EN 13418:2013

(Main)Plastics and rubber machines - Winding machines for film or sheet - Safety requirements

Plastics and rubber machines - Winding machines for film or sheet - Safety requirements

This European Standard deals with all significant hazards, hazardous situations and events relevant to the design and construction of winding machines used for the winding and/or unwinding and/or rewinding and/or slitting of film or sheet manufactured from rubber, plastic and composite materials, when the machines are used as intended and under the conditions of misuse which are reasonably foreseeable by the manufacturer (see Clause 4).

A machine used for winding or rewinding (winder or rewinder) begins at the intake of the film or sheet into the winding machine and ends at the discharge position of the reel(s).

A machine used for unwinding (unwind) begins at the take-up position of the reel(s) and ends at the film or sheet take-off point.

A machine used for unwinding, slitting and re-winding (slitter rewinder) begins at the take-up position of the reel(s) and ends at the discharge positions of the reel(s) and covers one or more integrated slitting/cutting units.

In some machines the winding, unwinding, rewinding and slitting functions may be combined.

Hazards due to electro-magnetic radiation, e.g. from the use of thickness monitoring devices, are not covered by this European Standard.

Toxic or chemical hazards and hazards due to dusts, fumes or gases, which could occur from the materials being wound, unwound, slit or rewound are not covered by this European Standard.

NOTE Directive 94/9/EC concerning equipment and protective systems intended for use in potentially explosive atmospheres can be applicable to the type of machine or equipment covered by this European Standard. The present standard is not intended to provide means of complying with the essential health and safety requirements of Directive 94/9/EC.

This European Standard is not applicable to winding machines which are manufactured before the date of its publication.

Kunststoff- und Gummimaschinen - Wickelmaschinen für flache Bahnen - Sicherheitsanforderungen

Diese Europäische Norm legt alle signifikanten Gefährdungen, Gefährdungssituationen und Gefähr-dungsereignisse bezüglich Konstruktion und Bau von Wickelmaschinen zum Aufwickeln, Abwickeln, Umwickeln und zum Schneiden von Gummi, Kunststoffen und Verbundmaterialien fest, wenn diese Maschinen bestimmungsgemäß und unter Bedingungen, die vom Hersteller als Fehlanwendung vernünftiger¬weise vorhersehbar sind, verwendet werden (siehe Abschnitt 4).

Eine Wickelmaschine zum Aufwickeln und zum Umwickeln (Wickler oder Umwickler) beginnt am Flachbahneinlauf in die Wickelmaschine und endet an der Entnahmestelle der Rolle(n).

Eine Wickelmaschine zum Abwickeln (Abwickler) beginnt an der Aufnahmestelle der Rolle(n) und endet am Flachbahnauslauf.

Eine Wickelmaschine zum Abwickeln, Schneiden und Aufwickeln (Schneid- und Wickelmaschine) beginnt an der Aufnahmestelle der Rolle(n) und endet an der Entnahmestelle der Rolle(n) und umfasst eine oder mehrere Schneideinrichtungen.

Bei einigen Maschinen können die Aufwickel-, Abwickel-, Umwickel- und Schneidfunktionen kombiniert sein.

Gefährdungen durch elektromagnetische Strahlung, z. B. durch die Verwendung von Dickenmess-einrichtungen, werden in dieser Europäischen Norm nicht behandelt.

Toxische oder chemische Gefährdungen und Gefährdungen durch Stäube, Dämpfe oder Gase, die durch die aufzuwickelnden, abzuwickelnden, zu schneidenden oder umzuwickelnden Materialien auftreten könnten, werden in dieser Europäischen Norm nicht behandelt.

ANMERKUNG Die Richtlinie 94/9/EG bezüglich Geräte und Schutzsysteme zur bestimmungsgemäßen Verwendung in explosionsgefährdeten Bereichen kann bei Maschinen oder Bauteilen nach dieser Europäischen Norm zur Anwendung kommen. Die vorliegende Norm ist nicht als Mittel zum Nachweis der Übereinstimmung mit den grundlegenden Gesundheits- und Sicherheitsanforderungen der Richtlinie 94/9/EG vorgesehen.

Diese Europäische Norm gilt nicht für Wickelmaschinen, die vor ihrer Veröffentlichung hergestellt worden sind.

Machines pour les matières plastiques et le caoutchouc - Enrouleurs pour films ou feuilles - Prescriptions de sécurité

La présente Norme européenne traite de tous les phénomènes dangereux, situations et événements

dangereux significatifs pertinents pour la conception et la construction des enrouleurs utilisés pour enrouler

et/ou dérouler et/ou rebobiner et/ou refendre des films ou des feuilles fabriqués en caoutchouc, matières

plastiques et matériaux composites, en cas d’utilisation normale ou de mauvais usage raisonnablement

prévisible par le constructeur (voir Article 4).

Une machine utilisée pour enrouler (enrouleur) ou rebobiner (rebobineuse) commence au point d’introduction

du film ou de la feuille dans la machine et se termine au poste de déchargement de la (des) bobine(s).

Une machine utilisée pour dérouler (dérouleur) commence au poste de montage de la (des) bobine(s) et se

termine au poste de sortie du film ou de la feuille déroulé(e).

Une machine utilisée pour dérouler, couper et rebobiner (bobineuse coupeuse) commence au poste de

montage de la (des) bobine(s) et se termine au(x) poste(x) de déchargement de la (des) bobine(s) et

comprend un ou plusieurs dispositifs de coupe/refente intégrés.

Sur certaines machines, les fonctions d’enroulement, de déroulement, de rebobinage et de refente peuvent

être combinées.

Les phénomènes dangereux engendrés par les rayonnements électromagnétiques, par exemple lors de

l’utilisation des dispositifs de contrôle d’épaisseur, ne sont pas couverts par la présente Norme européenne.

Les phénomènes dangereux chimiques ou toxiques et les phénomènes dangereux engendrés par les

poussières, fumées ou gaz qui pourraient être émis par les matières en cours d’enroulement, de déroulement,

de refente ou de rebobinage ne sont pas couverts par la présente Norme européenne.

NOTE La Directive 94/9/CE relative aux appareils et systèmes de protection destinés à être utilisés en atmosphères

explosibles peut s’appliquer aux machines ou composants couverts par la présente Norme européenne. La présente

norme n’est pas destinée à fournir un moyen de satisfaire aux exigences essentielles de santé et de sécurité de la

Directive 94/9/CE.

La présente Norme européenne ne s'applique pas aux enrouleurs fabriqués avant sa date de publication.

Stroji za predelavo gume in plastike - Navijalniki za folije (filme) ali trakove - Varnostne zahteve

Ta evropski standard obravnava vse večje nevarnosti, nevarne situacije in dogodke, pomembne za načrtovanje in gradnjo navijalnikov, ki se uporabljajo za navijanje in/ali odvijanje in/ali ponovno navijanje in/ali rezanje folij (filmov) ali trakov iz gume, plastike in kompozitnih materialov, kadar se stroji uporabljajo v skladu z njihovim namenom in pod pogoji pričakovane nepravilne uporabe, ki jih določa proizvajalec (glej točko 4). Stroj za navijanje ali ponovno navijanje (navijalnik ali ponovni navijalnik) se začne pri vstopu folije ali traka v navijalnik in konča pri izpustu s koluta. Stroj za odvijanje (odvijanje) se začne pri prevzemnem položaju koluta in konča pri odvzemnem položaju folije ali traka. Stroj za odvijanje, rezanje in ponovno navijanje (rezalnik – ponovni navijalnik) se začne pri prevzemnem položaja koluta in konča pri izpustu s koluta ter zajema eno vgrajeno enoto za rezanje ali več. V nekaterih strojih so lahko funkcije navijanja, odvijanja, ponovnega navijanja in rezanja združene. Nevarnosti zaradi elektromagnetnega sevanja, na primer zaradi uporabe naprav za spremljanje debeline, niso zajete v tem evropskem standardu. Strupene ali kemične nevarnosti in nevarnosti zaradi prahu, dima ali plinov, ki se lahko pojavijo zaradi materialov, ki se navijajo, odvijajo, režejo ali ponovno navijajo, niso zajete v tem evropskem standardu.

General Information

- Status

- Published

- Publication Date

- 28-May-2013

- Technical Committee

- CEN/TC 145 - Rubber and plastics machines - Safety

- Drafting Committee

- CEN/TC 145/WG 12 - Winding machines for film or sheet - Safety

- Current Stage

- 9060 - Closure of 2 Year Review Enquiry - Review Enquiry

- Start Date

- 03-Jun-2024

- Completion Date

- 03-Jun-2024

- Directive

- Harmonized Standard2006/42/EC - Directive 2006/42/EC of the European Parliament and of the Council of 17 May 2006 on machinery, and amending Directive 95/16/EC (recast)OJ Ref: C 348, C 348, C 348, C 348, C 348, C 348, C 348, C OJ Date: 28-Nov-2013

Relations

- Effective Date

- 30-Jan-2010

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 13418:2013 - "Plastics and rubber machines - Winding machines for film or sheet - Safety requirements" is a European (Type C) standard that specifies safety requirements for the design and construction of winding, unwinding, rewinding and slitter‑rewinder machines used with films or sheets made of rubber, plastics and composite materials. It covers significant hazards, hazardous situations and events relevant to normal use and reasonably foreseeable misuse. The standard applies from the intake of the web to the reel discharge (or vice versa for unwinds) and replaces earlier editions.

The standard does NOT cover:

- hazards from electromagnetic radiation (e.g., thickness monitors),

- toxic/chemical hazards or hazards from dusts, fumes or gases,

- machines manufactured before its publication date.

Key topics and technical requirements

EN 13418:2013 organizes safety requirements and measures across the machine lifecycle. Important technical topics include:

- List of significant hazards relevant to winding, slitting and web handling operations.

- Protective measures and guarding: principles for distance guarding, fixed/movable guards and area guarding to prevent access to danger zones.

- Safety distances and ergonomics: positioning of safeguards relative to human approach speeds and reach.

- Drive, power transmission and unexpected start‑up prevention: safeguards to avoid accidental motion and restart.

- Cutting devices and slitting units: safety provisions for integrated slitting/cutting equipment.

- Control systems and safety‑related parts: design requirements and verification; updated to reflect performance levels in EN ISO 13849‑1.

- Electrical, pneumatic and hydraulic systems: general safety requirements for machine services and components.

- Emergency stop, manual intervention and start‑up procedures: defined procedures and human‑machine interaction aspects.

- Noise assessment: includes a normative noise test code (measurement and declaration of emission values).

- Verification and documentation: testing, information for use, marking and instruction manual content.

Practical applications and users

This standard is intended for:

- Machine manufacturers (OEMs) designing and building winders, rewinders, unwinds and slitter‑rewinders.

- Machine designers and safety engineers performing risk assessment, selecting guards and specifying safety controls.

- Plant managers and integrators procuring compliant equipment and implementing safe operating procedures.

- Notified bodies and conformity assessors evaluating compliance with EU Machinery Directive requirements (see Annex ZA relating to Directive 2006/42/EC).

Typical uses:

- Designing compliant guarding and control systems for web‑handling lines.

- Specifying safety‑related control performance (EN ISO 13849‑1) and emergency stop layouts.

- Preparing user manuals, marking and noise declarations required for CE conformity.

Related standards (selected)

- EN ISO 12100:2010 - Risk assessment and reduction (Type A/B/C standard relationship)

- EN ISO 13849‑1 - Safety‑related parts of control systems (performance levels)

- EN 60204‑1 - Electrical equipment of machines

- EN ISO 3744 / 3746 / 3747 / 11201 - Noise measurement and declaration

Keywords: EN 13418:2013, winding machines safety, slitter rewinder, plastics and rubber machines, machine guarding, EN ISO 13849-1, noise test code, CE Machinery Directive.

Get Certified

Connect with accredited certification bodies for this standard

Smithers Quality Assessments

US management systems and product certification.

DIN CERTCO

DIN Group product certification.

Sponsored listings

Frequently Asked Questions

EN 13418:2013 is a standard published by the European Committee for Standardization (CEN). Its full title is "Plastics and rubber machines - Winding machines for film or sheet - Safety requirements". This standard covers: This European Standard deals with all significant hazards, hazardous situations and events relevant to the design and construction of winding machines used for the winding and/or unwinding and/or rewinding and/or slitting of film or sheet manufactured from rubber, plastic and composite materials, when the machines are used as intended and under the conditions of misuse which are reasonably foreseeable by the manufacturer (see Clause 4). A machine used for winding or rewinding (winder or rewinder) begins at the intake of the film or sheet into the winding machine and ends at the discharge position of the reel(s). A machine used for unwinding (unwind) begins at the take-up position of the reel(s) and ends at the film or sheet take-off point. A machine used for unwinding, slitting and re-winding (slitter rewinder) begins at the take-up position of the reel(s) and ends at the discharge positions of the reel(s) and covers one or more integrated slitting/cutting units. In some machines the winding, unwinding, rewinding and slitting functions may be combined. Hazards due to electro-magnetic radiation, e.g. from the use of thickness monitoring devices, are not covered by this European Standard. Toxic or chemical hazards and hazards due to dusts, fumes or gases, which could occur from the materials being wound, unwound, slit or rewound are not covered by this European Standard. NOTE Directive 94/9/EC concerning equipment and protective systems intended for use in potentially explosive atmospheres can be applicable to the type of machine or equipment covered by this European Standard. The present standard is not intended to provide means of complying with the essential health and safety requirements of Directive 94/9/EC. This European Standard is not applicable to winding machines which are manufactured before the date of its publication.

This European Standard deals with all significant hazards, hazardous situations and events relevant to the design and construction of winding machines used for the winding and/or unwinding and/or rewinding and/or slitting of film or sheet manufactured from rubber, plastic and composite materials, when the machines are used as intended and under the conditions of misuse which are reasonably foreseeable by the manufacturer (see Clause 4). A machine used for winding or rewinding (winder or rewinder) begins at the intake of the film or sheet into the winding machine and ends at the discharge position of the reel(s). A machine used for unwinding (unwind) begins at the take-up position of the reel(s) and ends at the film or sheet take-off point. A machine used for unwinding, slitting and re-winding (slitter rewinder) begins at the take-up position of the reel(s) and ends at the discharge positions of the reel(s) and covers one or more integrated slitting/cutting units. In some machines the winding, unwinding, rewinding and slitting functions may be combined. Hazards due to electro-magnetic radiation, e.g. from the use of thickness monitoring devices, are not covered by this European Standard. Toxic or chemical hazards and hazards due to dusts, fumes or gases, which could occur from the materials being wound, unwound, slit or rewound are not covered by this European Standard. NOTE Directive 94/9/EC concerning equipment and protective systems intended for use in potentially explosive atmospheres can be applicable to the type of machine or equipment covered by this European Standard. The present standard is not intended to provide means of complying with the essential health and safety requirements of Directive 94/9/EC. This European Standard is not applicable to winding machines which are manufactured before the date of its publication.

EN 13418:2013 is classified under the following ICS (International Classification for Standards) categories: 83.200 - Equipment for the rubber and plastics industries. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13418:2013 has the following relationships with other standards: It is inter standard links to EN 13418:2004+A1:2008, EN 61496-1:2004, EN 61496-1:2004/A1:2008, EN 60529:1991, CLC/TS 61496-3:2008, EN 60204-1:2006/A1:2009, EN ISO 13857:2008, EN 1760-3:2004+A1:2009, EN ISO 3744:2010, EN 1088:1995+A2:2008, EN ISO 13849-1:2008, EN ISO 9614-2:1996, EN ISO 3746:2010, EN ISO 4871:2009, EN ISO 11201:2010. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13418:2013 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC; Standardization Mandates: M/BC/CEN/88/13. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13418:2013 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Stroji za predelavo gume in plastike - Navijalniki za folije (filme) ali trakove - Varnostne zahteveKunststoff- und Gummimaschinen - Wickelmaschinen für flache Bahnen - SicherheitsanforderungenMachines pour les matières plastiques et le caoutchouc - Bobineuses pour films ou feuilles - Prescriptions de sécuritéPlastics and rubber machines - Winding machines for film or sheet - Safety requirements83.200Oprema za gumarsko industrijo in industrijo polimernih materialovEquipment for the rubber and plastics industriesICS:Ta slovenski standard je istoveten z:EN 13418:2013SIST EN 13418:2013en,fr,de01-november-2013SIST EN 13418:2013SLOVENSKI

STANDARDSIST EN 13418:2004+A1:20081DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13418

May 2013 ICS 83.200 Supersedes EN 13418:2004+A1:2008English Version

Plastics and rubber machines - Winding machines for film or sheet - Safety requirements

Machines pour les matières plastiques et le caoutchouc - Bobineuses pour films ou feuilles - Prescriptions de sécurité

Kunststoff- und Gummimaschinen - Wickelmaschinen für flache Bahnen - Sicherheitsanforderungen This European Standard was approved by CEN on 11 April 2013.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2013 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 13418:2013: ESIST EN 13418:2013

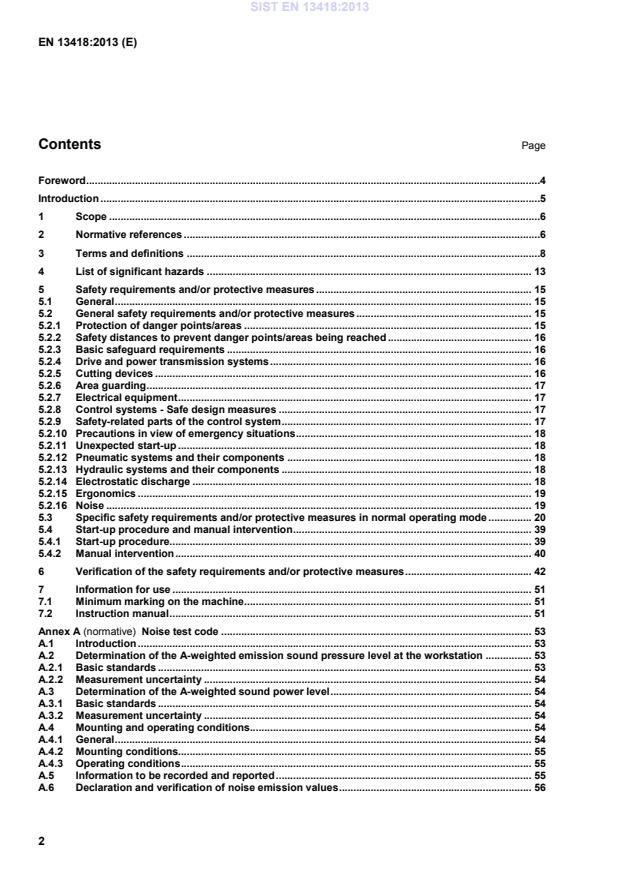

Noise test code . 53 A.1 Introduction . 53 A.2 Determination of the A-weighted emission sound pressure level at the workstation . 53 A.2.1 Basic standards . 53 A.2.2 Measurement uncertainty . 54 A.3 Determination of the A-weighted sound power level . 54 A.3.1 Basic standards . 54 A.3.2 Measurement uncertainty . 54 A.4 Mounting and operating conditions. 54 A.4.1 General . 54 A.4.2 Mounting conditions. 55 A.4.3 Operating conditions . 55 A.5 Information to be recorded and reported . 55 A.6 Declaration and verification of noise emission values . 56 SIST EN 13418:2013

Example of area guarding using a combination of distance guarding in conjunction with sensitive protective equipment (SPE) . 57 Annex C (informative)

Example of a safety concept and procedures for a centre turret winder . 59 Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC . 63 Bibliography . 64

A machine used for unwinding (unwind) begins at the take-up position of the reel(s) and ends at the film or sheet take-off point. A machine used for unwinding, slitting and re-winding (slitter rewinder) begins at the take-up position of the reel(s) and ends at the discharge positions of the reel(s) and covers one or more integrated slitting/cutting units. In some machines the winding, unwinding, rewinding and slitting functions may be combined. Hazards due to electro-magnetic radiation, e.g. from the use of thickness monitoring devices, are not covered by this European Standard.

Toxic or chemical hazards and hazards due to dusts, fumes or gases, which could occur from the materials being wound, unwound, slit or rewound are not covered by this European Standard. NOTE Directive 94/9/EC concerning equipment and protective systems intended for use in potentially explosive atmospheres can be applicable to the type of machine or equipment covered by this European Standard. The present standard is not intended to provide means of complying with the essential health and safety requirements of Directive 94/9/EC. This European Standard is not applicable to winding machines which are manufactured before the date of its publication. 2 Normative references The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 953:1997+A1:2009, Safety of machinery — Guards — General requirements for the design and construction of fixed and movable guards EN 1037:1995+A1:2008, Safety of machinery — Prevention of unexpected start-up EN 1088:1995+A2:2008, Safety of machinery — Interlocking devices associated with guards — Principles for design and selection EN 1760-1:1997+A1:2009, Safety of machinery — Pressure sensitive protective devices — Part 1: General principles for the design and testing of pressure sensitive mats and pressure sensitive floors EN 1760-3:2004+A1:2009, Safety of machinery — Pressure sensitive protective devices — Part 3: General principles for the design and testing of pressure sensitive bumpers, plates, wires and similar devices SIST EN 13418:2013

(IEC 61496-3:2008) EN ISO 3744:2010, Acoustics — Determination of sound power levels and sound energy levels of noise sources using sound pressure — Engineering methods for an essentially free field over a reflecting plane (ISO 3744:2010) EN ISO 3746:2010, Acoustics — Determination of sound power levels and sound energy levels of noise sources using sound pressure — Survey method using an enveloping measurement surface over a reflecting plane (ISO 3746:2010) EN ISO 3747:2010, Acoustics — Determination of sound power levels and sound energy levels of noise sources using sound pressure — Engineering/survey methods for use in situ in a reverberant environment (ISO 3747:2010) EN ISO 4413:2010, Hydraulic fluid power — General rules and safety requirements for systems and their components (ISO 4413:2010) EN ISO 4414:2010, Pneumatic fluid power — General rules and safety requirements for systems and their components (ISO 4414:2010) EN ISO 4871:2009, Acoustics — Declaration and verification of noise emission values of machinery and equipment (ISO 4871:1996) EN ISO 9614-2:1996, Acoustics — Determination of sound power levels of noise sources using sound intensity — Part 2: Measurement by scanning (ISO 9614-2:1996) EN ISO 11201:2010, Acoustics — Noise emitted by machinery and equipment — Determination of emission sound pressure levels at a work station and at other specified positions in an essentially free field over a reflecting plane with negligible environmental corrections (ISO 11201:2010) EN ISO 11202:2010, Acoustics — Noise emitted by machinery and equipment — Determination of emission sound pressure levels at a work station and at other specified positions applying approximate environmental corrections (ISO 11202:2010) EN ISO 11204:2010, Acoustics — Noise emitted by machinery and equipment — Determination of emission sound pressure levels at a work station and at other specified positions applying accurate environmental corrections (ISO 11204:2010) EN ISO 12100:2010, Safety of machinery — General principles for design — Risk assessment and risk reduction (ISO 12100:2010)

1) EN 60204-1:2006 is impacted by the stand-alone amendment EN 60204-1:2006/A1:2009, Safety of machinery Electrical equipment of machines Part 1: General requirements. 2) EN 61496-1:2004 is impacted by the stand-alone amendment EN 61496-1:2004/A1:2008, Safety of machinery Electro-sensitive protective equipment Part 1: General requirements and tests (IEC 61496-1:2004/A1:2007 + corrigendum Jul. 2008). SIST EN 13418:2013

Figure 1 — Centre winder 3.1.2 surface winder winding machine whose reel drive relies on friction at the driven reel surface

Figure 2 — Surface winder

3) EN ISO 13849-1:2008 is impacted by the corrigendum EN ISO 13849-1:2008/AC:2009. SIST EN 13418:2013

Figure 3 — Schematic drawing of a dancer roll 3.7.2 suspended roll guide roll that reciprocates between guides in a linear direction and over which the film or sheet runs. The load of the suspended roll determines the film or sheet tension

Figure 4 — Schematic drawing of a suspended roll SIST EN 13418:2013

Hazards

Danger points/areas Drawing-in between film or sheet and moving part, e. g. roll Drawing-in between film or sheet and reel Drawing-in between film or sheet and winding/ reel and fixed or moving machine parts or floor Drawing-in between moving parts, e. g. roll/roll Drawing-in between fixed and moving machine parts Crushing and/or shearing between moving machine parts Crushing and/or shearing between reels and/or fixed and moving machine parts and floor Crushing and/or shearing when inserting/chucking machine parts Drawing-in or trapping by moving machine parts Cutting by knives Cross-references to Table 3 (Safety requirements and/or protective measures for individual functional groups and/or machine parts in normal operating mode) Non-driven roll(s) x

x x

x

5.3.1 Driven roll(s) x

x x

5.3.2.1 Vacuum roll(s) x

x

5.3.2.2 Nip roll(s)

x

x

x x

5.3.2.3 Film or sheet tension control (e.g. dancer roll, suspended roll, force measuring roll) x

x

5.3.3 Material take-up point of a centre winder

x x

5.3.4.1.1 Intake nip of a surface winder

x x

5.3.4.1.2 Unwind position

x

5.3.4.2 Pivot arm

x x

5.3.4.3 Turret device

x

x

5.3.4.4 Guide carriage device

x

x

5.3.4.5 Contact/pressure roll x

x

x x

5.3.4.6 Winding core support

x x

5.3.4.7 Winding core loading device

x

5.3.4.8 Winding core unloading device

x

5.3.4.9 Lay on device

x x

x

5.3.5.1 Film or sheet splicing device

x

x

x 5.3.5.2 Impact cutting device

x

x 5.3.5.3.1 Draw type cutting device

x

x 5.3.5.3.2 Reel loading device

x

5.3.6 Reel unloading device

x

5.3.7 Spreader roll

x

5.3.8 Longitudinal cutting device

x

x 5.3.9 Splitting device

x 5.3.10 Film or sheet alignment device x

x

5.3.11 SIST EN 13418:2013

Hazards

Cross-references to 5.2 (General safety requirements and/or protective measures) Drive and power transmission systems Drawing-in, crushing and shearing

5.2.4 Cutting devices Cutting during handling of cutting knives/blades (setting-up, maintenance, assembly and disassembly)

5.2.5 Electrical equipment Electric shock or burns due to direct or indirect contact with live conductive parts. 5.2.7 Failure of control systems Unexpected overrunning or starting of hazardous movements

Unexpected movement of machine parts 5.2.8, 5.2.9, 5.2.11 Entrapment within the machine Drawing-in, trapping and crushing between rolls and/or machine parts 5.2.10 Malfunction of hydraulic or pneumatic systems Unexpected movement of machine parts, ejection of pressurised fluids, etc. 5.2.12, 5.2.13 Electrostatic discharge Electric shock due to electrostatic discharge and subsequent dangerous movement (e.g. fall). 5.2.14 Neglecting ergonomic principles Hazards resulting from unfavourable posture or excess efforts 5.2.15 Noise Hearing impairment

Interference with speech communication or with the perception of acoustic signals 5.2.16

5 Safety requirements and/or protective measures

5.1 General Machinery shall comply with the safety requirements and/or protective measures of this clause. In addition, the machine shall be designed according to the principles of EN ISO 12100:2010 for hazards relevant but not significant, which are not dealt with by this document (e.g. sharp edges). 5.2 General safety requirements and/or protective measures 5.2.1 Protection of danger points/areas Access to danger points/areas in working zones shall be protected by measures in accordance with Clause 6 of EN ISO 12100:2010, subject to additional provisions for individual functional groups in 5.3. SIST EN 13418:2013

there is a minimum distance of 120 mm between a roll and the nearest machine parts. Protection at material take-up points of non-driven rolls is not required, if: the roll can be stopped with one hand;

and there are no hazards which are due to any property of the material such as adhesion, roughness, etc. 5.2.2 Safety distances to prevent danger points/areas being reached 5.2.2.1 Upper limbs The safety distances for the upper limbs shall be in accordance with EN ISO 13857:2008.

A hazard zone that is at a height of ≥ 2 700 mm does not need safeguarding. For selection of tables to be used concerning "reaching over protective structures", see Table 3 in 5.3. 5.2.2.2 Lower limbs The safety distances for the lower limbs shall be in accordance with EN ISO 13857:2008. 5.2.3 Basic safeguard requirements

Guards shall comply with EN 953:1997+A1:2009. Interlocking guards without guard locking shall be positioned in accordance with Clause 9 of EN ISO 13855:2010. Sensitive protective equipment shall be in accordance with 6.3.2.5 of EN ISO 12100:2010. Light curtains shall be in accordance with EN 61496-1:2004 and positioned in accordance with EN ISO 13855:2010. Scanners (AOPDDR) shall be in accordance with CLC/TS 61496-3:2008 and positioned in accordance with 6.1.4 of EN ISO 13855:2010. Pressure sensitive mats or floors shall be in accordance with EN 1760-1:1997+A1:2009 and installed in accordance with Clause 7 of EN ISO 13855:2010.

Pressure sensitive bumpers shall be in accordance with EN 1760-3:2004+A1:2009. 5.2.4 Drive and power transmission systems Moving parts of drive and power transmission systems, for example shafts, clutches, chains or belts shall be protected by fixed guards in accordance with fixed guards as defined in 3.27.1 of EN ISO 12100:2010. 5.2.5 Cutting devices All cutting devices (impact, cross cutting, and draw type cutting device) shall be fitted with safeguarding to minimise operator contact with the cutting surface and prevent the hazard of cutting when not in use. See also 7.2.f). SIST EN 13418:2013

5.2.7 Electrical equipment 5.2.7.1 General The electrical equipment shall comply with EN 60204-1:2006 and with the following additional requirements: 5.2.7.2 Supply disconnecting (isolating) device The supply disconnecting devices shall be in accordance with 5.3.2 and 5.3.3 of EN 60204-1:2006. The supply disconnecting (isolating) device can be used for maintenance and machine inspection, as defined in 6.3.5.4 of EN ISO 12100:2010. 5.2.7.3 Protection against direct contact Protection against direct contact shall be as defined in 6.2 of EN 60204-1:2006, including the IP codes according to EN 60529:1991. 5.2.7.4 Protection against indirect contact Protection against indirect contact shall be as defined in 6.3 of EN 60204-1:2006, 5.2.7.5 Control functions – Start and Stop The start function shall conform to 9.2.1 and 9.2.5.2 of EN 60204-1:2006. The stop shall function as a category 0 stop and in accordance with 9.2.2 of EN 60204-1:2006, If stop category 0 can result in additional hazards, e.g. due to inertia of the winding, stop category 1 shall be used. Stop category 2 may be used if it is necessary to leave the winding machine energised after stopping, e.g. to keep the film or sheet tensioned in the production line when it is stationary. 5.2.8 Control systems - Safe design measures

The design measures of the control system shall be chosen so that their safety-related performance provides a sufficient amount of risk reduction in accordance with 6.2.11 of EN ISO 12100:2010.

5.2.9 Safety-related parts of the control system

The safety-related parts of the control system shall be at least in accordance with EN ISO 13849-1:2008 and the control system will be a minimum of PLr=b, subject to specific provisions for individual functional groups in 5.3 and specific operations in 5.4. SIST EN 13418:2013

EN 60204-1:2006. Protective measures against hazards due to unexpected start-up from individual functional groups are described in the corresponding subclauses of 5.3 in this standard. 5.2.12 Pneumatic systems and their components The pneumatic systems and their components shall be in accordance with EN ISO 4414:2010. When designing pneumatic systems for machinery, all intended operations and use of systems shall be considered.

5.2.13 Hydraulic systems and their components The hydraulic systems and their components shall be in accordance with EN ISO 4413:2010 When designing hydraulic systems for machinery, all intended operations and use of systems shall be considered.

5.2.14 Electrostatic discharge 5.2.14.1 General Hazards arising from static electricity shall be prevented by bonding all conductive structural parts of the electrical equipment and the machine and connecting to earth. Earthing points for temporary connections shall be provided where a machine assembly includes moveable metal items, which cannot be permanently earthed. See also 7.2 k). 5.2.14.2 Additional requirements for machinery processing non-conductive film or sheet Additional measures shall be employed to prevent hazards due to electrostatic discharge where a winding machine is used to process non-conductive film or sheet, for example by: reducing friction between the film or sheet and guiding system by minimising the area of contact; SIST EN 13418:2013

The right-hand column contains the additional protective measures that have to be fulfilled. The following supplements give further requirements or information in relation to particular safety requirements and/or protective measures in Table 3. In the table, the word supplement is abbreviated to “Supp.”. Supplement 1 Where used for area guarding light barriers, scanners (AOPDDR) and pressure sensitive mats or floors shall be positioned at the minimum safety distance calculated in accordance with the following formula: mmKxTS850)10/(+=

T = overall system stopping performance

For the definition of T, see 3.1.2 of EN ISO 13855:2010 and for the calculation of T, see 5.1 of EN ISO 13855:2010.

NOTE For winding machines, the formula given in EN ISO 13855:2010 is modified due to high inertia of the rolls and because the SPE are positioned to prevent unintentional access only. For the possible residual risk see 7.2 o). For an example see Annex B. s mm K / 600 1 = SIST EN 13418:2013

Danger point/area Protective measures

Guards Protective devices Combi. Further requirements

Guards as defined in 3.27 of EN ISO 12100:2010 Fixed guards as defined in 3.27.1 of EN ISO 12100:2010 Interlocking guards as defined in 3.27.4 of EN ISO 12100:2010 Interlocking guards with guard locking as defined in both 3.27.5 of EN ISO 12100:2010 and according to the choice criteria of EN 1088:1995+A2:2008 Required Performance Level (PLr) for the safety related parts of the control system in accordance with EN ISO 13849-1:2008 Table for the safety distances for the upper limbs for reaching over protective structures in accordance with EN ISO 13857:2008 Hold-to-run control device as defined in 3.28.3 of EN ISO 12100:2010 and EN ISO 13849-1:2008. The maximum speed of the movement shall not exceed 5 m/min monitored to PLr=b Sensitive protective equipment as defined in 3.28.5 and 3.28.6 of EN ISO 12100:2010 and in accordance with EN ISO 13849-1:2008 A combination of the devices in columns "Guards" and/or "Protective devices" where their use is indicated as permissible The danger zone shall be visible to the operator from the actuator operating position It shall be ensured that machine parts cannot move unintentionally as a result of stopping the machine or due to a failure of the energy supply (see EN 1037:1995+A1:2008) Additional protective measures 5.3.1 Non-driven roll(s)

x + Supp. 4 x x PLr=b 2

5.3.2 Fixed point roll(s)

5.3.2.1 Driven roll(s)

x + Supp. 4 x x PLr=c 2

5.3.2.2 Vacuum roll(s)

x + Supp. 4 x x PLr=c 2

Guards Protective devices Combi. Further requirements

Guards as defined in 3.27 of EN ISO 12100:2010 Fixed guards as defined in 3.27.1 of EN ISO 12100:2010 Interlocking guards as defined in 3.27.4 of EN ISO 12100:2010 Interlocking guards with guard locking as defined in both 3.27.5 of EN ISO 12100:2010 and according to the choice criteria of EN

1088:1995+A2:2008 Required Performance Level (PLr) for the safety related parts of the control system in accordance with EN ISO 13849-1:2008 Table for the safety distances for the upper limbs for reaching over protective structures in accordance with EN ISO 13857:2008 Hold-to-run control device as defined in 3.28.3 of EN ISO 12100:2010 and EN ISO 13849-1:2008. The maximum speed of the movement shall not exceed 5 m/min monitored to PLr=b Sensitive protective equipment as defined in 3.28.5 and 3.28.6 of EN ISO 12100:2010 and in accordance with EN ISO 13849-1:2008 A combination of the devices in columns "Guards" and/or "Protective devices" where their use is indicated as permissible The danger zone shall be visible to the operator from

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...