EN 12013:2018

(Main)Plastics and rubber machines - Internal mixers - Safety requirements

Plastics and rubber machines - Internal mixers - Safety requirements

This European Standard deals with all significant hazards, hazardous situations or hazardous events relevant to the design and construction of internal mixers during all phases of the machine life cycle (see EN ISO 12100:2010, 5.4), irrespective of their size and of the control modes of the feeding door and discharge door, for production and laboratory applications, when the machines are used as intended and under the conditions of misuse which are reasonably foreseeable by the manufacturer (see Annex A).

An internal mixer for production and a tandem mixer with manual feeding begins at the feeding door and ends at the lower edge of the material discharge opening.

An internal mixer for production and a tandem mixer with automatic feeding begins at the conveyor, which is an integral part of the machine, and ends at the lower edge of the material discharge opening.

A laboratory internal mixer begins at the feeding door and ends at the material container, which is an integral part of the mixer.

With regard to noise emission measurement and declaration, only laboratory mixers are covered.

Explosion hazards are not dealt with in this document.

NOTE Internal mixers usually do not produce explosive atmospheres. Where materials are processed, which may cause an explosive atmosphere, the Directive 2014/34/EU on the Equipment and protective systems intended for use in potentially explosive atmospheres (ATEX) can be applied.

Exhaust systems are not covered.

This European Standard is not applicable to internal mixers manufactured before the date of its publication.

Kunststoff- und Gummimaschinen - Innenmischer - Sicherheitsanforderungen

Diese Europäische Norm behandelt alle signifikanten Gefährdungen, Gefährdungssituationen und Gefähr-dungsereignisse, die für die Konstruktion und den Bau von Innenmischern in sämtlichen Phasen der Lebensdauer der Maschine (siehe EN ISO 12100:2010, 5.4) relevant sind, unabhängig von ihrer Größe und von den Steuerungsarten für die Beschickungsklappe und die Entleerungsklappe, wenn die Maschinen bestimmungsgemäß und unter Bedingungen, die vom Hersteller als Fehlanwendung vernünftigerweise vorhersehbar sind, verwendet werden (siehe Anhang A).

Ein Innenmischer für die Produktion und ein Tandemmischer mit manueller Beschickung beginnt an der Beschickungsklappe und endet an der unteren Kante der Materialentleerungsöffnung.

Ein Innenmischer für die Produktion und ein Tandemmischer mit automatischer Beschickung beginnt am Förderband, das integraler Bestandteil der Maschine ist, und endet an der unteren Kante der Materialentleerungsöffnung.

Ein Labor-Innenmischer beginnt an der Beschickungsklappe und endet am Materialbehälter, der integraler Bestandteil der Maschine ist.

Was die Messung und Erklärung der Lärmemission betrifft, so sind nur Labor-Innenmischer behandelt.

Gefährdungen durch Explosion werden nicht in diesem Dokument behandelt.

ANMERKUNG Innenmischer bilden in der Regel keine explosionsgefährdeten Atmosphären. Werden Materialien verarbeitet, die eine explosionsfähige Atmosphäre verursachen können, kann die Richtlinie 2014/34/EU für Geräte und Schutzsysteme zur bestimmungsgemäßen Verwendung in explosionsgefährdeten Bereichen (ATEX) angewendet werden.

Absaugsysteme werden nicht behandelt.

Diese Europäische Norm gilt nicht für Innenmischer, die vor dem Datum ihrer Veröffentlichung hergestellt wurden.

Machines pour les matières plastiques et le caoutchouc - Mélangeurs internes - Prescritions de sécurité

La présente Norme européenne traite de tous les phénomènes dangereux, situations et événements dangereux significatifs pertinents pour la conception et la fabrication des mélangeurs internes au cours de toutes les phases du cycle de vie des machines (voir l'EN ISO 12100:2010, 5.4), quels que soient leurs dimensions et les modes de commande de la porte de chargement et de la porte de déchargement, pour des applications de production et de laboratoire, lorsque ces machines sont utilisées normalement et en cas de mauvais usage raisonnablement prévisible par le fabricant (voir Annexe A).

Un mélangeur interne pour la production et un mélangeur tandem à chargement manuel commencent à la porte de chargement et se terminent au bord inférieur de l'ouverture de déchargement des matériaux.

Un mélangeur interne pour la production et un mélangeur tandem à chargement automatique commencent au convoyeur, qui est une partie intégrale de la machine, et se terminent au bord inférieur de l'ouverture de déchargement des matériaux.

Un mélangeur interne de laboratoire commence à la porte de chargement et se termine au conteneur de matériaux, qui est une partie intégrale du mélangeur.

En ce qui concerne le mesurage et la déclaration des émissions de bruit, seuls les mélangeurs de laboratoire sont couverts.

Le présent document ne traite pas des risques d'explosion.

NOTE En général les mélangeurs internes ne génèrent pas d'atmosphères explosibles. Lorsque les matériaux travaillés peuvent engendrer une atmosphère explosible, la directive 2014/34/UE pour les appareils et les systèmes de protection destinés à être utilisés en atmosphères explosibles (ATEX) peut-être appliquée.

Les systèmes d'aspiration ne sont pas couverts.

La présente Norme européenne ne s'applique pas aux mélangeurs internes fabriqués avant sa date de publication comme Norme européenne.

Stroji za predelavo gume in plastike - Notranji mešalniki - Varnostne zahteve

Ta evropski standard opisuje vsa večja tveganja, nevarne situacije ali nevarne dogodke v zvezi z načrtovanjem in izdelavo notranjih mešalnikov za uporabo v proizvodnji in laboratorijih, kadar se uporabljajo v skladu z svojim namenom in pod pogoji pričakovane nepravilne uporabe, ki jih določi proizvajalec (glej dodatek A).

Notranji mešalnik sega od odprtin za polnjenje do odprtine za izmet.

Notranji mešalniki običajno ne proizvajajo eksplozivnih atmosfer. Če se obdelujejo materiali, ki lahko ustvarijo eksplozivno atmosfero, je treba uporabiti Direktivo 94/9/ES v zvezi z opremo in zaščitnimi sistemi, namenjenimi za uporabo v potencialno eksplozivnih atmosferah (ATEX). Ta dokument ne zajema nevarnosti eksplozije.

Varnostne zahteve za načrtovanje izpušnih sistemov in pomožne opreme niso zajete. Varnostne zahteve za interakcijo med notranjimi mešalniki in pomožno opremo so zajete.

Ta evropski standard se ne uporablja za notranje mešalnike, izdelane pred objavo tega standarda.

General Information

- Status

- Published

- Publication Date

- 16-Jan-2018

- Withdrawal Date

- 30-Jul-2018

- Technical Committee

- CEN/TC 145 - Rubber and plastics machines - Safety

- Drafting Committee

- CEN/TC 145/WG 7 - Internal mixers - Safety

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 07-Sep-2023

- Completion Date

- 11-Feb-2026

Relations

- Replaces

EN 12013:2000+A1:2008 - Plastics and rubber machines - Internal mixers - Safety requirements - Effective Date

- 24-Jan-2018

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 12013:2018 - Plastics and rubber machines - Internal mixers - Safety requirements is a CEN type‑C standard that specifies safety requirements for the design and construction of internal mixers used in production and laboratory applications. It addresses all significant hazards, hazardous situations and events throughout the machine life cycle in line with EN ISO 12100:2010. The document covers single and tandem internal mixers, defines the machine work envelope for production and laboratory equipment, and clarifies what is excluded (notably explosion hazards and exhaust systems).

Key topics and technical requirements

- Scope and machine boundaries - Defines start/end points for production mixers, tandem mixers (manual and automatic feeding), and laboratory mixers so hazards are consistently assessed.

- Risk reduction and guarding - Requirements for safeguarding feeding, transition chute and discharge areas to prevent mechanical hazards.

- Control functions - Expectations for start/stop/restart, emergency stop systems and safety‑related parts of control systems (performance levels referenced to EN ISO 13849‑1).

- Operation, maintenance and cleaning - Additional safeguards and conditions for major cleaning, maintenance and repair activities (including laboratory‑specific provisions).

- Electrical, thermal and ergonomic hazards - Protection against electric shock, thermal risks and ergonomic considerations during design and use.

- Noise emission - Normative annex with test code and declaration rules for noise measurements applies specifically to laboratory internal mixers.

- Fire and hazardous substances - Guidance and informative examples for handling fire risks (e.g., exothermic compounds) and substances hazardous to health.

- Exclusions - Explosion atmospheres are not covered; ATEX Directive 2014/34/EU applies where relevant. Exhaust systems are outside the standard’s scope.

- Documentation and marking - Requirements for instruction handbooks, safety information, markings and warnings for compliant machines.

Applications and who uses it

- Machine manufacturers and designers - Primary users for integrating safeguards and control performance requirements during product development.

- Health & safety authorities and conformity assessors - Use the standard to evaluate compliance with machinery safety expectations and to support conformity to EU machinery directives.

- Plant managers, maintenance teams and service providers - Use for safe operation, maintenance planning and performing risk assessments.

- Laboratory equipment suppliers and users - Refer to noise test code and laboratory‑specific safety clauses.

Related standards and references

- EN ISO 12100:2010 - Fundamental principles for risk assessment and reduction (referenced for lifecycle approach).

- EN ISO 13849‑1 - Performance levels for safety‑related control systems (used to specify control requirements).

- EU/ATEX Directive 2014/34/EU - Applicable when potentially explosive atmospheres may arise (explosion hazards are excluded from EN 12013).

EN 12013:2018 is essential for stakeholders in the rubber and plastics industries who need clear, harmonized safety requirements for internal mixers used in production and laboratory settings.

Get Certified

Connect with accredited certification bodies for this standard

Smithers Quality Assessments

US management systems and product certification.

DIN CERTCO

DIN Group product certification.

Sponsored listings

Frequently Asked Questions

EN 12013:2018 is a standard published by the European Committee for Standardization (CEN). Its full title is "Plastics and rubber machines - Internal mixers - Safety requirements". This standard covers: This European Standard deals with all significant hazards, hazardous situations or hazardous events relevant to the design and construction of internal mixers during all phases of the machine life cycle (see EN ISO 12100:2010, 5.4), irrespective of their size and of the control modes of the feeding door and discharge door, for production and laboratory applications, when the machines are used as intended and under the conditions of misuse which are reasonably foreseeable by the manufacturer (see Annex A). An internal mixer for production and a tandem mixer with manual feeding begins at the feeding door and ends at the lower edge of the material discharge opening. An internal mixer for production and a tandem mixer with automatic feeding begins at the conveyor, which is an integral part of the machine, and ends at the lower edge of the material discharge opening. A laboratory internal mixer begins at the feeding door and ends at the material container, which is an integral part of the mixer. With regard to noise emission measurement and declaration, only laboratory mixers are covered. Explosion hazards are not dealt with in this document. NOTE Internal mixers usually do not produce explosive atmospheres. Where materials are processed, which may cause an explosive atmosphere, the Directive 2014/34/EU on the Equipment and protective systems intended for use in potentially explosive atmospheres (ATEX) can be applied. Exhaust systems are not covered. This European Standard is not applicable to internal mixers manufactured before the date of its publication.

This European Standard deals with all significant hazards, hazardous situations or hazardous events relevant to the design and construction of internal mixers during all phases of the machine life cycle (see EN ISO 12100:2010, 5.4), irrespective of their size and of the control modes of the feeding door and discharge door, for production and laboratory applications, when the machines are used as intended and under the conditions of misuse which are reasonably foreseeable by the manufacturer (see Annex A). An internal mixer for production and a tandem mixer with manual feeding begins at the feeding door and ends at the lower edge of the material discharge opening. An internal mixer for production and a tandem mixer with automatic feeding begins at the conveyor, which is an integral part of the machine, and ends at the lower edge of the material discharge opening. A laboratory internal mixer begins at the feeding door and ends at the material container, which is an integral part of the mixer. With regard to noise emission measurement and declaration, only laboratory mixers are covered. Explosion hazards are not dealt with in this document. NOTE Internal mixers usually do not produce explosive atmospheres. Where materials are processed, which may cause an explosive atmosphere, the Directive 2014/34/EU on the Equipment and protective systems intended for use in potentially explosive atmospheres (ATEX) can be applied. Exhaust systems are not covered. This European Standard is not applicable to internal mixers manufactured before the date of its publication.

EN 12013:2018 is classified under the following ICS (International Classification for Standards) categories: 83.200 - Equipment for the rubber and plastics industries. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12013:2018 has the following relationships with other standards: It is inter standard links to EN 12013:2000+A1:2008, EN 61496-2:2013, EN 60204-1:2006, CLC/TR 60079-32-1:2015, EN 60529:1991, EN 61310-1:2008, EN 61496-1:2013, EN ISO 4414:2010, EN ISO 3744:2010, EN 614-1:2006+A1:2009, EN ISO 11202:2010, EN ISO 13850:2015, EN ISO 14122-3:2016, EN ISO 13732-1:2008, EN 619:2002+A1:2010. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12013:2018 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC; Standardization Mandates: M/396, M/BC/CEN/88/13. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12013:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Stroji za predelavo gume in plastike - Notranji mešalniki - Varnostne zahteveKunststoff- und Gummimaschinen - Innenmischer - SicherheitsanforderungenMachines pour les matières plastiques et le caoutchouc - Mélangeurs internes - Prescritions de sécuritéPlastics and rubber machines - Internal mixers - Safety requirements83.200Oprema za gumarsko industrijo in industrijo polimernih materialovEquipment for the rubber and plastics industriesICS:Ta slovenski standard je istoveten z:EN 12013:2018SIST EN 12013:2018en,de01-junij-2018SIST EN 12013:2018SLOVENSKI

STANDARDSIST EN 12013:2000+A1:20081DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 12013

January

t r s z ICS

z uä t r r Supersedes EN

s t r s uã t r r r ªA sã t r r zEnglish Version

Plastics and rubber machines æ Internal mixers æ Safety requirements Machines pour les matières plastiques et le caoutchouc æ Mélangeurs internes æ Prescritions de sécurité

Kunststoffæ und Gummimaschinen æ Innenmischer æ Sicherheitsanforderungen This European Standard was approved by CEN on

z September

t r s yä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Serbiaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey and United Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Rue de la Science 23,

B-1040 Brussels

t r s z CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s t r s uã t r s z ESIST EN 12013:2018

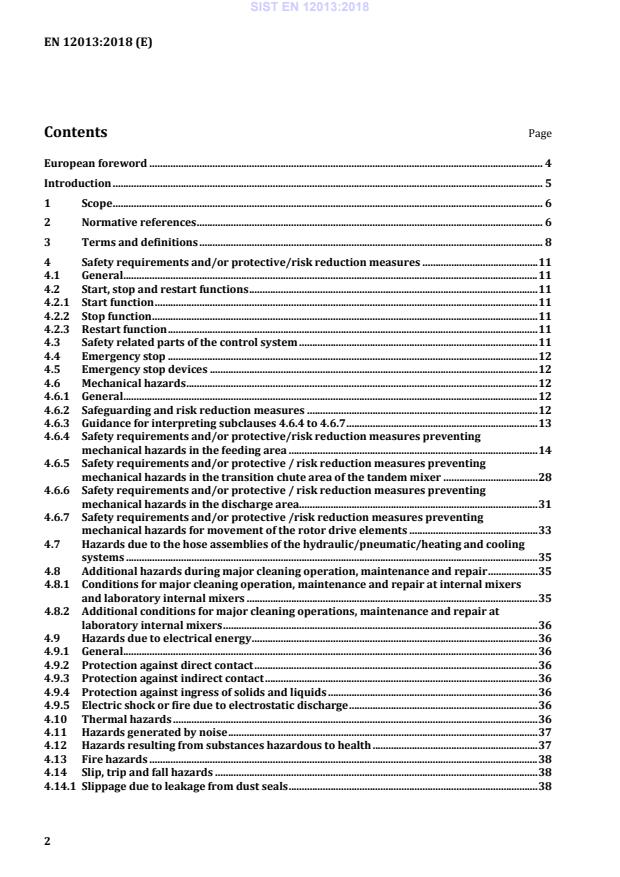

Page European foreword . 4 Introduction . 5 1 Scope . 6 2 Normative references . 6 3 Terms and definitions . 8 4 Safety requirements and/or protective/risk reduction measures . 11 4.1 General . 11 4.2 Start, stop and restart functions . 11 4.2.1 Start function . 11 4.2.2 Stop function . 11 4.2.3 Restart function . 11 4.3 Safety related parts of the control system . 11 4.4 Emergency stop . 12 4.5 Emergency stop devices . 12 4.6 Mechanical hazards . 12 4.6.1 General . 12 4.6.2 Safeguarding and risk reduction measures . 12 4.6.3 Guidance for interpreting subclauses 4.6.4 to 4.6.7 . 13 4.6.4 Safety requirements and/or protective/risk reduction measures preventing mechanical hazards in the feeding area . 14 4.6.5 Safety requirements and/or protective / risk reduction measures preventing mechanical hazards in the transition chute area of the tandem mixer . 28 4.6.6 Safety requirements and/or protective / risk reduction measures preventing mechanical hazards in the discharge area . 31 4.6.7 Safety requirements and/or protective /risk reduction measures preventing mechanical hazards for movement of the rotor drive elements . 33 4.7 Hazards due to the hose assemblies of the hydraulic/pneumatic/heating and cooling systems . 35 4.8 Additional hazards during major cleaning operation, maintenance and repair . 35 4.8.1 Conditions for major cleaning operation, maintenance and repair at internal mixers and laboratory internal mixers . 35 4.8.2 Additional conditions for major cleaning operations, maintenance and repair at laboratory internal mixers . 36 4.9 Hazards due to electrical energy . 36 4.9.1 General . 36 4.9.2 Protection against direct contact . 36 4.9.3 Protection against indirect contact . 36 4.9.4 Protection against ingress of solids and liquids . 36 4.9.5 Electric shock or fire due to electrostatic discharge . 36 4.10 Thermal hazards . 36 4.11 Hazards generated by noise . 37 4.12 Hazards resulting from substances hazardous to health . 37 4.13 Fire hazards . 38 4.14 Slip, trip and fall hazards . 38 4.14.1 Slippage due to leakage from dust seals . 38 SIST EN 12013:2018

List of significant hazards . 48 A.1 General . 48 A.2 Design versions of internal mixers and their working levels . 48 A.3 Hazards, hazardous situations and events . 49 Annex B (normative)

Noise test code for laboratory internal mixers . 62 B.1 Introduction. 62 B.2 Determination of the A-weighted emission sound pressure level at the workstation . 62 B.2.1 Basic standards and measurement procedure . 62 B.2.2 Measurement uncertainty . 63 B.3 Determination of the A-weighted sound power level . 63 B.3.1 Basic standards and measurement procedure . 63 B.3.2 Measurement uncertainty . 64 B.4 Mounting and operating conditions. 64 B.5 Information to be recorded and reported . 65 B.5.1 General . 65 B.5.2 General data. 65 B.5.3 Mounting and operating conditions. 65 B.5.4 Standards . 65 B.5.5 Noise data . 65 B.6 Declaration and verification of noise emission values . 65 Annex C (informative)

Examples of possible technical measures to prevent fire hazards due to exothermically reacting compounds . 68 Annex ZA (informative)

Relationship between this European Standard and the essential requirements of EU Directive 2006/42/EC aimed to be covered . 69 Bibliography . 70

With regard to noise emission measurement and declaration, only laboratory mixers are covered. Explosion hazards are not dealt with in this document. NOTE Internal mixers usually do not produce explosive atmospheres. Where materials are processed, which may cause an explosive atmosphere, the Directive 2014/34/EU on the Equipment and protective systems intended for use in potentially explosive atmospheres (ATEX) can be applied. Exhaust systems are not covered. This European Standard is not applicable to internal mixers manufactured before the date of its publication. 2 Normative references The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 574:1996+A1:2008, Safety of machinery - Two-hand control devices - Functional aspects - Principles for design EN 614-1:2006+A1:2009, Safety of machinery - Ergonomic design principles - Part 1: Terminology and general principles EN 619:2002+A1:2010, Continuous handling equipment and systems - Safety and EMC requirements for equipment for mechanical handling of unit loads EN 1037:1995+A1:2008, Safety of machinery - Prevention of unexpected start-up EN 60204-1:2006, Safety of machinery - Electrical equipment of machines - Part 1: General requirements (IEC 60204-1:2005, modified) EN 60529:1991, Degrees of protection provided by enclosures (IP Code) (IEC 60529:1989/A1:1999/A2:2013)1)

1) This document is impacted by the amendments EN 60529:1991/A1:2000 and EN 60529:1991/A2:2013. SIST EN 12013:2018

Key a rotors f feed opening for connection to the material handling system b mixing chamber g floating weight for applying pressure on the compound c feed hopper h discharge device d feeding door n working platform e rear opening/rear door o internal mixer platform, material discharge level Figure 1 — Main parts of an internal mixer 3.2 laboratory internal mixer internal mixer with a chamber volume up to 10 l 3.3 tandem mixer combination of two internal mixers, whereby the lower internal mixer is equipped with a transition chute and a pusher flap instead of a floating weight Note 1 to entry: The main parts of a tandem mixer are shown in Figure 2. SIST EN 12013:2018

Key 1 tandem mixer 2 upper internal mixer

3 lower internal mixer

a rotors i transition chute b mixing chamber k pusher flap c feed hopper l opening d feeding door m inspection door e rear door opening n working platform f feed opening for material handling system connections o internal mixer platform, material discharge level of the upper mixer g floating weight for applying pressure on the compound p internal mixer platform, material discharge level of the tandem mixer h discharge device

Figure 2 — Main parts of a tandem mixer 3.4 mixing chamber part of the machine comprising two mixing chamber halves, rotors, side walls and discharge door, where the mixing process runs SIST EN 12013:2018

Key h1 height of the opened feeding door h2 height of fixed enclosing guard or interlocking guard or openings in fixed enclosing guard h3 height of conveyor acting as a guard d1 distance between guard and movable part of the machine d2 distance between guard and fixed part of the machine to prevent whole body access d3 safety distance between light curtain and movable part of the machine / danger zone Figure 3 — Example of maximum distances to prevent whole body access 4.6.3 Guidance for interpreting subclauses 4.6.4 to 4.6.7 The different protective measures for each hazard are separated in table rows. Each measure in a row shall be deemed to be a self-contained alternative. The first column "Admissible protective measures" contains one or more alternative safety solutions. The second column "Mandatory requirements for the protective measures" contains requirements which need to be applied for the corresponding protective measure in the first column of the same row. The third column contains, if any, the required performance level. See also list of significant hazards in Annex A. SIST EN 12013:2018

— The conveyor shall be so designed that access to dangerous movements is prevented; and — the maximum distance between the conveyor and fixed or movable parts of the machine shall be 120 mm in order to avoid whole body access (see dimension d2 in Figure 3); and — the position of the conveyor shall be monitored. The removal or shifting of the conveyor shall stop the feeding door. PLr = d Where the movement of the feeding door can only be released manually: PLr = c Two-hand control device, Type III for triggering the movement of the feeding door The danger area shall be clearly visible. PLr = c Hold-to-run control device for triggering the movement of the feeding door. — The danger area shall be clearly visible; and — the minimum distance to the closest crushing and shearing points shall be at least 2 m. PLr = c Operator monitoring by means of presence detecting devices. The triggering of the devices (e.g. pressure sensitive mats/floors or light curtains) shall stop the movements of the feeding door. ESPE and AOPD shall be in accordance with Type 3 or 4 EN 61496-1:2013 and shall be positioned in accordance with EN ISO 13855:2010. PLr = d SIST EN 12013:2018

not relevant 4.6.4.3 Reaching through lateral or rear openings Admissible protective measure Mandatory requirement for the protective measures Required performance level PLr Ducts, feeding channels or covers on lateral or rear openings The ducts, feeding channels and covers shall be so designed that they act as fixed enclosing guards. For reaching through openings in the guards the safety distances shall be in accordance with EN ISO 13857:2008, Table 4. not relevant 4.6.4.4 Reaching through exhaust openings Admissible protective measure Mandatory requirement for the protective measures Required performance level PLr Connection ducts acting as fixed enclosing guards For reaching through openings in the guards the safety distances shall be in accordance with EN ISO 13857:2008, Table 4. not relevant SIST EN 12013:2018

Use of a feeding door acting as an interlocking guard Opening of the feeding door shall stop the movement of the floating weight. PLr = d Manual mode: Two-hand control device, Type III B for triggering the movement of the floating weight — The manual mode shall be activated by a mode selector in accordance EN ISO 12100:2010, 6.2.11.10 and EN 60204-1:2006, 9.2.4; and — the danger area shall be clearly visible. PLr = c Manual mode: Hold-to-run control device — The manual mode shall be activated by a mode selector in accordance EN ISO 12100:2010, 6.2.11.10 and EN 60204-1:2006, 9.2.4; and — and the danger area shall be clearly visible; and — the minimum distance to the closest crushing and shearing points shall be at least 2 m. PLr = c Interlocking guard with guard locking The movement of the floating weight shall only be possible if — the interlocking guard is closed and locked; or — the feeding door is closed; or — the machine is in ”Manual mode”; the movement of the floating weight shall be initiated by either a two-hand control device, Type III B or a hold-to-run control device Unlocking of the interlocking guard shall only be possible if the feeding door is closed or the machine is in manual mode. PLr = d SIST EN 12013:2018

For reaching through openings in the guards, the safety distances shall be in accordance with EN ISO 13857:2008, Table 4. not relevant Fixed enclosing guard Fixed guard or fixed conveyor shall act as a fixed enclosing guard with a minimum height of 1 100 mm (see height h3 in Figure 3). For reaching through openings in the guards, the safety distances shall be in accordance with EN ISO 13857:2008, Table 4. not relevant Movable conveyor acting as an interlocking guard with guard locking. The Conveyor shall be in accordance with EN 619:2002+A1:2010. — The interlocking shall prevent the opening of the feeding door. — Unlocking of the conveyor shall only be possible when the feeding door is closed. PLr = d Limitation of the dimensions of the feed opening The maximum dimensions for A and B shall be in accordance with the dimensions in Figure 4: 500 mm x 400 mm, respectively 400 mm x 500 mm not relevant

Key A opening length B opening width Figure 4 — Feeding door — Dimensions of the access opening

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...