EN 12301:2019

(Main)Plastics and rubber machines - Calenders - Safety requirements

Plastics and rubber machines - Calenders - Safety requirements

This document specifies safety requirements relating to the design and construction of calenders (see 3.1.1) intended for the calendering, polishing, laminating or embossing of rubber or plastics.

This document concerns the calender alone, including the following integrated components: cutting device, stock guides and feeding device, secondary roller.

Annex C shows examples of various types of calenders and Annex D shows examples of calendaring processes.

This document deals with all significant hazards, hazardous situations or hazardous events relevant to the design and construction of calenders, when the machines are used as intended and under the conditions of misuse which are reasonably foreseeable by the manufacturer during all the phases of the life of the machine as described in EN ISO 12100:2010, 5.4 (see Annex B).

This document does not deal with:

- hazards generated by the processing of explosive materials, or materials which give rise to an explosive atmosphere;

- hazards due to laser or ionizing radiation;

- hazards generated if the calender is installed in an explosive atmosphere.

Two roll mills are covered by EN 1417.

This document is not applicable to calenders manufactured before the date of its publication.

Kunststoff- und Gummimaschinen - Kalander - Sicherheitsanforderungen

Dieses Dokument legt Sicherheitsanforderungen an die Konstruktion und den Bau von Kalandern (siehe 3.1.1) fest, die für das Kalandrieren, Glätten, Laminieren oder Prägen von Gummi oder Kunststoff vorgesehen sind.

Dieses Dokument betrifft nur Kalander, einschließlich der folgenden integrierten Komponenten: Schneideinrichtung, Führungsbacken, Beschickungseinrichtung und Nebenwalzen.

Anhang C enthält Beispiele von verschiedenen Kalanderbauarten und Anhang D enthält Beispiele für Kalandrierverfahren.

Dieses Dokument behandelt alle signifikanten Gefährdungen, Gefährdungssituationen oder Gefährdungsereignisse, die für die Konstruktion und den Bau von Kalandern in sämtlichen Lebensphasen der Maschine wie in EN ISO 12100:2010, 5.4 beschreiben wesentlich sind, wenn die Maschinen wie vorgesehen und unter den Bedingungen, die vom Hersteller als Fehlanwendung vernünftigerweise vorhersehbar sind, verwendet werden (siehe Anhang B).

Dieses Dokument behandelt nicht:

Gefährdungen, die durch die Verarbeitung von explosiven Stoffen oder Materialien entstehen, die zu einer explosionsfähigen Atmosphäre führen;

Gefährdungen durch Laser oder ionisierender Strahlung;

Gefährdungen, die entstehen, wenn der Kalander in einer explosionsfähigen Atmosphäre aufgestellt wird.

Walzwerke sind durch EN 1417 abgedeckt.

Dieses Dokument gilt nicht für Kalander, die vor dessen Veröffentlichung hergestellt worden sind.

Machines pour les matières plastiques et le caoutchouc - Calandres - Prescriptions de sécurité

Le présent document spécifie les prescriptions de sécurité relatives à la conception et à la construction des calandres (voir 3.1.1) destinées au calandrage, polissage, doublage ou grainage du caoutchouc ou des matières plastiques.

Le présent document concerne la calandre seule, y compris les éléments suivants, faisant partie intégrante de la calandre : le dispositif de coupe, les oreilles, le dispositif d'alimentation et le rouleau annexe.

L'Annexe C donne des exemples de différents types de calandres et l'Annexe D donne des exemples de procédés de calandrage.

Le présent document traite de tous les phénomènes dangereux, situations dangereuses ou événements dangereux significatifs pertinents pour la conception et la construction des calandres, en cas d’utilisation normale ou de mauvais usage raisonnablement prévisible par le fabricant pendant toutes les phases de la vie de la machine, tel que décrit dans l'EN ISO 12100:2010, 5.4 (voir Annexe B).

Le présent document ne traite pas :

- des phénomènes dangereux engendrés par le travail de produits explosifs ou de produits générant une atmosphère explosive ;

- des phénomènes dangereux liés aux rayonnements laser ou ionisants ;

- des phénomènes dangereux liés à l'installation de la calandre dans une atmosphère explosive.

Les mélangeurs à cylindres sont traités dans l'EN 1417.

Le présent document ne s'applique pas aux calandres fabriquées avant sa date de publication.

Stroji za predelavo gume in plastike - Kalandri - Varnostne zahteve

General Information

- Status

- Published

- Publication Date

- 10-Dec-2019

- Withdrawal Date

- 29-Jun-2021

- Technical Committee

- CEN/TC 145 - Rubber and plastics machines - Safety

- Drafting Committee

- CEN/TC 145/WG 8 - Calenders - Safety

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 05-Jun-2025

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 15-Jan-2014

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 12301:2019 - Plastics and rubber machines: Calenders - Safety requirements is a CEN standard that specifies safety requirements for the design and construction of calenders used for calendering, polishing, laminating or embossing rubber and plastics. The standard covers the calender itself and integrated components such as cutting devices, stock guides, feeding devices and secondary rollers. It addresses hazards throughout the machine life-cycle in accordance with EN ISO 12100 and provides a normative noise test code (Annex A) plus informative examples of machine types (Annex C) and calendaring processes (Annex D).

Key topics and technical requirements

EN 12301:2019 focuses on practical machine-safety measures and verification. Major technical topics include:

- Risk assessment and design principles in line with EN ISO 12100 (scope of hazards, risk reduction hierarchy).

- Control systems and safety-related control performance, including specification of performance levels according to EN ISO 13849-1.

- Protection against mechanical hazards (guards, interlocks, crushing and entanglement zones), including requirements for braking systems and roll separation.

- Emergency stop and start-up prevention (EN ISO 13850, prevention of unexpected start-up).

- Stability, electrical, thermal and fire considerations for safe construction and operation.

- Noise measurement and reduction (full noise test code in Annex A; references to EN ISO 3744/3746/11201/11202).

- Ergonomics, access and maintenance (EN 614-1, EN ISO 14122 series) and marking/instruction handbook requirements.

- Verification and conformity procedures and manufacturer information for safe use, maintenance and foreseeable misuse.

- Exclusions: hazards from explosive atmospheres, laser or ionizing radiation, and calenders produced before publication.

Practical applications and users

EN 12301:2019 is intended for stakeholders involved with calendaring machinery:

- Machine manufacturers - to design, build and CE-mark calenders meeting current safety requirements.

- Safety engineers and compliance teams - to perform risk assessments, specify guards, control-system PLs and noise testing.

- Purchasers and plant owners - to assess machine safety during procurement, installation and commissioning.

- Maintenance and service providers - to follow safe access, lockout and maintenance instructions.

- Regulators and market surveillance bodies - to verify conformity and support enforcement.

This standard helps reduce injury risk in rubber and plastics production lines by providing harmonized safety requirements tailored to calenders.

Related standards

EN 12301 references and aligns with many EN/ISO standards, notably:

- EN ISO 12100 (risk assessment)

- EN ISO 13849-1 (safety-related control systems)

- EN ISO 14120 / 14119 (guards and interlocks)

- EN ISO 14122 (access)

- EN ISO 3744 / 3746 / 11201 (noise)

- Relationship with Machinery Directive 2006/42/EC is given in Annex ZA.

Keywords: EN 12301:2019, calenders safety requirements, plastics and rubber machines, calendaring safety, machine safety standard.

Get Certified

Connect with accredited certification bodies for this standard

Smithers Quality Assessments

US management systems and product certification.

DIN CERTCO

DIN Group product certification.

Sponsored listings

Frequently Asked Questions

EN 12301:2019 is a standard published by the European Committee for Standardization (CEN). Its full title is "Plastics and rubber machines - Calenders - Safety requirements". This standard covers: This document specifies safety requirements relating to the design and construction of calenders (see 3.1.1) intended for the calendering, polishing, laminating or embossing of rubber or plastics. This document concerns the calender alone, including the following integrated components: cutting device, stock guides and feeding device, secondary roller. Annex C shows examples of various types of calenders and Annex D shows examples of calendaring processes. This document deals with all significant hazards, hazardous situations or hazardous events relevant to the design and construction of calenders, when the machines are used as intended and under the conditions of misuse which are reasonably foreseeable by the manufacturer during all the phases of the life of the machine as described in EN ISO 12100:2010, 5.4 (see Annex B). This document does not deal with: - hazards generated by the processing of explosive materials, or materials which give rise to an explosive atmosphere; - hazards due to laser or ionizing radiation; - hazards generated if the calender is installed in an explosive atmosphere. Two roll mills are covered by EN 1417. This document is not applicable to calenders manufactured before the date of its publication.

This document specifies safety requirements relating to the design and construction of calenders (see 3.1.1) intended for the calendering, polishing, laminating or embossing of rubber or plastics. This document concerns the calender alone, including the following integrated components: cutting device, stock guides and feeding device, secondary roller. Annex C shows examples of various types of calenders and Annex D shows examples of calendaring processes. This document deals with all significant hazards, hazardous situations or hazardous events relevant to the design and construction of calenders, when the machines are used as intended and under the conditions of misuse which are reasonably foreseeable by the manufacturer during all the phases of the life of the machine as described in EN ISO 12100:2010, 5.4 (see Annex B). This document does not deal with: - hazards generated by the processing of explosive materials, or materials which give rise to an explosive atmosphere; - hazards due to laser or ionizing radiation; - hazards generated if the calender is installed in an explosive atmosphere. Two roll mills are covered by EN 1417. This document is not applicable to calenders manufactured before the date of its publication.

EN 12301:2019 is classified under the following ICS (International Classification for Standards) categories: 83.200 - Equipment for the rubber and plastics industries. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12301:2019 has the following relationships with other standards: It is inter standard links to EN 12301:2000+A1:2008, EN 61000-6-4:2007, CLC/TS 61496-3:2008, EN 61496-1:2013, EN 61000-6-2:2005, EN 60204-1:2018, EN 61310-1:2008, EN 60947-5-8:2006, EN ISO 13850:2015, EN ISO 7731:2008, EN ISO 4414:2010, EN ISO 3744:2010, EN 614-1:2006+A1:2009, EN ISO 14122-3:2016, EN ISO 13857:2008. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12301:2019 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC; Standardization Mandates: M/396, M/BC/CEN/88/13. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12301:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-september-2020

Nadomešča:

SIST EN 12301:2000+A1:2008

Stroji za predelavo gume in plastike - Kalandri - Varnostne zahteve

Plastics and rubber machines - Calenders - Safety requirements

Kunststoff- und Gummimaschinen - Kalander - Sicherheitsanforderungen

Machines pour le caoutchouc et les matières plastiques - Calandres - Prescriptions de

sécurité

Ta slovenski standard je istoveten z: EN 12301:2019

ICS:

83.200 Oprema za gumarsko Equipment for the rubber and

industrijo in industrijo plastics industries

polimernih materialov

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 12301

EUROPEAN STANDARD

NORME EUROPÉENNE

December 2019

EUROPÄISCHE NORM

ICS 83.200 Supersedes EN 12301:2000+A1:2008

English Version

Plastics and rubber machines - Calenders - Safety

requirements

Machines pour les matières plastiques et le caoutchouc Kunststoff- und Gummimaschinen - Kalander -

- Calandres - Prescriptions de sécurité Sicherheitsanforderungen

This European Standard was approved by CEN on 5 August 2019.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2019 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 12301:2019 E

worldwide for CEN national Members.

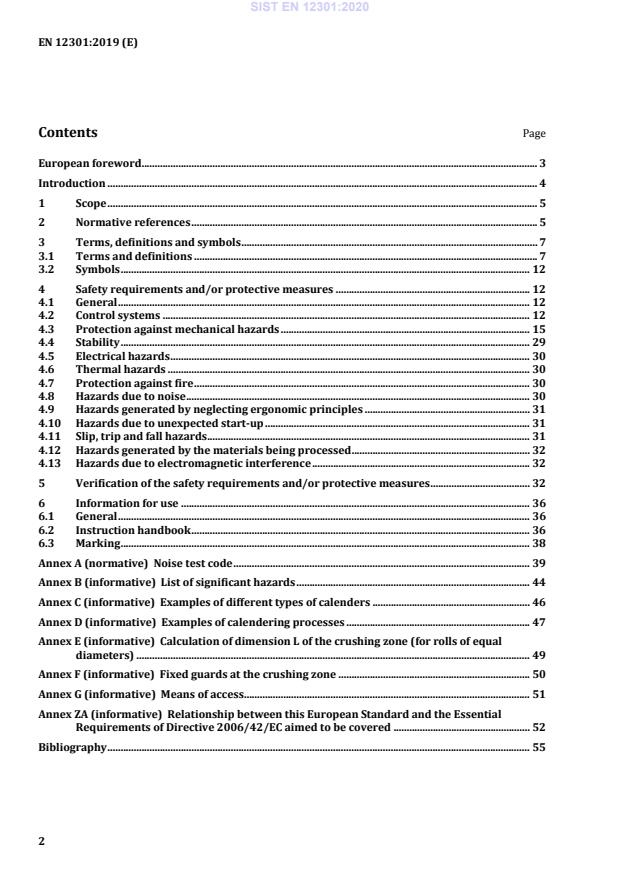

Contents Page

European foreword . 3

Introduction . 4

1 Scope . 5

2 Normative references . 5

3 Terms, definitions and symbols . 7

3.1 Terms and definitions . 7

3.2 Symbols . 12

4 Safety requirements and/or protective measures . 12

4.1 General . 12

4.2 Control systems . 12

4.3 Protection against mechanical hazards . 15

4.4 Stability . 29

4.5 Electrical hazards . 30

4.6 Thermal hazards . 30

4.7 Protection against fire . 30

4.8 Hazards due to noise . 30

4.9 Hazards generated by neglecting ergonomic principles . 31

4.10 Hazards due to unexpected start-up . 31

4.11 Slip, trip and fall hazards . 31

4.12 Hazards generated by the materials being processed . 32

4.13 Hazards due to electromagnetic interference . 32

5 Verification of the safety requirements and/or protective measures . 32

6 Information for use . 36

6.1 General . 36

6.2 Instruction handbook . 36

6.3 Marking . 38

Annex A (normative) Noise test code . 39

Annex B (informative) List of significant hazards . 44

Annex C (informative) Examples of different types of calenders . 46

Annex D (informative) Examples of calendering processes . 47

Annex E (informative) Calculation of dimension L of the crushing zone (for rolls of equal

diameters) . 49

Annex F (informative) Fixed guards at the crushing zone . 50

Annex G (informative) Means of access . 51

Annex ZA (informative) Relationship between this European Standard and the Essential

Requirements of Directive 2006/42/EC aimed to be covered . 52

Bibliography . 55

European foreword

This document (EN 12301:2019) has been prepared by Technical Committee CEN/TC 145 “Plastics and

rubber machines”, the secretariat of which is held by UNI.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by June 2020 and conflicting national standards shall be

withdrawn at the latest by June 2021.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 12301:2000+A1:2008.

This document has been prepared under a mandate given to CEN by the European Commission and the

European Free Trade Association, and supports essential requirements of EU Directive(s).

For relationship with EU Directive(s), see informative Annex ZA, which is an integral part of this

document.

The main changes with respect to the previous edition EN 12301:2000+A1:2008 are as follows:

— the Scope is extended to cover also two-roll calenders forming an integral unit with an extruder

(roller head) and two or three-roll polishing, laminating or embossing units installed downstream of

extruders in film processing lines;

— the structure is modified;

— the list of significant hazards is moved to an informative annex;

— technical developments in safeguards are taken into account;

— requirements for braking system and roll separation are updated;

— revised type-A and type-B standards are taken into account;

— the performance levels of safety related parts of control systems are specified in accordance with

EN ISO 13849-1:2015;

— a full noise test code is provided in a normative annex.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

Introduction

This document is a type C standard as stated in EN ISO 12100:2010.

This document is of relevance, in particular, for the following stakeholder groups representing the market

players with regard to machinery safety:

— machine manufacturers (small, medium and large enterprises);

— health and safety bodies (regulators, accident prevention organizations, market surveillance, etc.).

Others can be affected by the level of machinery safety achieved with the means of the document by the

above-mentioned stakeholder groups:

— machine users/employers (small, medium and large enterprises);

— machine users/employees (e.g. trade unions, organizations for people with special needs);

— service providers, e.g. for maintenance (small, medium and large enterprises).

The above-mentioned stakeholder groups have been given the possibility to participate at the drafting

process of this document.

The machinery concerned and the extent to which hazards, hazardous situations or hazardous events are

covered are indicated in the Scope of this document.

When requirements of this type-C standard are different from those which are stated in type-A or type-B

standards, the requirements of this type-C standard take precedence over the requirements of the other

standards for machines that have been designed and built according to the requirements of this type-C

standard.

1 Scope

This document specifies safety requirements relating to the design and construction of calenders (see

3.1.1) intended for the calendering, polishing, laminating or embossing of rubber or plastics.

This document concerns the calender alone, including the following integrated components: cutting

device, stock guides, feeding device and secondary roller.

Annex C shows examples of various types of calenders and Annex D shows examples of calendaring

processes.

This document deals with all significant hazards, hazardous situations or hazardous events relevant to

the design and construction of calenders, when the machines are used as intended and under the

conditions of misuse which are reasonably foreseeable by the manufacturer during all the phases of the

life of the machine as described in EN ISO 12100:2010, 5.4 (see Annex B).

This document does not deal with:

— hazards generated by the processing of explosive materials, or materials which give rise to an

explosive atmosphere;

— hazards due to laser or ionizing radiation;

— hazards generated if the calender is installed in an explosive atmosphere.

Two roll mills are covered by EN 1417.

This document is not applicable to calenders manufactured before the date of its publication.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

CLC/TS 61496-3:2008, Safety of machinery - Electro-sensitive protective equipment - Part 3: Particular

requirements for Active Opto-electronic Protective Devices responsive to Diffuse Reflection (AOPDDR)

EN 349:1993+A1:2008, Safety of machinery - Minimum gaps to avoid crushing of parts of the human body

EN 614-1:2006+A1:2009, Safety of machinery - Ergonomic design principles - Part 1: Terminology and

general principles

EN 619:2002+A1:2010, Continuous handling equipment and systems — Safety and EMC requirements for

equipment for mechanical handling of unit loads

EN 12198-1:2000+A1:2008, Safety of machinery - Assessment and reduction of risks arising from radiation

emitted by machinery - Part 1: General principles

EN 60204-1:2018, Safety of machinery - Electrical equipment of machines - Part 1: General requirements

(IEC 60204-1:2016, modified)

EN 60947-5-8:2006, Low-voltage switchgear and controlgear - Part 5-8: Control circuit devices and

switching elements - Three-position enabling switches (IEC 60947-5-8:2006)

EN 61000-6-2:2005, Electromagnetic compatibility (EMC) - Part 6-2: Generic standards - Immunity for

industrial environments (IEC 61000-6-2:2005)

EN 61000-6-4:2007, Electromagnetic compatibility (EMC) - Part 6-4: Generic standards - Emission

standard for industrial environments (IEC 61000-6-4:2006)

EN 61310-1:2008, Safety of machinery - Indication, marking and actuation - Part 1: Requirements for

visual, acoustic and tactile signals (IEC 61310-1:2007)

EN 61496-1:2013, Safety of machinery - Electro-sensitive protective equipment - Part 1: General

requirements and tests (IEC 61496-1:2012)

EN ISO 3744:2010, Acoustics - Determination of sound power levels and sound energy levels of noise sources

using sound pressure - Engineering methods for an essentially free field over a reflecting plane (ISO

3744:2010)

EN ISO 3746:2010, Acoustics - Determination of sound power levels and sound energy levels of noise sources

using sound pressure - Survey method using an enveloping measurement surface over a reflecting plane (ISO

3746:2010)

EN ISO 4413:2010, Hydraulic fluid power - General rules and safety requirements for systems and their

components (ISO 4413:2010)

EN ISO 4414:2010, Pneumatic fluid power - General rules and safety requirements for systems and their

components (ISO 4414:2010)

EN ISO 4871:2009, Acoustics - Declaration and verification of noise emission values of machinery and

equipment (ISO 4871:1996)

EN ISO 7731:2008, Ergonomics - Danger signals for public and work areas - Auditory danger signals (ISO

7731:2003)

EN ISO 9614-2:1996, Acoustics - Determination of sound power levels of noise sources using sound intensity

- Part 2: Measurement by scanning (ISO 9614-2:1996)

EN ISO 11201:2010, Acoustics - Noise emitted by machinery and equipment - Determination of emission

sound pressure levels at a work station and at other specified positions in an essentially free field over a

reflecting plane with negligible environmental corrections (ISO 11201:2010)

EN ISO 11202:2010, Acoustics - Noise emitted by machinery and equipment - Determination of emission

sound pressure levels at a work station and at other specified positions applying approximate environmental

corrections (ISO 11202:2010)

EN ISO 11204:2010, Acoustics - Noise emitted by machinery and equipment - Determination of emission

sound pressure levels at a work station and at other specified positions applying accurate environmental

corrections (ISO 11204:2010)

EN ISO 11688-1:2009, Acoustics - Recommended practice for the design of low-noise machinery and

equipment - Part 1: Planning (ISO/TR 11688-1:1995)

EN ISO 12100:2010, Safety of machinery - General principles for design - Risk assessment and risk reduction

(ISO 12100:2010)

EN ISO 13732-1:2008, Ergonomics of the thermal environment - Methods for the assessment of human

responses to contact with surfaces - Part 1: Hot surfaces (ISO 13732-1:2006)

EN ISO 13849-1:2015, Safety of machinery - Safety-related parts of control systems - Part 1: General

principles for design (ISO 13849-1:2015)

EN ISO 13850:2015, Safety of machinery - Emergency stop function - Principles for design (ISO 13850:2015)

EN ISO 13851:2019, Safety of machinery - Two-hand control devices - Principles for design and selection

(ISO 13851:2019)

EN ISO 13855:2010, Safety of machinery - Positioning of safeguards with respect to the approach speeds of

parts of the human body (ISO 13855:2010)

EN ISO 13856-1:2013, Safety of machinery - Pressure-sensitive protective devices - Part 1: General

principles for design and testing of pressure-sensitive mats and pressure-sensitive floors (ISO 13856-1:2013)

EN ISO 13857:2008, Safety of machinery - Safety distances to prevent hazard zones being reached by upper

and lower limbs (ISO 13857:2008)

EN ISO 14118:2018, Safety of machinery - Prevention of unexpected start-up (ISO 14118:2017)

EN ISO 14119:2013, Safety of machinery - Interlocking devices associated with guards - Principles for

design and selection (ISO 14119:2013)

EN ISO 14120:2015, Safety of machinery - Guards - General requirements for the design and construction

of fixed and movable guards (ISO 14120:2015)

EN ISO 14122-1:2016, Safety of machinery - Permanent means of access to machinery - Part 1: Choice of

fixed means and general requirements of access (ISO 14122-1:2016)

EN ISO 14122-2:2016, Safety of machinery - Permanent means of access to machinery - Part 2: Working

platforms and walkways (ISO 14122-2:2016)

EN ISO 14122-3:2016, Safety of machinery - Permanent means of access to machinery - Part 3: Stairs,

stepladders and guard-rails (ISO 14122-3:2016)

EN ISO 14122-4:2016, Safety of machinery - Permanent means of access to machinery - Part 4: Fixed

ladders (ISO 14122-4:2016)

ISO 7010:2019, Graphical symbols - Safety colours and safety signs - Registered safety signs

3 Terms, definitions and symbols

3.1 Terms and definitions

For the purposes of this document, the terms and the definitions given in EN ISO 12100:2010 and the

following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp

3.1.1

calender

machine for processing rubber, plastics, solutions or dispersions by continuous drawing between two or

more rolls, which are supported at both ends by a frame

Note 1 to entry: The processing operations may be, for example:

— continuous calendering of sheets or profiles of rubber or plastics;

— application of one or more sheet(s) or layer(s) onto a support material;

— laminating of two or more sheets of rubber or plastics under pressure or by using heat or adhesive;

— embossing or polishing of plastics (for example smoothing roll stack).

The calender can be equipped with power operated wheels for the horizontal movement of the complete machine,

e.g. for engaging/disengaging it from an extruder head during setting-up operations.

Note 2 to entry: Figure 1 shows a typical calendering sequence and the positions of most of the components and

zones defined hereafter. Figure 2 shows a typical 3-roll stack supplied by an extruder.

Note 3 to entry: Annex C shows examples of various types of calenders.

Note 4 to entry: Annex D shows examples of various calendering processes.

Key

rubber/plastic circuits

cord/fabric circuit

calendered product circuit

1 calender rolls 4 stock guides

2 secondary rollers 5 feeding devices

3 cutting devices 6 working zones

Figure 1 — Example of a 4-roll calender showing the materials circuit for bilateral coating of

(textile or metallic) fabric or cords

Key

1 calender roll 5 cleaning zone

2 extruder head 6 crushing zone

3 frame 7 working zone

4 film

Figure 2 — Example of a 3-roll stack supplied by an extruder

3.1.2

calender roll

roll which is positioned in relation to other calender rolls in order to process the material

Note 1 to entry: The roll can be counterbored or drilled to enable its temperature to be controlled by fluid

circulation.

3.1.3

secondary roller

roller, which is used to support the calendering process

Note 1 to entry: It can be driven and temperature regulated.

Note 2 to entry: Examples of secondary rollers are: pressure rollers, embossing rollers, filament guide rollers,

tension rollers, stripper rollers, crease removing rollers, take-off rollers.

3.1.4

cutting device

equipment for trimming the edges of the sheet to one or more specified widths

EXAMPLE Fixed knives (wires or blades), rotating knives (cutting discs).

3.1.5

stock guides

devices located on either side of the feed zone which determine the width of the sheet to be calendered

and retain the stock thus preventing it from extending beyond the normal working area

3.1.6

feeding device

equipment for feeding and distributing the stock in the feed zone

EXAMPLE Table, grid, chute, conveyor, reciprocating feed conveyor.

3.1.7

stopping angle

angle through which the calender rolls rotate from the stop signal triggered by a protective device until

the calender rolls have come to rest

3.1.8

feed zone

zone in which stock (rubber or plastic etc.) and/or material (cords, web, fabric etc.) is fed into the

calender

3.1.9

working zone

area around the calender or standing zone where the operators carry out their normal duties

3.1.10

crushing zone

zone existing between two calender rolls close to each other rotating in opposite directions towards the

nip

Note 1 to entry: See Figure 3.

Key

1 crushing zone

2 danger zone

S line dimensioned at the entrance to the crushing zone

X length of calender roll

L depth of the crushing zone, expressed in millimetres

D diameter of the calender rolls, expressed in millimetres

α stopping angle, expressed in radians

F radius equivalent to the length of the arcs of circle on the calender rolls corresponding with the specified

stopping angle, expressed in millimetres

a

S needs to be taken as 12 mm when the rolls are theoretically in contact, irrespective of the roll diameter.

b

LD6×

; where the roll diameters are different D shall be taken as the larger diameter

c

D

F = α

NOTE 1 The danger zone is the volume at the inrunning side of the rolls circumscribed by the length X of the rolls

and the shaded cross-section. This section is delimitated by:

— the line dimensioned S at the entrance to the crushing zone (see 3.1.10);

— the two arcs of circle on the calender rolls corresponding with the specified stopping angle α (see 3.1.7);

— the arc of a circle whose centre is the middle of the line dimensioned S and whose radius F is equivalent to the

length of the arcs of circle on the calender rolls corresponding with the specified stopping angle α.

NOTE 2 An example for the calculation of L is given in Annex E; L remains constant irrespective of the nip

between the rolls.

Figure 3 — Crushing and danger zones at the calender rolls

=

3.1.11

setting

preparing the machine for production, machine set-up, etc.

3.1.12

cleaning

removal of dust, residual material on the rolls, etc.

3.2 Symbols

α stopping angle of the calender roll when running with production speed v

p

α maximum stopping angle of the calender roll when running with maximum speed v

max max

α reduced stopping angle of the calender roll when running with reduced speed v

r r

v production rotational speed of calender rolls

p

v maximum rotational speed of the calender rolls

max

v reduced rotational speed of the calender rolls

r

D (larger) diameter of the calender rolls

F length of arc α on the calender roll surface

F length of arc α on the calender roll surface

r r

S height of entrance of the crushing zone

L depth of crushing zone

4 Safety requirements and/or protective measures

4.1 General

Calenders shall comply with the safety requirements and/or protective/risk reduction measures of this

clause. In addition, the machine shall be designed according to the principles of EN ISO 12100:2010 for

relevant but not significant hazards, which are not dealt with by this document (e.g. sharp edges).

The hydraulic equipment and its components shall be designed in accordance with EN ISO 4413:2010.

The pneumatic equipment and its components shall be designed in accordance with EN ISO 4414:2010.

4.2 Control systems

4.2.1 General

The safety related parts of the control system shall be designed in accordance with EN ISO 13849-1:2015.

The required performance level (PL ) for each safety function is specified in the relevant subclauses.

r

In the case where the calender is provided with a mode selector, it shall be in accordance with

EN ISO 12100:2010, 6.2.11.10.

4.2.2 Starting

The start of an operation shall be possible only when all safeguards are in place and functional

(see EN 60204-1:2018, 9.2.3.2). The machine shall only be started by actuation of the start device

provided for that purpose.

4.2.3 Normal stopping

A normal stop device shall be provided to bring the machine to a complete stop.

The normal stop command shall function as a stop category 0 or 1 in accordance with EN 60204-1:2018,

9.2.2, depending on the used technology.

4.2.4 Emergency stop devices

The emergency stop devices shall comply with EN ISO 13850:2015. For electrical braking, stop category

1 of that standard shall apply. For calenders with simple mechanical braking systems which are not

dependent on electrical energy, stop category 0 may be selected. An emergency stop device shall be

provided on the control panel of the calender. Other emergency stop actuators shall be installed in the

vicinity of and on each side of the working zones.

The actuation of any emergency stop device shall

— cause stopping of the calender rolls in accordance with 4.2.6;

— allow the roll separation or cause automatic roll separation on machines equipped with protective

device requiring automatic roll separation (see 4.3.1.3, 4.3.1.4, 4.3.1.5 and 4.3.1.6);

— allow the rescue reverse movement in accordance with 4.2.7;

— cause the stopping of all integrated components according to PL = c;

r

— trigger a visual and/or auditory signal, with manual resetting.

See also EN 60204-1:2018, 10.7.

4.2.5 Failure of energy supply

An interruption or a failure of the power supply shall not result in a loss of safety function and restoration

of the energy supply shall not result in the automatic restarting of the machine (see EN ISO 12100:2010,

6.2.11.4 and 6.2.11.5).

Failure of the energy supply which causes opening of a contactor of one of the roll drive motors shall also

cause stopping of the rolls as specified in 4.2.6.

The calender shall also be equipped with a device to enable roll separation to be achieved even in the

event of energy failure (see 6.2.3 m)).

4.2.6 Braking system

In case where the calender rolls can stop without material from maximum speed within a maximum

stopping angle α of 120° there are no specific requirements for braking system.

max

In the case where inrunning nips are protected by fixed guards there are no specific requirements for

braking system and stopping angle (see 4.3.1.2).

In the case where inrunning nips are protected by an interlocking guard with guard locking function in

accordance to PLr = d, there are no specific requirements for braking system and stopping angle.

If one or more of the inrunning nips are protected by:

— interlocking guard without guard locking or with guard locking function according to PL = a, PL = b

r r

or PL = c; or

r

— trip devices (e.g. trip bar),

the affected calender shall be equipped with a two channel braking system in accordance with PL = d,

r

category 3 using:

— either two mechanical brakes, spring operated; or

— one mechanical brake, spring operated and an electronic braking system, operating also without

power supply.

Braking shall be started as soon as a protective device is actuated.

The overall system stopping performance (see EN ISO 13855:2010, 3.1.2) shall be calculated taking

power failure into account.

For interlocking guards and trip devices, if EN ISO 13855:2010 cannot be respected, interlocking guards

with guard locking shall be adopted.

For trip bar, the rolls shall be brought to rest within a maximum stopping angle α of 120° even in the

max

case of failure of the energy supply. Where the maximum rotating speed of the calender rolls v is

max

greater than 120 m/min, α may vary proportionally to v up to a maximum value of 160°.

max max

EXAMPLE For calender rolls with a maximum rotating speed v of 140 m/min then:

max

α =120×=140

max

with PLr = d, category 3, where αmax is expressed in degrees.

See also 6.2.2 and 6.2.3 a).

The manual release of the brake shall be interlocked with the control circuit in accordance with PL = d,

r

so that the powered rotation of the calender rolls is prevented as long as the brake is manually released.

4.2.7 Rescue reverse movement

Following stoppage of the calender rolls due to opening of an interlocking guard or voluntary or

involuntary actuation of a trip device or actuation of an emergency stop device, it shall be possible to

make a reverse movement of the rolls by actuation of a dedicated hold-to-run control device in

accordance with EN ISO 12100:2010, 3.28.3 or a manually operated device (e.g. hand wheel) in order to

release a person trapped between the rolls or between a roll and the material.

This control device shall function without the need for manual resetting and independently of the

position of the mode selector specified in 4.3.1.8.4; it shall be clearly labelled “Rescue Reverse

Movement”. The reverse velocity of the rolls shall not exceed 5 m/min. The rescue reverse movement

shall stop under action of the brake as soon as the manual control is released. The visual and auditory

warning signals specified in 4.3.1.8.4 shall be given (see 6.2.3 p)).

The requirements of 4.3.1.8.4 for safety related parts of the control system (SRP/CS) for the hold to run

control and for speed limitation shall be applied.

A rescue reverse movement is not required, if

— an automatic roll separation > 120 mm is possible within 12 s, in accordance with PL = d, category 3;

r

or

— the inrunning nip is protected by a fixed guard (see 4.3.1.2); or

— the inrunning nip is protected by an interlocking guard with guard locking (see 4.3.1.3) with a

performance level at least PL = d for the locking function.

r

The roll separation shall not create additional hazards, e.g. crushing between roll and fixed part.

See 6.2.3 b).

4.3 Protection against mechanical hazards

4.3.1 Preventing access to the crushing zone

4.3.1.1 General

The access to the crushing zone (see Figure 3) when the rolls are rotating shall be prevented by one or

more of the following means:

— fixed guards in accordance with 4.3.1.2; or

— interlocking guards in accordance with 4.3.1.3; or

— trip bar in accordance with 4.3.1.4; or

— pressure sensitive mat or floor in accordance with 4.3.1.5; or

— a non-mechanically actuated trip device in accordance with 4.3.1.6, e.g. light curtain in accordance

with EN 61496-1:2013 or scanners in accordance with CLC/TS 61496-3:2008.

The end of an activation of a trip device or closing of an interlocking guard shall not automatically initiate

any further movement. A new start command shall be required. A separate device for manual reset shall

be installed in a position giving full view of the danger zone and designed in accordance with

EN ISO 13849-1:2015, 5.2.2, except for rescue reverse movement see 4.2.7.

If the smallest horizontal gap between the machine frame and

— an interlocking guard is ≥ 100 mm; or

— a non-mechanically actuated trip device is ≥ 150 mm,

an operator can stand between the guard/trip device and machine frame. In this case, restarting of the

dangerous movements while an operator remains in that area shall be prevented by additional protective

measures (e.g. presence sensing devices), unless for technical reasons this is not possible, e.g. due to a

part of the machine being in the way.

The closing movement to engage the calender rolls shall be possible only:

— when the interlocking guards are closed or trip devices are not actuated; or

— by a hold-to-run control device and closing speed limited to 10 mm/s in accordance with PL = c; the

r

control station shall be positioned in a place that gives the operator a clear view of the dangerous

area.

4.3.1.2 Fixed guards

Fixed guards as defined in EN ISO 14120:2015, 3.2 shall prevent the access to the danger zone from all

sides in combination with the calendar frame.

Safety distances shall be in accordance with EN ISO 13857:2008, Table 2, Table 3 and Table 4.

If the fixed guard is positioned between the calender rolls:

— it shall extend along the whole length of the rolls; and

— the gap between the guard and the surface of the roll shall be ≤4 mm; and

— the angle between the guard and the tangent to the surface of the roll shall be ≥ 90°.

Examples of layout are given in informative Annex F. Other profiles may be used but circular cross

sections are prohibited.

A feeding device alone shall not replace a fixed guard positioned between the calender rolls. However, it

may contribute to protecting access to the inrunning nip.

In this case:

— it shall fulfill the above requirements for guards positioned between rolls;

— it shall be associated with fixed guards preventing access to the inrunning nip according to

EN ISO 13857:2008, Table 2, Table 3 and Table 4.

Where for operating processes (for cleaning or setting operations, for example) the access into the danger

area is necessary a fixed guard shall not be used but an interlocking guard according to 4.3.1.3 shall be

installed.

In the case of a fixed guard positioned between the calender rolls, there is no need for automatic roll

separation.

4.3.1.3 Interlocking guards

The interlocking function shall be in accordance with PL = d.

r

Interlocking guards without guard locking shall be positioned in accordance with EN ISO 13855:2010,

Clause 9.

Safety distances shall be in accordance with EN ISO 13857:2008, Table2, Table 3 and Table 4.

The type of interlocking device shall be selected in accordance with EN ISO 14119:2013.

The braking system shall be in accordance with 4.2.6.

If interlocking guards with guards locking are used, the unlocking signal of the guard locking shall be in

accordance with PL = c.

r

The opening of an interlocking guard shall:

— cause automatic roll separation at least in 50 mm within 5 s, in accordance with PL = d, category 3.

r

The roll separation shall not create additional hazards e.g. crushing between roll and fixed part; and

— allow rescue reverse movement as specified in 4.2.7.

If the interlocking guard with guard locking has a performance level at least PL =d for the locking

r

function, the automatic roll separation is not necessary.

A feeding device installed as in 4.3.1.2 shall act as an interlocking guard with guard locking which shall

allow the rolls to rotate only when the feeding device is in position and which does not allow to remove

the feeding device from the working position until the rolls have come to rest. The PL of the control

r

circuit shall be the same of interlocking guard with guard locking.

4.3.1.4 Trip bar

The trip bar is a mechanically actuated trip device in form of a horizontal rigid bar which when actuated

by any part of the body shall:

— cause stopping of the calender rolls as specified in 4.2.6;

— cause automatic roll separation at least in 50 mm within 5 s, in accordance with PL = d, category 3.

r

The roll separation shall not create additional hazards e.g. crushing between roll and fixed part;

— allow rescue reverse movement as specified in 4.2.7.

The trip bar shall meet the following requirements:

— it shall be actuated by a displacement not exceeding 10 mm created by a movement of the operator's

body toward the rolls;

— actuation of the bar shall not require a force greater than 200 N, on each end and at the middle of the

trip bar;

— wherever the pushing action occurs along the length of the bar, the 10 mm displacement of the bar

shall trigger at least one position sensor actuated in the positive mode (see EN ISO 14119:2013, 5.4);

— return of the trip bar to its rest position shall not cause restarting. A separate device for manual reset

shall be installed in a position giving full view of the danger zone and designed in accordance with

EN ISO 13849-1:2015, 5.2.2 (for rescue reverse movement see 4.2.7).

See also 6.2.3 c) and 6.2.3 d).

The protection shall be completed with a fixed guard or interlocking guards with guard locking in

accordance with 4.3.1.3 preventing access to the crushing zone from below the trip bar. This guard shall

be so designed as to prevent foothold. Moreover, if there is access from the sides of the calender to the

ends of the rolls on the inrunning side, lateral fixed guards shall be provided taking account of safety

distances specified in EN ISO 13857:2008, Table 2, Table 3 and Table 4.

The trip bar shall extend over the full length of the calender rolls.

It shall be fitted at a height (1 200 ± 50) mm (above the level on which the operator stands) and be

positioned according to Figure 4.

See also 6.2.3 e).

Linear dimensions in millimetres, α in radians

Key

1 trip bar (in rest position)

L depth of crushing zone (see Figure 3)

F length equivalent to the stopping arc length at vmax,

D larger diameter of the calender rolls

α stopping angle

Figure 4 — Positioning of the trip bar

4.3.1.5 Pressure sensitive mats or floors

Pressure sensitive mats or floors shall be in accordance with EN ISO 13856-1:2013, positioned in

accordance with EN ISO 13855:2010, Clause 7.

Actuation of the trip devices shall:

— cause stopping of the calender rolls as specified in 4.2.6;

— cause automatic roll separation at least in 50 mm within 5 s, in accordance with PL = d, category 3.

r

The roll separation shall not create additional hazards e.g. crushing between roll and fixed part;

— allow rescue reverse movement as specified in 4.2.7.

4.3.1.6 Non-mechanically actuated trip devices

Light curtains shall be in accordance with EN 61496-1:2013, type 3 or type 4 positioned in accordance

with EN ISO 13855:2010, Clause 6. Scanners shall be in accordance with CLC/TS 61496-3:2008, type 3.

Actuation of a non-mechanically actuated trip device shall:

— cause stopping of the calender rolls as specified in 4.2.6;

— cause automatic roll separation at least in 50 mm within 5 s, in accordance with PL = d, category 3.

r

The roll separation shall not create additional hazards, e.g. crushing between roll and fixed part;

— allow rescue reverse movement as specified in 4.2.7.

4.3.1.7 Inhibition of interlocked guards or protective devices for setting only

4.3.1.7.1 General

For machine setting it can be necessary to rotate or move the calender rolls with one or more guards or

protective devices, preventing access to the inrunning nip, inhibited. In this case, safety of the operator

shall be achieved using a specific control mode activated by a mode selector according to 4.2.1 that

disables all other control modes. The safety related part of the control system (SRP/CS) shall be in

accordance with PL = d, category 3. Operation of the hazardous elements shall only be possible if:

r

a) a guard positioned at a distance from the crushing zone according to the dimensions specified in

EN ISO 13857:2008, Table 4 and 4.3.1.2 of this standard (see Figure 5) is detected in accordance with

PL = d, category 3 acting as an interlocking guard specified in 4.3.1.3; or

r

b) the requirements in 4.3.1.7.2, 4.3.1.7.3 or 4.3.1.7.4 are fulfilled for the specific movement.

Key

1 danger zone

2 cleaning zone

3 guard positioned in accordance with EN ISO 13857:2008 and 4.3.1.2 of this standard

Figure 5 — Example of a guard specifically designed for cleaning in the danger zone of the rolls

4.3.1.7.2 Requirements for calender rolls rotation during setting

If one or more guards or protective devices preventing access to the inrunning nip are inhibited and the

guard mentioned in 4.3.1.7.1 a) is not used, the rotation of the calender rolls shall only be permitted if all

the following requirements are fulfilled:

— the rotation of the calender rolls shall be controlled by continuous actuation of a hold-to-run control

device in accordance with PL = c. If the hold to run control is fitted on a portable unit, it shall be a

r

three-position enabling switch as defined in EN 60947-5-8:2006, 2.2; and

— the rotation speed shall be limited to a maximum of 3 m/min according to PL = d; and

r

— the gap between both the calender rolls themselves and between the calender rolls and the fixed

parts shall be more than or equal to 50 mm; the interlocking circuit between separation and calender

rolls rotation shall be in accordance with PL = c; and

r

— the control station shall be positioned in a place that gives the operator a clear view of the dangerous

area.

4.3.1.7.3 Requirements for closing movement for setting the gap between the calender rolls

If one or more guards or protective devices preventing access to the crushing zone are inhibited and the

guard mentioned in 4.3.1.7.1 a) is not used, the closing movem

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...