EN 16474:2025

(Main)Plastics and rubber machines - Tyre curing machines - Safety requirements

Plastics and rubber machines - Tyre curing machines - Safety requirements

This document applies to tyre curing machines having the following configuration:

- crossing flow tyre curing machines, with one cavity with manual or automatic feeding and discharge;

- crossing flow tyre curing machines, with two cavities, with manual or automatic feeding and discharge and with:

- common curing cycle and common safeguarding; or

- independent curing cycles and common safeguarding; or

- independent curing cycles and independent safeguarding;

- tyre curing machines with automatic rear feeding and discharge.

The safety requirements and/or protective measures specified in this document apply to tyre curing machines used to cure bicycle, motorcycle, passenger vehicle and truck tyres or other tyres that can be cured according to the requirements of this document.

This document deals with the following ancillary equipment that are an integral part in a tyre curing machine:

- loading/unloading device;

- take-away conveyor;

- Post Cure Inflator (PCI) integrated in the rear side of a crossing flow machines for passenger vehicle tyres;

- spraying jib.

This document does not deal with:

- feeding system and discharge system;

- tyre curing machines with manual loading of the green tyre into the mould and manual unloading of the cured tyre from the mould;

- ancillary equipment which is not an integral part of the tyre curing machine, e.g. conveying equipment;

- exhaust systems.

This document deals with all significant hazards, hazardous situations and events relevant to tyre curing machines, when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer (see Annex A).

It does not deal with hazards associated with falling of parts of the container or mould because they are not part of the machinery.

This document is not applicable to tyre curing machines which are manufactured before the date of its publication as an EN.

Kunststoff- und Gummimaschinen - Reifenvulkanisiermaschinen - Sicherheitsanforderungen

Dieses Dokument gilt für Reifenvulkanisiermaschinen mit folgender Konfiguration:

- Kreuzstrom-Reifenvulkanisiermaschinen, mit einer Kavität mit manueller oder automatischer Beschickung und Entnahme;

- Kreuzstrom-Reifenvulkanisiermaschinen, mit zwei Kavitäten, mit manueller oder automatischer Beschickung und Entnahme und mit:

- gemeinsamem Vulkanisierzyklus und gemeinsamer technischer Schutzmaßnahme; oder

- voneinander unabhängigen Vulkanisierzyklen und gemeinsamer technischer Schutzmaßnahme; oder

- voneinander unabhängigen Vulkanisierzyklen und unabhängiger technischer Schutzmaßnahme;

- Reifenvulkanisiermaschinen mit automatischer rückseitiger Beschickung und Entnahme.

Die in diesem Dokument festgelegten Sicherheitsanforderungen und/oder Schutzmaßnahmen gelten für Reifenvulkanisiermaschinen, die für die Vulkanisierung von Fahrrad-, Motorrad-, Personenkraftwagen- und Lastkraftwagenreifen oder anderen Reifen, die entsprechend den Anforderungen dieses Dokuments vulkanisiert werden können, verwendet werden.

Dieses Dokument behandelt die folgenden Zusatzeinrichtungen, die integraler Bestandteil einer Reifenvulkanisiermaschine sind:

- Lade-/Entladeeinrichtung;

- Abförderband;

Post Cure Inflator (PCI), der in die Rückseite einer Kreuzstrommaschine für Reifen von Personenkraftwagen integriert ist;

- Sprühausleger.

Dieses Dokument behandelt nicht:

- Beschickungs- und Entnahmesysteme;

- Reifenvulkanisiermaschinen, bei denen das Beladen des Reifenrohlings in die Form und das Entladen des Fertigreifens aus der Form manuell erfolgt;

- Zusatzeinrichtungen, die kein Bestandteil der Reifenvulkanisiermaschine sind, z. B. Fördereinrichtungen;

- Absaugsysteme.

Dieses Dokument behandelt alle wesentlichen Gefährdungen, Gefährdungssituationen und Ereignisse mit Bezug zu Reifenvulkanisiermaschinen, wenn sie bestimmungsgemäß und unter Bedingungen von durch den Hersteller vernünftigerweise vorhersehbaren Fehlanwendungen verwendet werden (siehe Anhang A).

Es behandelt nicht die Gefährdungen in Verbindung mit dem Herabfallen von Teilen des Containers oder der Form, da diese nicht Teil der Maschine sind.

Dieses Dokument gilt nicht für Reifenvulkanisiermaschinen, die vor dem Zeitpunkt ihrer Veröffentlichung als EN hergestellt wurden.

Machines pour les matières plastiques et le caoutchouc - Machines à vulcaniser les pneumatiques - Exigences de sécurité

Le présent document s’applique aux machines à vulcaniser les pneumatiques dont la configuration est la suivante :

— machines à vulcaniser les pneumatiques à flux traversant, à une cavité à alimentation et évacuation manuelles ou automatiques ;

— machines à vulcaniser les pneumatiques à flux traversant, à deux cavités avec alimentation et évacuation manuelles ou automatiques et avec :

— un cycle de vulcanisation commun et des mesures de protection communes ; ou

— des cycles de vulcanisation indépendants et des mesures de protection communes ; ou

— des cycles de vulcanisation indépendants et des mesures de protection indépendantes ;

— machines à vulcaniser les pneumatiques à alimentation et évacuation automatiques par l’arrière.

Les exigences de sécurité et/ou les mesures de prévention spécifiées dans le présent document s’appliquent aux machines à vulcaniser les pneumatiques utilisées pour vulcaniser les pneumatiques de bicyclettes, de motocycles, de véhicules de tourisme et de véhicules poids lourds ou d’autres pneumatiques qui peuvent être vulcanisés conformément aux exigences du présent document.

Le présent document traite des équipements auxiliaires suivants, qui font partie intégrante d’une machine à vulcaniser les pneumatiques :

— dispositif de chargement/déchargement ;

— convoyeur d’évacuation ;

— dispositif de gonflage post-vulcanisation (PCI) intégré à l’arrière d’une machine à flux traversant pour les pneumatiques de véhicules de tourisme ;

— potence de pulvérisation.

Le présent document ne traite pas :

— du système d’alimentation ni du système d’évacuation de la machine ;

— des machines à vulcaniser les pneumatiques avec chargement manuel du bandage dans le moule et déchargement manuel de l’enveloppe du moule ;

— d'équipement auxiliaire qui ne fait pas partie intégrante de la machine à vulcaniser, par exemple les équipements de convoyage ;

— des systèmes d’aspiration.

Le présent document traite tous les phénomènes dangereux, situations dangereuses et événements dangereux qui sont pertinents pour les machines à vulcaniser les pneumatiques lorsqu’elles sont utilisées normalement et dans les conditions de mauvais usage raisonnablement prévisible par le fabricant (voir l’Annexe A).

Il ne traite pas des phénomènes dangereux associés à la chute de pièces du container ou du moule car ceux-ci ne font pas partie de la machine.

Le présent document n’est pas applicable aux machines à vulcaniser les pneumatiques fabriqués avant sa date de publication comme EN.

Stroji za predelavo gume in plastike - Stiskalnice za vulkaniziranje - Varnostne zahteve

General Information

- Status

- Published

- Publication Date

- 14-Oct-2025

- Technical Committee

- CEN/TC 145 - Rubber and plastics machines - Safety

- Drafting Committee

- CEN/TC 145/WG 17 - Tyre curing presses

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 15-Oct-2025

- Due Date

- 11-Dec-2023

- Completion Date

- 15-Oct-2025

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 16474:2025 - Plastics and rubber machines: Tyre curing machines - Safety requirements (CEN) defines safety requirements and protective measures for a range of tyre curing machines used to vulcanise bicycle, motorcycle, passenger vehicle and truck tyres. The standard covers typical machine configurations such as crossing flow machines (one- or two-cavity), machines with automatic rear feeding/discharge, and integral ancillaries like loading/unloading devices, take-away conveyors, Post Cure Inflator (PCI) and spraying jibs. It addresses significant hazards when machines are used as intended or under reasonably foreseeable misuse and replaces earlier editions of EN 16474.

Key topics and technical requirements

- Scope and machine types: Crossing flow configurations (single and dual cavity), common or independent curing cycles/safeguarding, automatic rear feeding.

- Safety requirements / protective measures: General and specific measures for machine parts (movable upper part, bladders, moulds, containers), guarding, interlocks and pressure-related controls.

- Emergency stop and rescue movement: Requirements for emergency stop functions and rescue movements for movable components and loading devices.

- Bladder and pressure management: Rules covering inflatable bladders (loading pressure, allowed pressurisation during safeguard activation and limited short-time overpressure), and options for shields.

- Fire hazard and related measures: New provisions to identify and mitigate fire risks associated with curing operations.

- Noise control: Requirements and a normative Noise Test Code (Annex A) for declaration and verification of sound emission levels.

- Verification and documentation: Procedures for verifying safety measures and required information for use, including instruction handbook content, marking and warning signs.

- Ancillary equipment: Safety rules for integral devices (PCI, loading/unloading, take-away conveyors, spraying jib) while excluding non-integral conveying systems, exhaust systems and machines with fully manual loading/unloading.

Applications and who should use this standard

EN 16474:2025 is essential for:

- Tyre curing machine manufacturers (design, build, CE marking)

- OEMs and equipment integrators implementing automatic feeding/discharge and PCI

- Safety and compliance engineers performing risk assessments and conformity checks

- Maintenance personnel and facility managers managing safe operation and servicing

- Notified bodies and certification agencies evaluating compliance with the Machinery Directive (see Annex ZA)

Practical benefits include harmonised safety design, clearer requirements for guarding/interlocks, and standardized noise and fire risk controls that help manufacturers and users reduce accidents and meet regulatory obligations.

Related standards

Key referenced standards include:

- EN ISO 12100 (risk assessment), EN ISO 13849-1 (safety-related control systems), EN 60204-1 (electrical safety), EN ISO 13850 (emergency stop), EN IEC 61496 series (AOPDs), and acoustics standards (EN ISO 11201/11202/11204, EN ISO 4871). These support implementation of EN 16474:2025 requirements.

Get Certified

Connect with accredited certification bodies for this standard

Smithers Quality Assessments

US management systems and product certification.

DIN CERTCO

DIN Group product certification.

Sponsored listings

Frequently Asked Questions

EN 16474:2025 is a standard published by the European Committee for Standardization (CEN). Its full title is "Plastics and rubber machines - Tyre curing machines - Safety requirements". This standard covers: This document applies to tyre curing machines having the following configuration: - crossing flow tyre curing machines, with one cavity with manual or automatic feeding and discharge; - crossing flow tyre curing machines, with two cavities, with manual or automatic feeding and discharge and with: - common curing cycle and common safeguarding; or - independent curing cycles and common safeguarding; or - independent curing cycles and independent safeguarding; - tyre curing machines with automatic rear feeding and discharge. The safety requirements and/or protective measures specified in this document apply to tyre curing machines used to cure bicycle, motorcycle, passenger vehicle and truck tyres or other tyres that can be cured according to the requirements of this document. This document deals with the following ancillary equipment that are an integral part in a tyre curing machine: - loading/unloading device; - take-away conveyor; - Post Cure Inflator (PCI) integrated in the rear side of a crossing flow machines for passenger vehicle tyres; - spraying jib. This document does not deal with: - feeding system and discharge system; - tyre curing machines with manual loading of the green tyre into the mould and manual unloading of the cured tyre from the mould; - ancillary equipment which is not an integral part of the tyre curing machine, e.g. conveying equipment; - exhaust systems. This document deals with all significant hazards, hazardous situations and events relevant to tyre curing machines, when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer (see Annex A). It does not deal with hazards associated with falling of parts of the container or mould because they are not part of the machinery. This document is not applicable to tyre curing machines which are manufactured before the date of its publication as an EN.

This document applies to tyre curing machines having the following configuration: - crossing flow tyre curing machines, with one cavity with manual or automatic feeding and discharge; - crossing flow tyre curing machines, with two cavities, with manual or automatic feeding and discharge and with: - common curing cycle and common safeguarding; or - independent curing cycles and common safeguarding; or - independent curing cycles and independent safeguarding; - tyre curing machines with automatic rear feeding and discharge. The safety requirements and/or protective measures specified in this document apply to tyre curing machines used to cure bicycle, motorcycle, passenger vehicle and truck tyres or other tyres that can be cured according to the requirements of this document. This document deals with the following ancillary equipment that are an integral part in a tyre curing machine: - loading/unloading device; - take-away conveyor; - Post Cure Inflator (PCI) integrated in the rear side of a crossing flow machines for passenger vehicle tyres; - spraying jib. This document does not deal with: - feeding system and discharge system; - tyre curing machines with manual loading of the green tyre into the mould and manual unloading of the cured tyre from the mould; - ancillary equipment which is not an integral part of the tyre curing machine, e.g. conveying equipment; - exhaust systems. This document deals with all significant hazards, hazardous situations and events relevant to tyre curing machines, when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer (see Annex A). It does not deal with hazards associated with falling of parts of the container or mould because they are not part of the machinery. This document is not applicable to tyre curing machines which are manufactured before the date of its publication as an EN.

EN 16474:2025 is classified under the following ICS (International Classification for Standards) categories: 83.200 - Equipment for the rubber and plastics industries. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 16474:2025 has the following relationships with other standards: It is inter standard links to EN 16474:2015, EN IEC 61496-3:2019, EN IEC 61496-2:2020, EN IEC 61496-1:2020, ISO 1402:2021, EN 60204-1:2018, EN ISO 7010:2020/A2:2022, EN ISO 4414:2010, EN 1005-4:2005+A1:2008, EN ISO 7010:2020/A5:2023, EN ISO 13850:2015, EN ISO 14119:2025, EN ISO 14122-3:2016, EN 619:2022, EN ISO 13856-2:2013. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 16474:2025 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 2023/1230; Standardization Mandates: M/396, M/605. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 16474:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-februar-2026

Stroji za predelavo gume in plastike - Stiskalnice za vulkaniziranje - Varnostne

zahteve

Plastics and rubber machines - Tyre curing machines - Safety requirements

Kunststoff- und Gummimaschinen - Reifenvulkanisiermaschinen -

Sicherheitsanforderungen

Machines pour les matières plastiques et le caoutchouc - Machines à vulcaniser les

pneumatiques - Prescriptions de sécurité

Ta slovenski standard je istoveten z: EN 16474:2025

ICS:

25.120.10 Kovaški stroji. Stiskalnice. Forging equipment. Presses.

Škarje Shears

83.200 Oprema za gumarsko Equipment for the rubber and

industrijo in industrijo plastics industries

polimernih materialov

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 16474

EUROPEAN STANDARD

NORME EUROPÉENNE

October 2025

EUROPÄISCHE NORM

ICS 83.200 Supersedes EN 16474:2015

English Version

Plastics and rubber machines - Tyre curing machines -

Safety requirements

Machines pour les matières plastiques et le caoutchouc Kunststoff- und Gummimaschinen -

- Machines à vulcaniser les pneumatiques - Exigences Reifenvulkanisiermaschinen -

de sécurité Sicherheitsanforderungen

This European Standard was approved by CEN on 18 August 2025.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2025 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 16474:2025 E

worldwide for CEN national Members.

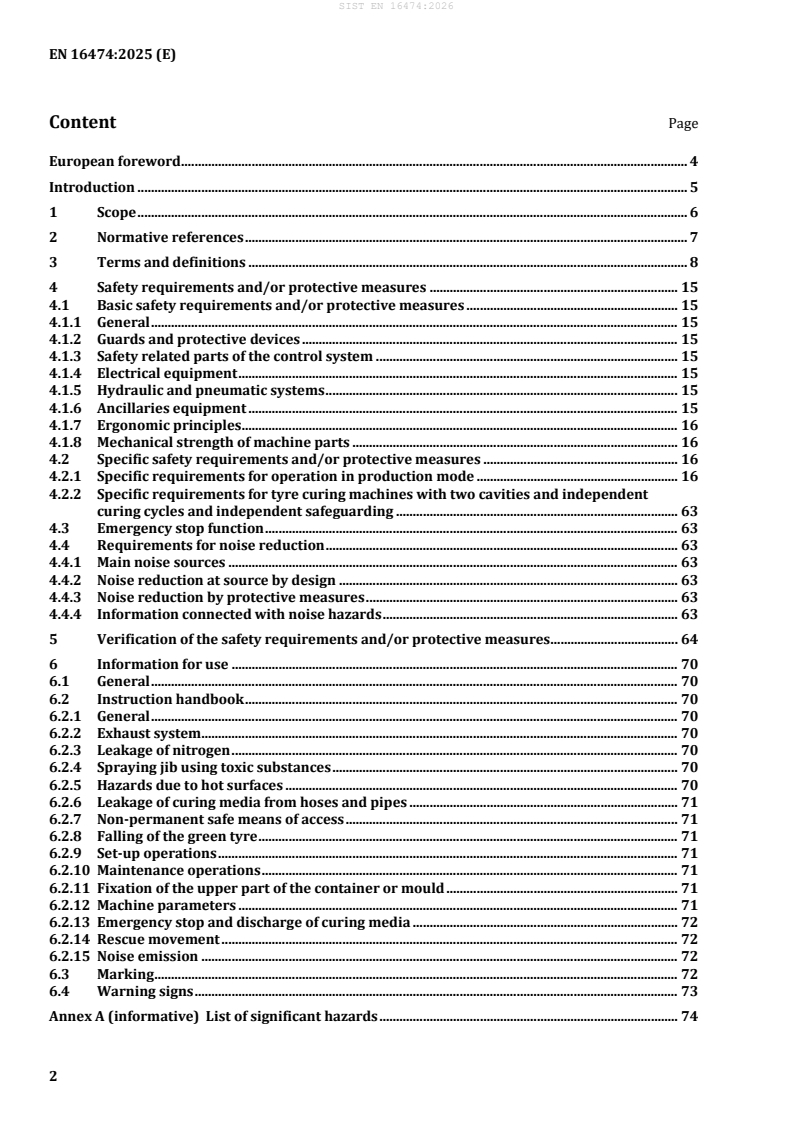

Content Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 7

3 Terms and definitions . 8

4 Safety requirements and/or protective measures . 15

4.1 Basic safety requirements and/or protective measures . 15

4.1.1 General . 15

4.1.2 Guards and protective devices . 15

4.1.3 Safety related parts of the control system . 15

4.1.4 Electrical equipment . 15

4.1.5 Hydraulic and pneumatic systems . 15

4.1.6 Ancillaries equipment . 15

4.1.7 Ergonomic principles . 16

4.1.8 Mechanical strength of machine parts . 16

4.2 Specific safety requirements and/or protective measures . 16

4.2.1 Specific requirements for operation in production mode . 16

4.2.2 Specific requirements for tyre curing machines with two cavities and independent

curing cycles and independent safeguarding . 63

4.3 Emergency stop function . 63

4.4 Requirements for noise reduction . 63

4.4.1 Main noise sources . 63

4.4.2 Noise reduction at source by design . 63

4.4.3 Noise reduction by protective measures . 63

4.4.4 Information connected with noise hazards . 63

5 Verification of the safety requirements and/or protective measures . 64

6 Information for use . 70

6.1 General . 70

6.2 Instruction handbook . 70

6.2.1 General . 70

6.2.2 Exhaust system . 70

6.2.3 Leakage of nitrogen . 70

6.2.4 Spraying jib using toxic substances . 70

6.2.5 Hazards due to hot surfaces . 70

6.2.6 Leakage of curing media from hoses and pipes . 71

6.2.7 Non-permanent safe means of access . 71

6.2.8 Falling of the green tyre . 71

6.2.9 Set-up operations . 71

6.2.10 Maintenance operations . 71

6.2.11 Fixation of the upper part of the container or mould . 71

6.2.12 Machine parameters . 71

6.2.13 Emergency stop and discharge of curing media . 72

6.2.14 Rescue movement . 72

6.2.15 Noise emission . 72

6.3 Marking . 72

6.4 Warning signs . 73

Annex A (informative) List of significant hazards . 74

Annex B (normative) Noise test code . 83

Annex ZA (informative) Relationship between this European Standard and the essential

requirements of Directive 2006/42/EC aimed to be covered . 89

Annex ZB (informative) Relationship between this European Standard and the essential

requirements of Regulation (EU) 2023/1230 aimed to be covered. 91

Bibliography . 94

European foreword

This document (EN 16474:2025) has been prepared by Technical Committee CEN/TC 145 “Plastics and

rubber machines”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by April 2026 and conflicting national standards shall be

withdrawn at the latest by April 2026.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 16474:2015.

In comparison with the previous edition, the following technical modifications have been made:

— modification of the scope including machines for bicycle and motorcycle tyres and Post Curing

Inflator (PCI);

— consideration of revised type-A and type-B standards;

— added safety requirements for Post Curing Inflator;

— added requirements related to rescue movement for the movable upper part and the loading device;

— introduced fire hazard and related safety requirements;

— considered the possibility to leave pressurized the bladder above the semi-closed position for a

limited time and also when safeguards are activated and to increase the pressure above the threshold

for a very short time;

— considered the possibility to install a shield in order to leave pressurized the bladder below the semi-

closed position for a limited time when safeguards are activated.

This document has been prepared under a standardization request addressed to CEN by the European

Commission. The Standing Committee of the EFTA States subsequently approves these requests for its

Member States.

For the relationship with EU Legislation, see informative Annexes ZA and ZB, which are an integral part

of this document.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organizations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

Introduction

This document is a type-C standard as stated in EN ISO 12100.

This document is of relevance, in particular, for the following stakeholder groups representing the market

players with regard to machinery safety:

— machine manufacturers (small, medium and large enterprises);

— health and safety bodies (regulators, accident prevention organizations, market surveillance etc.).

Others can be affected by the level of machinery safety achieved with the means of the document by the

above-mentioned stakeholder groups:

— machine users/employers (small, medium and large enterprises);

— machine users/employees (e.g. trade unions, organizations for people with special needs);

— service providers, e.g. for maintenance (small, medium and large enterprises);

— consumers (in case of machinery intended for use by consumers).

The above-mentioned stakeholder groups have been given the possibility to participate at the drafting

process of this document.

The machinery concerned and the extent to which hazards, hazardous situations and hazardous events

are covered are indicated in the scope of this document.

When provisions of this type-C standard are different from those which are stated in type-A or type-B

standards, the provisions of this type-C standard take precedence over the provisions of the other

standards for machines that have been designed and built in accordance with the provisions of this type-C

standard.

1 Scope

This document applies to tyre curing machines having the following configuration:

— crossing flow tyre curing machines, with one cavity with manual or automatic feeding and discharge;

— crossing flow tyre curing machines, with two cavities, with manual or automatic feeding and

discharge and with:

— common curing cycle and common safeguarding; or

— independent curing cycles and common safeguarding; or

— independent curing cycles and independent safeguarding;

— tyre curing machines with automatic rear feeding and discharge.

The safety requirements and/or protective measures specified in this document apply to tyre curing

machines used to cure bicycle, motorcycle, passenger vehicle and truck tyres or other tyres that can be

cured according to the requirements of this document.

This document deals with the following ancillary equipment that are an integral part in a tyre curing

machine:

— loading/unloading device;

— take-away conveyor;

— Post Cure Inflator (PCI) integrated in the rear side of a crossing flow machines for passenger vehicle

tyres;

— spraying jib.

This document does not deal with:

— feeding system and discharge system;

— tyre curing machines with manual loading of the green tyre into the mould and manual unloading of

the cured tyre from the mould;

— ancillary equipment which is not an integral part of the tyre curing machine, e.g. conveying

equipment;

— exhaust systems.

This document deals with all significant hazards, hazardous situations and events relevant to tyre curing

machines, when they are used as intended and under conditions of misuse which are reasonably

foreseeable by the manufacturer (see Annex A).

It does not deal with hazards associated with falling of parts of the container or mould because they are

not part of the machinery.

This document is not applicable to tyre curing machines which are manufactured before the date of its

publication as an EN.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 619:2022, Continuous handling equipment and systems - Safety requirements for equipment for

mechanical handling of unit loads

EN 1005-3:2002+A1:2008, Safety of machinery - Human physical performance - Part 3: Recommended

force limits for machinery operation

EN 1005-4:2005+A1:2008, Safety of machinery - Human physical performance - Part 4: Evaluation of

working postures and movements in relation to machinery

EN 60204-1:2018, Safety of machinery - Electrical equipment of machines - Part 1: General requirements

EN IEC 61496-1:2020, Safety of machinery - Electro-sensitive protective equipment - Part 1: General

requirements and tests (IEC 61496-1:2020)

EN IEC 61496-2:2020, Safety of machinery - Electro-sensitive protective equipment - Part 2: Particular

requirements for equipment using active opto-electronic protective devices (AOPDs) (IEC 61496-2:2020)

EN IEC 61496-3:2019, Safety of machinery - Electro-sensitive protective equipment - Part 3: Particular

requirements for active opto-electronic protective devices responsive to diffuse reflection (AOPDDR)

(IEC 61496-3:2018)

EN ISO 4413:2010, Hydraulic fluid power - General rules and safety requirements for systems and their

components (ISO 4413:2010)

EN ISO 4414:2010, Pneumatic fluid power - General rules and safety requirements for systems and their

components (ISO 4414:2010)

EN ISO 4871:2009, Acoustics - Declaration and verification of noise emission values of machinery and

equipment (ISO 4871:1996)

EN ISO 7010:2020, Graphical symbols - Safety colours and safety signs - Registered safety signs (ISO

7010:2019, Corrected version 2020-06)

EN ISO 11201:2010, Acoustics - Noise emitted by machinery and equipment - Determination of emission

sound pressure levels at a work station and at other specified positions in an essentially free field over a

reflecting plane with negligible environmental corrections (ISO 11201:2010)

EN ISO 11202:2010, Acoustics - Noise emitted by machinery and equipment - Determination of emission

sound pressure levels at a work station and at other specified positions applying approximate environmental

corrections (ISO 11202:2010)

EN ISO 11204:2010, Acoustics - Noise emitted by machinery and equipment - Determination of emission

sound pressure levels at a work station and at other specified positions applying accurate environmental

corrections (ISO 11204:2010)

As impacted by EN ISO 7010:2020/A1:2020, EN ISO 7010:2020/A2:2022, EN ISO 7010:2020/A3:2022,

EN ISO 7010:2020/A4:2023, EN ISO 7010:2020/A5:2023 and EN ISO 7010:2020/A6:2023.

As impacted by EN ISO 11202:2010/A1:2021.

EN ISO 11688-1:2009, Acoustics - Recommended practice for the design of low-noise machinery and

equipment - Part 1: Planning (ISO/TR 11688-1:1995)

EN ISO 12100:2010, Safety of machinery - General principles for design - Risk assessment and risk reduction

(ISO 12100:2010)

EN ISO 13732-1:2008, Ergonomics of the thermal environment - Methods for the assessment of human

responses to contact with surfaces - Part 1: Hot surfaces (ISO 13732-1:2006)

EN ISO 13849-1:2023, Safety of machinery - Safety-related parts of control systems - Part 1: General

principles for design (ISO 13849-1:2023)

EN ISO 13850:2015, Safety of machinery - Emergency stop function - Principles for design (ISO 13850:2015)

EN ISO 13855:2024, Safety of machinery - Positioning of safeguards with respect to the approach of the

human body (ISO 13855:2024)

EN ISO 13856-2:2013, Safety of machinery - Pressure-sensitive protective devices - Part 2: General

principles for design and testing of pressure-sensitive edges and pressure-sensitive bars (ISO 13856-2:2013)

EN ISO 13856-3:2013, Safety of machinery - Pressure-sensitive protective devices - Part 3: General

principles for design and testing of pressure-sensitive bumpers, plates, wires and similar devices

(ISO 13856-3:2013)

EN ISO 13857:2019, Safety of machinery - Safety distances to prevent hazard zones being reached by upper

and lower limbs (ISO 13857:2019)

EN ISO 14119:2025, Safety of machinery - Interlocking devices associated with guards - Principles for

design and selection (ISO 14119:2024)

EN ISO 14120:2015, Safety of machinery - Guards - General requirements for the design and construction

of fixed and movable guards (ISO 14120:2015)

EN ISO 14122-2:2016, Safety of machinery - Permanent means of access to machinery - Part 2: Working

platforms and walkways (ISO 14122-2:2016)

EN ISO 14122-3:2016, Safety of machinery - Permanent means of access to machinery - Part 3: Stairs,

stepladders and guard-rails (ISO 14122-3:2016)

EN ISO 14122-4:2016, Safety of machinery - Permanent means of access to machinery - Part 4: Fixed

ladders (ISO 14122-4:2016)

ISO 1402:2021, Rubber and plastics hoses and hose assemblies - Hydrostatic testing

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN ISO 12100:2010 and the

following apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at http://www.iso.org/obp/

— IEC Electropedia: available at http://www.electropedia.org/

3.1

tyre curing machine

machine used for vulcanisation of tyres usually comprising fixed and movable parts that can be locked

together, inside which the green tyre assumes its final shape and characteristics by the use of pressure

and heating

Note 1 to entry: See Figure 1 and Figure 2.

3.2

crossing flow

machine type in which green tyres are fed and loaded from the front and cured tyres are unloaded and

discharged from the rear

3.3

cavity

part of the machine in which the container and/or the mould and the bladder are installed

3.4

green tyre

assembly of rubber parts partially reinforced with other, strength-enhancing materials intended to be

cured

3.5

cured tyre

tyre in its final form after vulcanisation

3.6

bladder

inflatable rubber component used to push the green tyre into contact with the mould while being inflated

by the curing media

Note 1 to entry: The bladder could be connected to the machine by means of the top ring and bottom ring or

automatic clamped on the lower foot.

3.7

bottom ring

assembly of the bottom bladder clamping plate

3.8

top ring

assembly of the top bladder clamping plate

3.9

green tyre stand

supporting element for the green tyre before loading

3.10

chuck

device for holding or gripping the green or cured tyre

3.11

movable upper part

part of the machine that is opened for loading the green tyre and unloading the cured tyre and is closed

and locked during curing

3.12

heating platen

equipment used to heat sidewalls of the mould by contact

3.13

steam dome

equipment used to heat the complete mould by direct contact with the steam

3.14

container

exchangeable equipment used to heat the curing mould or part of it

Note 1 to entry: The container is fixed to the tyre curing machine by use of screws or automatic fixation device.

3.15

mould

exchangeable equipment used to give the external shape to the cured tyre

Note 1 to entry: The mould could be a two halves mould or a segmented mould.

3.16

dummy mould

subassembly representative of the mould

3.17

mould segment

movable part of the mould

3.18

loading pressure

pressure inflated into the bladder in order to make it able to hold the green tyre in place while the loading

device deposits it into the cavity

3.19

pre-shaping pressure

pressure inflated into the bladder in order to make it able to pre-shape the green tyre while the curing

machine is closing the mould

3.20

opening pressure

pressure inflated into the bladder in order to make it able to hold the cured tyre in place while the curing

machine is opening the mould

3.21

semi-closed position

position of the movable upper part above which the loading pressure is applied and below which the pre-

shaping pressure or the opening pressure is applied

Note 1 to entry: The position depends on the height of the mould and the height of the green tyre.

3.22

feeding

manual or automatic operation to feed green tyres to the loading device

3.23

loading device

device that is an integrated ancillary equipment of the machine and it is used to pick up the green tyre

and insert it into the tyre curing machine

3.24

curing cycle

period of time in which the curing process is completed, i.e. from full closing, squeezing and locking until

the pressure is dropped down

3.25

unloading device

device that is an integrated ancillary equipment of the machine and it is used to remove the cured tyre

from the tyre curing machine

3.26

discharge

manual or automatic operation to remove cured tyres from the unloading device

3.27

take-away conveyor

conveyor that is an integral part of the machine and on which the unloading device deposits the cured

tyres for discharge to the rear of the tyre curing machine

3.28

spraying device

static or dynamic nozzle(s) used to treat the mould and/or the bladder with treatment fluid

3.29

distance guard

guard which does not completely enclose a danger zone, but which prevents or reduces access by virtue

of its dimensions and its distance from the danger zone, e.g. perimeter fence or tunnel guard

[SOURCE: EN ISO 14120:2015, 3.2.2]

3.30

enclosing guard

guard which prevents access to the danger zone from all sides

[SOURCE: EN ISO 14120:2015, 3.2.1]

3.31

integrated ancillary equipment

ancillary equipment which cannot in itself perform a specific application but need to be integrated with

a curing machine in order to carry out the intended use

Note 1 to entry: A stand-alone PCI is not an integrated ancillary equipment.

3.32

Post Cure Inflator

PCI

integrated ancillary equipment used for the inflation of the still hot cured tyre during its cooling

3.33

PCI half rim

exchangeable mechanical tool to keep the tyre in shape while inflating it

3.34

machine designed for automatic feeding only

machinery designed to operate only with automatic feeding equipment to feed green tyres to the loading

device and when it is not possible to operate the machinery without those devices

3.35

machine designed for automatic discharging only

machinery designed to operate only with automatic discharging equipment to remove cured tyres from

the unloading device and when it is not possible to operate the machinery without those devices

3.36

rescue pushbutton

control device to rescue trapped person reversing the movements of some elements

3.37

mould or container change mode

selectable mode of operation of the machine that allows individual motions at a low speed, low pressure

and low force, used for changing the mould or container

Key

1 container

2 top ring

3 bottom ring or bottom clamping

4 bladder

5 heating platen

Figure 1 — Main parts of tyre curing machines (front view)

Key

1 unloading device

2 take-away conveyor

3 green tyre stand

4 top ring

5 green tyre

6 loading device

7 chuck

8 movable upper part

9 cured tyre

Figure 2 — Main parts of tyre curing machines (side view)

4 Safety requirements and/or protective measures

4.1 Basic safety requirements and/or protective measures

4.1.1 General

Machinery shall comply with the safety requirements and/or protective measures of this clause. In

addition, the machines shall be designed according to the principles of EN ISO 12100:2010 for relevant

but not significant hazards, which are not dealt with by this document.

Pressure requirements are given in Table 1.

NOTE All pressure values in this document are given as gauge pressure.

4.1.2 Guards and protective devices

Safety distances for fixed distance guards and machine parts acting as fixed guards shall comply with

EN ISO 13857:2019. For “reaching over protective structures”, if not otherwise specified in the relevant

subclauses, Table 2 shall be applied for crushing and shearing hazards, otherwise Table 1 shall be used.

For reaching through openings, Table 3 and Table 4 shall be used.

Guards shall be designed and manufactured in accordance with EN ISO 14120:2015. Interlocking devices

shall comply with EN ISO 14119:2025. The choice between interlocking guards and interlocking guards

with guard locking shall comply with EN ISO 14119:2025, Clause 7 and EN ISO 13855:2024, Clause 12.

Interlocking guards may be power operated on tyre curing machines with automatic rear feeding and

discharge. In case of interlocking guards with guard locking giving access to areas where whole body

access is possible, an escape release device shall be provided according to EN ISO 14119:2025, 6.9.1.

Light curtains shall be in accordance with EN IEC 61496-1:2020 and EN IEC 61496-2:2020.

Scanners shall comply with EN IEC 61496-3:2019.

Light curtains and interlocking guards without guard locking shall be positioned in accordance with

EN ISO 13855:2024.

4.1.3 Safety related parts of the control system

The safety related parts of the control system (SRP/CS) shall be designed in accordance with

) for each safety function is specified in the

EN ISO 13849-1:2023. The required performance level (PLr

relevant subclauses taking into account the risk assessment. When safety measures other than SRP/CS

are listed in the Table 1, they don’t require any PL .

r

In Table 1 some safety functions related to pressure in the bladder depend by appropriate position of the

movable upper part and/or by suitable conditions of the tyre curing machine. They are parts of the safety

functions, therefore they concur to reach the PL stated in Table 1. Hazards involved are the following:

r

n° 21, 22, 23, 24, 25, 26.

4.1.4 Electrical equipment

The electrical equipment shall be in accordance with EN 60204-1:2018.

4.1.5 Hydraulic and pneumatic systems

The hydraulic equipment and its components shall be designed in accordance with EN ISO 4413:2010.

The pneumatic equipment and its components shall be designed in accordance with EN ISO 4414:2010.

4.1.6 Ancillary equipment

Power operated take-away conveyors shall be in accordance with EN 619:2022.

4.1.7 Ergonomic principles

Ergonomic principles shall be in accordance with EN 1005-3:2002+A1:2008 and

EN 1005-4:2005+A1:2008 for the design of green tyre stands in case of manual feeding as well as

recurring activities such as PCI rims change, mould change, bladder change, etc.

4.1.8 Mechanical strength of machine parts

For tyre curing machines which include pressure equipment, the manufacturer shall consider the forces

resulting from the pressurization for the calculation of the mechanical strength of machine parts

subjected to these forces. See also Table 1, hazards 21 to 25.

The machine shall be designed taking into consideration the max values with reference to 6.2.12.

4.2 Specific safety requirements and/or protective measures

4.2.1 Specific requirements for operation in production mode

4.2.1.1 Protection against hazards associated with specific machine parts or areas

Safety requirements and/or protective measures for operation in production mode are given in Table 1

for crossing flow tyre curing machines and for tyre curing machines with automatic rear feeding and

discharge. Safeguards and/or protective measures are expressed in tabular form in precise and clearly

understandable terms.

The lines of Table 1 are related to the respective significant hazards listed in A.3.

In Table 1, the safety requirements and/or protective measures are specified for the front, rear and side

positions on the tyre curing machine. Figure 3 and Figure 4 show these positions.

Key Key

1 front position 1 front position

2 rear position 2 rear position

3 side position 3 side position

Figure 3 — Positions on crossing flow tyre Figure 4 — Position on tyre curing machine

curing machines with automatic rear feeding and discharge

Table 1 — Safety requirements and/or protective measures for tyre curing machines in production mode (1 of 45)

Tyre curing machines with automatic rear feeding and

Crossing flow tyre curing machines

Hazard Dangerous Significant Position/

discharge

N° situation hazard(s) location

Safeguards and/or protective measures PLr Safeguards and/or protective measures PLr

Scanner

or

Light curtain

or

Combination of fixed distance guards and machine

parts acting as fixed guards preventing access.

Where these safeguards cannot be practically

d

implemented, e.g. due to lack of space, pressure

sensitive protective devices in accordance with for the safe-

EN ISO 13856-3:2013 shall be installed under the guarding

following conditions: function

— the pressure sensitive protective devices shall c

be dimensioned and positioned so that the

only for the

dangerous moving part has stopped before

stopping

any injury can occur and that nobody can

function of

stand between the pressure sensitive

the

protective device and crushing/shearing

downward

points;

movement

— if the pressure sensitive protective device is in case of

adjustable, its safe position with respect to the use of the

size of the container and mould shall be interlocking

Crushing

Closing of the detected by the safety related parts of the guard with

Shearing

movable upper Position 1: control system of the machine before the guard

1 part Trapping front movement can be started. d Interlocking guard with or without guard locking. locking

A rescue pushbutton according to 4.2.1.7 shall be

installed.

Tyre curing machines with automatic rear feeding and

Crossing flow tyre curing machines

Hazard Dangerous Significant Position/

discharge

N° situation hazard(s) location

Safeguards and/or protective measures PLr Safeguards and/or protective measures PLr

Interlocking guard with guard locking for the

Fixed distance guard

feeding/discharge system

Position 2: and/or

and/or

rear

Take-away conveyor, acting as a fixed distance

Interlocking guard without guard locking

guard according to EN 619:2022

associated with light curtains.

Fixed distance guard and interlocking guard with

or without guard locking

Position 3:

or Fixed distance guard.

side

Combination of fixed distance guards and machine

parts acting as fixed guards preventing access.

Scanner

or

Position 1: Light curtain

Interlocking guard with or without guard locking.

front

or b b

Combination of fixed distance guards and machine if no access if no access

parts acting as fixed guards preventing access. to the to the

crushing/ crushing/

Crushing

Interlocking guard with guard locking for the

shearing shearing

Opening of the Fixed distance guard

Shearing

feeding/discharge system

hazard hazard

2 movable upper

Position 2: and/or

Entanglement

and/or

part

d d

rear

Take-away conveyor, acting as a fixed distance

Impact

Interlocking guard without guard locking

if access to if access to

guard according to EN 619:2022.

associated with light curtains.

crushing/ crushing/

shearing shearing

Fixed distance guard and interlocking guard with

hazard hazard

or without guard locking

Position 3:

or Fixed distance guard.

side

Combination of fixed distance guards and machine

parts acting as fixed guards preventing access.

Tyre curing machines with automatic rear feeding and

Crossing flow tyre curing machines

Hazard Dangerous Significant Position/

discharge

N° situation hazard(s) location

Safeguards and/or protective measures PLr Safeguards and/or protective measures PLr

Combination of fixed distance guards and machine

parts acting as fixed guards preventing access

Upper part mechanical restraint device that is

Position 1: or

automatically engaged. The engagement of this

front

Mechanical restraint device that is automatically

device shall be visually indicated.

engaged; the engagement of this device shall be

Unexpected

visually indicated.

falling of the

movable upper Fixed distance guard

3 Crushing d d

part when it is

and/or

in the fully open

Take-away conveyor acting as fixed distance guard,

position.

Upper part mechanical restraint device that is

Position 2: according to EN 619:2022

automatically engaged. The engagement of this

rear

or

device shall be visually indicated.

Mechanical restraint device that is automatically

engaged; the engagement of this device shall be

visually indicated.

Combination of fixed distance guards and machine

Fixed distance guard

parts acting as fixed guards preventing access

and

Position 3: or

Upper part mechanical restraint device that is

side

Mechanical restraint device that is automatically

automatically engaged. The engagement of this

engaged; the engagement of this device shall be

device shall be visually indicated.

visually indicated.

Tyre curing machines with automatic rear feeding and

Crossing flow tyre curing machines

Hazard Dangerous Significant Position/

discharge

N° situation hazard(s) location

Safeguards and/or protective measures PLr Safeguards and/or protective measures PLr

Combination of fixed distance guards and machine Combination of fixed distance guards and machine

parts acting as fixed guards preventing access parts acting as fixed guards preventing access

or or

Position 1:

Restraint system activated by opening an Restraint system activated by opening an

front

interlocking guard or actuating a protective device interlocking guard or actuating a protective device

that achieves a stopping distance of the moveable that achieves a stopping distance of the moveable

upper part of less than 20 mm, e.g. restraint valves upper part of less than 20 mm, e.g. restraint valves

fitted directly on the cylinder, a brake system, etc. fitted directly on the cylinder, a brake system, etc.

Fixed distance guard Fixed distance guard

and/or and/or

d

Unexpected Take-away conveyor, acting as a fixed distance Take-away conveyor, acting as a fixed distance

Not

gravity fall of guard according to EN 619:2022 guard

applicable if

the movable Position 2:

or or

4 Crushing d

interlocking

upper part rear

Restraint system activated by opening an Restraint system activated by opening an guard with

when it is in any

interlocking guard or actuating a protective device interlocking guard or actuating a protective device

guard

raised position

that achieves a stopping distance of the moveable that achieves a stopping distance of the moveable

locking

upper part of less than 20 mm, e.g. restraint valves upper part of less than 20 mm, e.g. restraint valves

fitted directly on the cylinder, a brake system, etc. fitted directly on the cylinder, a brake system, etc.

Combination of fixed distance guards and machine Combination of fixed distance guards and machine

parts acting as fixed guard preventing access parts acting as fixed guards preventing access

or or

Position 3:

Restraint system activated by opening an Restraint system activated by opening an

side

interlocking guard or actuating a protective device interlocking guard or actuating a protective device

that achieves a stopping distance of the moveable that achieves a stopping distance of the moveable

upper part of less than 20 mm, e.g. restraint valves upper part of less than 20 mm, e.g. restraint valves

fitted directly on the cylinder, a brake system, etc. fitted directly on the cylinder, a brake system, etc.

Tyre curing machines with automatic rear feeding and

Crossing flow tyre curing machines

Hazard Dangerous Significant Position/

discharge

N° situation hazard(s) location

Safeguards and/or protective measures PLr Safeguards and/or protective measures PLr

Scanner

or

Light curtain

Interlocking guard with or without guard locking

or

Position 1:

or

Combination of fixed distance guards and machine

front

parts acting as fixed guards preventing access Fixed distance guard.

and/or

Fixed enclosing guard shall be compliant with

EN ISO 13857:2019, Table 4.

Fixed distance guard Interlocking guard with guard locking for the

feeding/discharge system

and/or

Locking of the

Crushing

and/or

Take-away conveyor, acting as a fixed distance

5 movable upper d d

Position 2:

Shearing

guard according to EN 619:2022 Interlocking guard without guard locking

part

rear

associated with light curtains

or

or

Fixed enclosing guard shall be compliant with

EN ISO 13857:2019, Table 4. Fixed distance guard.

Fixed distance guard and interlocking guard with

or without guard locking

or

Position 3: Combination of fixed distance guards and machine

Fixed distance guard.

side parts acting as fixed guards preventing access

or

Fixed enclosing guard shall be compliant with

EN ISO 13857:2019, Table 4.

Tyre curing machines with automatic rear feeding and

Crossing flow tyre curing machines

Hazard Dangerous Significant Position/

discharge

N° situation hazard(s) location

Safeguards and/or protective measures PLr Safeguards and/or protective measures PLr

Scanner

or

Light curtain

Interlocking guard with or without guard locking

or

Position 1:

or

Combination of fixed distance guards and machine

front

parts acting as fixed guards preventing access Fixed distance guard.

and/or

Fixed enclosing guard shall be compliant with

EN ISO 13857:2019, Table 4.

Fixed distance guard Interlocking guard with guard locking for the

feeding/discharge system

and/or

Unlocking of the and/or

Crushing Take-away conveyor, acting as a fixed distance

Position 2:

6 movable upper d d

guard according to EN 619:2022 Interlocking guard without guard locking

Shearing

rear

part

associated with light curtains

or

or

Fixed enclosing guard shall be compliant with

EN ISO 13857:2019, Table 4. Fixed distance guard.

Fixed distance guard and

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...