EN 1612:2019

(Main)Plastics and rubber machines - Reaction moulding machines and plants - Safety requirements

Plastics and rubber machines - Reaction moulding machines and plants - Safety requirements

This document specifies the essential safety requirements applicable to the design and construction of reaction moulding machines and plants as defined in 3.1 and 3.2.

This document deals with all significant hazards, hazardous situations or hazardous events during all phases of the machine life cycle (see EN ISO 12100:2010, 5.4), when reaction moulding machines and plants are used as intended and under conditions of misuse that are reasonably foreseeable by the manufacturer (see Annex A).

A reaction moulding machine begins at the working tank(s) and ends at the mixing head(s).

A reaction moulding plant begins at the working tank(s) and ends at the product shaping and transport equipment or at the moulding equipment (see 3.6 and 3.7).

This document is not applicable to reaction moulding machines and plants manufactured before the date of its publication.

NOTE Reaction moulding machines and plants usually do not produce explosive atmospheres. Where materials are processed, which may cause an explosive atmosphere, the Directive 2014/34/EU on the Equipment intended for use in Potentially Explosive Atmospheres (ATEX) can be applied.

Explosion hazards are not dealt with in this document.

Fire hazards are not dealt with in this document.

This document does not cover the requirements for the design of the exhaust systems.

Kunststoff- und Gummimaschinen - Reaktionsgießmaschinen und -anlagen - Sicherheitsanforderungen

Dieses Dokument legt die wesentlichen Sicherheitsanforderungen für die Konstruktion und den Bau von Reaktionsgießmaschinen und -anlagen, wie in 3.1 und 3.2 definiert, fest.

Dieses Dokument behandelt alle signifikanten Gefährdungen, Gefährdungssituationen und Gefähr-dungsereignisse in sämtlichen Phasen der Lebensdauer der Maschine (siehe EN ISO 12100:2010, 5.4), wenn Reaktionsgießmaschinen und -anlagen bestimmungsgemäß und unter Bedingungen, die vom Hersteller als Fehlanwendung vernünftigerweise vorhersehbar sind, verwendet werden (siehe Anhang A).

Eine Reaktionsgießmaschine beginnt am Arbeitsbehälter/an den Arbeitsbehältern und endet am Mischkopf/an den Mischköpfen.

Eine Reaktionsgießanlage beginnt am Arbeitsbehälter/an den Arbeitsbehältern und endet an der Produktformungs- und Transporteinrichtung oder an der Formgebungseinrichtung (siehe 3.6 und 3.7).

Dieses Dokument gilt nicht für Reaktionsgießmaschinen und -anlagen, die vor dem Datum ihrer Veröffentlichung hergestellt wurden.

ANMERKUNG Reaktionsgießmaschinen erzeugen üblicherweise keine explosionsfähigen Atmosphären. Wenn Materialien verarbeitet werden, die eine explosionsfähige Atmosphäre hervorrufen können, kann die Richtlinie 2014/34/EU für Geräte und Schutzsysteme zur bestimmungsgemäßen Verwendung in explosionsgefährdeten Bereichen (ATEX) angewendet werden.

Explosionsgefahren sind in diesem Dokument nicht behandelt.

Brandgefahren sind in diesem Dokument nicht behandelt.

Dieses Dokument behandelt nicht die Anforderungen für die Konstruktion von Absaugsystemen.

Machines pour les matières plastiques et le caoutchouc - Machines et installations de moulage par réaction - Prescriptions de sécurité

Le présent document spécifie les prescriptions essentielles de sécurité applicables à la conception et à la construction des machines et installations de moulage par réaction, telles que définies en 3.1 et 3.2.

Le présent document traite de tous les phénomènes dangereux, situations dangereuses ou événements dangereux pendant toutes les phases de son cycle de vie (voir l’EN ISO 12100:2010, 5.4), lorsque les des machines et installations de moulage par réaction sont utilisées selon l’usage prévu ou font l’objet d’un mauvais usage raisonnablement prévisible par le fabricant (voir Annexe A).

Une machine de moulage par réaction commence au(x) cuve(s) de stockage et se termine au(x) tête(s) de mélange.

Une installation de moulage par réaction commence au(x) cuve(s) de stockage et se termine à l'équipement de mise en forme et de transport de produit ou à l'équipement de moulage (voir 3.6 et 3.7).

Le présent document n’est pas applicable aux machines et installations de moulage par réaction fabriquées avant sa date de publication.

NOTE Les machines et installations de moulage par réaction ne produisent généralement pas d'atmosphères explosives. Lorsque les matériaux transformés sont susceptibles de produire une atmosphère explosive, la Directive 2014/34/EU relative aux appareils et systèmes de protection destinés à être utilisés en atmosphères explosibles (ATEX) peut être appliquée.

Les phénomènes dangereux d’explosion ne sont pas traités dans le présent document.

Les phénomènes dangereux d’incendie ne sont pas traités dans le présent document.

Le présent document ne contient pas de prescriptions relatives à la conception des systèmes d'aspiration.

Stroji za predelavo gume in plastike - Stroji in naprave za tlačno litje - Varnostne zahteve

Ta osnutek evropskega standarda določa osnovne varnostne zahteve za načrtovanje ter izdelavo strojev in naprav za tlačno litje. Vsa večja in znatna tveganja so navedena v dodatku A ter obravnavana v tem osnutku evropskega standarda. Ta osnutek evropskega standarda ne obravnava nevarnosti, povezanih z rezalno enoto (glej standard EN 14886:2008). Ta osnutek evropskega standarda ne zajema zahtev za načrtovanje izpušnih sistemov. Ta osnutek evropskega standarda ne zajema nevarnosti, ki izhajajo iz sestava ločenih enot, ki jih ne dobavi istočasno isti proizvajalec. Ta osnutek evropskega standarda se uporablja za stroje in naprave za tlačno litje, ki so bili izdelani po datumu njegove objave. Stroji in naprave za tlačno litje običajno ne proizvajajo eksplozivnih atmosfer. Če se obdelujejo materiali, ki lahko ustvarijo eksplozivno atmosfero, je priporočljivo uporabiti Direktivo 94/9/ES v zvezi z opremo, namenjeno za uporabo v potencialno eksplozivnih atmosferah (ATEX). Ta dokument ne zajema nevarnosti eksplozije.

General Information

- Status

- Published

- Publication Date

- 15-Oct-2019

- Withdrawal Date

- 29-Apr-2020

- Technical Committee

- CEN/TC 145 - Rubber and plastics machines - Safety

- Drafting Committee

- CEN/TC 145/WG 9 - Reaction injection moulding machines - Safety

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 05-Jun-2025

- Completion Date

- 23-Sep-2025

Relations

- Effective Date

- 23-Oct-2019

Overview

EN 1612:2019 - issued by CEN - defines essential safety requirements for the design and construction of reaction moulding machines and plants used in the plastics and rubber industries. It is a type‑C standard (referencing EN ISO 12100) that addresses significant hazards throughout the machine life cycle for equipment that, for machines, begins at the working tank(s) and ends at the mixing head(s), and for plants, extends to product shaping, transport or moulding equipment. The standard is applicable to machines and plants manufactured on or after its publication and explicitly excludes explosion, fire and exhaust‑system design hazards.

Key topics and technical requirements

EN 1612:2019 covers a comprehensive set of machine‑safety topics, including:

- Risk assessment and life‑cycle hazards - requirements when used as intended and for reasonably foreseeable misuse (see informative Annex A).

- Control functions - start, stop and restart behaviours, and safety‑related parts of control systems (performance levels aligned with EN ISO 13849‑1:2015 are specified in the standard).

- Safeguarding moving parts - crushing/impact hazards from drives, power transmission, mixing heads, moulding and transport equipment.

- Hydraulic, pneumatic and pressure hazards - malfunction, overpressure, hose whiplash and fluid ejection risks (references to EN ISO 4413 and EN ISO 4414).

- Ergonomics and human interaction - design per EN 614‑1 / EN 614‑2 and human performance guidance (EN 1005 series).

- Electrical safety - protection against direct/indirect contact and ingress (EN 60204‑1, IP code EN 60529).

- Emergency stop and positioning - technical specifications for emergency stop devices and their placement.

- Noise measurement and declaration - revised annex for noise testing and reporting (EN ISO 3744/3746, EN ISO 4871).

- Information for use - marking and instruction handbook requirements for safe operation and maintenance.

Note: Explosion and fire hazards are not addressed; ATEX (Directive 2014/34/EU) applies where explosive atmospheres could occur.

Practical applications and users

EN 1612:2019 is intended for:

- Machine manufacturers designing reaction moulding machines and plants to meet EU machinery safety requirements.

- Safety engineers and integrators assessing machine risk, specifying safeguards, and validating safety‑related control functions.

- Plant owners, employers and maintenance teams who need guidance on safe operation, guarding, noise emission data and user information.

- Regulators and market surveillance bodies verifying conformity with the Machinery Directive (see Annex ZA).

Practical benefits include clearer requirements for safeguarding moulding and transport units, defined control performance levels, and harmonized noise measurement procedures.

Related standards

- EN ISO 12100 (general principles of risk assessment)

- EN ISO 13849‑1 (safety‑related parts of control systems)

- EN 60204‑1 (electrical equipment)

- EN ISO 4413 / EN ISO 4414 (hydraulic and pneumatic systems)

- EN ISO 3744 / EN ISO 3746 / EN ISO 4871 (noise)

Keywords: EN 1612:2019, reaction moulding machines, safety requirements, plastics and rubber machines, machinery safety, CEN, risk assessment, control systems, noise declaration.

Frequently Asked Questions

EN 1612:2019 is a standard published by the European Committee for Standardization (CEN). Its full title is "Plastics and rubber machines - Reaction moulding machines and plants - Safety requirements". This standard covers: This document specifies the essential safety requirements applicable to the design and construction of reaction moulding machines and plants as defined in 3.1 and 3.2. This document deals with all significant hazards, hazardous situations or hazardous events during all phases of the machine life cycle (see EN ISO 12100:2010, 5.4), when reaction moulding machines and plants are used as intended and under conditions of misuse that are reasonably foreseeable by the manufacturer (see Annex A). A reaction moulding machine begins at the working tank(s) and ends at the mixing head(s). A reaction moulding plant begins at the working tank(s) and ends at the product shaping and transport equipment or at the moulding equipment (see 3.6 and 3.7). This document is not applicable to reaction moulding machines and plants manufactured before the date of its publication. NOTE Reaction moulding machines and plants usually do not produce explosive atmospheres. Where materials are processed, which may cause an explosive atmosphere, the Directive 2014/34/EU on the Equipment intended for use in Potentially Explosive Atmospheres (ATEX) can be applied. Explosion hazards are not dealt with in this document. Fire hazards are not dealt with in this document. This document does not cover the requirements for the design of the exhaust systems.

This document specifies the essential safety requirements applicable to the design and construction of reaction moulding machines and plants as defined in 3.1 and 3.2. This document deals with all significant hazards, hazardous situations or hazardous events during all phases of the machine life cycle (see EN ISO 12100:2010, 5.4), when reaction moulding machines and plants are used as intended and under conditions of misuse that are reasonably foreseeable by the manufacturer (see Annex A). A reaction moulding machine begins at the working tank(s) and ends at the mixing head(s). A reaction moulding plant begins at the working tank(s) and ends at the product shaping and transport equipment or at the moulding equipment (see 3.6 and 3.7). This document is not applicable to reaction moulding machines and plants manufactured before the date of its publication. NOTE Reaction moulding machines and plants usually do not produce explosive atmospheres. Where materials are processed, which may cause an explosive atmosphere, the Directive 2014/34/EU on the Equipment intended for use in Potentially Explosive Atmospheres (ATEX) can be applied. Explosion hazards are not dealt with in this document. Fire hazards are not dealt with in this document. This document does not cover the requirements for the design of the exhaust systems.

EN 1612:2019 is classified under the following ICS (International Classification for Standards) categories: 83.200 - Equipment for the rubber and plastics industries. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1612:2019 has the following relationships with other standards: It is inter standard links to EN 1612-1:1997+A1:2008. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1612:2019 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC; Standardization Mandates: M/396, M/BC/CEN/88/13. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

You can purchase EN 1612:2019 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of CEN standards.

Standards Content (Sample)

SLOVENSKI STANDARD

01-januar-2020

Nadomešča:

SIST EN 1612-1:2000+A1:2008

Stroji za predelavo gume in plastike - Stroji in naprave za tlačno litje - Varnostne

zahteve

Plastics and rubber machines - Reaction moulding machines and plants - Safety

requirements

Kunststoff- und Gummimaschinen - Reaktionsgießmaschinen und -anlagen -

Sicherheitsanforderungen

Machines pour les matières plastiques et le caoutchouc - Machines et installations de

moulage par réaction - Prescriptions de sécurité

Ta slovenski standard je istoveten z: EN 1612:2019

ICS:

83.200 Oprema za gumarsko Equipment for the rubber and

industrijo in industrijo plastics industries

polimernih materialov

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 1612

EUROPEAN STANDARD

NORME EUROPÉENNE

October 2019

EUROPÄISCHE NORM

ICS 83.200 Supersedes EN 1612-1:1997+A1:2008

English Version

Plastics and rubber machines - Reaction moulding

machines and plants - Safety requirements

Machines pour les matières plastiques et le caoutchouc Kunststoff- und Gummimaschinen -

- Machines et installations de moulage par réaction - Reaktionsgießmaschinen und -anlagen -

Prescriptions de sécurité Sicherheitsanforderungen

This European Standard was approved by CEN on 21 July 2019.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2019 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 1612:2019 E

worldwide for CEN national Members.

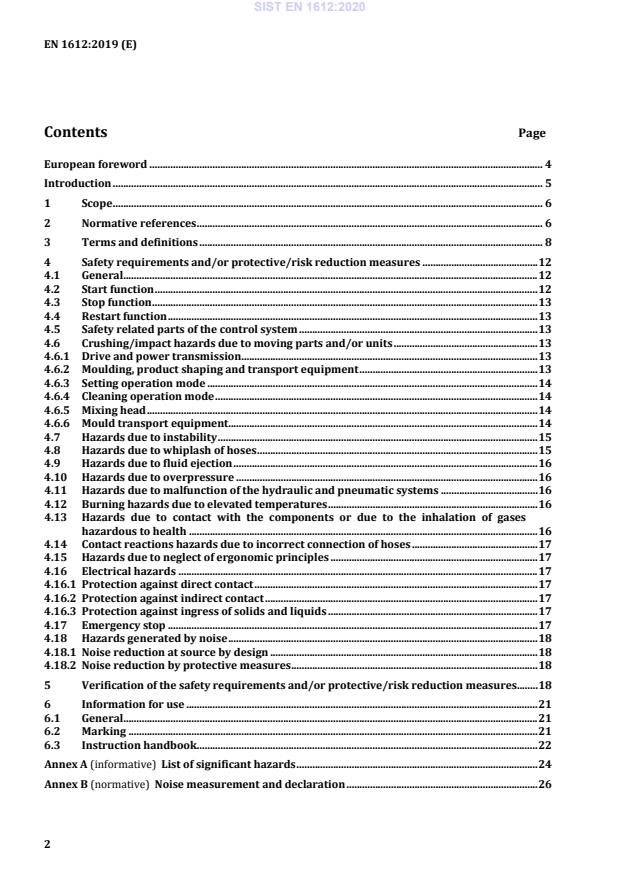

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 8

4 Safety requirements and/or protective/risk reduction measures . 12

4.1 General . 12

4.2 Start function . 12

4.3 Stop function . 13

4.4 Restart function . 13

4.5 Safety related parts of the control system . 13

4.6 Crushing/impact hazards due to moving parts and/or units . 13

4.6.1 Drive and power transmission . 13

4.6.2 Moulding, product shaping and transport equipment . 13

4.6.3 Setting operation mode . 14

4.6.4 Cleaning operation mode . 14

4.6.5 Mixing head . 14

4.6.6 Mould transport equipment. 14

4.7 Hazards due to instability . 15

4.8 Hazards due to whiplash of hoses . 15

4.9 Hazards due to fluid ejection . 16

4.10 Hazards due to overpressure . 16

4.11 Hazards due to malfunction of the hydraulic and pneumatic systems . 16

4.12 Burning hazards due to elevated temperatures . 16

4.13 Hazards due to contact with the components or due to the inhalation of gases

hazardous to health . 16

4.14 Contact reactions hazards due to incorrect connection of hoses . 17

4.15 Hazards due to neglect of ergonomic principles . 17

4.16 Electrical hazards . 17

4.16.1 Protection against direct contact . 17

4.16.2 Protection against indirect contact . 17

4.16.3 Protection against ingress of solids and liquids . 17

4.17 Emergency stop . 17

4.18 Hazards generated by noise . 18

4.18.1 Noise reduction at source by design . 18

4.18.2 Noise reduction by protective measures . 18

5 Verification of the safety requirements and/or protective/risk reduction measures . 18

6 Information for use . 21

6.1 General . 21

6.2 Marking . 21

6.3 Instruction handbook . 22

Annex A (informative) List of significant hazards . 24

Annex B (normative) Noise measurement and declaration . 26

B.1 Introduction. 26

B.2 Determination of the A-weighted emission sound pressure level at the workstation . 26

B.2.1 Basic standards and measurement procedure . 26

B.2.2 Measurement uncertainty . 26

B.3 Determination of the A-weighted sound power level . 27

B.3.1 General . 27

B.3.2 Basic standards and measurement procedure . 27

B.3.3 Measurement uncertainty . 27

B.4 Mounting and operating conditions. 27

B.5 Information to be recorded and reported . 28

B.5.1 General . 28

B.5.2 General data. 28

B.5.3 Mounting and operating conditions. 28

B.5.4 Standards . 28

B.5.5 Noise data . 28

B.6 Declaration and verification of noise emission values . 28

Annex ZA (informative) Relationship between this European Standard and the essential

requirements of EU Directive 2006/42/EC aimed to be covered . 30

Bibliography . 32

European foreword

This document (EN 1612:2019) has been prepared by Technical Committee CEN/TC 145 “Plastics and

rubber machines”, the secretariat of which is held by UNI.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by April 2020, and conflicting national standards shall be

withdrawn at the latest by April 2020.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document will supersede EN 1612-1:1997+A1:2008.

In comparison with the previous edition, the following technical modifications have been made:

— clarification that reaction moulding machines and plants are dealt with;

— revised type-A and type-B standards are taken into account;

— list of significant hazards moved into an informative annex;

— the performance levels of safety related parts of control systems are specified in accordance with

EN ISO 13849-1:2015;

— technical specifications for moulding and transport equipment safeguarding are given;

— technical specifications for positioning of the emergency stop devices are given;

— the annex for noise measurement and declaration has been revised.

This document has been prepared under a mandate given to CEN by the European Commission and the

European Free Trade Association, and supports essential requirements of EU Directives.

For relationship with EU Directive(s), see informative Annex ZA, which is an integral part of this

document.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

Introduction

This document is a type-C standard as stated in EN ISO 12100:2010.

This document is of relevance, in particular, for the following stakeholder groups representing the market

players with regard to machinery safety:

— machine manufacturers (small, medium and large enterprises);

— health and safety bodies (regulators, accident prevention organizations, market surveillance etc.)

Others can be affected by the level of machinery safety achieved with the means of the document by the

above-mentioned stakeholder groups:

— machine users/employers (small, medium and large enterprises);

— machine users/employees (e.g. trade unions, organizations for people with special needs);

— service providers, e.g. for maintenance (small, medium and large enterprises);

— consumers (in case of machinery intended for use by consumers).

The above-mentioned stakeholder groups have been given the possibility to participate at the drafting

process of this document.

The machinery concerned and the extent to which hazards, hazardous situations or hazardous events are

covered are indicated in the Scope of this document.

When requirements of this type-C standard are different from those which are stated in type-A or type-B

standards, the requirements of this type-C standard take precedence over the requirements of the other

standards for machines that have been designed and built according to the requirements of this type-C

standard.

1 Scope

This document specifies the essential safety requirements applicable to the design and construction of

reaction moulding machines and plants as defined in 3.1 and 3.2.

This document deals with all significant hazards, hazardous situations or hazardous events during all

phases of the machine life cycle (see EN ISO 12100:2010, 5.4), when reaction moulding machines and

plants are used as intended and under conditions of misuse that are reasonably foreseeable by the

manufacturer (see Annex A).

A reaction moulding machine begins at the working tank(s) and ends at the mixing head(s).

A reaction moulding plant begins at the working tank(s) and ends at the product shaping and transport

equipment or at the moulding equipment (see 3.6 and 3.7).

This document is not applicable to reaction moulding machines and plants manufactured before the date

of its publication.

NOTE Reaction moulding machines and plants usually do not produce explosive atmospheres. Where materials

are processed, which may cause an explosive atmosphere, the Directive 2014/34/EU on the Equipment intended

for use in Potentially Explosive Atmospheres (ATEX) can be applied.

Explosion hazards are not dealt with in this document.

Fire hazards are not dealt with in this document.

This document does not cover the requirements for the design of the exhaust systems.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 574:1996+A1:2008, Safety of machinery — Two-hand control devices — Functional aspects —

Principles for design

EN 614-1:2006+A1:2009, Safety of machinery — Ergonomic design principles — Part 1: Terminology and

general principles

EN 614-2:2000+A1:2008, Safety of machinery — Ergonomic design principles — Part 2: Interactions

between the design of machinery and work tasks

EN 1005 (all parts), Safety of machinery — Human physical performance

EN 60204-1:2006, Safety of machinery — Electrical equipment of machines — Part 1: General

requirements (IEC 60204-1:2005, modified)

EN 60529:1991, Degrees of protection provided by enclosures (IP Code) (IEC 60529:1989)

EN 61496-1:2013, Safety of machinery — Electro-sensitive protective equipment — Part 1: General

requirements and tests (IEC 61496-1:2012)

As impacted by EN 60204-1:2006/A1:2009.

EN ISO 3744:2010, Acoustics — Determination of sound power levels and sound energy levels of noise

sources using sound pressure — Engineering methods for an essentially free field over a reflecting plane (ISO

3744:2010)

EN ISO 3746:2010, Acoustics — Determination of sound power levels and sound energy levels of noise

sources using sound pressure — Survey method using an enveloping measurement surface over a reflecting

plane (ISO 3746:2010)

EN ISO 4413:2010, Hydraulic fluid power — General rules and safety requirements for systems and their

components (ISO 4413:2010)

EN ISO 4414:2010, Pneumatic fluid power — General rules and safety requirements for systems and their

components (ISO 4414:2010)

EN ISO 4871:2009, Acoustics — Declaration and verification of noise emission values of machinery and

equipment (ISO 4871:1996)

EN ISO 9614-2:1996, Acoustics — Determination of sound power levels of noise sources using sound

intensity — Part 2: Measurement by scanning (ISO 9614-2:1996)

EN ISO 11201:2010, Acoustics — Noise emitted by machinery and equipment — Determination of emission

sound pressure levels at a work station and at other specified positions in an essentially free field over a

reflecting plane with negligible environmental corrections (ISO 11201:2010)

EN ISO 11202:2010, Acoustics — Noise emitted by machinery and equipment — Determination of emission

sound pressure levels at a work station and at other specified positions applying approximate environmental

corrections (ISO 11202:2010)

EN ISO 11204:2010, Acoustics — Noise emitted by machinery and equipment — Determination of emission

sound pressure levels at a work station and at other specified positions applying accurate environmental

corrections (ISO 11204:2010)

EN ISO 12100:2010, Safety of machinery — General principles for design — Risk assessment and risk

reduction (ISO 12100:2010)

EN ISO 13732-1:2008, Ergonomics of the thermal environment — Methods for the assessment of human

responses to contact with surfaces — Part 1: Hot surfaces (ISO 13732-1:2006)

EN ISO 13849-1:2015, Safety of machinery — Safety-related parts of control systems — Part 1: General

principles for design (ISO 13849-1:2015)

EN ISO 13850:2015, Safety of machinery — Emergency stop function — Principles for design (ISO

13850:2015)

EN ISO 13855:2010, Safety of machinery — Positioning of safeguards with respect to the approach speeds

of parts of the human body (ISO 13855:2010)

EN ISO 13856-1:2013, Safety of machinery — Pressure-sensitive protective devices — Part 1: General

principles for design and testing of pressure-sensitive mats and pressure-sensitive floors (ISO 13856-1:2013)

EN ISO 13857:2008, Safety of machinery — Safety distances to prevent hazard zones being reached by

upper and lower limbs (ISO 13857:2008)

EN ISO 14119:2013, Safety of machinery — Interlocking devices associated with guards — Principles for

design and selection (ISO 14119:2013)

EN ISO 14120:2015, Safety of machinery — Guards — General requirements for the design and construction

of fixed and movable guards (ISO 14120:2015)

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN ISO 12100:2010 and the

following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at http://www.iso.org/obp

3.1

reaction moulding machine

machine that consists of at least one working tank, a metering unit and a mixing head

3.2

reaction moulding plant

complex installation for reaction moulding which consists of one or more reaction moulding machine(s),

a moulding equipment or a product shaping and transport equipment for the feeding of products

Note 1 to entry: See 3.1, 3.6 and 3.7.

3.3

working tank

tank which is part of the reaction moulding machine and contains at least one of the components

Note 1 to entry: See Figure 1.

Note 2 to entry: One tank may be used for each component or a mixture of more components.

3.4

mixing head

part of the reaction moulding machine for mixing components and delivery that can be manually operated

or powered

Note 1 to entry: See Figure 1.

Key

1 working tank

2 metering unit

3 mixing head

Figure 1 — Example of reaction moulding machine (side view)

3.5

components

chemical and mineral components that need to be mixed in the process to produce the final product

3.6

product shaping and transport equipment

part of the plant for the transport and shaping of the continuous product

Note 1 to entry: See Figure 2.

Key

1 product

2 side wall of product shaping and transport equipment for limiting the width of the product

3 equipment for feeding side cover sheet

4 product shaping and transport area

5 mixing head

6 equipment for manipulating the mixing head

Figure 2 — Product shaping and transport equipment (top view)

3.7

moulding equipment

equipment for continuous or discontinuous production of cured parts by one or more moulds

Note 1 to entry: See Figure 3 and Figure 4.

3.8

mould transport equipment

part of the plant for the transport of the moulds for continuous production

Note 1 to entry: Loading/unloading could be automatic or manual in a restricted area that is not shown in the

figures.

3.9

non-electrically controlled mixing head

mixing head opened and closed mechanically

Key

1 mould carrier frame

2 lower mould

3 upper mould

4 mixing head

Figure 3 — Fixed moulding equipment with fixed/movable mixing head for discontinuous

production (side view)

Key

1 mould transport equipment

2 open mould

3 closed mould

4 mixing head

Figure 4 — Mobile moulding equipment with fixed/movable mixing head, for continuous

production (top view)

4 Safety requirements and/or protective/risk reduction measures

4.1 General

Machinery shall comply with the safety requirements and/or protective/risk reduction measures of this

clause. In addition, the machine shall be designed according to the principles of EN ISO 12100:2010 for

relevant but not significant hazards, which are not dealt with by this document.

4.2 Start function

The start of an operation shall be possible only when all safeguards are in place and functional (see

EN 60204-1:2006, 9.2.5.2). The machine shall only be started by actuation of the start device provided

for that purpose.

4.3 Stop function

A normal stop command shall be provided to bring the machine to a stop. The normal stop command

shall function as a category 0 or 1 in accordance with EN 60204-1:2006, 9.2.2 and required Performance

level (PL ) = c EN ISO 13849-1:2015.

r

An additional operational stop that does not cut off the energy supply to the actuators may be installed

according to category 2 in accordance with EN 60204-1:2006, 9.2.2 and PL = b EN ISO 13849-1:2015 for

r

the movements which are enclosed by safeguards.

4.4 Restart function

An interruption or a failure of the power supply shall not result in a loss of safety function and restoration

of the energy supply shall not result in the automatic restarting of the machine (see EN ISO 12100:2010,

6.2.11.4 and 6.2.11.5).

4.5 Safety related parts of the control system

The safety related parts of the control system shall be in accordance with EN ISO 13849-1:2015. PL for

r

the relevant safety functions are given in the corresponding subclauses.

4.6 Crushing/impact hazards due to moving parts and/or units

4.6.1 Drive and power transmission

The access to moving parts of the drive and power transmission shall be prevented by enclosing guards

according to EN ISO 14120:2015. The openings in the guards shall comply with EN ISO 13857:2008,

Table 4.

4.6.2 Moulding, product shaping and transport equipment

The access to all the moving parts during production shall be prevented by distance guards in accordance

with EN ISO 13857:2008, Table 2 and Table 4 and EN ISO 14120:2015, in combination with one or more

of the following safeguards, in order to stop all dangerous movements if actuated:

— interlocking guards with or without guard locking in accordance with EN ISO 14119:2013; for

interlocked guards where full body access is possible, it shall be possible to open them from the inside

without the use of ancillary means;

— trip devices:

— electro-sensitive protective equipment in accordance with EN 61496-1:2013, type 2;

— pressure-sensitive protective mats in accordance with EN ISO 13856-1:2013;

— laser scanner in accordance with EN 61496-1:2013.

Interlocking guards without guard locking and trip devices shall be positioned in accordance with

EN ISO 13855:2010.

If full body access is possible a reset device according to EN ISO 13849-1:2015, 5.2.2 shall be installed to

prevent the unexpected restart when somebody is inside the protected area.

of the safety related parts of the control system in accordance with EN ISO 13849-1:2015 for the

The PLr

stopping of dangerous moving parts of the machine shall be as follows:

— handling unit (e.g. for parts or mixing head or moulds) ≤ 3 axes: PL = c;

r

— handling unit (e.g. for parts or mixing head or moulds) > 3 axes: PL = d;

r

— moulds closing: PL = d;

r

— moulds opening: PL = b.

r

4.6.3 Setting operation mode

If the safeguards shall be disabled for setting, a lockable mode selector in accordance with

EN ISO 12100:2010, 6.2.11.10 and EN 60204-1:2006, 9.2.3 and 9.2.4 shall be used in combination with

one of the following devices:

a) a two-hand control device in accordance with EN 574:1996+A1:2008 type IIIB and positioned in

accordance with EN ISO 13855:2010; for movements that can create crushing/shearing hazards (e.g.

mould closing) the safety related part of the control circuit shall be in accordance with PL = d of

r

EN ISO 13849-1:2015; for other hazards (e.g. mould opening) PL = b of EN ISO 13849-1:2015; the

r

operator shall have a clear view of the dangerous area;

b) a hold-to-run control device as defined in EN ISO 12100:2010, 3.28.3 according to PL = c of

r

EN ISO 13849-1:2015, in combination with a max speed of 2 m/min in accordance with PL = d of

r

EN ISO 13849-1:2015 for mould closing and PL = b of EN ISO 13849-1:2015 for mould opening; the

r

operator shall have a clear view of the dangerous area; the hold-to-run control shall be a three-

position device:

1) 1st position: stop;

2) 2nd position: run;

3) 3rd position: stop.

The operating procedures shall be described in the information for use (see 6.3).

4.6.4 Cleaning operation mode

Cleaning shall be done with the machine at rest. If it is necessary to clean while the machine is running

the same requirements described above for setting shall be applied.

4.6.5 Mixing head

The position of the mixing head during production shall be in the area protected by guards and safeguards

of 4.6.2. If for operational reasons, e.g. testing purposes, the position of the mixing head shall be outside

of the protected area, the movement of the mixing head shall be controlled by a hold to run control device

according to PL = c EN ISO 13849-1:2015 in combination with a max speed of 2 m/min and in

r

accordance with PL = d EN ISO 13849-1:2015. The operator shall have a clear view of the dangerous

r

area.

4.6.6 Mould transport equipment

The access to all dangerous areas of the mould transport equipment shall be prevented by distance

guards in accordance with EN ISO 14120:2015 and EN ISO 13857:2008, Table 2 and Table 4 except of the

working area(s) for manual loading and unloading operations. In this working area any movement of the

mould shall be prevented except transport and access to any other movement shall be prevented by

distance guards according to EN ISO 14120:2015 and EN ISO 13857:2008, Table 2 and Table 4.

In this working area the operator shall be protected, when standing in front of the mould transport

equipment, by the fo

...

The article discusses EN 1612:2019, which outlines safety requirements for reaction moulding machines and plants. It covers all significant hazards and events throughout the machine's life cycle, including foreseeable misuse. The document defines reaction moulding machines and plants and specifies that it does not apply to those manufactured before its publication. It also notes that if materials processed by these machines could create explosive atmospheres, the ATEX Directive can be applied. However, explosion and fire hazards are not covered in this document, and the design requirements for exhaust systems are not addressed.

The article discusses the safety requirements for reaction moulding machines and plants. It specifies that this document applies to the design and construction of these machines and plants. It addresses all significant hazards during all phases of the machine's life cycle. The document does not cover machines and plants manufactured before its publication. It also notes that while reaction moulding machines and plants typically do not produce explosive atmospheres, the ATEX Directive can be applied if materials are processed that may cause an explosive atmosphere. The document does not address explosion hazards, fire hazards, or the design requirements for exhaust systems.

기사 제목: EN 1612:2019 - 플라스틱 및 고무 기계 - 반응성 성형 기계 및 공장 - 안전 요구사항 기사 내용: 이 문서는 반응성 성형 기계 및 공장의 설계 및 건설에 적용되는 필수적인 안전 요구사항을 명시한다. 이 문서는 기계 수명 주기 전체에서 나타날 수 있는 모든 중요한 위험, 위험상황 또는 위험사건에 대해 다룬다. 반응성 성형 기계 및 공장이 의도된 대로 사용되거나 제조업자가 합리적으로 예상할 수 있는 오용 조건하에서 사용될 때 해당된다. 반응성 성형 기계는 작업 탱크에서 혼합 헤드까지의 범위를 가지며, 반응성 성형 공장은 작업 탱크에서 제품 성형 및 운반 장비 또는 성형 장비까지의 범위를 가진다. 이 문서는 발표일 이전에 제조된 반응성 성형 기계 및 공장에는 적용되지 않는다. 주의: 반응성 성형 기계 및 공장은 일반적으로 폭발성 환경을 생성하지 않는다. 폭발성 환경을 일으킬 수 있는 물질을 처리하는 경우 잠재적으로 폭발성 환경용 장비에 대한 2014/34/EU 지침(ATEX)을 적용할 수 있다. 폭발 위험과 불 발화 위험은 이 문서에서 다루지 않는다. 이 문서는 배기 시스템의 설계 요구사항을 다루지 않는다.

기사 제목: EN 1612:2019 - 플라스틱 및 고무 기계 - 반응성 성형 기계 및 시설 - 안전 요구 사항 기사 내용: 이 문서는 3.1과 3.2에서 정의된 반응성 성형 기계 및 시설의 설계 및 건설에 적용되는 필수적인 안전 요구 사항을 명시합니다. 이 문서는 반응성 성형 기계 및 시설이 의도된 대로 사용되고 제조업자가 예견 가능한 오용 조건 하에서 사용되는 경우 기계 수명주기의 모든 단계에서 발생할 수 있는 모든 중요한 위험, 위험 상황 또는 위험 사건을 다룹니다 (EN ISO 12100:2010, 5.4 참조). 반응성 성형 기계는 작동 탱크에서 시작하여 혼합 헤드에서 끝납니다. 반응성 성형 시설은 작동 탱크에서 시작하여 제품 성형 및 이송 장비 또는 성형 장비에서 끝납니다 (3.6 및 3.7 참조). 이 문서는 발표 일 이전에 제조된 반응성 성형 기계와 시설에는 적용되지 않습니다. 참고: 반응성 성형 기계와 시설은 일반적으로 폭발성 분위기를 생성하지 않습니다. 폭발성 분위기를 일으킬 수 있는 물질이 처리되는 경우, 폭발성 분위기에서 사용하기 위한 장비에 대한 2014/34/EU 지침(ATEX)이 적용될 수 있습니다. 이 문서에서는 폭발 위험과 화재 위험에 대해 다루지 않습니다. 또한, 배기 시스템 설계 요구 사항도 다루지 않습니다.

記事のタイトル:EN 1612:2019 - プラスチックとゴムの機械 - 反応成形機とプラント - 安全要件 記事の内容:この文書は、3.1および3.2で定義された反応成形機とプラントの設計および構築に適用される必須の安全要件を明示しています。 この文書は、反応成形機とプラントが意図した使用方法および製造業者によって予見可能な誤用の条件下で使用される場合に、機械のライフサイクルのすべての段階で発生する可能性のあるすべての重大な危険、危険な状況、または危険なイベントに対処します(EN ISO 12100:2010、5.4を参照)。 反応成形機は作業タンクから始まり、ミキシングヘッドで終わります。 反応成形プラントは作業タンクから始まり、製品形状および輸送設備または成形設備で終わります(3.6および3.7を参照)。 この文書は、発行日より前に製造された反応成形機およびプラントには適用されません。 注意:反応成形機とプラントは通常、爆発性の大気を生成しません。爆発性の大気を引き起こす可能性のある材料が処理される場合、ATEX指令(2014/34/EU)が適用される場合があります。 本文書では爆発の危険および火災の危険については取り扱いません。 また、排気システムの設計要件についても取り扱いません。

記事のタイトル:EN 1612:2019 - プラスチックおよびゴム機械 - 反応成形機および設備 - 安全要求事項 記事内容:この文書は、反応成形機および設備の設計および構築に適用される必須の安全要求事項を規定しています。この文書では、反応成形機および設備のすべての重要な危険、危険な状況、または予見可能な誤用に関する事象を、機械のライフサイクルのすべてのフェーズで取り扱います(EN ISO 12100:2010、5.4を参照)。なお、反応成形機とは、作業タンクから混合ヘッドまでの範囲であり、反応成形設備は、作業タンクから製品成形および輸送設備または成形設備までの範囲であると定義されています(3.6および3.7を参照)。 この文書は、発行日以前に製造された反応成形機および設備には適用されません。 注:反応成形機および設備は通常、爆発性の環境を生成しません。爆発性の環境を生じる可能性のある材料を処理する場合は、ATEX指令(2014/34/EU)が適用されることがあります。 爆発のリスクについては、この文書では取り扱われていません。また、火災の危険についても取り扱われていません。 本文書では、排気システムの設計要件については触れていません。

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...