linearity calibration of each

pixel . 18

7 Calibration . 19

7.1 Calibration lookup table . 19

7.2 Reference for establishing the representative output value in the effective

area . 20

8 Test report . 21

Annex A (informative) Test report . 23

Test environment specification . 23

Specification of CMOS photonic array sensor . 24

A.3 Calibration lookup table . 24

Representative value look up table for planarization calibration of the sensor . 24

Representative value look up table for linearity calibration of the sensor . 25

Bibliography . 26

Figure 1 – Example of box plot. 9

Figure 2 – Example of measurement system with integrating sphere . 10

Figure 3 – Example of measurement system with incident parallel light . 10

Figure 4 – Example of photoelectric measurement schematic . 11

Figure 5 – Measurement flow . 12

Figure 6 – n trial data of frame capture . 13

Figure 7 – Two frame subtracted data . 13

Figure 8 – Dark frame subtracted data . 14

Figure 9 – Example of output electric signal non-linearity of 2D pixel array . 15

Figure 10 – Example of output electric signal non-linearity of one row of pixels . 15

Figure 11 – Example of one pixel’s output electric signal according to input light power . 16

Figure 12 – Example of determining the reference pixel . 17

Figure 13 – Example of the representative value for planarization . 17

Figure 14 – Example of light intensity effective area for linearity . 18

Figure 15 – Example of the representative value for linearity . 19

Figure 16 – Example of a simplified pixel structure and cross-sectional view with bio

reaction . 19

Figure 17 – Example of the representative value of the sensor . 21

Table 1 – Calibration lookup table . 20

Table 2 – Representative value table of the sensor . 21

– 4 – IEC 60747-18-1:2019 © IEC 2019

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

SEMICONDUCTOR DEVICES –

Part 18-1: Semiconductor bio sensors – Test method and data analysis

for calibration of lens-free CMOS photonic array sensors

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60747-18-1 has been prepared by subcommittee 47E: Discrete

semiconductor devices, of IEC technical committee 47: Semiconductor devices.

The text of this International Standard is based on the following documents:

FDIS Report on voting

47E/643A/FDIS 47E/657/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts of the IEC 60747 series, published under the general title Semiconductor

devices, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates that it

contains colours which are considered to be useful for the correct understanding of its

contents. Users should therefore print this document using a colour printer.

– 6 – IEC 60747-18-1:2019 © IEC 2019

INTRODUCTION

The IEC 60747-18 series on semiconductor bio sensors is expected to be composed of the

following parts:

• IEC 60747-18-1 defines the test method and data analysis for calibration of lens-free

CMOS photonic array sensor

• IEC 60747-18-2 defines the evaluation process of lens-free CMOS photonic array sensor

package module

• IEC 60747-18-3 defines the fluid flow characteristics of lens-free CMOS photonic array

sensor package module with fluidic system

The IEC 60747-18 series includes subjects such as noise analysis, long-term reliability tests,

test methods for lens-free CMOS photonic array sensor package module under patchable

environments, test methods under implantable environments, etc.

The International Electrotechnical Commission (IEC) draws attention to the fact that it is

claimed that compliance with this document may involve the use of patents given in several

subclauses as indicated in the table below. These patents are held by their respective

inventors under license to SOL Inc.:

The method of calibration of photon sensor pixel Subclauses 5.1, 5.2.1,

KR1020150081134 [SOL]

array by evaluating its characteristic 5.2.2, 5.3, 7.1

PCT/KR2016/006109

Subclauses 5.1, 5.2.1,

METHOD FOR CORRECTING OPTICAL SENSOR

5.2.2, 5.3, 7.1

[SOL] ARRAY MODULE THROUGH CHARACTERISTIC

US15/577586

EVALUATION

Clause 6

JP2017562062

IEC takes no position concerning the evidence, validity and scope of this patent right.

The holder of this patent right has assured the IEC that he/she is willing to negotiate licences

under reasonable and non-discriminatory terms and conditions with applicants throughout the

world. In this respect, the statement of the holder of this patent right is registered with IEC.

Information may be obtained from:

SOL Inc.

H Business Park

C1010, 26, Beobwon-ro 9-gil, SongPa-Gu

Seoul 05838

Republic of Korea

Attention is drawn to the possibility that some of the elements of this document may be the

subject of patent rights other than those identified above. IEC shall not be held responsible for

identifying any or all such patent rights.

—————————

Under preparation. Stage at the time of publication: IEC/PRVC 60747-18-2:2019.

Under preparation. Stage at the time of publication: IEC/PRVC 60747-18-3:2019.

ISO (www.iso.org/patents) and IEC (http://patents.iec.ch) maintain on-line data bases of

patents relevant to their standards. Users are encouraged to consult the data bases for the

most up to date information concerning patents.

– 8 – IEC 60747-18-1:2019 © IEC 2019

SEMICONDUCTOR DEVICES –

Part 18-1: Semiconductor bio sensors – Test method and data analysis

for calibration of lens-free CMOS photonic array sensors

1 Scope

This part of IEC 60747 specifies the test methods and data analysis for the calibration of lens-

free CMOS photonic array sensors. This document includes the test conditions of each

process, configuration of lens-free CMOS photonic array sensors, statistical analysis of test

data, calibration for planarization and linearity, and test reports.

2 Normative references

There are no normative references in this document.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

lens-free CMOS photonic array sensor

semiconductor-based optical detector or sensor whose sensing elements are arrayed in a

two-dimensional way and integrated with processing circuits on a chip

Note 1 to entry: Lens-free CMOS photonic array sensors are extensively utilized in bio diagnostic devices,

healthcare devices, lens-free microscopes, and patchable/implantable medical devices.

Note 2 to entry: The sensing environments of such a lens-free CMOS photonic array sensor are typically different

from those of general-purpose image sensors which are normally mounted with an external lens in module

housings.

3.2

quantum efficiency

QE

ratio of the number of elementary events (such as release of an electron) contributing to the

detector output, to the number of incident photons

Note 1 to entry: QE is the ability of a semiconductor to produce electron from incident photons.

Note 2 to entry: QE in general depends on the wavelength of the incident photon and can be obtained from

spectral responsivity and conversion gain of the sensor.

[SOURCE: IEC 60050-845:1987, 845-05-67, modified – The abbreviated term and the notes

to entry have been added.]

3.3

linearity

ability of a pixel of an array sensor to provide an output having a linear relationship with an

input light power

3.4

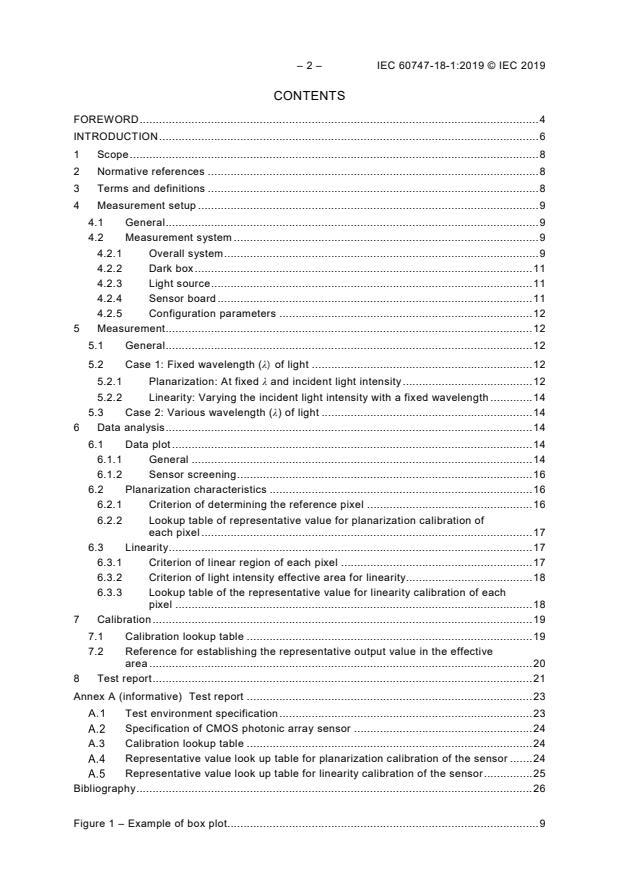

box plot

graphically depicting group of numerical data through their quartiles Q1, Q2, and Q3

SEE: Figure 1.

Note 1 to entry: In this document, the noise RMS (root mean square) and average signal are added. The average

signal is different from the median value, which is real measured data, whereas the average is calculated. Noise

RMS is the root mean square value of the difference between the incident signal and average signal.

Max

Whisker

Q3

Average + noise RMS

Average

Box

Median (Q2)

Q1

Whisker

Min

IEC

Figure 1 – Example of box plot

4 Measurement setup

4.1 General

Input factors and environmental factors affecting sensor performance are: (1) input

component: light power (wavelength, intensity, incident angle, polarization) and its

two-dimensional distribution as well as stability over time; electric inputs (drive pulses, bias

voltages, etc.); and (2) environmental factor: temperature. The evaluation environment

provides a method that allows us to control these factors and to obtain numerical results with

the necessary accuracy. The performance of the lens-free CMOS photonic array sensor

depends on the resolution, pixel size, pixel type, fill factor, quantum efficiency, conversion

gain, sensitivity, saturation level, dynamic range, image lag, black level, dark signal, temporal

noise, fixed-pattern noise, cross talk, etc. Clause A.1 and Clause A.2 show the required

parameters.

4.2 Measurement system

4.2.1 Overall system

All tests shall be performed under well certified and defined conditions to avoid any external

disturbances. Basic measurement setup schematics are depicted in Figure 2 or Figure 3.

– 10 – IEC 60747-18-1:2019 © IEC 2019

Light source

Sensor board

Jig

Jig for alignment of sensor's position

- x, y, z, azimuth, rotation

Integrating sphere

Source

Light

source

θ

PC

Baffle

Sensor θ

Detection

Sensor

plane

(pixel)

Incident light Sensor board

- Wavelength - Temperature

- Intensity - Clocks

Dark box

- Biases

- Incident angle

- Two-dimensional distribution

- Temporal variation

- Polarization

IEC

Figure 2 – Example of measurement system with integrating sphere

Light source

Sensor board

Jig

Jig for alignment of sensor's position

- x, y, z, azimuth, rotation

Parallel light

Light

source

θ

Sensor θ

Sensor

(pixel)

PC

Dark box

Incident light Sensor board

- Wavelength - Temperature

- Intensity - Clocks

- Incident angle - Biases

- Two-dimensional distribution

- Temporal variation

- Polarization

IEC

Figure 3 – Example of measurement system with incident parallel light

The photoelectric characteristics of a sensor board can be measured using the measurement

setup shown in Figure 4. This measurement setup utilizes a collimated light beam. The

temperature of the sensor array is measured to calibrate the thermal effect on the array

sensor. A calibrated photonic sensor will be used to provide a reference signal for the

collimated light.

Collimated light

V

I =

d

R

t

Digital number

V

ADC

Signal

R

t

chain

Temperature

sensor

I

d

CMOS Photonic

array sensor

Calibrated

photonic sensor

IEC

Figure 4 – Example of photoelectric measurement schematic

4.2.2 Dark box

A dark box shall block all other light sources that may affect the sensor under test except the

certified light source for

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...