EN 12952-2:2011

(Main)Water-tube boilers and auxiliary installations - Part 2: Materials for pressure parts of boilers and accessories

Water-tube boilers and auxiliary installations - Part 2: Materials for pressure parts of boilers and accessories

This European Standard specifies the requirements for the product forms for use in pressure parts of water-tube boilers and for parts welded on to pressure parts:

- plates;

- wrought seamless tubes;

- electrically welded tubes;

- submerged, plasma and TIG arc-welded tubes;

- forgings;

- castings;

- rolled bars;

- welding consumables;

- fasteners;

- seamless composite tubes.

Wasserrohrkessel und Anlagenkomponenten - Teil 2: Werkstoffe für drucktragende Kesselteile und Zubehör

Diese Europäische Norm legt die Anforderungen an Erzeugnisformen für die Anwendung in drucktragenden Teilen von Wasserrohrkesseln und an deren angeschweißte Teile fest:

- Bleche;

- warmgefertigte nahtlose Rohre;

- elektrisch geschweißte Rohre;

- Unterpulver-, Plasma- und Wolfram-Inertgas-geschweißte Rohre;

- Schmiedestücke;

- Gussstücke;

- gewalzte Stäbe;

- Schweißzusätze;

- Befestigungen;

⎯ nahtlose Verbundrohre.

Chaudières à tubes d'eau et installations auxiliaires - Partie 2: Matériaux des parties sous pression des chaudières et accessoires

La présente Norme européenne définit les prescriptions relatives aux formes de produits utilisables pour les parties

sous pression de chaudières à tubes d'eau et les parties soudées sur les parties sous pression :

- les tôles ;

- les tubes corroyés sans soudure ;

- les tubes soudés électriquement ;

- les tubes soudés à l'arc immergé ; sous plasma, ou par procédé TIG ;

- les pièces forgées ;

- les pièces moulées ;

- les pièces laminées ;

- les produits de soudage ;

- les éléments de fixation ;

- les tubes composites sans soudure.

Vodocevni kotli in pomožne napeljave - 2. del: Materiali za tlačno obremenjene dele in opremo kotla

Ta evropski standard določa zahteve za oblike proizvodov, ki se uporabljajo v tlačno obremenjenih delih vodocevnih kotlov, in za proizvode, privarjene na tlačno obremenjene dele: ploščice; kovane nevarjene cevi; električno varjene cevi; cevi, varjene pod praškom, plazemsko varjene cevi in cevi, obločno varjene z inertnim plinom in volframovo elektrodo; odkovke; ulitke; valjane palice; dodajne in potrošne materiale za varjenje; vezne elemente; nevarjene kompozitne cevi.

General Information

- Status

- Withdrawn

- Publication Date

- 09-Aug-2011

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 269 - Shell and water tube boilers

- Drafting Committee

- CEN/TC 269/WG 1 - Water-tube boilers

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 22-Dec-2021

- Completion Date

- 11-Feb-2026

- Directive

- 97/23/EC - Pressure equipment

Relations

- Effective Date

- 13-Aug-2011

- Effective Date

- 29-Dec-2021

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

DNV Energy Systems

Energy and renewable energy certification.

Sponsored listings

Frequently Asked Questions

EN 12952-2:2011 is a standard published by the European Committee for Standardization (CEN). Its full title is "Water-tube boilers and auxiliary installations - Part 2: Materials for pressure parts of boilers and accessories". This standard covers: This European Standard specifies the requirements for the product forms for use in pressure parts of water-tube boilers and for parts welded on to pressure parts: - plates; - wrought seamless tubes; - electrically welded tubes; - submerged, plasma and TIG arc-welded tubes; - forgings; - castings; - rolled bars; - welding consumables; - fasteners; - seamless composite tubes.

This European Standard specifies the requirements for the product forms for use in pressure parts of water-tube boilers and for parts welded on to pressure parts: - plates; - wrought seamless tubes; - electrically welded tubes; - submerged, plasma and TIG arc-welded tubes; - forgings; - castings; - rolled bars; - welding consumables; - fasteners; - seamless composite tubes.

EN 12952-2:2011 is classified under the following ICS (International Classification for Standards) categories: 27.040 - Gas and steam turbines. Steam engines; 77.140.01 - Iron and steel products in general. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12952-2:2011 has the following relationships with other standards: It is inter standard links to EN 12952-2:2001, EN 12952-2:2021, ISO 18275:2011, EN ISO 2566-2:2021, EN ISO 18276:2006, EN 10308:2001, EN 10253-2:2007, EN 764-4:2002, EN ISO 8495:2013, EN ISO 10893-10:2011, EN 12952-3:2011, EN 10217-2:2002, EN 1503-1:2000, EN 12952-6:2011, EN 10216-2:2024. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12952-2:2011 is associated with the following European legislation: EU Directives/Regulations: 2014/68/EU, 97/23/EC; Standardization Mandates: M/071. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12952-2:2011 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Wasserrohrkessel und Anlagenkomponenten - Teil 2: Werkstoffe für Druck tragende Kesselteile und ZubehörChaudières à tubes d'eau et installations auxiliaires - Partie 2 : Matériaux des parties sous pression des chaudières et accessoiresWater-tube boilers and auxiliary installations - Part 2: Materials for pressure parts of boilers and accessories27.060.30Grelniki vode in prenosniki toploteBoilers and heat exchangersICS:Ta slovenski standard je istoveten z:EN 12952-2:2011SIST EN 12952-2:2011en,fr,de01-november-2011SIST EN 12952-2:2011SLOVENSKI

STANDARDSIST EN 12952-2:20021DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 12952-2

August 2011 ICS 27.040 Supersedes EN 12952-2:2001English Version

Water-tube boilers and auxiliary installations - Part 2: Materials for pressure parts of boilers and accessories

Chaudières à tubes d'eau et installations auxiliaires -Partie 2: Matériaux des parties sous pression des chaudières et accessoires

Wasserrohrkessel und Anlagenkomponenten - Teil 2: Werkstoffe für drucktragende Kesselteile und Zubehör This European Standard was approved by CEN on 25 June 2011.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2011 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 12952-2:2011: ESIST EN 12952-2:2011

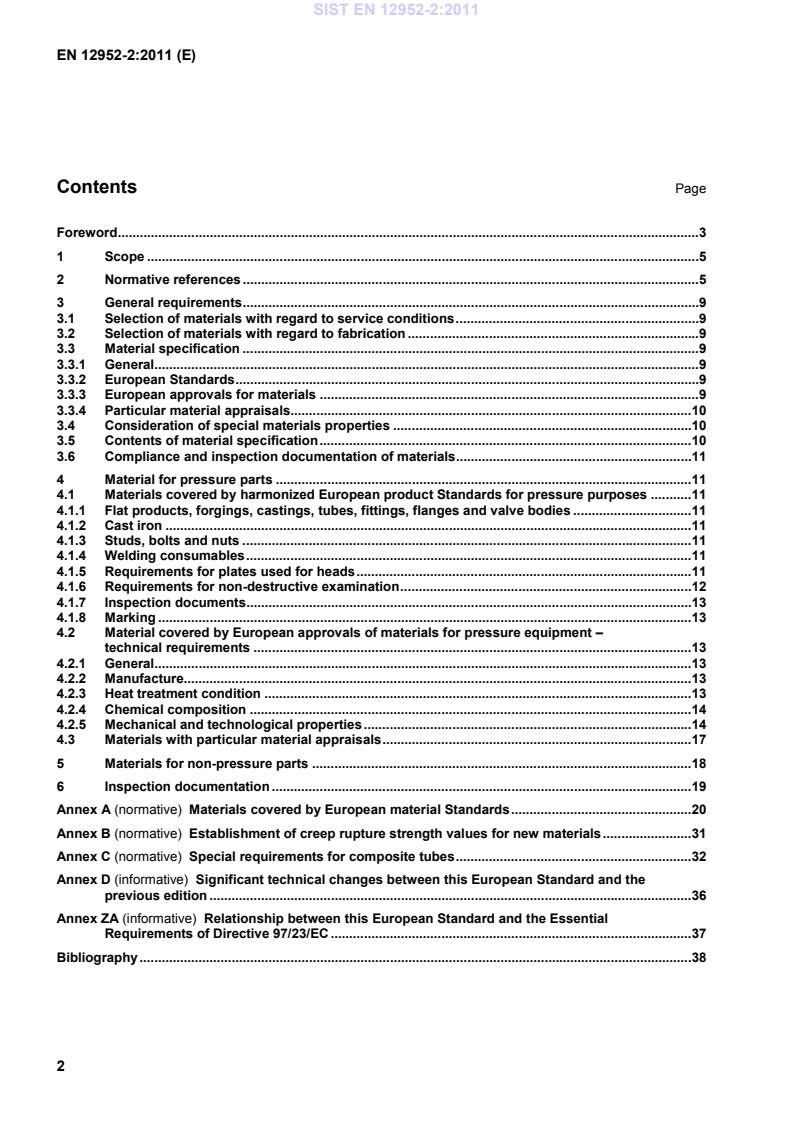

technical requirements . 134.2.1General . 134.2.2Manufacture. 134.2.3Heat treatment condition . 134.2.4Chemical composition . 144.2.5Mechanical and technological properties . 144.3Materials with particular material appraisals . 175Materials for non-pressure parts . 186Inspection documentation . 19Annex A (normative)

Materials covered by European material Standards . 20Annex B (normative)

Establishment of creep rupture strength values for new materials . 31Annex C (normative)

Special requirements for composite tubes . 32Annex D (informative)

Significant technical changes between this European Standard and the previous edition . 36Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of Directive 97/23/EC . 37Bibliography . 38SIST EN 12952-2:2011

According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and the United Kingdom.

(ISO 2566-1:1984) EN ISO 2566-2, Steel — Conversion of elongation values — Part 2: Austenitic steels (ISO 2566-2:1984) EN ISO 3580:2011, Welding consumables — Covered electrodes for manual metal arc welding of creep-resisting steels — Classification (ISO 3580:2010) SIST EN 12952-2:2011

Table 3.5-1 as a minimum. Table 3.5-1 — Content of specifications for materials for pressure parts Clauses

EN standards European material data sheets Particular material appraisals Unrestricted a restricted Scope X see EN 764-4 References X Definitions (X) Requirements X Inspection X Marking X Guidelines for processing the material etc. (welding, heat treatment, forming, flame-cutting) Z Restrictions on application Z X

=

in all cases (X)

= if necessary Z

=

the relevant guidelines for fabrication and the restrictions on application are, where necessary, given in EN 12952-5 a If applicable by reference to a European Standard for pressure purposes. SIST EN 12952-2:2011

EN 10216-2:2002+A2:2007, EN 10216-3:2002, EN 10216-5:2004, EN 10217-2:2002, EN 10217-3:2002, EN 10217-7:2005, EN 10222-2:1999, EN 10222-5:1999, EN 10253-2:2007, EN 10254:1999 and EN 10273:2007. The additional requirements given in this clause shall be taken into account. Harmonized supporting standards are EN 1092-1:2007, EN 1503-1:2000, EN 1503-2:2000, EN 1759-1:2004. In case EN 12952-3:2011 requires Z35 quality in 10.3.1 for flat ends machined from a plate, this should be determined in accordance with EN 10164:2004. 4.1.2 Cast iron Spheroidal graphite cast iron shall not be used in the construction of pressure parts, except for valves and fittings as indicated in EN 12952-7:2002, within the design limits specified in EN 12952-3:2011. The use of other types of cast iron is not permitted. 4.1.3 Studs, bolts and nuts Requirements for studs, bolts and nuts shall be in accordance with EN 10269:1999. 4.1.4 Welding consumables The welding consumables (electrodes, filler wires, filler rods, fluxes, fusible inserts) shall be selected so that the mechanical properties of the weld metal are compatible with the relevant requirements of the base materials. The welding consumables are classified or specified, respectively, in accordance with the following standards: EN 757:1997, EN 760:1996, EN 1600:1997, EN 12074:2000, EN 12536:2000, EN 13479:2004, EN ISO 544:2011, EN ISO 636:2008, EN ISO 2560:2009, EN ISO 3580:2011, EN ISO 14171:2010, prEN ISO 14174:2010, EN ISO 14341:2008, EN ISO 14343:2009, EN ISO 14344:2010, EN ISO 16834:2007, EN ISO 17632:2008, EN ISO 17633:2006, EN ISO 17634:2006, EN ISO 18276:2006, EN ISO 21952:2007, EN ISO 24598:2007, EN ISO 26304:2009, ISO 3581:2003, ISO 18275:2011. Technical delivery conditions for welding consumables and additives used for welding of pressure parts and their structural attachments shall comply with EN 12074:2000 or EN ISO 544:2011. NOTE Equivalent national/international provisions are admissible, provided they meet the same criteria concerning the requirements for the manufacturing, delivery, distribution, test procedures and evaluation of welding consumables and additives regarding the requirements for the quality management system. 4.1.5 Requirements for plates used for heads Plates which are to be used in the manufacture of heads shall represent the quality class Z35 in accordance with EN 10164:2004 (see EN 12952-3:2011, 10.3.1). SIST EN 12952-2:2011

UT in accordance with EN ISO 10893-10:2011

acceptance level:

U2 sub-category B for cold finished and machined tubes

U2 sub-category C for all other conditions. 2) transverse imperfections:

UT in accordance with EN ISO 10893-10:2011

acceptance level:

U2 sub-category C for all headers with outside diameters > 142 mm. 3) tube ends:

UT in accordance with EN ISO 10893-10:2011, Annex B;

acceptance level:

U2 sub-category B or C as for longitudinal imperfections. NOTE This is only mandatory for fixed length tubes. When the tubes are in close end to end contact, it can be accepted that 100 % (full length) ultrasonic examination has taken place, and therefore no additional tube end examination is required. c) tubes – welded: Welded tubes of test category 2 (TC2) in accordance with EN 10217-2:2002. For unalloyed welded steel tubes with design temperatures below 450 °C and design pressures below 42 bar, it is permitted to perform test category 1 (TC1) in accordance with EN 10217-2:2002. However, the longitudinal weld shall be subject to ultrasonic testing. 1) longitudinal imperfections:

UT in accordance with EN ISO 10893-10:2011

acceptance level: U2 sub-category C. 2) transverse imperfections:

UT in accordance with EN ISO 10893-10:2011

acceptance level: U2 sub-category C for all headers with outside diameter > 142 mm. 3) tube ends:

UT in accordance with EN ISO 10893-10:2011, Annex B

acceptance level: U2 sub-category C as for longitudinal imperfections. NOTE This is only mandatory for fixed length tubes. When the tubes are in close end to end contact, it can be assumed that 100 % (full length) ultrasonic testing has taken place, and therefore no additional tube end examination is required. The requirements Annex I, 3.1.2 and 3.1.3 of Pressure Equipment Directive 97/23/EC should be taken into account. d) Forgings and rolled bars: For pressure part of boilers, rolled bars in accordance with EN 10273:2007 as well as forgings shall be examined according to EN 10222-2:1999, EN 10222-3:1998, EN 10222-4:1998 and EN 10222-5:1999 in SIST EN 12952-2:2011

technical requirements 4.2.1 General The material shall be covered by a European approval of material (EAM) established in EN 764-4. This data sheet shall meet the requirements in accordance with Table 3.5-1. The non-destructive examination (NDE) requirement for materials in the various product forms according to 4.1.6 shall be specified as well for materials according to EN as for materials covered by European approvals as for materials with particular material appraisal. NOTE The term "cast", when related to chemical composition, is used in the same way as in all European base materials standards and refers to the material in its molten condition. 4.2.2 Manufacture If the properties specified can be reliably achieved only when special methods of manufacture are applied (e.g. vacuum melting, treatment of the cast with nitrogen binding elements, or, in the case of welded tubes, defined welding methods are applied), these methods shall be considered. Rimming steels and semi-killed steels shall not be used. 4.2.3 Heat treatment condition The heat treatment condition of the material at the time of delivery shall be specified. NOTE Plates to be hot formed may be supplied in any suitable condition, e.g. as rolled, hot finished, normalized and tempered. SIST EN 12952-2:2011

Steel

Maximum content according to analysis

% C % P % S cast product cast product cast product Ferritic steels

0,23 0,25 0,035 0,040 0,020 0,025 Austenitic steels

0,10 0,11 0,035 0,040 0,015 0,018

Elements not specified in the EAM shall not be added intentionally, except for finishing the cast. All reasonable precautions shall be taken to prevent the addition of elements from scrap or other materials used in the manufacture, but residual elements may be present, provided the mechanical properties and applicability are not adversely affected. 4.2.5 Mechanical and technological properties 4.2.5.1 General The following property values shall be specified for each type of material, so that they reflect the specific properties of the individual steel grade. 4.2.5.2 Tensile properties at room temperature The tests shall be carried out in accordance with EN ISO 6892-1. a) Yield or proof strength values For all ferritic steels, the minimum value for the upper yield strength ReH, min or, for cases where no yield phenomenon occurs, the minimum proof strength for 0,2 % non-proportional extension Rp0,2, min shall be specified. For austenitic steels, the minimum proof strength values for 1 % non-proportional extension Rp1,0, min and, where appropriate, additionally Rp0,2, min values shall be specified. b) Tensile strength For the tensile strength, a minimum value Rm, min and, unless no maximum yield or proof strength value is specified, a maximum value Rm, max shall be specified. SIST EN 12952-2:2011

and

≥ 16 % for the longitudinal direction, or where this is the less critical direction, the transverse direction. However, lower elongation values than specified in 4.2 (e.g. fasteners or castings) may also be applied, provided that appropriate measures are proposed, discussed and agreed to compensate for these lower values. NOTE Examples for compensation:

– application of higher safety factors in design;

– performance of appropriate burst tests to demonstrate ductile material behaviour. For gauge lengths other than 0065,5SL= the minimum value for elongation after fracture shall be determined by conversion of the above specified values of 14 % and 16 % using the conversion tables given in EN ISO 2566-1 for carbon and low alloy steels; in EN ISO 2566-2 for austenitic steels. 4.2.5.4 Charpy V – notch impact energy The tests shall be carried out with Charpy V-notch specimens in accordance with EN ISO 148-1. Transverse specimens shall be used, if possible. The specified average impact energy value obtained from a set of three specimens at a temperature not greater than 20 °C but not higher than the lowest scheduled operating temperature shall be

≥ 27 J for transverse specimens, or

≥ 35 J for longitudinal specimens. Only one individual value may be lower than the specified average value, but it shall not be less than 70 % of the average value. The sequential test method in accordance with EN 10021 shall be applied. SIST EN 12952-2:2011

The minimum values specified for room temperature may be used for temperatures equal to or less than 50 °C.

For other than austenitic and austenitic-ferritic stainless steels, the specified value of ReH ( Rp0,2) at room temperature (RT) may be used for temperatures less than or equal to 50 °C. Interpolation between 50 °C and 100 °C shall be performed with the values of RT and 100 °C and using 20 °C as the starting point for interpolation. Above 100 °C linear interpolation shall be performed between the tabulated values given in the relevant material standard. The specified minimum elevated temperature proof strength values shall be derived in accordance with EN 10314. 4.2.5.6 Creep rupture strength For materials intended for the application at temperatures in the creep range, the average stress rupture values shall be specified in accordance with ISO 6303, taking into account the requirements of Annex B. When only stress rupture values with extended time or stress extrapolation or such values derived from an insufficient number of test results (see ISO 6303) are available, account of this shall be taken either by increasing the safety factor or by shortened intervals between repeated inspections. The material supplier shall provide the boiler manufacturer with a written statement declaring that the product supplied complies with the specified properties and that the manufacturing processes have remained equivalent to those for the steel from which the test results were obtained. 4.2.5.7 Technological properties Where necessary, requirements for formability shall be specified e.g. on the basis of flattening or drift expanding tests or on the basis of tests for the deformation properties perpendicular to the surface of the product (see EN 10164) or requirements for other technological properties important for the processing or use of the material. 4.2.5.8 Other properties Where necessary, the requirements for properties other than those covered under 4.2.5.2 to 4.2.5.7 shall be specified, e.g. requirements referring to the corrosion resistance of the material and the relevant verification procedure. 4.2.5.9 Surface condition and internal soundness The products shall be free from surface and internal imperfections which might impair their usability. The requirements for non-destructive examination shall be the same as for the same type of products of a comparable material listed in Annex A and as given in 4.1.6. SIST EN 12952-2:2011

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...