SIST EN 1034-17:2012

(Main)Safety of machinery - Safety requirements for the design and construction of paper making and finishing machines - Part 17: Tissue making machines

Safety of machinery - Safety requirements for the design and construction of paper making and finishing machines - Part 17: Tissue making machines

This European Standard applies to tissue making machines for the production of soft and crepe paper and applies together with EN 1034-1:2000+A1:2010. It deals with all significant hazards, hazardous situations and hazard events relevant to tissue making machines when used as intended and under the conditions foreseen by the manufacturer (see Clause 4).

This document does not deal with pressure hazards in steam-heated drying cylinders and Yankee cylinders.

NOTE Directive 97/23/EC give essential safety requirements for equipment under pressure.

This document does not apply to:

- paper and board making machines;

- tissue winder (plying machines);

- tissue converting machines.

At this stage this standard does not deal with tissue making machines which apply the dry process for sheet forming. These machines are intended to be included in the standard at a later date.

This document is not applicable to tissue making machines which are manufactured before the date of publication of this document by CEN.

Sicherheit von Maschinen - Sicherheitstechnische Anforderungen an Konstruktion und Bau von Maschinen der Papierherstellung und Ausrüstung - Teil 17: Tissuemaschinen

Die vorliegende Europäische Norm gilt für Tissuemaschinen, die zur Herstellung von weichen oder gekreppten Papiersorten bestimmt sind, und ist in Verbindung mit EN 1034-1:2000+A1:2010 anzuwenden. Sie behandelt alle signifikanten Gefährdungen, Gefährdungssituationen und Gefährdungsereignisse für Tissuemaschinen, die bestimmungsgemäß und unter den vom Hersteller vorzusehenden Bedingungen verwendet werden (siehe Abschnitt 4).

Nicht behandelt werden druckbedingte Gefährdungen in dampfbeheizten Zylindern und Yankee-Zylindern.

ANMERKUNG Die grundlegenden Sicherheitsanforderungen für Druckgeräte sind in der Druckgeräte-Richtlinie 97/23/EG enthalten.

Diese Norm gilt nicht für:

- Papier- und Kartonmaschinen;

- Doubliermaschinen;

- Maschinen zur Verarbeitung von Tissue.

Im derzeitigen Stadium der Norm werden Tissuemaschinen, bei denen die Blattbildung im Trockenverfahren erfolgt, nicht behandelt. Diese Maschinen sollen später in die Norm aufgenommen werden.

Dieses Dokument gilt nicht für Tissuemaschinen, die vor dem Datum der Veröffentlichung als Europäische Norm hergestellt wurden.

Sécurité des machines - Prescriptions de sécurité pour la conception et la construction de machines de fabrication et de finition du papier - Partie 17: Machines de fabrication du papier non tissé

La présente Norme européenne s'applique aux machines de fabrication du papier non tissé employées pour

la production de papier crêpe doux et s'applique conjointement à l'EN 1034-1:2000+A1:2010. Elle traite de

tous les phénomènes dangereux, situations et événements dangereux significatifs spécifiques aux machines

de fabrication du papier non tissé, lorsqu'elles sont utilisées normalement et dans les conditions prévues par

le constructeur (voir Article 4).

Le présent document ne traite pas des phénomènes dangereux engendrés par la pression dans les cylindres

sécheurs chauffés à la vapeur et les cylindres Yankee.

NOTE La Directive 97/23/CE donne les exigences essentielles de sécurité pour les équipements sous pression.

Le présent document ne s'applique pas aux :

- machines de fabrication du papier et du carton ;

- visiteuses pour papier non tissé (machines de fabrication de papier multicouches) ;

- machines de transformation du papier non tissé.

A ce stade, la présente norme ne traite pas des machines de fabrication du papier non tissé appliquant un

procédé par voie sèche pour la formation des feuilles. Ces machines doivent être incorporées dans la norme

à une date ultérieure.

Le présent document ne s'applique pas aux machines de fabrication du papier non tissé fabriquées avant la

date de publication du présent document par le CEN.

Varnost strojev - Varnostne zahteve za načrtovanje in konstrukcijo strojev in opreme za izdelavo papirja - 17. del: Stroji za izdelavo vpojnega papirja

Ta evropski standard se nanaša na stroje za izdelavo vpojnega papirja, ki se uporabljajo pri izdelavi mehkega in krep papirja, pri čemer velja skupaj s standardom EN 1034-1:2000+A1:2010. Opisuje večja tveganja, nevarne situacije in nevarne dogodke v zvezi s stroji za izdelavo vpojnega papirja, kadar se uporabljajo v skladu z njihovim namenom in pod pogoji, ki jih določa proizvajalec (glejte točko 4). Ta dokument ne obravnava nevarnosti tlaka v parno ogrevanih sušilnih cilindrih in cilindrih Yankee.

General Information

- Status

- Published

- Publication Date

- 10-Sep-2012

- Technical Committee

- GRT - Graphical technology

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 28-Aug-2012

- Due Date

- 02-Nov-2012

- Completion Date

- 11-Sep-2012

Overview - EN 1034-17:2012 (Tissue making machines)

EN 1034-17:2012 is a CEN European Standard that specifies safety requirements for the design and construction of tissue making machines used to produce soft and crepe paper. It is intended to be used together with EN 1034-1:2000+A1:2010 (Common requirements) and follows the type C standard approach defined in EN ISO 12100. The standard addresses all significant hazards related to tissue making machines when used as intended under manufacturer foreseen conditions. It does not cover pressure hazards arising from steam-heated drying or Yankee cylinders (these are covered by pressure equipment directives), nor does it apply to paper & board machines, tissue winders (plying), converting machines, or machines manufactured before its publication.

Key topics and technical requirements

EN 1034-17:2012 focuses on machine-level safety topics including (but not limited to):

- Hazard identification and list of significant hazards specific to tissue making

- Workplaces, access and walkways - safe means of access and egress

- Start-up warning, emergency stop and braking systems - prevention and mitigation of accidental start-up

- Isolation, energy dissipation and prevention of unexpected start-up

- Drive systems, power transmission, control systems and actuators

- Electrical, hydraulic and pneumatic equipment safety

- Make‑ready, maintenance, lubrication, cleaning and broke removal measures

- Noise, hot surfaces and ergonomic design principles

- Dust, health hazards and explosive atmospheres (paper dust and zones)

- Fire prevention and protection

- Rolls, knives, felts, wires, drying sections and reel/reel-up safety

- Verification, testing and information for use (instructions, marking, handbooks)

The standard contains safety functions, verification methods and references to performance requirements (see its normative tables and Annex ZA for alignment with EU Directive 2006/42/EC).

Practical applications - who uses EN 1034-17:2012

- Machine designers and OEMs who design or build tissue making machines

- Safety engineers preparing risk assessments and compliance documentation

- Plant managers and maintenance teams implementing safe procedures for tissue production lines

- Notified bodies and conformity assessors verifying compliance with the Machinery Directive and CEN standards

- Procurement and project teams specifying safety requirements for new tissue plants

Using this standard helps reduce mechanical, electrical, ergonomic and process-related risks in tissue production, and supports regulatory compliance across European markets.

Related standards and references

- EN 1034-1:2000+A1:2010 (Common requirements for paper machinery)

- EN 1034 series (parts on pulpers, calenders, roll handling, etc.)

- EN ISO 12100 (risk assessment and type C standard approach)

- Applicable electrical, explosion-atmosphere and pressure-equipment standards (refer to Annex ZA and normative references in the document)

For machine builders and safety professionals, citing EN 1034-17:2012 in specifications and risk documentation improves legal clarity and demonstrates adherence to best practice for tissue making machine safety.

Frequently Asked Questions

SIST EN 1034-17:2012 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Safety of machinery - Safety requirements for the design and construction of paper making and finishing machines - Part 17: Tissue making machines". This standard covers: This European Standard applies to tissue making machines for the production of soft and crepe paper and applies together with EN 1034-1:2000+A1:2010. It deals with all significant hazards, hazardous situations and hazard events relevant to tissue making machines when used as intended and under the conditions foreseen by the manufacturer (see Clause 4). This document does not deal with pressure hazards in steam-heated drying cylinders and Yankee cylinders. NOTE Directive 97/23/EC give essential safety requirements for equipment under pressure. This document does not apply to: - paper and board making machines; - tissue winder (plying machines); - tissue converting machines. At this stage this standard does not deal with tissue making machines which apply the dry process for sheet forming. These machines are intended to be included in the standard at a later date. This document is not applicable to tissue making machines which are manufactured before the date of publication of this document by CEN.

This European Standard applies to tissue making machines for the production of soft and crepe paper and applies together with EN 1034-1:2000+A1:2010. It deals with all significant hazards, hazardous situations and hazard events relevant to tissue making machines when used as intended and under the conditions foreseen by the manufacturer (see Clause 4). This document does not deal with pressure hazards in steam-heated drying cylinders and Yankee cylinders. NOTE Directive 97/23/EC give essential safety requirements for equipment under pressure. This document does not apply to: - paper and board making machines; - tissue winder (plying machines); - tissue converting machines. At this stage this standard does not deal with tissue making machines which apply the dry process for sheet forming. These machines are intended to be included in the standard at a later date. This document is not applicable to tissue making machines which are manufactured before the date of publication of this document by CEN.

SIST EN 1034-17:2012 is classified under the following ICS (International Classification for Standards) categories: 13.110 - Safety of machinery; 21.020 - Characteristics and design of machines, apparatus, equipment; 85.100 - Equipment for the paper industry. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 1034-17:2012 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 94/9/EC; Standardization Mandates: M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 1034-17:2012 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Sicherheit von Maschinen - Sicherheitstechnische Anforderungen an Konstruktion und Bau von Maschinen der Papierherstellung und Ausrüstung - Teil 17: TissuemaschinenSécurité des machines - Prescriptions de sécurité pour la conception et la construction de machines de fabrication et de finition du papier - Partie 17: Machines de fabrication du papier non tisséSafety of machinery - Safety requirements for the design and construction of paper making and finishing machines - Part 17: Tissue making machines85.100Oprema za papirno industrijoEquipment for the paper industry21.020Characteristics and design of machines, apparatus, equipment13.110Varnost strojevSafety of machineryICS:Ta slovenski standard je istoveten z:EN 1034-17:2012SIST EN 1034-17:2012en,fr,de01-oktober-2012SIST EN 1034-17:2012SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1034-17

August 2012 ICS 85.100 English Version

Safety of machinery - Safety requirements for the design and construction of paper making and finishing machines - Part 17: Tissue making machines

Sécurité des machines - Prescriptions de sécurité pour la conception et la construction de machines de fabrication et de finition du papier - Partie 17: Machines de fabrication du papier non tissé

Sicherheit von Maschinen - Sicherheitstechnische Anforderungen an Konstruktion und Bau von Maschinen der Papierherstellung und Ausrüstung - Teil 17: Tissuemaschinen This European Standard was approved by CEN on 13 July 2012.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2012 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1034-17:2012: ESIST EN 1034-17:2012

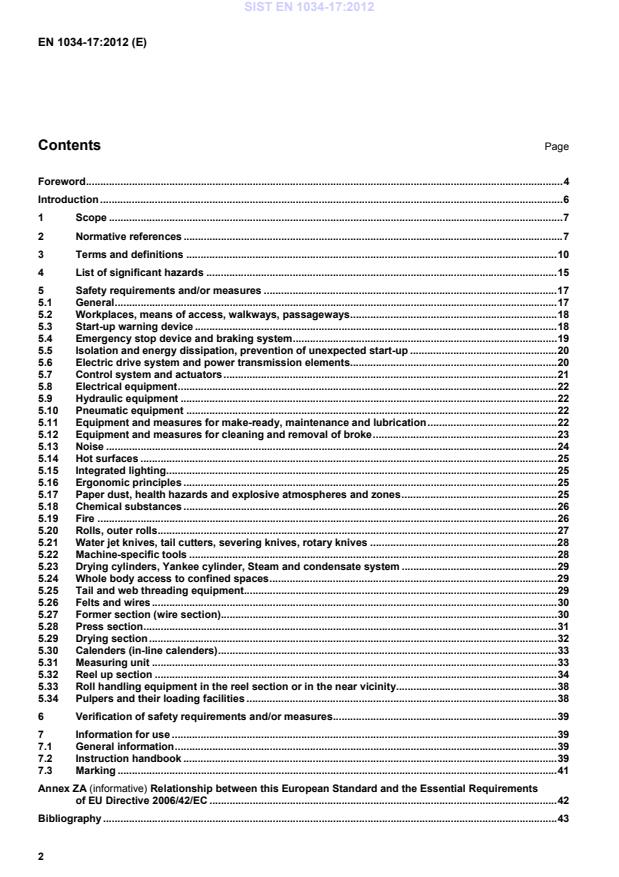

Figures Figure 1 — Example of a large complex tissue making machine with a "closed" reel section (Safety devices are not shown) . 11Figure 2 — Example of a tissue making machine with an "open" reel section (Safety devices are not shown) . 12Figure 3 — Example of the former and press section on a tissue making machine . 13Figure 4 — Example of a reel section (Safety devices are not shown) . 14Figure 5 — Safety distance ≥ 2,70 m on drum reeler . 34Figure 6 — Safety distance ≥ 500 mm to prevent crushing by reels behind the drum reeler . 37 Tables Table 1 — List of significant hazards . 16Table 2 — List of safety functions, Performance Level and Safety Integrity Level specified in this standard . 21Table 3 — Methods used to verify safety requirements and/or measures . 39 SIST EN 1034-17:2012

According to the CEN/CENELEC Internal Regulations, the national standards organisations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, SIST EN 1034-17:2012

1 Scope This European Standard applies to tissue making machines for the production of soft and crepe paper and applies together with EN 1034-1:2000+A1:2010. It deals with all significant hazards, hazardous situations and hazard events relevant to tissue making machines when used as intended and under the conditions foreseen by the manufacturer (see Clause 4).

This document does not deal with pressure hazards in steam-heated drying cylinders and Yankee cylinders.

NOTE Directive 97/23/EC gives essential safety requirements for equipment under pressure. This document does not apply to: paper and board making machines;

tissue winder (plying machines);

tissue converting machines. At this stage this standard does not deal with tissue making machines which apply the dry process for sheet forming. These machines are intended to be included in the standard at a later date. This document is not applicable to tissue making machines which are manufactured before the date of publication of this document by CEN. 2 Normative references The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 349:1993+A1:2008, Safety of machinery — Minimum gaps to avoid crushing of parts of the human body EN 547-1:1996+A1:2008, Safety of machinery — Human body measurements — Part 1: Principles for determining the dimensions required for openings for whole body access into machinery EN 614-1:2006+A1:2009, Safety of machinery — Ergonomic design principles — Part 1: Terminology and general principles EN 614-2:2000+A1:2008, Safety of machinery — Ergonomic design principles — Part 2: Interaction between the design of machinery and work tasks EN 626-1:1994+A1:2008, Safety of machinery — Reduction of risks to health from hazardous substances emitted by machinery — Part 1: Principles and specifications for machinery manufacturers EN 746-1:1997+A1:2009, Industrial thermoprocessing equipment — Part 1: Common safety requirements for industrial thermoprocessing equipment EN 746-2:2010, Industrial thermoprocessing equipment — Part 2: Safety requirements for combustion and fuel handling systems EN 894-1:1997+A1:2008, Safety of machinery — Ergonomic requirements for the design of displays and control actuators — Part 1: General principles for human interactions with displays and control actuators EN 894-2:1997+A1:2008, Safety of machinery — Ergonomic requirements for the design of displays and control actuators — Part 2: Displays SIST EN 1034-17:2012

(IEC 60204-1:2005, modified) EN 60204-11:2000, Safety of machinery — Electrical equipment of machines — Part 11: Requirements for HV equipment for voltages above 1 000 V a.c. or 1 500 V d.c. and not exceeding 36 kV (IEC 60204-11:2000) EN 61000-6-2:2005, Electromagnetic compatibility (EMC) — Part 6-2: Generic standards — Immunity for industrial environments (IEC 61000-6-2:2005) EN 61241-0, Electrical apparatus for use in the presence of combustible dust – Part 0: General requirements (IEC 61241-0:2004, modified + corrigendum November 2005) EN 61496-1:2004, Safety of machinery — Electro-sensitive protective equipment — Part 1: General requirements and tests (IEC 61496-1:1997, modified) EN 61511-1:2004, Functional safety — Safety instrumented systems for the process industry sector — Part 1: Framework, definitions, system, hardware and software requirements (IEC 61511-1:2003 + Corrigendum 2004) SIST EN 1034-17:2012

(ISO 13849-2:2003) EN ISO 13850:2008, Safety of machinery — Emergency stop — Principles for design (ISO 13850:2006) EN ISO 13855:2010, Safety of machinery — Positioning of safeguards with respect to the approach speeds of parts of the human body (ISO 13855:2010) EN ISO 13857:2008, Safety of machinery — Safety distances to prevent hazard zones being reached by upper and lower limbs (ISO 13857:2008) EN ISO 14122-1:2001, Safety of machinery — Permanent means of access to machinery — Part 1: Choice of fixed means of access between two levels (ISO 14122-1:2001) EN ISO 14122-2:2001, Safety of machinery — Permanent means of access to machinery — Part 2: Working platforms and walkways (ISO 14122-2:2001) EN ISO 14122-3:2001, Safety of machinery — Permanent means of access to machinery — Part 3: Stairs, stepladders and guard-rails (ISO 14122-3:2001) EN ISO 14122-4:2004, Safety of machinery — Permanent means of access to machinery — Part 4: Fixed ladders (ISO 14122-4:2004) SIST EN 1034-17:2012

EN ISO 12100:2010 and the following apply: 3.1 tissue soft crepe paper with a grammage normally less than 25 g/m² Note 1 to entry: Soft tissue is the base material for certain single-ply and multi-ply products such as serviettes, towels, handkerchiefs, toilet paper, tea-bag´s etc.

3.2 tissue making machine an assembly of machine sections systems extending from the head box to the reel-up unit and including former (wire) section, press section, dryer section, calender, measuring units, reel-up unit and reel stand including machine pulpers, shaft puller equipment, lifting table, core bin exit device, machine process ventilation

Note 1 to entry: Drive system, control system(s), hydraulic system, lubrications system etc. are also included in the scope. EXAMPLE 1 A large complex tissue making machine with a "closed" reel section where the parent roll ends up at a lifting table for further handling such as: kick out on a conveyor, kick out on the floor (lifting table in lower position); lifting the paper roll away with an overhead crane; fetching the paper roll with a truck or with an auto carrier or a combination. Note 2 to entry: Figure 1 illustrates a large complex tissue making machine with a "closed" reel section. SIST EN 1034-17:2012

Key 1 tissue making machine 2 former section (wire section) 3 press section 4 TAD dryer with hood and air systems 5 Yankee dryer, hood with air system 6 calender 7 measuring device 8 reel and reel stand 9 roll handling 10 broke chuter equipment 11 shaft puller 12 lifting table 13 hydraulic system 14 grease and/or oil lubrication system 15 mist removal system 16 control system 17 machine pulper 18 heat water or oil system 19 mechanical drive equipment 20 AC or DC drive system Figure 1 — Example of a large complex tissue making machine with a "closed" reel section

(Safety devices are not shown)SIST EN 1034-17:2012

EXAMPLE 2 A tissue making machine with an "open" reel section where the finished paper rolls are ready to be picked up at the end station. In the "open" reel section the paper rolls normally are lifted away with an overhead crane. Figure 2 illustrates a tissue making machine with an "open" reel section.

Key 1 example tissue machine (open reel) 2 former section 3 press section 4 Yankee dryer/creeping ventilation (hood) 5 measuring unit 6 reel and reel stand 7 broke chuter 8 weighing station 9 end station 10 control system 11 hydraulic system 12 lubrication system 13 machine pulper 14 drive equipment 15 drive system/control system Figure 2 — Example of a tissue making machine with an "open" reel section

(Safety devices are not shown) 3.3 former section (wire section) device for forming a continuous web from fibre diluted in water (stock) using wire formers for forming the sheets and including head box, wires, rollers, roller stretching equipment, lifting devices and spraying pipes

Note 1 to entry: An example of the former and press section is shown in Figure 3. For sheet forming, the stock is supplied onto a large-diameter roll (forming roll) designed to preserve and enhance the paper properties created in the head box. The head box delivers the stock by means of spray jets with uniform velocity over the entire machine width. Growing demands for softness and more efficient fibre use have led to increased application of head boxes suitable for multiple-ply products. There are two types of former sections, one equipped with a pick-up system and one where the sheet is carried directly to the pressure rolls and the Yankee dryer so that a pick-up system is not required. 3.4 press section part of the wet end of a tissue making machine which carries out one or several press functions extending from the sheet pick-up to the first dryer section and including all pressure and lead rolls, spraying pipes, suction boxes and wire tension devices, being nowadays generally designed as cantilever for easier changing of felts and wires

Note 1 to entry: An example of a press section is illustrated in Figure 3. Felt conditioning is normally located between the last pressure roll and the first paper side felt roll in the return run. Tissue machines can be equipped with one or two pressure rolls. The first roll is normally a suction pressure roll and the optional second roll is a blind drilled roll. Press roll configuration influences the sheet properties and sheet dryness. Paper with higher bulk and softness can be produced on single-roll machines. SIST EN 1034-17:2012

NOTE Safety devices are not shown. Key

spraying pipe

doctor

rolls

chemical spraying pipe 1 former section

2 press section

3 drying section 4 wire guide roll 5 couche/pick up roll 6 breast roll 7 felt tensing roll 8 wire guide roll 9 chemical spraying pipe 10 wire guide roll 11 cantiliver 12 spaying pipe 13 press roll

14 press roll

15 coating spraying pipe Figure 3 — Example of the former and press section on a tissue making machine

3.5 drying section section in which the water remaining in the web after wet pressing is evaporated by the action of the heat extending from first drying cylinder to where the calender and/or measuring unit area starts and including in some configurations broke chute equipment, broke conveyor, process ventilation equipment, tail threading equipment, sheet support equipment etc.

Note 1 to entry: Some terms special for the drying section are defined below. Yankee cylinder (creping cylinder): steam-heated drying cylinder with a very large diameter and a polished surface, completely or largely responsible for drying the paper web. It works in conjunction with the press roll to dry the paper in combination with the drying hood and finally provides the surface of the creping process; Yankee dryer: assembly within a Yankee cylinder, press roll and drying hood; drying hood: equipment that functions to improve the drying process and the tissue quality by optimising the air temperature, velocity and distance to the tissue web Air circulation and heat recovery systems may also be included in this machinery; creping: the creping process is affected by both the blade geometry and the surface conditions of the Yankee dryer. The creping process can be optimised by using adjustable creping doctors. Tissue making machines are normally equipped with spray systems for coating the Yankee surface with chemical substances; through-air drying (TAD): method for increasing bulk and softness. Conventional tissue making machines press the sheet onto a Yankee cylinder. TAD removes water by a process to dry a sheet by passing high temperature air through the sheet that has not been pressed; tail threading device: device for threading the paper web through the machine, for example following the creeping doctor; equipment for web support: equipment to prevent the web from fluttering or creating waves; equipment for dust removal: system for removal of dusts. 3.6 calender assembly where the shape and surface of the paper tissue is changed by a combination of heat and/or mechanical treatment in a roll nip. 3.7 measuring device, scanner measuring device consisting of a traversing measuring sensor used to determine the basis weight and moisture content and which is generally located between creping unit and the reel section SIST EN 1034-17:2012

Note 1 to entry: The reel stand and the shaft magazine are also included in this section. 3.8.1 drum reeler reeler where the paper web is wound onto a reel which rests on and is driven by a supporting cylinder (drum) whose peripheral speed is equal to that of the paper web Note 1 to entry: Figure 4 illustrates an example of a reel section with a drum reeler. 3.8.2 "open" reel section reel section without automatic roll handling where the parent rolls are handled with a crane 3.8.3 "closed" reel section

reel section with automatic roll handling equipment described in 3.9

Key 1 spool storage

2 frames 3 reel drum 4 primary arms 5 secondary arms 6 brake stopper and damper 7 doctor

8 reel spool starter 9 reel spool storage rails 10 guards 11 weighing station 12 lowering arms

Figure 4 — Example of a reel section (Safety devices are not shown) 3.9 roll handling equipment in the reel section or in the near vicinity equipment necessary for handling paper roll/parent roll and tambour rolls and paper winder cores in the end station

Note 1 to entry: Depending on the configuration of this area, equipment such as: a) shaft puller; b) lifting table; c) core bin exit device; d) core stand; e) conveyor; SIST EN 1034-17:2012

Table 1 — List of significant hazards

No Hazards subclause of this standard EN 1034-1:2000 +A1:2010 Origin (source) Potential consequences

Mechanical hazards

1 Inadequate design of workplaces, means of access, walkways, passageways Slipping, tripping and falling 5.2.1-5.2.5; 5.2.7; 5.11.1; 5.11.3; 5.11.4; 5.12.4; 5.12.9; 5.20.4; 5.23.5; 5.26.5; 5.27.3; 5.27.5; 5.27.6; 5.28.2; 5.29.3; 5.29.2; 5.32.4; 5.32.14; 5.34.1; 5.34.2; 5.34.3 5.5 2 Obstacles in the area of workplaces, means of access, walkways, passageways Impact injuries for the head 5.2.3; 5.8.4; 5.15.2; 5.29.2 5.5.9 3 Inrunning nips on rotating rolls, reels, cylinders;

Wrapping points of fabrics, wires, ropes, power transmissions elements Drawing-in or trapping, crushing injuries, amputation, death

5.2.6; 5.2.7; 5.3; 5.4; 5.6.1; 5.6.2; 5.11.2; 5.11.3; 5.12.1; 5.12.3; 5.12.9; 5.20.2; 5.20.3; 5.20.4; 5.23.4; 5.25; 5.26.3; 5.26.5; 5.27.2; 5.28.1; 5.28.2; 5.28.3; 5.28.4; 5.28.5; 5.28.6; 5.28.7; 5.29.5; 5.30.1; 5.30.2; 5.32.1; 5.32.2; 5.32.6; 5.32.7; 5.32.8; 5.32.9; 5.32.12 5.1; 5.4; 5.7 4 Linear and swivelling movements of machinery parts Crushing injuries 5.2.6; 5.2.7; 5.3; 5.4; 5.11.4; 5.12.6; 5.12.7; 5.26.2; 5.27.1; 5.27.3; 5.27.4; 5.28.6; 5.29.2; 5.29.4; 5.30.1; 5.31.1; 5.32.3; 5.32.4; 5.32.9; 5.32.10; 5.33.2; 5.32.13; 5.34.2 5.1; 5.3; 5.7 5 Linear and swivelling movements of machinery parts Shearing injuries 5.2.7; 5.4; 5.25; 5.27.3; 5.29.1; 5.31.1; 5.32.3; 5.33.2 5.1; 5.7 6 Knives, edges of wires, sharp edges of machinery frame Cutting injuries 5.2.7; 5.12.5; 5.12.9; 5.21.1; 5.21.2; 5.26.3; 5.26.4; 5.27.3 5.1; 5.11; 5.12 7 Movement of crane, reels Impact, crushing injuries 5.20.1; 5.29.1; 5.32.4; 5.32.9; 5.32.10; 5.32.12; 5.33.1 5.1; 5.7 8 Hydraulic and pneumatic equipment Injuries by injection of high-pressure fluids

5.9; 5.10; 5.12.8; 5.20; 5.21.1; 5.27.5 5.24 9 Ejection and falling of machinery part Crushing, impact of persons5.6.3; 5.26.1; 5.27.3; 5.32.10; 5.32.11 5.2

Electrical hazards

10 Electrical equipment Electric shock 5.5.1; 5.6.1; 5.8.1; 5.8.2; 5.24 5.23 11 Electrical equipment Outside effects on electrical equipment 5.8.1; 5.8.3 5.23

Thermal hazards

12 Hot surfaces of machinery parts Burning and scalds by contact of persons 5.14; 5.23.2; 5.24 5.13; 5.17

No Hazards subclause of this standard EN 1034-1:2000 +A1:2010 Origin (source) Potential consequences

Noise hazards

13 Running machine, drives, power transmission elements, hydraulic aggregate, ventilation system Hearing loss or other physical disorders, stress, interference with speech communication and acoustic signals 5.6.1; 5.13 5.15

Radiation hazards

14 Measuring unit with radioactive source Ionising radiation 5.31.2; 5.31.3 5.20

Hazards generated by material and substances

15 Chemical substances Loss of health, injuries of the skin or eyes 5.17.1; 5.18; 5.24; 5.27.5 5.16 16 Paper (tissue), paper (tissue) dust Fire and explosion 5.17.2; 5.19; 5.23.2; 5.29.6 5.13; 5.18; 5.19; 5.23

Hazards generated by neglecting ergonomic principles 17 Neglect of ergonomic principles Discomfort, fatigue, stress, overload 5.2.4; 5.11.1; 5.12.2; 5.12.9; 5.16; 5.22; 5.25; 5.27.6 5.22 18 Inadequate lighting of the workplace Blinding, falling, stress 5.15 5.18

Hazards caused by failure of energy supply, control system and other functional disorders 19 Unexpected start-up Crushing, shearing, in drawing, impact injuries 5.3; 5.5; 5.7; 5.9; 5.10; 5.24; 5.23.3; 5.24 5.6; 5.8 20 Malfunction in the control system Crushing, shearing, impact, in drawing injuries, overturn 5.2.6; 5.4.3; 5.5.2; 5.6.3; 5.6.4; 5.7.1; 5.7.2; 5.7.3; 5.12.9; 5.21.1; 5.25; 5.27.1; 5.28.6; 5.29.5; 5.30.2; 5.31.1; 5.32.2; 5.32.3; 5.32.4; 5.33.1; 5.33.2; 5.34.2

5.14 21 Falling or ejection of objects Crushing, impact injuries 5.26.1; 5.26.2; 5.32.10; 5.32.11

5.2

Combination of hazards

22 Combination of hazards In drawing, crushing, shearing, impact 5.1; 5.2; 5.3; 5.4; 5.5; 5.11; 5.12.1; 5.22; 5.23.1; 5.24; 5.25; 5.27.3; 5.28.1; 5.33.1 5.6 23 Work in confined spaces Asphyxiate, inhalation of chemical substances, crushing, shearing, impact, electric shock, stress 5.23; 5.24

5 Safety requirements and/or measures 5.1 General Tissue making machines shall comply with the safety requirements and/or protective measures of Clause 5 and the requirements of EN 1034-1:2000+A1:2010. For guidance in connection with risk reduction by design, see EN ISO 12100:2010, 6.2 and for safeguarding measures, see EN ISO 12100:2010, 6.3. In addition, the machine shall be designed in accordance with the principles of EN ISO 12100:2010 for hazards relevant but not significant, which are not dealt with by this document (e.g. sharp edges of the machine frame). SIST EN 1034-17:2012

EN ISO 14122-2:2001, EN ISO 14122-3:2001 and EN ISO 14122-4:2004 shall be satisfied. 5.2.2 Doctor blades and creping blades shall be accessible from floor level as far as possible. Where this is not possible for constructional reasons, working platforms and machine walkways, as well as cross walkways, shall be provided for cleaning, adjustment and maintenance and repair operations, including their means of access according to 5.2.1. 5.2.3 The clear passage height over platforms and walkways shall be at least 2,10 m, in deviation from EN 1034-1:2000+A1:2010, 5.5.9. In exceptional cases where this requirement cannot be satisfied for constructional reasons, all danger areas shall be provided with padding with black/yellow danger marking. 5.2.4 The clear walking width of walkways and working platforms shall, when possible, be at least 0,80 m in accordance with EN ISO 14122-2:2001. If this is not achievable, the clear walking width shall be at least 0,60 m. Where this requirement cannot be complied with due to design or constructional reasons,

EN 1034-1:2000+A1:2010, 5.5.6 shall be satisfied. 5.2.5 Where pulpers are provided for removal of broke, the requirements of EN 1034-4:2005+A1:2009 shall be satisfied. 5.2.6 Cross walkways shall be designed in such a way that inrunning nips or crushing points with adjacent moving parts of the machine, for example rollers, are avoided. If this requirement is not achievable, the danger area shall be safeguarded by: safety distances according to EN 1034-1:2000+A1:2010, 5.4.1; and/or minimum gaps in accordance with EN 349:1993+A1:2008 and safety distances in accordance with EN ISO 13857:2008, Tables 2 and 4; and/or protective structures in accordance with EN ISO 13857:2008, Tables 2 and 4; and/or fixed guards and/or movable interlocking guards with guard locking in accordance with

EN 1034-1:2000+A1:2010, 5.4 and EN 953:1997+A1:2009. The safety distances of

EN ISO 13857:2008, Table 2 and Table 4 for distance guards and the safety distances of

EN ISO 13857:2008, Table 3 and Table 4 for guards with openings shall be taken into account. Movable interlocking guards with guard locking shall be provided if frequent access or access to the danger area for removal of broke or cleaning is required. Interlocking and guard locking devices shall be in compliance with

EN 1088:1995+A2:2008. The control system of the interlocking shall comply with at least EN ISO 13849-1:2008, Performance Level PL d or EN 62061:2005, Safety Integrity Level SIL 2.

5.2.7 Adjustment, cleaning and changing of nozzles for spraying water and chemical substances shall be safe. The spray devices should be capable of being swung out of the danger area or moved towards the operator without the use of tools. Working platforms, walkways and means of access shall be provided and their design shall accord with EN 1034-1:2000+A1:2010, 5.5. 5.3 Start-up warning device 5.3.1 Prior to the start-up of the sectional drives, a start-up warning shall be given in accordance with

EN 1034-1:2000+A1:2010, 5.6.

For some machine assemblies which are temporarily taken out of the production run, for example Yankee cylinders, it may be important that they do not remain stationary for a long period, but that they can continue rotate at a low speed. A start-up warning shall be given before they can start up to production speed from the low speed. 5.3.2 A sufficient number of warning devices shall be provided to make sure that every person within or close to a danger area can be reached by the warning signal. 5.3.3 The start-up warning device shall comply with category A of EN 1034-1:2000+A1:2010, 5.6.2. SIST EN 1034-17:2012

EN 1034-1:2000+A1:2010, 5.7, EN ISO 13850:2008 and EN 60204-1:2006, 10.7. The emergency stop function shall act on all hazards of the entire machine including the machine pulper and measuring device. Steam and condensate system and burners shall be included in the emergency stop function. The emergency stop system shall act on the whole machine.

NOTE In cases where stopping the machine ventilation systems could create new hazards, a separate emergency stop circuit could be allowed beside the machine emergency stop circuit based on the risk assessment for this individual system (see the last paragraph of 5.19.2). The emergency stop function shall be available and operational at all times, regardless of the operating mode. Emergency stop devices shall be a back-up to other safeguarding measures and not a substitute for them.

5.4.2 If the roll nips are separated in the course of an emergency stop, the guarding of the roll nips shall remain effective. The calendar rolls should be separated before standstill in order to protect the surface of the rolls. 5.4.3 The emergency stop control system of the sectional drives shall comply with at least EN ISO 13849-1:2008, Performance Level PL d or EN 62061:2005, Safety Integrity Level SIL 2.

Those parts of emergency stop control system relating to machinery parts with hydraulic, pneumatic or electrical drives for linear or swivelling movements, i.e. headbox, rolls,

suction box, doctors,

belt conveyors for tail and web threading, hood,

traversing measuring device, movable center-drive of reel up, primary and secondary arms of the reel up, rail gates in the reel stand,

roll handling equipment in the reel section or in the near vicinity (automatic crane, lifting table, conveyor, shaft puller)

shall comply with at least EN ISO 13849-1:2008, Performance Level PL c or EN 62061:2005, Safety Integrity Level SIL 1.

5.4.4 Machines shall be fitted with braking devices which operate on the actuation of the emergency stop device, for example mechanical or electro-dynamic brakes. Braking devices shall operate in such a way that the stopping time following actuation of the emergency stop is as short as possible without causing additional hazards. The requirement "as short as possible" implies that the stopping time is less than the shortest possible start-up time. SIST EN 1034-17:2012

EN 60204-1:2006, 9.2.5.4.2. Where the stop is ensured by a timer function, it shall act as the second channel to ensure the removal of the power.

5.4.5 For the location of emergency stop actuators, the requirements of EN 1034-1:2000+A1:2010, 5.7 shall be complied with. 5.4.6 Emergency stop buttons shall be designed in accordance with EN ISO 13850:2008, 4.4.1 and 4.4.2. The requirements of EN 60204-1:2006, 10.7.3 shall be satisfied. 5.5 Isolation and energy dissipation, prevention of unexpected start-up 5.5.1 Devices for isolation and energy dissipation for all sources of power shall be provided in accordance with EN 1034-1:2000+A1:2010, 5.8.1. Disconnection from electrical supply shall comply with EN 60204-1:2006, 5.3. EN 1037:1995+A1:2008 shall also be complied with. 5.5.2 Devices for the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...