SIST EN 1034-26:2012

(Main)Safety of machinery - Safety requirements for the design and construction of paper making and finishing machines - Part 26: Roll packaging machines

Safety of machinery - Safety requirements for the design and construction of paper making and finishing machines - Part 26: Roll packaging machines

This European Standard applies to roll packaging machines for use in papermaking and applies together with EN 1034-1:2000+A1:2010. It deals with all significant hazards, hazardous situations and hazardous events relevant to roll packaging machines, when used as intended and under the conditions foreseen by the manufacturer (see Clause 4).

This document is not applicable to roll packaging machines which are manufactured before the date of publication as an EN.

Sicherheit von Maschinen - Sicherheitsanforderungen an Konstruktion und Bau von Maschinen der Papierherstellung und Ausrüstung - Teil 26: Rollenpackmaschinen

Die vorliegende Europäische Norm gilt für Rollenpackmaschinen, die in der Papierherstellung verwendet werden, und gilt zusammen mit EN 1034-1:2000+A1:2010. Sie behandelt alle signifikanten Gefährdungen, Gefährdungssituationen und Gefährdungsereignisse für Rollenpackmaschinen, die bestimmungsgemäß und unter den vom Hersteller vorzusehenden Bedingungen verwendet werden (siehe Abschnitt 4). Diese Norm gilt nicht für Rollenpackmaschinen, die vor dem Datum der Veröffentlichung als Europäische Norm hergestellt wurden.

Sécurité de machines - Exigences techniques de sécurité pour la conception et la construction de machines de fabrication et de finition du papier - Partie 26: Machines à emballer les bobines

La présente Norme européenne s'applique aux machines à emballer les bobines utilisées dans la fabrication du papier et s'applique conjointement avec l’EN 1034-1:2000+A1:2010. Elle traite de l’ensemble des phénomènes dangereux et situations et événements dangereux significatifs qui concernent les machines à emballer les bobines, quand celles-ci sont utilisées conformément à leur destination et dans les conditions prévues par le fabricant (voir Article 4).

Le présent document ne s’applique pas aux machines à emballer les bobines fabriquées avant sa date de publication en tant que norme EN.

Varnost strojev - Varnostne zahteve za načrtovanje in konstrukcijo strojev in opreme za izdelavo papirja - 26. del: Stroji za pakiranje zvitkov

Ta evropski standard se nanaša na stroje za pakiranje zvitkov, ki se uporabljajo pri izdelavi papirja, in se uporablja skupaj s standardom EN 1034-1:2000+A1:2010. Obravnava vsa večja tveganja, nevarne razmere in dogodke v zvezi s stroji za pakiranje zvitkov, ki se uporabljajo v skladu z namenom in pod pogoji, ki jih je predvidel proizvajalec (glej točko 4). Ta dokument se ne uporablja za stroje za pakiranje zvitkov, ki so bili izdelani, preden je bil objavljen kot standard EN.

General Information

- Status

- Published

- Public Enquiry End Date

- 06-Jun-2010

- Publication Date

- 07-Jun-2012

- Technical Committee

- GRT - Graphical technology

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 01-Jun-2012

- Due Date

- 06-Aug-2012

- Completion Date

- 08-Jun-2012

Overview

EN 1034-26:2012 - published by CEN - is the Type C European standard that specifies safety requirements for the design and construction of roll packaging machines used in papermaking. It is to be applied together with EN 1034-1:2000+A1:2010 (common requirements for paper-making and finishing machines). The standard addresses all significant hazards, hazardous situations and events relevant to roll packaging machines when used as intended and under manufacturer‑foreseen conditions. It is not applicable to machines manufactured before its publication as an EN.

Key topics and technical requirements

EN 1034-26 covers a comprehensive set of safety topics, including:

- Risk assessment principles (as a Type C standard aligned with EN ISO 12100)

- List of significant hazards and required safety functions (see Tables in the standard)

- Machine access and workplaces: stairs, catwalks, walkways and ergonomic design

- Emergency stop and control‑interface requirements (EN ISO 13850, ergonomic standards)

- Control systems and actuators: functional safety considerations (EN ISO 13849, EN 62061)

- Isolation and prevention of unexpected start‑up (EN 1037 principles)

- Make‑ready and maintenance: safe procedures and guards

- Noise, lighting and ergonomic principles (EN 13023, EN 1837, EN 614 series)

- Electrical, hydraulic and pneumatic safety (EN 60204‑1, EN ISO 4413, EN ISO 4414)

- Power transmission, hot surfaces and fire prevention (EN ISO 13732, EN 13478)

- Specific packaging components: packaging unit, folding devices, head‑disc presses, unwinds, traversing unwinds, integrated conveyors, roll pushers/stoppers, centring stations, threading, cutting and edge‑trimming devices, automatic labelling, robots (EN ISO 10218)

- Electro‑sensitive protective devices (ESPDs) and muting guidance (informative Annex B)

- Verification and validation methods and required information for use, instruction handbook and marking

- Relationship with Machinery Directive (2006/42/EC) covered in informative Annex ZA

Practical applications and intended users

Who uses EN 1034-26:

- Machine designers and manufacturers of roll packaging equipment for the paper industry

- System integrators and robotics integrators working with packaging lines

- Safety and compliance engineers preparing CE marking documentation and risk assessments

- Plant owners, maintenance teams and safety officers implementing safe operation and maintenance procedures

- Notified bodies and inspectors evaluating conformity to EU requirements

Practical uses:

- Designing machine safeguards, control architectures and emergency systems

- Selecting and validating safety components (ESPDs, interlocks, safety PLCs)

- Preparing instruction manuals, marking and verification test plans

- Ensuring conformity with EU Machinery Directive and related standards referenced in EN 1034-26

Related standards (selected)

- EN 1034-1:2000+A1:2010 (common requirements)

- EN ISO 12100, EN ISO 13849-1/-2, EN 62061 (functional safety)

- EN 60204-1 (electrical equipment)

- EN ISO 10218 (industrial robots)

- EN 614 series (ergonomics), EN 13023 (noise), EN 13478 (fire)

Keywords: EN 1034-26, roll packaging machines, paper industry safety, CEN standard, machine safety, packaging unit, electrosensitive protective devices, functional safety, Machinery Directive.

Frequently Asked Questions

SIST EN 1034-26:2012 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Safety of machinery - Safety requirements for the design and construction of paper making and finishing machines - Part 26: Roll packaging machines". This standard covers: This European Standard applies to roll packaging machines for use in papermaking and applies together with EN 1034-1:2000+A1:2010. It deals with all significant hazards, hazardous situations and hazardous events relevant to roll packaging machines, when used as intended and under the conditions foreseen by the manufacturer (see Clause 4). This document is not applicable to roll packaging machines which are manufactured before the date of publication as an EN.

This European Standard applies to roll packaging machines for use in papermaking and applies together with EN 1034-1:2000+A1:2010. It deals with all significant hazards, hazardous situations and hazardous events relevant to roll packaging machines, when used as intended and under the conditions foreseen by the manufacturer (see Clause 4). This document is not applicable to roll packaging machines which are manufactured before the date of publication as an EN.

SIST EN 1034-26:2012 is classified under the following ICS (International Classification for Standards) categories: 13.110 - Safety of machinery; 21.020 - Characteristics and design of machines, apparatus, equipment; 85.100 - Equipment for the paper industry. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 1034-26:2012 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC; Standardization Mandates: M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 1034-26:2012 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Sicherheit von Maschinen - Sicherheitsanforderungen an Konstruktion und Bau von Maschinen der Papierherstellung und Ausrüstung - Teil 26: RollenpackmaschinenSécurité de machines - Exigences techniques de sécurité pour la conception et la construction de machines de fabrication et de finition du papier - Partie 26: Machines à emballer les bobinesSafety of machinery - Safety requirements for the design and construction of paper making and finishing machines - Part 26: Roll packaging machines85.100Oprema za papirno industrijoEquipment for the paper industry21.020Characteristics and design of machines, apparatus, equipment13.110Varnost strojevSafety of machineryICS:Ta slovenski standard je istoveten z:EN 1034-26:2012SIST EN 1034-26:2012en,fr,de01-julij-2012SIST EN 1034-26:2012SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1034-26

April 2012 ICS 85.100 English Version

Safety of machinery - Safety requirements for the design and construction of paper making and finishing machines - Part 26: Roll packaging machines

Sécurité des machines - Prescriptions de sécurité pour la conception et la construction de machines de fabrication et de finition du papier - Partie 26: Machines à emballer les bobines

Sicherheit von Maschinen - Sicherheitstechnische Anforderungen an Konstruktion und Bau von Maschinen der Papierherstellung und Ausrüstung - Teil 26: Rollenpackmaschinen This European Standard was approved by CEN on 19 February 2012.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2012 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1034-26:2012: ESIST EN 1034-26:2012

Figures . 18Annex B (informative)

Muting of electrosensitive protective devices on paper making and paper finishing machines . 22SIST EN 1034-26:2012

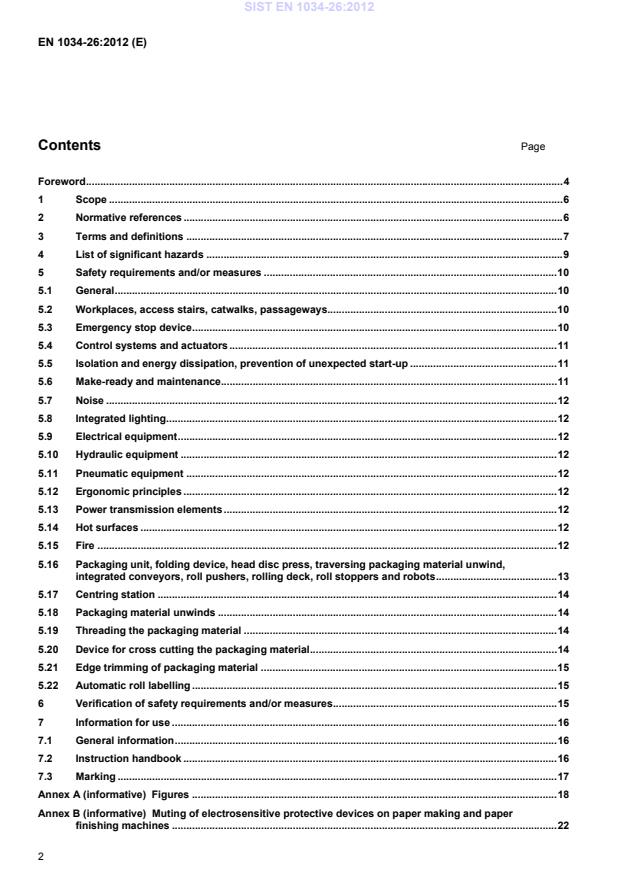

Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC . 24 FiguresFigure A.1 — Example of a roll packaging machine with robots . 18Figure A.2 — Example of a roll packaging machine with robots. 19Figure A.3 — Principle of a roll packaging machine with a traversing unwind for spiral winding of the packaging material web . 20Figure A.4 — Example of a roll packaging machine with four wrapping paper unwinds . 21Figure B.1 — Equipment (paper roll turner) provided with electrosensitive protective devices (ESPDs) which are muted for letting pass a paper roll . 23Figure B.2 — Muting principle of an ESPD with a laser scanner. 23 Tables Table 1 — List of significant hazards (1 of 2) . 9Table 1 (2 of 2) . 10Table 2 — List of safety functions, Performance Level and Safety Integrity Level specified in this standard . 11Table 3 — Methods used to verify safety requirements and/or protective measures . 16 SIST EN 1034-26:2012

EN ISO 12100:2010 and the following apply: 3.1 roll packaging machine machine used for packaging paper rolls; the rolls are mounted on supporting drums and their axial rotational movement causes them to be wrapped with a paper or plastic web and, where applicable, head discs (cardboard discs) are finally applied to the ends of the rolls by pressing and gluing, consisting of several machine sections/functional units including packaging material unwind(s), packaging unit, folding device, head disc press, rolls for pulling the packaging material, integrated conveyors, robots, roll pusher, roll stopper, drives and control system

3.2 roll paper roll 3.3 packaging material unwind unwind for rolls of packaging paper or plastic film 3.4 packaging unit unit with supporting drums allowing rotation of the roll for packaging 3.5 folding device device usually with rotating and pivoted paddles for folding packaging paper side laps over rolls 3.6 centring station unit for moving the rolls in the direction of the axle for centring them before the packaging process 3.7 head disc press device for pressing and affixing the head discs provided with for example, glue or hotmelt glue onto the roll ends 3.8 head disc round disc cut from paper or cardboard

3.9 roll pusher device for pushing rolls so that they roll to another position 3.10 roll stopper device for catching and retaining the rolling roll so that it stops in a specified position 3.11 rolling deck area where the rolls roll by impact from a roll pusher or by gravity to a roll stopper

3.12 roll-in-area area where the rolls are transported e.g. by a conveyor into the roll packaging machine 3.13 roll-out-area area where the rolls are transported e.g. by a conveyor out of the roll packaging machine 3.14 integrated conveyor conveyor for roll handling in the area of the roll packaging machine 3.15 labelling station station intended for marking the rolls or for applying labels onto the rolls manually or in an automatic operation e.g. using a robot SIST EN 1034-26:2012

Table 1 — List of significant hazards (1 of 2) No Hazard sub-clause of this standard EN 1034-1:2000+A1:2010 Origin (source) Potential consequences

Mechanical hazards

1 Inadequate design of workplaces, means of access, walkways, passageways Slipping, tripping and falling, fractures of arms and legs, injury of head by impact 5.2; 5.18.1; 5.19.2 5.5; 5.5.9 2 Inrunning nips on conveyors, rotating rolls and drums, rollers

Wrapping points on transmissions elements Drawing-in or trapping, crushing, amputation

5.3; 5.13; 5.16.1; 5.16.2; 5.19.3 5.1; 5.4; 5.7 3 Linear movements of machinery parts Crushing, shearing, impact injuries, contusion 5.3; 5.16.1; 5.16.2; 5.17; 5.22.2 5.1; 5.3; 5.7 4 Swivelling machinery parts Shearing, crushing injuries 5.3; 5.16.1; 5.16.2; 5.22.1 5.1; 5.7 5 Knives, sharp edges of machinery frame Cutting injuries 5.1; 5.20; 5.21.1; 5.21.2 5.1; 5.11; 5.12 6 Movement of

rolls

Crushing, impact injuries

5.16.1; 5.16.3 5.1 7 Hydraulic and pneumatic equipment Injuries by ejection of high-pressure fluids 5.10; 5.11 5.24; 5.25 8 Ejection and falling of machinery parts Crushing, impact of persons 5.18.3 5.2

Electrical hazards

9 Electrical equipment Electric shock, death, fire, burning and blinding by electric arc 5.9.1 5.23 10 Electrical equipment Outside effects on electrical equipment 5.9.2 5.23

Thermal hazards

11 Hot surfaces of machinery parts, head disc press, hotmelt glue jets Burning by contact of persons 5.14; 5.16.1 5.17

Noise hazards

12 drives, power transmission elements, hydraulic aggregate

Hearing loss, stress, interference with speech communication and acoustic signals 5.7 5.15

13 Paper, leakage of hydraulic and lubrication oil, material of electrical equipment Fire 5.9; 5.15 5.19; 5.23

Hazards generated by neglecting ergonomic principles

14 Neglect of ergonomic principles Discomfort, fatigue, stress, overload 5.18.2; 5.19.2 5.22 15 Inadequate lighting of the workplace Blinding, falling, stress 5.8 5.18

Hazards caused by failure of energy supply, control system and other functional disorders

16 Unexpected start-up Crushing, shearing, impact 5.5; 5.6 5.6; 5.8 17 Malfunction in the control system Crushing, shearing, impact 5.3.2; 5.4.1; 5.4.2; 5.4.3; 5.6; 5.16.1; 5.16.3; 5.17; 5.18.3; 5.19.3; 5.20 5.14

Combination of hazards

18 Combination of hazards Drawing-in, crushing, shearing, impact 5.3; 5.6; 5.16.1; 5.16.2; 5.16.4; 5.19.1 5.7 5 Safety requirements and/or measures 5.1 General The machine shall comply with the safety requirements and/or protective measures of Clause 5. In addition, the machine shall be designed according to the principles of EN ISO 12100 for hazards relevant but not significant which are not dealt with by this standard (for example, sharp edges of the machine frame). The common requirements of EN 1034-1:2000+A1:2010 shall also be satisfied unless amended by this clause.

For further guidance in connection with inherently safe design measures, see 6.2 of EN ISO 12100:2010 and for safeguarding measures, see 6.3 of EN ISO 12100:2010. 5.2 Workplaces, access stairs, catwalks, passageways Workplaces, access stairs, catwalks and passageways shall comply with 5.5 of EN 1034-1:2000+A1:2010,

EN ISO 14122-2:2001 and EN ISO 14122-3:2001. 5.3

Emergency stop device 5.3.1 An emergency stop device with a sufficient number of appropriately positioned, manually applied actuators (e.g. mushroom-head buttons) shall be provided and shall comply with the requirements of 5.7 of EN 1034-1:2000+A1:2010 and EN ISO 13850:2008. The emergency stop function shall act on all hazards of the machine including the integrated conveyors and robots.

5.3.2 The control system of the emergency stop device shall comply with at least Performance Level PL d of EN ISO 13849-1:2008 or Safety Integrity Level SIL 2 of EN 62061:2005. 5.3.3 In addition to emergency stop manual actuators provided on the control panels of the machine, such actuators shall also be located in the vicin

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...