EN 1417:2023

(Main)Plastics and rubber machines - Two-roll mills - Safety requirements

Plastics and rubber machines - Two-roll mills - Safety requirements

This document deals with all significant hazards, hazardous situations or hazardous events relevant to two-roll mills for the processing of rubber and/or plastics (see Annex A), when used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer during all the phases of the life of the machine as described in EN ISO 12100:2010, 5.4.

This document covers two-roll mills as defined in 3.1.

This document covers two-roll mills intended to be used in normal production and two-roll mills intended to be used in laboratories (testing of mixtures by batchwise processing of small amounts, not continuously).

This document is applicable to the following ancillary equipment as integral part of the machine:

- powered stock guides;

- strip cutting device;

- stock blender;

- recovery conveyor belt;

- retractable ploughs;

- secondary roller;

- supply of heating and/or cooling fluids.

This document does not apply to the design of a local exhaust ventilation system that might be necessary in specific applications of the machine not known by the manufacturer.

This document does not apply to two-roll mills manufactured before the date of its publication as a European Standard.

Kunststoff- und Gummimaschinen - Walzwerke - Sicherheitsanforderungen

Dieses Dokument behandelt alle signifikanten Gefährdungen, Gefährdungssituationen oder Gefährdungsereignisse, die für Walzwerke zur Verarbeitung von Kunststoff und/oder Gummi (siehe Anhang A) bei bestimmungsgemäßem Gebrauch und unter vom Hersteller vernünftigerweise vorhersehbaren Fehlanwendungen während sämtlicher Phasen der Lebensdauer der Maschine nach EN ISO 12100:2010, 5.4, relevant sind.

Dieses Dokument ist anwendbar für Walzwerke nach der Definition in 3.1.

Dieses Dokument ist anwendbar für Walzwerke, die für den Einsatz in der üblichen Produktion bestimmt sind, und für Walzwerke, die für den Einsatz in Laboratorien bestimmt sind (Prüfung von Mischungen durch chargenweise Verarbeitung kleiner Mengen, nicht kontinuierlich).

Dieses Dokument behandelt folgende Zusatzgeräte als integraler Bestandteil der Maschine:

kraftbetätigte Führungsbacken;

Streifenschneideinrichtung;

Stockblender;

Rückführband;

Wendeeinrichtungen;

Nebenwalze;

Versorgung mit Heiz- und/oder Kühlflüssigkeiten;

Dieses Dokument behandelt nicht die Konstruktion einer lokalen Absaugeinrichtung, die bei bestimmten Anwendungen der Maschine erforderlich sein könnten und dem Hersteller nicht bekannt sind.

Dieses Dokument ist nicht anwendbar für Walzwerke, die vor Veröffentlichung dieser Europäischen Norm hergestellt wurden.

Machines pour les matières plastiques et le caoutchouc - Mélangeurs à cylindres - Prescriptions de sécurité

Le présent document traite de tous les phénomènes dangereux, situations dangereuses ou événements dangereux significatifs pertinents pour les mélangeurs à cylindres pour le traitement du caoutchouc et / ou des plastiques (voir Annexe A), en cas d’utilisation normale ou de mauvais usage raisonnablement prévisible par le fabricant pendant toutes les phases de la vie de la machine, tel que décrit dans l'EN ISO 12100:2010, 5.4.

Le présent document traite des mélangeurs à cylindres, tels que définis en 3.1.

Le présent document traite des mélangeurs à cylindres destinés à être utilisés en production normale et les mélangeurs à cylindres destinés à être utilisés en laboratoire (contrôle des mélanges par traitement par lots de petites quantités, non en continu)

Le présent document s’applique à l’équipement auxiliaire suivant faisant partie intégrante de la machine :

- oreilles motorisées ;

- dispositif de coupe de bande ;

- blender (unité d’homogénéisation) ;

- tapis releveur ;

- socs de mélangeage relevables ;

- rouleau annexe ;

- alimentation en fluide chaud et/ou de refroidissement.

Le présent document ne traite pas de la conception du système d'aspiration locale qui peut être nécessaire dans des applications spécifiques de la machine, non connues du fabricant.

Le présent document ne s'applique pas aux mélangeurs à cylindres fabriqués avant sa date de publication comme Norme Européenne.

Stroji za predelavo gume in plastike - Dvovaljni gnetilniki - Varnostne zahteve

Ta evropski standard obravnava vse večje nevarnosti, nevarne situacije in dogodke v zvezi s dvovaljnimi gnetilniki za predelavo gume in/ali plastike, kadar se ti uporabljajo v skladu s svojim namenom in pod pogoji nepravilne uporabe, ki jih razumno predvidi proizvajalec (glej točko 4).

Ta evropski standard zajema dvovaljne gnetilnike, kot so opredeljeni v točki 3.1.

Ta evropski standard ne obravnava zasnove lokalnega izpušnega prezračevalnega sistema, ki je lahko nujna pri določenih vrstah uporabe stroja, ki niso znane proizvajalcu.

Ta evropski standard se ne uporablja za dvovaljne gnetilnike, ki so bili izdelane pred datumom objave tega standarda kot evropskega standarda.

General Information

- Status

- Published

- Publication Date

- 14-Nov-2023

- Technical Committee

- CEN/TC 145 - Rubber and plastics machines - Safety

- Drafting Committee

- CEN/TC 145/WG 4 - Two roll mills - Safety

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 15-Nov-2023

- Due Date

- 23-Jan-2023

- Completion Date

- 15-Nov-2023

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 1417:2023 - Plastics and rubber machines: Two‑roll mills - Safety requirements is a CEN type‑C standard that specifies safety requirements for two‑roll mills used in the processing of rubber and/or plastics. The standard addresses all significant hazards throughout the machine’s life (design, manufacture, installation, operation, maintenance and foreseeable misuse) as described in EN ISO 12100. It applies to production and laboratory two‑roll mills and to specified ancillary equipment (see below). EN 1417:2023 supersedes EN 1417:2014 and includes updated safeguards, trip device requirements and noise/braking guidance.

Key topics and technical requirements

EN 1417:2023 focuses on practical, machine‑level safety measures and verification. Major topics include:

- Scope of coverage: hazards relevant to two‑roll mills, lifecycle approach and foreseeable misuse.

- Ancillary equipment (integral parts covered): powered stock guides, strip cutting devices, stock blenders, recovery conveyor belts, retractable ploughs, secondary rollers, and heating/cooling fluid supplies.

- Control systems: safe start/stop, emergency stop, power‑failure behaviour and control‑system integrity.

- Mechanical hazards: guarding, trip bars/devices, secondary roller hazards, requirements differentiated for large (D > 200 mm) and small (D ≤ 200 mm) mills.

- Braking systems and protection: updated to reflect state of the art.

- Electromagnetic and electrical safety: protection against electric shock, electrostatic discharge and EMC immunity.

- Thermal, gas/dust/vapour and ergonomic hazards: requirements to limit risk from heat, emissions and poor ergonomics.

- Noise: noise test code, measurement of A‑weighted sound power and emission levels, and information to users.

- Hydraulics/pneumatics: safe design and prevention of hazards from stored energy.

- Verification and documentation: test procedures, instruction handbook content, marking and warning signage (including Annexes on trip positioning and noise testing).

Applications and users

This standard is intended for:

- Machine manufacturers - design and CE‑compliance of two‑roll mills.

- Safety and regulatory bodies - conformity assessment and market surveillance.

- Plant designers and employers - selecting, installing and operating compliant mills.

- Maintenance and service providers - safe repair, inspection and verification.

- Laboratories using small batch mills - specific lab‑scale requirements are included.

EN 1417:2023 is especially relevant when implementing machine safety, risk reduction measures, and preparing instruction handbooks and markings required under machinery directives (see Annex ZA).

Related standards

Relevant referenced standards include:

- EN ISO 12100 (risk assessment principles)

- EN 60204‑1 (electrical equipment of machines)

- EN IEC 61496 (opto‑electronic protective devices)

- EN IEC 61000‑6‑2, EN ISO 3744/3746 (EMC and acoustics/noise measurement)

Use EN 1417:2023 as the authoritative safety specification when designing, manufacturing, installing or assessing two‑roll mills for plastics and rubber processing.

Get Certified

Connect with accredited certification bodies for this standard

Smithers Quality Assessments

US management systems and product certification.

DIN CERTCO

DIN Group product certification.

Sponsored listings

Frequently Asked Questions

EN 1417:2023 is a standard published by the European Committee for Standardization (CEN). Its full title is "Plastics and rubber machines - Two-roll mills - Safety requirements". This standard covers: This document deals with all significant hazards, hazardous situations or hazardous events relevant to two-roll mills for the processing of rubber and/or plastics (see Annex A), when used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer during all the phases of the life of the machine as described in EN ISO 12100:2010, 5.4. This document covers two-roll mills as defined in 3.1. This document covers two-roll mills intended to be used in normal production and two-roll mills intended to be used in laboratories (testing of mixtures by batchwise processing of small amounts, not continuously). This document is applicable to the following ancillary equipment as integral part of the machine: - powered stock guides; - strip cutting device; - stock blender; - recovery conveyor belt; - retractable ploughs; - secondary roller; - supply of heating and/or cooling fluids. This document does not apply to the design of a local exhaust ventilation system that might be necessary in specific applications of the machine not known by the manufacturer. This document does not apply to two-roll mills manufactured before the date of its publication as a European Standard.

This document deals with all significant hazards, hazardous situations or hazardous events relevant to two-roll mills for the processing of rubber and/or plastics (see Annex A), when used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer during all the phases of the life of the machine as described in EN ISO 12100:2010, 5.4. This document covers two-roll mills as defined in 3.1. This document covers two-roll mills intended to be used in normal production and two-roll mills intended to be used in laboratories (testing of mixtures by batchwise processing of small amounts, not continuously). This document is applicable to the following ancillary equipment as integral part of the machine: - powered stock guides; - strip cutting device; - stock blender; - recovery conveyor belt; - retractable ploughs; - secondary roller; - supply of heating and/or cooling fluids. This document does not apply to the design of a local exhaust ventilation system that might be necessary in specific applications of the machine not known by the manufacturer. This document does not apply to two-roll mills manufactured before the date of its publication as a European Standard.

EN 1417:2023 is classified under the following ICS (International Classification for Standards) categories: 83.200 - Equipment for the rubber and plastics industries. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1417:2023 has the following relationships with other standards: It is inter standard links to EN 1417:2014, EN 60204-1:2018, EN IEC 61496-1:2020, EN IEC 61000-6-2:2019, EN IEC 61496-2:2020, EN ISO 3744:2010, EN ISO 13850:2015, EN ISO 13732-1:2008, EN ISO 13857:2019, EN ISO 9614-2:1996, EN ISO 14119:2013, EN ISO 3746:2010, EN ISO 4871:2009, EN ISO 11201:2010, EN ISO 13851:2019. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1417:2023 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC; Standardization Mandates: M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1417:2023 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-april-2024

Stroji za predelavo gume in plastike - Dvovaljni gnetilniki - Varnostne zahteve

Plastics and rubber machines - Two-roll mills - Safety requirements

Kunststoff- und Gummimaschinen - Walzwerke - Sicherheitsanforderungen

Machines pour les matières plastiques et le caoutchouc - Mélangeurs à cylindres -

Prescriptions de sécurité

Ta slovenski standard je istoveten z: EN 1417:2023

ICS:

83.200 Oprema za gumarsko Equipment for the rubber and

industrijo in industrijo plastics industries

polimernih materialov

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 1417

EUROPEAN STANDARD

NORME EUROPÉENNE

November 2023

EUROPÄISCHE NORM

ICS 83.200 Supersedes EN 1417:2014

English Version

Plastics and rubber machines - Two-roll mills - Safety

requirements

Machines pour les matières plastiques et le caoutchouc Kunststoff- und Gummimaschinen - Walzwerke -

- Mélangeurs à cylindres - Prescriptions de sécurité Sicherheitsanforderungen

This European Standard was approved by CEN on 18 September 2023.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2023 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 1417:2023 E

worldwide for CEN national Members.

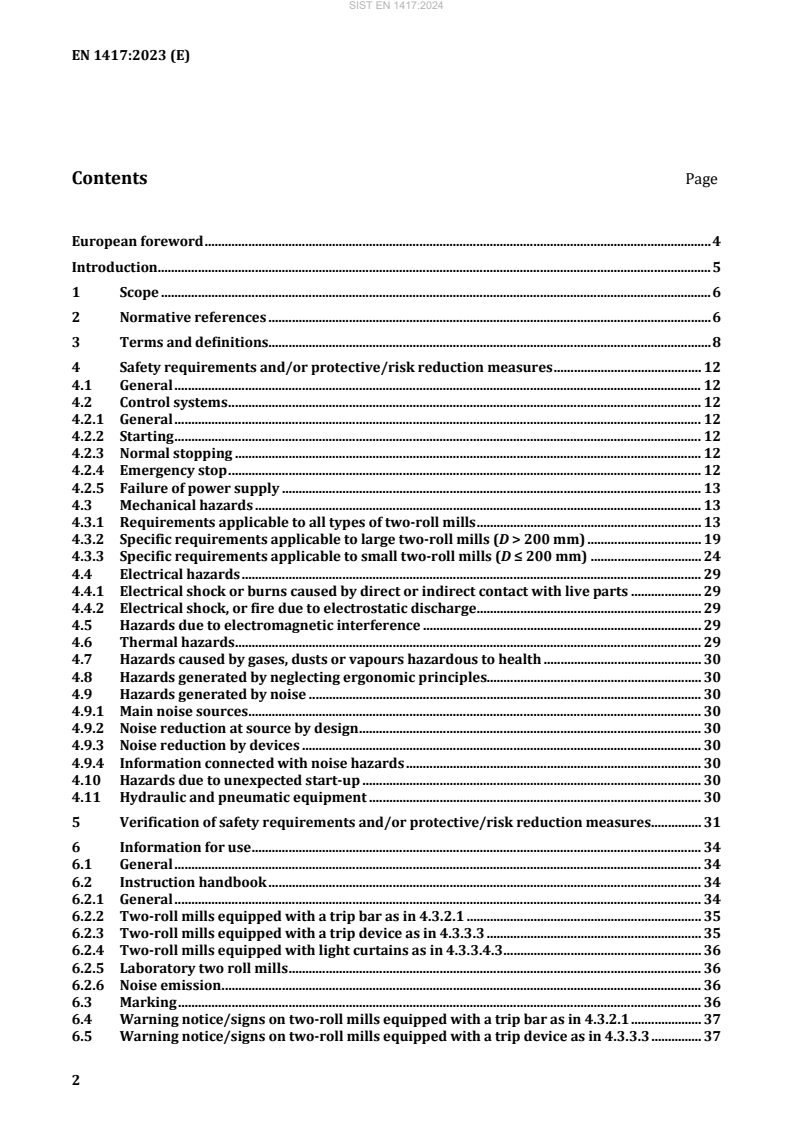

Contents Page

European foreword . 4

Introduction. 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions. 8

4 Safety requirements and/or protective/risk reduction measures . 12

4.1 General . 12

4.2 Control systems . 12

4.2.1 General . 12

4.2.2 Starting . 12

4.2.3 Normal stopping . 12

4.2.4 Emergency stop . 12

4.2.5 Failure of power supply . 13

4.3 Mechanical hazards . 13

4.3.1 Requirements applicable to all types of two-roll mills . 13

4.3.2 Specific requirements applicable to large two-roll mills (D > 200 mm) . 19

4.3.3 Specific requirements applicable to small two-roll mills (D ≤ 200 mm) . 24

4.4 Electrical hazards . 29

4.4.1 Electrical shock or burns caused by direct or indirect contact with live parts . 29

4.4.2 Electrical shock, or fire due to electrostatic discharge . 29

4.5 Hazards due to electromagnetic interference . 29

4.6 Thermal hazards . 29

4.7 Hazards caused by gases, dusts or vapours hazardous to health . 30

4.8 Hazards generated by neglecting ergonomic principles. 30

4.9 Hazards generated by noise . 30

4.9.1 Main noise sources . 30

4.9.2 Noise reduction at source by design . 30

4.9.3 Noise reduction by devices . 30

4.9.4 Information connected with noise hazards . 30

4.10 Hazards due to unexpected start-up . 30

4.11 Hydraulic and pneumatic equipment . 30

5 Verification of safety requirements and/or protective/risk reduction measures. 31

6 Information for use . 34

6.1 General . 34

6.2 Instruction handbook . 34

6.2.1 General . 34

6.2.2 Two-roll mills equipped with a trip bar as in 4.3.2.1 . 35

6.2.3 Two-roll mills equipped with a trip device as in 4.3.3.3 . 35

6.2.4 Two-roll mills equipped with light curtains as in 4.3.3.4.3 . 36

6.2.5 Laboratory two roll mills . 36

6.2.6 Noise emission . 36

6.3 Marking . 36

6.4 Warning notice/signs on two-roll mills equipped with a trip bar as in 4.3.2.1 . 37

6.5 Warning notice/signs on two-roll mills equipped with a trip device as in 4.3.3.3 . 37

Annex A (informative) List of significant hazards . 38

Annex B (normative) Positioning of the trip devices specified in 4.3.3.4.2. 42

B.1 Production applications . 42

B.2 Laboratory applications . 45

Annex C (normative) Noise test code. 46

C.1 General . 46

C.2 Determination of the A-weighted emission sound pressure level at the workstation . 46

C.2.1 Basic standards and measurement procedure . 46

C.2.2 Measurement uncertainty . 47

C.3 Determination of the A-weighted sound power level . 47

C.3.1 Basic standards and measurement procedure . 47

C.3.2 Measurement uncertainty . 47

C.4 Mounting and operating conditions . 47

C.5 Information to be recorded and reported . 48

C.5.1 General . 48

C.5.2 General data . 48

C.5.3 Mounting and operating conditions . 48

C.5.4 Standards . 48

C.5.5 Noise data . 49

C.6 Declaration and verification of noise emission values . 49

Annex D (informative) Positioning of trip bar . 52

Annex ZA (informative) Relationship between this European Standard and the essential

requirements of Directive 2006/42/EC aimed to be covered . 53

Bibliography . 56

European foreword

This document (EN 1417:2023) has been prepared by Technical Committee CEN/TC 145 “Plastics and

rubber machines”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by May 2024, and conflicting national standards shall be

withdrawn at the latest by November 2024.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 1417:2014.

In comparison with the previous edition EN 1417:2014, the following technical modifications have been

made:

a) the structure of the document has been modified;

b) covered ancillary equipment has been clarified in the scope;

c) the list of significant hazards has been moved to an informative annex;

d) technical developments in safeguards have been taken into account;

e) revised type-A and type-B standards have been taken into account;

f) the class of intermediate two-roll mills (requirements integrated in large and/or small two-roll mills)

has been removed;

g) requirements for braking system have been adapted to the state of the art;

h) requirements for trip bar have been modified;

i) hazard and measures related to secondary roller have been added;

j) requirements for small mill rolls have been modified.

This document has been prepared under a standardization request addressed to CEN by the European

Commission. The Standing Committee of the EFTA States subsequently approves these requests for its

Member States.

For the relationship with EU Legislation, see informative Annex ZA, which is an integral part of this

document.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

Introduction

This document is a type-C standard as stated in EN ISO 12100.

This document is of relevance, in particular, for the following stakeholder groups representing the market

players with regard to machinery safety:

— machine manufacturers (small, medium and large enterprises);

— health and safety bodies (regulators, accident prevention organizations, market surveillance, etc.).

Others can be affected by the level of machinery safety achieved with the means of the document by the

above-mentioned stakeholder groups:

— machine users/employers (small, medium and large enterprises);

— machine users/employees (e.g. trade unions, organizations for people with special needs);

— service providers, e.g. for maintenance (small, medium and large enterprises);

— consumers (in the case of machinery intended for use by consumers).

The above-mentioned stakeholder groups have been given the possibility to participate in the drafting

process of this document.

The machinery concerned and the extent to which hazards, hazardous situations or hazardous events are

covered are indicated in the scope of this document.

When requirements of this type-C standard are different from those which are stated in type-A or type-B

standards, the requirements of this type-C standard take precedence over the requirements of the other

standards for machines that have been designed and built according to the requirements of this type-C

standard.

1 Scope

This document deals with all significant hazards, hazardous situations or hazardous events relevant to

two-roll mills for the processing of rubber and/or plastics (see Annex A), when used as intended and

under conditions of misuse which are reasonably foreseeable by the manufacturer during all the phases

of the life of the machine as described in EN ISO 12100:2010, 5.4.

This document covers two-roll mills as defined in 3.1.

This document covers two-roll mills intended to be used in normal production and two-roll mills

intended to be used in laboratories (testing of mixtures by batchwise processing of small amounts, not

continuously).

This document is applicable to the following ancillary equipment as integral part of the machine:

— powered stock guides;

— strip cutting device;

— stock blender;

— recovery conveyor belt;

— retractable ploughs;

— secondary roller;

— supply of heating and/or cooling fluids.

This document does not apply to the design of a local exhaust ventilation system that might be necessary

in specific applications of the machine not known by the manufacturer.

This document does not apply to two-roll mills manufactured before the date of its publication as a

European Standard.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 60204-1:2018, Safety of machinery - Electrical equipment of machines - Part 1: General requirements

(IEC 60204-1:2016, modified)

EN IEC 61000-6-2:2019, Electromagnetic compatibility (EMC) - Part 6-2: Generic standards - Immunity

standard for industrial environments (IEC 61000-6-2:2016)

EN IEC 61496-1:2020, Safety of machinery - Electro-sensitive protective equipment - Part 1: General

requirements and tests (IEC 61496-1:2020)

EN IEC 61496-2:2020, Safety of machinery - Electro-sensitive protective equipment - Part 2: Particular

requirements for equipment using active opto-electronic protective devices (AOPDs) (IEC 61496-2:2020)

EN ISO 3744:2010, Acoustics - Determination of sound power levels and sound energy levels of noise sources

using sound pressure - Engineering methods for an essentially free field over a reflecting plane (ISO

3744:2010)

EN ISO 3746:2010, Acoustics - Determination of sound power levels and sound energy levels of noise sources

using sound pressure - Survey method using an enveloping measurement surface over a reflecting plane (ISO

3746:2010)

EN ISO 4413:2010, Hydraulic fluid power - General rules and safety requirements for systems and their

components (ISO 4413:2010)

EN ISO 4414:2010, Pneumatic fluid power - General rules and safety requirements for systems and their

components (ISO 4414:2010)

EN ISO 4871:2009, Acoustics - Declaration and verification of noise emission values of machinery and

equipment (ISO 4871:1996)

EN ISO 9614-2:1996, Acoustics - Determination of sound power levels of noise sources using sound intensity

- Part 2: Measurement by scanning (ISO 9614-2:1996)

EN ISO 11201:2010, Acoustics - Noise emitted by machinery and equipment - Determination of emission

sound pressure levels at a work station and at other specified positions in an essentially free field over a

reflecting plane with negligible environmental corrections (ISO 11201:2010)

EN ISO 11202:2010, Acoustics - Noise emitted by machinery and equipment - Determination of emission

sound pressure levels at a work station and at other specified positions applying approximate environmental

corrections (ISO 11202:2010)

EN ISO 11204:2010, Acoustics - Noise emitted by machinery and equipment - Determination of emission

sound pressure levels at a work station and at other specified positions applying accurate environmental

corrections (ISO 11204:2010)

EN ISO 12100:2010, Safety of machinery - General principles for design - Risk assessment and risk reduction

(ISO 12100:2010)

EN ISO 13732-1:2008, Ergonomics of the thermal environment - Methods for the assessment of human

responses to contact with surfaces - Part 1: Hot surfaces (ISO 13732-1:2006)

EN ISO 13849-1:2015, Safety of machinery — Safety-related parts of control systems — Part 1: General

principles for design (ISO 13849-1:2015)

EN ISO 13850:2015, Safety of machinery - Emergency stop function - Principles for design (ISO 13850:2015)

EN ISO 13851:2019, Safety of machinery - Two-hand control devices - Principles for design and selection

(ISO 13851:2019)

EN ISO 13854:2019, Safety of machinery - Minimum gaps to avoid crushing of parts of the human body (ISO

13854:2017)

EN ISO 13855:2010, Safety of machinery - Positioning of safeguards with respect to the approach speeds of

parts of the human body (ISO 13855:2010)

EN ISO 13857:2019, Safety of machinery - Safety distances to prevent hazard zones being reached by upper

and lower limbs (ISO 13857:2019)

EN ISO 14119:2013, Safety of machinery - Interlocking devices associated with guards - Principles for

design and selection (ISO 14119:2013)

EN ISO 14120:2015, Safety of machinery - Guards - General requirements for the design and construction

of fixed and movable guards (ISO 14120:2015)

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN ISO 12100:2010 and the

following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at https://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp

3.1

two-roll mill

machine with two counter-rotating cylinders (known as mill rolls) which are not enclosed, which may be

smooth or grooved, and whose axes are on substantially the same horizontal plane for the mixing of

plastics or rubber

Note 1 to entry: The two-roll mill can be equipped with several devices, e.g. strip cutting device, stock blender, mill

tray

Note 2 to entry: See Figure 1.

Key

1 frame 6 stock blender

2 mill roll 6.1 stock blender rolls

3 drive and transmission unit 6.2 stock blender carriage

4 stock guide 6.3 guiding rolls of stock blender carriage

5 strip cutting device 6.4 guiding roll below stock blender carriage

7 mill tray

Figure 1 — Example of a two-roll mill shown without safety devices and without retractable

ploughs secondary-rollers and recovery conveyor belt

3.1.1

large two-roll mill

two-roll mill with a mill roll diameter D > 200 mm

3.1.2

small two-roll mill

two-roll mill with a mill roll diameter D ≤ 200 mm

Note 1 to entry: Small two-roll mills are usually not equipped with stock blenders and strip cutting devices.

Note 2 to entry: Small two-roll mills are mostly used in laboratory applications (testing of new mixtures by

batchwise processing of small amounts, not continuously).

3.2

principal crushing zone

zone extending over the full length of the mill rolls indicated by V in Figure 2 and Figure 3

Dimensions in millimetres

Figure 2 — Principal crushing zone V, safety limits S and stopping angle α on a large two-roll mill

Dimensions in millimetres

Figure 3 — Principal crushing zone V, safety limit S and stopping angle α on a small two-roll mill

3.3

stopping angle

α

angle through which the mill rolls rotate from the stop signal triggered by a protective device until the

mill rolls have come to rest with the machine unloaded, and running at maximum rated speed

3.4

safety limit

vertical plane indicated by Line S in Figure 2 (for large two-roll mills) or horizontal plane indicated by

Line S in Figure 3 (for small two-roll mills) demarcating the zone which is unsafe for operators who can

reach into it without actuating the trip bar

3.5

stock guide

part which prevents material being processed from going beyond the mill roll end

Note 1 to entry: See Figure 1, Location 4.

3.6

strip cutting device

device equipped with rotating discs or stationary blades to cut off strips of processed material from a mill

roll

Note 1 to entry: See Figure 1, Location 5.

3.7

stock blender

equipment used to continuously recirculate the material being processed to obtain a uniform mixing,

distributing it with a reciprocating motion along the length of the mill rolls

Note 1 to entry: See Figure 1, Location 6.

Note 2 to entry: The horizontal movement of the processed material is achieved by guiding rolls fixed on the stock

blender carriage (see item 6.3 in Figure 1). An additional horizontal guiding roll below the stock blender (see item

6.4 in Figure 1) can be used for better guidance of the material.

3.8

mill tray

equipment for catching material which falls under the mill rolls

Note 1 to entry: See Figure 1, Location 7.

3.9

recovery conveyor belt

equipment for recirculating material which falls under the mill rolls

Note 1 to entry: See Figure A.3.

3.10

retractable plough

equipment which can be moved towards the mill roll in order to cut and turn over the material, and which

can be retracted

Note 1 to entry: See Figure A.2.

3.11

secondary roller

additional roller, which is used to support the mixing process

Note 1 to entry: See Figure 7.

Note 2 to entry: Examples are take-off rollers or pressure rollers applying pressure on the material processed by

the two-roll mill. The pressure can be applied by the weight of the roller or by a power-driven actuator.

3.12

knee plate

pressure sensitive protective device installed at a height so that it can be activated by the knee of the

operator

4 Safety requirements and/or protective/risk reduction measures

4.1 General

Two-roll mills shall comply with the safety requirements and/or protective/risk reduction measures of

this clause. In addition, the machine shall be designed according to the principles of EN ISO 12100:2010

for relevant but not significant hazards which are not dealt with by this document.

4.2 Control systems

4.2.1 General

The electrical part of the control system shall be designed in accordance with EN 60204-1:2018, Clause 9

and in addition with the specific requirements given in this standard.

The safety related parts of the control system (SRP/CS) shall be designed in accordance with

EN ISO 13849-1:2015. The required performance level (PL ) for each safety function is specified in the

r

relevant subclauses.

4.2.2 Starting

The start of an operation shall be possible only when all safeguards are in place and functional (see

EN 60204-1:2018, 9.2.3.2). The machine shall only be started by actuation of the start device provided

for that purpose.

4.2.3 Normal stopping

A normal stop device (e.g. a push button) shall be provided to stop the machine.

The normal stop command shall function as a stop category 0 or 1 in accordance with EN 60204-1:2018,

9.2.2, depending on the actuators and braking systems used.

4.2.4 Emergency stop

Emergency stop devices shall be positioned on each control panel and on each working side of the two-

roll mill and shall conform to EN ISO 13850:2015 and to category 0 or 1 according to EN 60204-1:2018,

9.2.2, whichever provides the best stopping performance.

The actuation of any emergency stop device shall

— cause stopping of the mill rolls in accordance with 4.3.1.1.2. If the installed protective device requires

to respect a maximum braking angle, this shall also be met (see 4.3.2.1.5, 4.3.3.4.2, B.2); and

— on machines equipped with protective device requiring roll automatic separation (see 4.3.2.1.5,

4.3.3.4.2, 4.3.3.5), cause automatic roll separation achieving

— a gap of at least 50 mm within 5 s in accordance with PL = d; or

r

— a gap of at least 30 mm within 3 s in accordance with PL = d and automatic reversal of the mill

r

rolls commencing in a time not greater than 2 s and achieving a rotation of 60 ± 5°. See also

4.3.2.2.2;

and

— on machines not equipped with automatic separation allow the roll separation for emergency release

of persons (see 4.3.2.3); and

— on large two-roll mills, allow the rescue reverse movement in accordance with 4.3.2.3; and

— cause the stopping of all integrated components (powered stock guides, strip cutting device, stock

blender, recovery conveyor belt, retractable ploughs, supply of heating and cooling fluid) according

to PL = c.

r

See also 6.2.1.

4.2.5 Failure of power supply

An interruption or a failure of the power supply shall not result in a loss of safety function and restoration

of the energy supply shall not result in the automatic restarting of the machine (see EN ISO 12100:2010,

6.2.11.4 and 6.2.11.5).

4.3 Mechanical hazards

4.3.1 Requirements applicable to all types of two-roll mills

4.3.1.1 Hazards of drawing-in and crushing between the mills rolls during normal (forward and

reverse) operation

4.3.1.1.1 General

Access to the principal crushing zone, as defined in 3.2, shall be prevented by guards. On two-roll mills

with roll diameter > 200 mm, a trip bar may be used as alternative, provided that the requirements in

4.3.2.1.2 are met. For two-roll mills with roll diameter ≤ 200 mm see also 4.3.3.2.

Guards shall be designed in accordance with EN ISO 14120:2015 and positioned according to

EN ISO 13857:2019, Table 2, Table 3 and/or Table 4 unless specified different in specific clauses of this

standard.

Interlocking devices associated with guards shall fulfil the requirements of EN ISO 14119:2013,

especially regarding the selection, arrangement and mounting. Reasonably foreseeable manipulation

shall be prevented. Type 3 interlocking devices according to EN ISO 14119:2013 shall only be used if in

the specific application they cannot be defeated. When a Type 3 or Type 4 interlocking device according

to EN ISO 14119:2013 is used, it shall have two independent electrical contacts, and both shall be

independently connected to the control and monitoring system.

Interlocking guards shall be positioned in accordance with EN ISO 13855:2010, Clause 9, taking into

account the braking performance achieved by the braking system described in 4.3.1.1.2. Opening of an

interlocking guard shall stop the rotation of the rolls in accordance with PL = d.

r

If EN ISO 13855:2010, Clause 9 cannot be respected, interlocking guards with guard locking shall be

adopted. The unlocking signal for the guard locking shall be in accordance with PL = c.

r

Where the smallest horizontal distance between the guard in its closed position and the mill rolls is more

than 100 mm and it is possible to stand between the guard in its closed position and the mill rolls, a

manual reset actuator shall be designed and located in accordance with EN ISO 13849-1:2015, 5.2.2 and

with PL = d.

r

4.3.1.1.2 Braking system

The two-roll mill shall be equipped with a two-channel braking system in accordance with PL = d,

r

category 3 using:

— either two mechanical brakes, spring operated; or

— one mechanical brake, spring operated and an electronic or hydraulic braking system, operating also

without power supply.

The overall system stopping performance (see EN ISO 13855:2010, 3.1.2) shall be calculated taking

power failure into account.

The braking system shall be so designed that in the case of a power failure a braking action will

automatically bring the mill rolls to rest. Where the two brakes are not directly linked to the roll shaft

and they are acting on a single transmission component, it shall be dimensioned in order to exclude its

fault, according to EN ISO 13849-1:2015, Clause 7.

The thermal characteristics shall be sufficient to allow rapid dissipation of the heat produced by the

braking action.

If it is possible to manually deactivate the braking system, the deactivation shall be interlocked with the

control circuit in accordance with PL = d, so that the powered rotation of the mill rolls is prevented as

r

long as the brake is manually deactivated.

4.3.1.2 Hazards of drawing-in and crushing in drive mechanisms

Access to the dangerous area of drive mechanisms shall be prevented by guards in accordance with

4.3.1.1.1.

Opening of an interlocking guard shall stop the movement in accordance with PL = c.

r

4.3.1.3 Hazard of drawing-in and crushing between the stock guides and the mill rolls

Rotation of the rolls shall only be possible:

— with stock guides in working position with maximum gap between stock guides and rolls not

exceeding 4 mm. The position shall be detected in accordance with PL = c; or

r

— with stock guides in rest position with gap between stock guides and rolls more than 120 mm. The

position shall be detected in accordance with PL = c; or

r

— using a hold-to-run control device (see EN ISO 12100:2010, 3.28.3) in accordance with PL = c

r

positioned on a control panel to give a clear view of the danger area, positioned at least 2 m from the

dangerous area; or

— using a three-position hold-to-run control device (see EN ISO 12100:2010, 3.28.3) in accordance

with PL = c, positioned to give a clear view of the danger area with the following features:

r

— Position 1: stop function (actuator is not operated);

— Position 2: start function (actuator is operated in its mid position);

— Position 3: stop function (actuator is operated past its mid position);

— after the actuator has passed the pressure point to position 3, a restart shall only be possible

after returning the actuator to position 1

with a maximum speed limited to 5 m/min in accordance with PL = d; or

r

— a two-hand control device Type IIIA as per EN ISO 13851:2019, PL = c positioned on a control panel

r

to give a clear view of the danger area, positioned in accordance with EN ISO 13855:2010, Clause 8

and with a maximum speed limited to 5 m/min in accordance with PL = c.

r

4.3.1.4 Powered stock guides

Movement of powered stock guides shall only be effected:

— by a hold-to-run control device in accordance with PL = c positioned at least 2 m from the dangerous

r

area; or

— by a two-hand control device Type I as per EN ISO 13851:2019, PL = c positioned in accordance with

r

EN ISO 13855:2010, Clause 8.

Where gravity fall hazard exists, this hazard shall be prevented by a restraint device (e.g. a check valve)

even in the case of power failure. Where control circuit is involved it shall be in accordance with PL = c.

r

4.3.1.5 Strip cutting device

4.3.1.5.1 Cutting hazards due to involuntary contact with the cutting edges of blades or rotating

discs

Unless the cutting edges are inherently safe due to their location, they shall be protected by fixed guards

against involuntary contact; see also 6.2.1. Only the part necessary to cut during operation shall be

uncovered.

4.3.1.5.2 Cutting, shearing and crushing hazards caused by movements of the strip cutting

devices (with cutting or non-cutting edges) and their actuating mechanisms

Movement of the strip cutting devices from the rest position to the working position shall only be effected:

a) manually, provided that both hands are required in order to achieve the movement, e.g. two

mechanical devices activated simultaneously; or

b) by a hold-to-run control device according to PL = c positioned at least 2 m from the strip cutting

r

device in the rest position; or

c) by a two-hand control device Type I as per EN ISO 13851:2019, PL = c positioned in accordance with

r

EN ISO 13855:2010, Clause 8.

Access under the trip bar to cutting, shearing or crushing hazards due to contact of the cutting device

against the rotating mill roll shall be prevented by guards. The access over the trip bar shall be prevented

with a minimum distance of 850 mm between the front of the trip bar and the cutting device. The

positioning of the trip bar shall be in accordance with 4.3.2.1.3.

The guards shall be interlocking guards with guard locking positioned as shown on Figure 8, location 2.

The interlocking shall be designed so that:

— it is not possible to open the guard before the strip cutting device is in its rest position or the mill

rolls have come to rest; and

— the machine cannot be started until the strip cutting device is in its rest position or the guard is closed

and locked.

The SRP/CS shall be in accordance with PL = c.

r

The setting of the strip cutting devices shall be performed:

— with the guard closed; or

— with the guard open after the mill rolls have come to rest, the setting movement of the strip cutting

device being controlled by a hold-to-run control device according to PL = c positioned at least 2 m

r

from the strip cutting device in the rest position.

4.3.1.6 Stock blender carriage

Crushing hazards between the stock blender carriage and the machine frame shall be prevented by

mechanically limiting the travel of the carriage to maintain the minimum gaps in accordance with

EN ISO 13854:2019, Table 1 with respect to the finger.

nd

See also 4.3.2.1.6, 2 dash.

If the guiding rolls of the stock blender carriage can be moved power operated individually so that the

distance changes, the minimum gap between the rolls shall be in accordance with EN ISO 13854:2019,

Table 1 with respect to the hand.

To avoid injuries due to shearing between the guiding rolls of the stock blender and material the guiding

rolls shall be able to spin freely.

4.3.1.7 Stock blender rolls

The stock blender rolls shall be protected by the trip bar specified in 4.3.2.1. The stock blender rolls shall

be positioned so that they cannot be reached without actuating the trip bar.

This positioning shall be determined using EN ISO 13857:2019, Table 1, taking 1 200 mm as the height

of the “protective structure” (a in Figure 4).

rd

See also 4.3.2.1.6, 3 dash.

Key

1 mill rolls

2 stock blender rolls

3 trip bar

4 trapping point between the rubber strip and the blender roll

a corresponds to dimension hh of EN ISO 13857:2019, Table 1

x corresponds to dimension sh of EN ISO 13857:2019, Table 1

y corresponds to dimension h of EN ISO 13857:2019, Table 1

ps

Figure 4 — Example for the positioning of the stock blender rolls

4.3.1.8 Recovery conveyor belt

For two-roll mills equipped with automatic and/or intentional mill roll reversal, the distance between

the mill roll and the recovery conveyor belt shall be at least 120 mm (Figure 5).

Dimension in millimetres

Figure 5 — Recovery conveyor belt

4.3.1.9 Mill tray

If the tray is moveable, it shall be equipped with a mechanical self-acting device to lock it in the working

position. The locking shall be ensured at a value greater than the traction force exerted by the compound

trapped between the roll and the tray.

The mill tray shall be designed to prevent footholds. Therefore, if a trip bar is used, dimension d in

Figure 8 shall be ≥ 300 mm or a complementary guard shall be installed to prevent footholds (see

4.3.2.1.7).

4.3.1.10 Retractable ploughs

Access to retractable ploughs shall be prevented by distance guards or interlocking guards with guard

locking meeting the following requirements:

— opening of an interlocking guard shall stop the movement of the ploughs according to PL = c; and

r

— guard locking shall be active so as to allow access only when the distance between the mill roll and

the ploughs is ≥ 120 mm (PL = c) as indicated in Figure 6.

r

The guards shall be designed in accordance with EN ISO 14120:2015 and positioned according to

EN ISO 13857:2019, Table 2, Table 3 and/or Table 4.

Where gravity fall hazard exists, this hazard shall be prevented by a restraint device (e.g. a check valve)

even in the case of power failure. Where control circuit is involved it shall be in accordance with PL = c.

r

Dimension in millimetres

Figure 6 — Retractable ploughs

4.3.1.11 Secondary roller

Crushing hazards at a secondary roller shall be prevented by allowing a lifting of at least 120 mm with a

maximum applied force of 75 N (Figure 7).

Dimension in millimetres

Figure 7 — Secondary roller

4.3.2 Specific requirements applicable to large two-roll mills (D > 200 mm)

4.3.2.1 Prevention of access to the principal crushing zone

4.3.2.1.1 General

Where it is not practical to use guards, then access to the principal crushing zone, as defined in 3.2, shall

be prevented by a mechanically actuated trip device in the form of a trip bar (see Figure 8).

4.3.2.1.2 Prerequisites for the installation of a trip bar

a) Installation of the machine:

The top of the mill rolls shall be at a height of not less than 1 300 mm above the normal standing level

of the operator (see 6.2.2).

b) Braking performance:

The maximum stopping angle α (see 3.3) shall be 45°.

When this requirement cannot be fulfilled, a trip bar may only be used if the two-roll mill is installed

within an interlocking guard with guard locking. Unlocking shall be possible only when the speed has

been reduced so as to achieve a stopping angle not exceeding 45°. The speed monitoring and

unlocking signal for the guard locking shall be in accordance with PL = c.

r

Where it is possible to stand between the guard in its closed position and the trip bar, because the

horizontal gap is more than 100 mm, a dedicated manual reset actuator shall be designed and located

in accordance with EN ISO 13849-1:2015, 5.2.2 and PL = d.

r

c) Measuring device:

Large two-roll mills shall be equipped with a device for the measuring of the stopping angle.

The two braking systems shall be tested individually.

Start of production shall only be possible if the brake has been successfully tested within the last

week.

If the machine is operating continuously in automatic mode, it is not necessary to stop the machine

for the test. In this case, a test is necessary before restarting production after the machine has been

stopped.

The control circuit requiring and performing the test (stopping angle and maximum speed

measurement and expiring time) and enabling the restart of the machine shall be part of the SRP/CS,

PL = d.

r

If a position transducer is used, particularly attention shall be paid for the correct and stable coupling

between the position transducer and the roll.

See 6.2.2 and 6.2.3.

4.3.2.1.3 Positioning of the trip bar

a) The trip bar shall extend over the full length of the mill rolls.

b) It shall be positioned as follows:

1)

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...