EN 12012-4:2019+A1:2021

(Main)Plastics and rubber machines - Size reduction machines - Part 4: Safety requirements for agglomerators

Plastics and rubber machines - Size reduction machines - Part 4: Safety requirements for agglomerators

This document deals with all significant hazards, hazardous situations and events relevant to agglomerators for the modification of plastic scraps in its form, size and flow characteristics, when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer (see Annex A). The hazards have been identified taking into account all phases of the machine life cycle according to EN ISO 12100:2010, 5.4.

Machines considered in this document begin at the outer edge of the feed opening and end at the outer edge of the discharge opening.

This document does not deal with:

- hazards due to emissions by processing materials that could be hazardous to health;

- hazards caused by ignition of flammable residues in material to be processed;

- requirements for exhaust ventilation systems.

This document is not applicable to agglomerators manufactured before the date of its publication.

Kunststoff- und Gummimaschinen - Zerkleinerungsmaschinen - Teil 4: Sicherheitsanforderungen für Agglomeratoren

Dieses Dokument behandelt alle signifikanten Gefährdungen, Gefährdungssituationen und Gefährdungs¬ereignisse für Agglomeratoren zum Verändern von Kunststoffabfällen in ihrer Form, ihrer Größe und ihren Fließeigenschaften, wenn sie bestimmungsgemäß und unter Bedingungen, die vom Hersteller als Fehl¬anwendung vernünftigerweise vorhersehbar sind (siehe Anhang A), verwendet werden. Die Gefährdungen sind unter Berücksichtigung aller Phasen der Lebensdauer der Maschine nach EN ISO 12100:2010, 5.4, identifiziert worden.

Die in diesem Dokument betrachteten Maschinen beginnen an der Außenkante der Beschickungsöffnung und enden an der Außenkante der Austragsöffnung.

Dieses Dokument behandelt nicht:

- Gefährdungen durch Emissionen bei der Verarbeitung von Materialien, die gesundheitsgefährdend sein können;

- Gefährdungen, die durch Entzünden brennbarer Rückstände in den zu verarbeitenden Materialien hervorgerufen werden;

- Anforderungen für Absaugsysteme;

- Agglomeratoren mit pneumatisch und/oder hydraulisch bewegten Antrieben.

Dieses Dokument ist nicht anzuwenden für Agglomeratoren, die vor dem Datum ihrer Veröffentlichung hergestellt wurden.

Machines pour les matières plastiques et le caoutchouc - Machines à fragmenter - Partie 4 : Prescriptions de sécurité relatives aux agglomérateurs

Le présent document traite de tous les phénomènes dangereux, situations et événements dangereux significatifs pertinents pour des agglomérateurs utilisés pour la modification de la forme, de la taille et des caractéristiques d'écoulement des déchets de matières plastiques, lorsqu’ils sont utilisés normalement et dans des conditions de mauvais usage raisonnablement prévisible par le fabricant (voir l'Annexe A). Les phénomènes dangereux ont été identifiés en prenant en compte toutes les phases du cycle de vie de la machine, conformément à l'EN ISO 12100:2010, 5.4.

Les machines prises en compte dans le présent document commencent au bord extérieur de l'ouverture d'alimentation et se terminent au bord extérieur de l'ouverture d'évacuation.

Le présent document ne traite pas :

- des phénomènes dangereux engendrés par les émissions dues à la transformation des matières qui pourraient être dangereuses pour la santé ;

- des phénomènes dangereux engendrés par l'inflammation de résidus inflammables dans les matières à traiter ;

- des exigences relatives aux systèmes d'aspiration ;

- des agglomérateurs actionnés par de l'énergie pneumatique et/ou hydraulique.

Le présent document n’est pas applicable aux agglomérateurs fabriqués avant sa date de publication.

Stroji za predelavo gume in plastike - Drobilni stroji - 4. del: Varnostne zahteve za aglomeratorje

General Information

- Status

- Published

- Publication Date

- 12-Oct-2021

- Withdrawal Date

- 29-Apr-2022

- Technical Committee

- CEN/TC 145 - Rubber and plastics machines - Safety

- Drafting Committee

- CEN/TC 145/WG 6 - Size reduction machines - Safety

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 03-Dec-2024

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 21-Jul-2021

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 12012-4:2019+A1:2021 - "Plastics and rubber machines - Size reduction machines - Part 4: Safety requirements for agglomerators" (CEN) is a European type‑C standard that defines essential safety requirements for agglomerators used to modify plastic scraps (form, size and flow characteristics). The standard adopts a machinery life‑cycle approach per EN ISO 12100:2010 and applies to machines measured from the outer edge of the feed opening to the outer edge of the discharge opening. It is not applicable to agglomerators manufactured before its publication and excludes hazards from material emissions, ignition of flammable residues, exhaust‑ventilation system requirements and agglomerators actuated by pneumatic or hydraulic energy.

Key topics and technical requirements

- Hazard identification - Covers significant hazards, hazardous situations and events relevant to agglomerators (see informative Annex A).

- Mechanical hazards - Protection against access through feed/discharge openings, risks from non‑precut feed material and moving parts of discharge systems.

- Control and safety functions - Requirements for control circuits including emergency stop, stop and start functions; measures to prevent unexpected start‑up.

- Functional safety - Performance level / Safety Integrity Level requirements are referenced to standards such as EN ISO 13849‑1 and EN 62061 for safety‑related control systems.

- Electrical safety - Conformance with EN 60204‑1 (electrical equipment of machines) and prevention of hazardous electrostatic charge accumulation.

- Noise - Noise measurement and emission requirements are detailed in Annex B (noise test code) referencing EN ISO 3744/3746 and related acoustics standards.

- Thermal, dust, fumes/gases - Identification and mitigation of thermal risks and hazards generated by dust, fumes and gases (excluding emissions that are hazardous to health, which are not dealt with).

- Verification and information for use - Conformity verification procedures, instruction handbook requirements, marking and safety signage.

Applications and who uses it

- Machine manufacturers - Design and build agglomerators to meet CEN safety requirements and harmonize with EU Machinery Directive (2006/42/EC).

- Health & safety bodies and market surveillance - Assess conformity and enforce safe machinery practice.

- Machine users / employers - Implement safe installation, operation and maintenance practices based on the instruction handbook and marking.

- Service and maintenance providers - Use the standard for safe servicing, testing and validation of safety functions.

Related standards (normative references)

- EN ISO 12100:2010 (risk assessment)

- EN ISO 14118 (prevention of unexpected start‑up)

- EN 60204‑1 (electrical equipment)

- EN 62061 / EN ISO 13849‑1 (functional safety)

- EN ISO 3744 / EN ISO 3746 (noise measurement)

EN 12012-4:2019+A1:2021 is SEO‑relevant for searches on agglomerator safety, plastics and rubber machines standards, size reduction machine requirements, CEN safety standards, machinery safety compliance, and noise/functional safety for agglomerators.

Get Certified

Connect with accredited certification bodies for this standard

Smithers Quality Assessments

US management systems and product certification.

DIN CERTCO

DIN Group product certification.

Sponsored listings

Frequently Asked Questions

EN 12012-4:2019+A1:2021 is a standard published by the European Committee for Standardization (CEN). Its full title is "Plastics and rubber machines - Size reduction machines - Part 4: Safety requirements for agglomerators". This standard covers: This document deals with all significant hazards, hazardous situations and events relevant to agglomerators for the modification of plastic scraps in its form, size and flow characteristics, when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer (see Annex A). The hazards have been identified taking into account all phases of the machine life cycle according to EN ISO 12100:2010, 5.4. Machines considered in this document begin at the outer edge of the feed opening and end at the outer edge of the discharge opening. This document does not deal with: - hazards due to emissions by processing materials that could be hazardous to health; - hazards caused by ignition of flammable residues in material to be processed; - requirements for exhaust ventilation systems. This document is not applicable to agglomerators manufactured before the date of its publication.

This document deals with all significant hazards, hazardous situations and events relevant to agglomerators for the modification of plastic scraps in its form, size and flow characteristics, when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer (see Annex A). The hazards have been identified taking into account all phases of the machine life cycle according to EN ISO 12100:2010, 5.4. Machines considered in this document begin at the outer edge of the feed opening and end at the outer edge of the discharge opening. This document does not deal with: - hazards due to emissions by processing materials that could be hazardous to health; - hazards caused by ignition of flammable residues in material to be processed; - requirements for exhaust ventilation systems. This document is not applicable to agglomerators manufactured before the date of its publication.

EN 12012-4:2019+A1:2021 is classified under the following ICS (International Classification for Standards) categories: 83.200 - Equipment for the rubber and plastics industries. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12012-4:2019+A1:2021 has the following relationships with other standards: It is inter standard links to EN 12012-4:2019, EN 12012-4:2019/prA1, EN 12312-5:2021, EN 12312-5:2021+A1:2025. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12012-4:2019+A1:2021 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC; Standardization Mandates: M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12012-4:2019+A1:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-december-2021

Stroji za predelavo gume in plastike - Drobilni stroji - 4. del: Varnostne zahteve za

aglomeratorje

Plastics and rubber machines - Size reduction machines - Part 4: Safety requirements

for agglomerators

Kunststoff- und Gummimaschinen - Zerkleinerungsmaschinen - Teil 4:

Sicherheitsanforderungen für Agglomeratoren

Machines pour les matières plastiques et le caoutchouc - Machines à fragmenter - Partie

4 : Prescriptions de sécurité relatives aux agglomérateurs

Ta slovenski standard je istoveten z: EN 12012-4:2019+A1:2021

ICS:

83.200 Oprema za gumarsko Equipment for the rubber and

industrijo in industrijo plastics industries

polimernih materialov

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 12012-4:2019+A1

EUROPEAN STANDARD

NORME EUROPÉENNE

October 2021

EUROPÄISCHE NORM

ICS 83.200 Supersedes EN 12012-4:2019

English Version

Plastics and rubber machines - Size reduction machines -

Part 4: Safety requirements for agglomerators

Machines pour les matières plastiques et le caoutchouc Kunststoff- und Gummimaschinen -

- Machines à fragmenter - Partie 4 : Prescriptions de Zerkleinerungsmaschinen - Teil 4:

sécurité relatives aux agglomérateurs Sicherheitsanforderungen für Agglomeratoren

This European Standard was approved by CEN on 29 April 2019 and includes Amendment 1 approved by CEN on 3 August 2021.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2021 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 12012-4:2019+A1:2021 E

worldwide for CEN national Members.

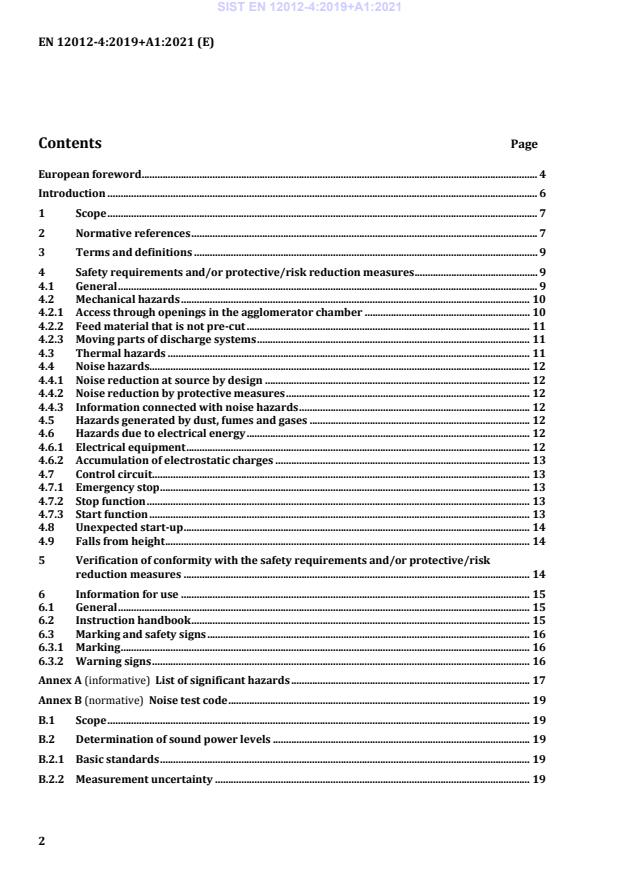

Contents Page

European foreword . 4

Introduction . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 9

4 Safety requirements and/or protective/risk reduction measures . 9

4.1 General . 9

4.2 Mechanical hazards . 10

4.2.1 Access through openings in the agglomerator chamber . 10

4.2.2 Feed material that is not pre-cut . 11

4.2.3 Moving parts of discharge systems . 11

4.3 Thermal hazards . 11

4.4 Noise hazards. 12

4.4.1 Noise reduction at source by design . 12

4.4.2 Noise reduction by protective measures . 12

4.4.3 Information connected with noise hazards . 12

4.5 Hazards generated by dust, fumes and gases . 12

4.6 Hazards due to electrical energy . 12

4.6.1 Electrical equipment . 12

4.6.2 Accumulation of electrostatic charges . 13

4.7 Control circuit. 13

4.7.1 Emergency stop . 13

4.7.2 Stop function . 13

4.7.3 Start function . 13

4.8 Unexpected start-up . 14

4.9 Falls from height . 14

5 Verification of conformity with the safety requirements and/or protective/risk

reduction measures . 14

6 Information for use . 15

6.1 General . 15

6.2 Instruction handbook . 15

6.3 Marking and safety signs . 16

6.3.1 Marking . 16

6.3.2 Warning signs . 16

Annex A (informative) List of significant hazards . 17

Annex B (normative) Noise test code . 19

B.1 Scope . 19

B.2 Determination of sound power levels . 19

B.2.1 Basic standards . 19

B.2.2 Measurement uncertainty . 19

B.3 Determination of emission sound pressure level at the workstation(s) . 20

B.3.1 Basic standards . 20

B.3.2 Measurement uncertainty . 20

B.4 Installation and mounting conditions for the noise measurement . 20

B.5 Operating conditions . 21

B.6 Information to be recorded and reported . 21

B.6.1 General . 21

B.6.2 General agglomerator data . 21

B.6.3 Agglomerator data . 21

B.6.4 Standards . 22

B.6.5 Noise data . 22

B.6.6 Specified test parameters . 22

B.6.7 Installation and operating conditions . 22

B.7 Declaration and verification of noise emission values . 22

Annex ZA (informative) Relationship between this European Standard and the essential

requirements of Directive 2006/42/EC aimed to be covered . 25

Bibliography . 27

European foreword

This document (EN 12012-4:2019+A1:2021) has been prepared by Technical Committee CEN/TC 145

“Plastics and rubber machines”, the secretariat of which is held by UNI.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by April 2022, and conflicting national standards shall be

withdrawn at the latest by April 2022.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes !EN 12012-4:2019".

The start and finish of text introduced or altered by amendment is indicated in the text by tags !".

This document has been prepared under a Standardization Request given to CEN by the European

Commission and the European Free Trade Association, and supports essential requirements of EU

Directive(s) / Regulation(s).

For relationship with EU Directive(s) / Regulation(s), see informative Annex ZA, which is an integral part

of this document.

The main changes compared to the EN 12012-4:2006+A1:2008 are:

— the revision of type-A and type-B standards have been considered;

— the list of significant hazards has been moved to an informative annex;

— the performance levels/safety integrity levels of safety related parts of control systems have been

specified in accordance with EN ISO 13849-1:2015 / EN 62061:2005, EN 62061:2005/A1:2013,

EN 62061:2005/A2:2015;

— the hazards related to the ejection of parts or materials from the agglomerator chamber have been

removed because reliable and well-designed chambers represent now the state of the art (no

projections and no broken chamber have been reported for a long time);

— feed openings of big dimensions are considered;

— requirements for moving parts of discharge systems are added;

!— the agglomerators with actuators moved by pneumatic and/or hydraulic energy have been

excluded from the Scope;"

— the annex for noise measurement has been revised.

!In comparison with the original version EN 12012-4:2019, the following technical and editorial

modifications have been made by amendment EN 12012-4:2019/A1:2021:

— European Foreword: dash added;

— Scope: editorial modification and dash added;

— Normative references: a reference date updated;

— 4.2.1: updated normative references;

— 4.2.3: updated normative reference;

— 4.6.1.3: modified text;

— 4.6.1.4: modified text;

— 4.7.2: modified text;

— 4.7.3: updated normative reference;

— 6.2.1: modified text;

— 6.3.2: modified text;

— Table Annex ZA: modified text."

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

Introduction

This document is a type-C standard as stated in EN ISO 12100:2010.

This document is of relevance, in particular, for the following stakeholder groups representing the market

players with regard to machinery safety:

— machine manufacturers (small, medium and large enterprises);

— health and safety bodies (regulators, accident prevention organizations, market surveillance, etc.).

Others can be affected by the level of machinery safety achieved with the means of the document by the

above-mentioned stakeholder groups:

— machine users/employers (small, medium and large enterprises);

— machine users/employees (e.g. trade unions, organizations for people with special needs);

— service providers, e.g. for maintenance (small, medium and large enterprises);

— consumers (in case of machinery intended for use by consumers).

The above-mentioned stakeholder groups have been given the possibility to participate at the drafting

process of this document.

The machinery concerned and the extent to which hazards, hazardous situations or hazardous events are

covered are indicated in the Scope of this document.

When requirements of this type-C standard are different from those which are stated in type-A or type-B

standards, the requirements of this type-C standard take precedence over the requirements of the other

standards for machines that have been designed and built according to the requirements of this type-C

standard.

1 Scope

!This document deals with all significant hazards, hazardous situations and events relevant to

agglomerators for the modification of plastic scraps in its form, size and flow characteristics, when they

are used as intended and under conditions of misuse which are reasonably foreseeable by the

manufacturer (see Annex A). The hazards have been identified taking into account all phases of the

machine life cycle according to EN ISO 12100:2010, 5.4.

Machines considered in this document begin at the outer edge of the feed opening and end at the outer

edge of the discharge opening.

This document does not deal with:

— hazards due to emissions by processing materials that could be hazardous to health;

— hazards caused by ignition of flammable residues in material to be processed;

— requirements for exhaust ventilation systems;

agglomerators moved by pneumatic and/or hydraulic energy.

This document is not applicable to agglomerators manufactured before the date of its publication."

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN ISO 14118:2018, Safety of machinery — Prevention of unexpected start-up (ISO 14118:2017)

EN 60204-1:2018, Safety of machinery — Electrical equipment of machines — Part 1: General requirements

(IEC 60204-1:2016, modified)

EN 62061:2005, Safety of machinery — Functional safety of safety-related electrical, electronic and

programmable electronic control systems (IEC 62061:2005)

EN 62061:2005/A1:2013, Safety of machinery — Functional safety of safety-related electrical, electronic

and programmable electronic control systems (IEC 62061:2005/AMD1:2012)

EN 62061:2005/A2:2015, Safety of machinery — Functional safety of safety-related electrical, electronic

and programmable electronic control systems (IEC 62061:2005/AMD2:2015)

EN ISO 3744:2010, Acoustics — Determination of sound power levels and sound energy levels of noise

sources using sound pressure — Engineering methods for an essentially free field over a reflecting plane

(ISO 3744:2010)

EN ISO 3746:2010, Acoustics — Determination of sound power levels and sound energy levels of noise

sources using sound pressure — Survey method using an enveloping measurement surface over a reflecting

plane (ISO 3746:2010)

EN ISO 4871:2009, Acoustics — Declaration and verification of noise emission values of machinery and

equipment (ISO 4871:1996)

EN ISO 9614-2:1996, Acoustics — Determination of sound power levels of noise sources using sound

intensity — Part 2: Measurement by scanning (ISO 9614-2:1996)

EN ISO 11201:2010, Acoustics — Noise emitted by machinery and equipment — Determination of emission

sound pressure levels at a work station and at other specified positions in an essentially free field over a

reflecting plane with negligible environmental corrections (ISO 11201:2010)

EN ISO 11202:2010, Acoustics — Noise emitted by machinery and equipment — Determination of emission

sound pressure levels at a work station and at other specified positions applying approximate environmental

corrections (ISO 11202:2010)

EN ISO 11204:2010, Acoustics — Noise emitted by machinery and equipment — Determination of emission

sound pressure levels at a work station and at other specified positions applying accurate environmental

corrections (ISO 11204:2010)

EN ISO 11688-1:2009, Acoustics — Recommended practice for the design of low-noise machinery and

equipment — Part 1: Planning (ISO/TR 11688-1:1995)

EN ISO 12100:2010, Safety of machinery — General principles for design — Risk assessment and risk

reduction (ISO 12100:2010)

EN ISO 13732-1:2008, Ergonomics of the thermal environment — Methods for the assessment of human

responses to contact with surfaces — Part 1: Hot surfaces (ISO 13732-1:2006)

EN ISO 13849-1:2015, Safety of machinery — Safety-related parts of control systems — Part 1: General

principles for design (ISO 13849-1:2015)

EN ISO 13850:2015, Safety of machinery — Emergency stop function — Principles for design

(ISO 13850:2015)

EN ISO 13855:2010, Safety of machinery — Positioning of safeguards with respect to the approach speeds

of parts of the human body (ISO 13855:2010)

EN ISO 13856-2:2013, Safety of machinery — Pressure-sensitive protective devices — Part 2: General

principles for design and testing of pressure-sensitive edges and pressure-sensitive bars (ISO 13856-2:2013)

EN ISO 13856-3:2013, Safety of machinery — Pressure-sensitive protective devices — Part 3: General

principles for design and testing of pressure-sensitive bumpers, plates, wires and similar devices

(ISO 13856-3:2013)

!EN ISO 13857:2019, Safety of machinery — Safety distances to prevent hazard zones being reached by

upper and lower limbs (ISO 13857:2019)"

EN ISO 14119:2013, Safety of machinery — Interlocking devices associated with guards — Principles for

design and selection (ISO 14119:2013)

EN ISO 14120:2015, Safety of machinery — Guards — General requirements for the design and construction

of fixed and movable guards (ISO 14120:2015)

EN ISO 14122-1:2016, Safety of machinery — Permanent means of access to machinery — Part 1: Choice

of fixed means and general requirements of access (ISO 14122-1:2016)

EN ISO 14122-2:2016, Safety of machinery — Permanent means of access to machinery — Part 2: Working

platforms and walkways (ISO 14122-2:2016)

EN ISO 14122-3:2016, Safety of machinery — Permanent means of access to machinery — Part 3: Stairs,

stepladders and guard-rails (ISO 14122-3:2016)

EN ISO 14122-4:2016, Safety of machinery — Permanent means of access to machinery — Part 4: Fixed

ladders (ISO 14122-4:2016)

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN ISO 12100:2010 and the

following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at https://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp

3.1

agglomerator

machine (sometimes called densifier) for modifying the form, size and flow characteristics of

thermoplastic scrap in a chamber

Note 1 to entry: The material is cut, kneaded, mixed, or heated by friction to increase the flow of the material.

3.2

agglomerating tool

tool, secured on a rotating structure (e.g. disc) which can be combined with a stationary counter tool, to

modify the material being processed in form, size and flow characteristics

3.3

feeding equipment

hopper, that is an integral part of the machine, used to feed the material to be processed

3.4

discharge system

equipment that is an integral part of the machine such as power rotating screw etc. used to discharge the

material from the agglomerator

4 Safety requirements and/or protective/risk reduction measures

4.1 General

Machinery shall comply with the safety requirements and/or protective/risk reduction measures of this

clause. In addition, the machine shall be designed according to the principles of EN ISO 12100:2010 for

relevant but not significant hazards that are not dealt with by this document.

The safety related parts of the control system shall be in accordance with EN ISO 13849-1:2015 or

EN 62061:2005, EN 62061:2005/A1:2013, EN 62061:2005/A2:2015. The required performance levels

(PL ) or Safety Integrity Levels (SIL) are given in the relevant subclauses.

r

4.2 Mechanical hazards

4.2.1 Access through openings in the agglomerator chamber

In the agglomerator there are openings designed and constructed for feeding the material, discharging

the material, inspecting the process inside the agglomerator chamber and changing or maintaining the

agglomerating tools.

Access to agglomerating tools and their rotating support elements in the agglomerator chamber through

openings shall be prevented by one or more of the following:

— fixed guards in accordance with EN ISO 14120:2015, that may be distance guards as defined in

EN ISO 14120:2015, 3.2.2;

— interlocking guards with guard locking in accordance with EN ISO 14120:2015 and

EN ISO 14119:2013, such that the guards remain closed and locked until all motions of the

agglomerating tools have ceased; safety related parts of the control system shall be according to:

— PL = d or SIL = 2 for the interlocking function and

r

— PL = c or SIL = 1 for the locking function.

r

Safety distances preventing access to agglomerating tools and their rotating support element, if any, shall

be in accordance with !EN ISO 13857:2019", Table 2, Table 3, Table 4 and/or Table 6.

If the feeding equipment, or its part or the discharge system act as a guard and is capable of being moved

out of position without the use of a tool and the resulting access to the agglomerator does not comply

with the above safety distances of !EN ISO 13857:2019", then it shall act as an interlocking guard

with guard locking in accordance with EN ISO 14119:2013, such that it remains locked in position until

all motions of the agglomerating tool have ceased; safety related parts of the control system shall be

according to:

— PL = d or SIL = 2 for the interlocking function and

r

— PL = c or SIL = 1 for the locking function.

r

If the dimensions of the opening are greater than 500 mm × 400 mm, so that whole body access is

possible, falling through the feed opening shall be prevented by positioning the lower edge of the opening

at a minimum height of 1,20 m from the working level.

If, for operational reasons, it is necessary to move agglomerating tools and their support when

interlocking guards are open, e.g. to change or to adjust the agglomerating tools, the rotating support

shall be designed to allow its manual movement and preventing any contact with the agglomerating tools

(e.g. fitting removable handles). See 6.2.3.

If the manual rotation is not possible (e.g. for large machines due to the mass of the rotating support) a

specific operational mode shall be allowed which permits the powered rotation of the agglomerating

tools and their support when the interlocking guards are open. This specific operational mode shall:

— be activated by a selector switch in accordance with EN ISO 12100:2010, 6.2.11.10, that can be locked

in all positions by a removable or coded key or other means that prevent unauthorised selection and

— enable the rotation of the agglomerating tools and their support by a hold-to-run control device in

combination with a maximum peripherical rotating speed of 2 m/min, in accordance with

EN ISO 12100:2010, 6.2.11.9 and with !EN 60204-1:2018, 9.2.3.5, 9.2.3.6 and 9.2.3.7".

The safety related parts of the control circuit shall be PL = d or SIL 2.

r

To avoid any unexpected motion of rotating support of agglomerating tools during their changing or

adjusting, appropriate devices, e.g. mechanical lock with pins, shall be provided.

See 6.2.2, 6.2.3 and 6.2.5.

The temperature of the material that is processed shall be automatically controlled, e.g. using a cooling

system or reducing the speed of the rotating agglomerating tools, etc., in order to prevent the blocking of

the rotating agglomerating tools.

The safety related parts of the control system shall be according to PL = b.

r

See 6.2.10.

4.2.2 Feed material that is not pre-cut

If the intended use of the agglomerator is to process continuous films, fibres, strands or similar materials

likely to cause entanglement, then sensitive mechanically actuated protective equipment (e.g. pressure

sensitive edge, wire, etc.), in accordance with EN ISO 13856-2:2013 or EN ISO 13856-3:2013 shall be

provided at the feed opening to automatically stop the material being fed in when actuated. The sensitive

protective equipment shall be positioned at a height between 1,20 and 1,40 m in a way that it is

automatically actuated in case of entanglement by a force less than or equal to 250 N.

The safety related parts of the control system shall be according to PL = d or SIL = 2.

r

See also 6.2.4.

4.2.3 Moving parts of discharge systems

Access to powered moving parts of discharge systems shall be prevented by one or more of the following:

— fixed guards in accordance with EN ISO 14120:2015;

— interlocking guard in accordance with EN ISO 14120:2015 and EN ISO 14119:2013 and positioned

in accordance with EN ISO 13855:2010.

Safety distances shall be in accordance with !EN ISO 13857:2019", Table 2, Table 3, Table 4 and

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...