SIST EN 1034-3:2012

(Main)Safety of machinery - Safety requirements for the design and construction of paper making and finishing machines - Part 3: Rereelers and winders

Safety of machinery - Safety requirements for the design and construction of paper making and finishing machines - Part 3: Rereelers and winders

This European Standard applies to rereelers and winders and applies together with

EN 1034-1:2000+A1:2010. It deals with all significant hazards, hazardous situations and hazard events relevant to machines for the production of paper and board, when used as intended and under the conditions foreseen by the manufacturer (see Clause 4).

This European Standard does not apply to machines used in paper converting.

This European Standard is not applicable to rereelers and winders which are manufactured before the date of publication as an EN.

Sicherheit von Maschinen - Sicherheitsanforderungen an Konstruktion und Bau von Maschinen der Papierherstellung und Ausrüstung - Teil 3: Umroller und Rollenschneider

Diese Europäische Norm gilt für Umroller und Rollenschneidemaschinen und gilt zusammen mit EN 1034-1:2000+A1:2010. Sie behandelt alle signifikanten Gefährdungen, Gefährdungssituationen und Gefährdungs-ereignisse für Umroller und Rollenschneidemaschinen, die bestimmungsgemäß und unter den vom Hersteller vorherzusehenden Bedingungen verwendet werden (siehe Abschnitt 4). Diese Europäische Norm gilt nicht für Maschinen der Papierverarbeitung. Diese Europäische Norm gilt nicht für Umroller und Rollenschneidemaschinen, die vor dem Datum der Veröf-fentlichung als europäische Norm hergestellt wurden.

Sécurité de machines - Exigences techniques de sécurité pour la conception et la construction de machines de fabrication et de finition du papier - Partie 3 : Visiteuses et bobineuses

La présente Norme européenne s'applique aux bobineuses et aux visiteuses et complète

l'EN 10341:2000+A1:2010. Elle traite tous les phénomènes, situations et événements dangereux significatifs

applicables aux bobineuses et aux visiteuses, lorsqu’elles sont utilisées normalement et dans les conditions

prévues par le fabricant (voir l’Article 4).

La présente Norme européenne ne s’applique pas aux machines de transformation du papier.

De plus, elle n’est pas applicable aux bobineuses et aux visiteuses fabriquées avant la date de publication en

tant qu'EN.

Varnost strojev - Varnostne zahteve za načrtovanje in konstrukcijo strojev in opreme za izdelavo papirja - 3. del: Stroji za rezanje in navijanje

Ta evropski standard se uporablja za stroje za rezanje in navijanje ter se uporablja skupaj s standardom EN 1034-1 2000+A1:2010. Opisuje večja tveganja, nevarne situacije in nevarne dogodke v zvezi s stroji za izdelavo papirja in kartona, kadar se uporabljajo v skladu z njihovim namenom in pod pogoji, ki jih določa proizvajalec (glejte točko 4).

Ta evropski standard se ne uporablja za stroje, ki se uporabljajo za obdelavo papirja. Ta evropski standard se ne uporablja za stroje za rezanje in navijanje, ki so bili izdelani, preden je bil objavljen kot standard EN.

General Information

- Status

- Published

- Publication Date

- 09-Jan-2012

- Technical Committee

- GRT - Graphical technology

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 05-Jan-2012

- Due Date

- 11-Mar-2012

- Completion Date

- 10-Jan-2012

Relations

- Effective Date

- 01-Feb-2012

Overview

EN 1034-3:2011 - issued by CEN - is the European safety standard for the design and construction of rereelers and winders used in paper and board production. It is Part 3 of the EN 1034 series and is intended to be applied together with EN 1034-1:2000+A1:2010 (common requirements). The standard addresses all significant hazards, hazardous situations and events relevant to rereelers and winders when used as intended and under manufacturer‑foreseen conditions. It does not apply to paper converting machines or machines manufactured before the EN publication date.

Key Topics

This standard defines practical safety requirements covering the full machine lifecycle and includes:

- Risk reduction and design principles - as a Type C standard, it complements EN 1034-1 and takes precedence over Type A/B standards where differences exist.

- List of significant hazards and specified safety functions (see Table of hazards and safety functions in the standard).

- Safety-related control systems - requirements aligned with EN ISO 13849-1 and EN 62061 for Performance Level (PL) and Safety Integrity Level (SIL).

- Protective devices and guarding - fixed/movable guards, interlocks, captive fastenings and prevention of unexpected start-up.

- Emergency stop, braking and isolation - design and verification of emergency stop systems and energy dissipation measures.

- Machine subsystems - detailed requirements for unwind, web threading, slitting, windup, web cutting, slitter scrap removal and shredders.

- Drive systems and power transmission - electrical, hydraulic and pneumatic equipment, electric drives, mechanical brakes and locking arrangements.

- Human factors - workstations, means of access, lighting, noise, ergonomics and maintenance/cleaning provisions.

- Verification and documentation - testing, verification of compliance and required information for use, marking and instruction handbooks.

- Annexes - informative figures illustrating rereeler and winder types and an Annex ZA relating the standard to EU Machinery Directive 2006/42/EC.

Applications and Who Uses It

EN 1034-3:2011 is used by:

- Machine manufacturers and designers to develop safe rereelers and winders and to meet CE compliance.

- Safety engineers and integrators for specifying safety functions, controls and guarding.

- Plant managers and maintenance personnel to ensure safe operation, maintenance, cleaning and changeover procedures.

- Notified bodies and conformity assessors for verification against Directive 2006/42/EC (see Annex ZA).

Practical applications include specifying guard systems, emergency stop architectures, control‑system safety levels (PL/SIL), safe threading mechanisms, integrated embossing calendars on tissue winders, pulper integration and shredder safety for trimmed material.

Related Standards

EN 1034-3 references and works with other standards such as:

- EN 1034-1 (Common requirements)

- EN ISO 12100 (Risk assessment)

- EN ISO 13849-1 / EN 62061 (Control system safety)

- EN 60204-1 (Electrical equipment)

- EN ISO 4413 / 4414 (Hydraulic/pneumatic systems)

- Machinery Directive 2006/42/EC (via Annex ZA)

Using EN 1034-3:2011 helps ensure that rereelers and winders meet current European safety expectations for paper‑making equipment design, operation and verification.

Frequently Asked Questions

SIST EN 1034-3:2012 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Safety of machinery - Safety requirements for the design and construction of paper making and finishing machines - Part 3: Rereelers and winders". This standard covers: This European Standard applies to rereelers and winders and applies together with EN 1034-1:2000+A1:2010. It deals with all significant hazards, hazardous situations and hazard events relevant to machines for the production of paper and board, when used as intended and under the conditions foreseen by the manufacturer (see Clause 4). This European Standard does not apply to machines used in paper converting. This European Standard is not applicable to rereelers and winders which are manufactured before the date of publication as an EN.

This European Standard applies to rereelers and winders and applies together with EN 1034-1:2000+A1:2010. It deals with all significant hazards, hazardous situations and hazard events relevant to machines for the production of paper and board, when used as intended and under the conditions foreseen by the manufacturer (see Clause 4). This European Standard does not apply to machines used in paper converting. This European Standard is not applicable to rereelers and winders which are manufactured before the date of publication as an EN.

SIST EN 1034-3:2012 is classified under the following ICS (International Classification for Standards) categories: 13.110 - Safety of machinery; 21.020 - Characteristics and design of machines, apparatus, equipment; 85.100 - Equipment for the paper industry. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 1034-3:2012 has the following relationships with other standards: It is inter standard links to SIST EN 1034-3:2000+A1:2010. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 1034-3:2012 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC; Standardization Mandates: M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 1034-3:2012 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.MHSicherheit von Maschinen - Sicherheitsanforderungen an Konstruktion und Bau von Maschinen der Papierherstellung und Ausrüstung - Teil 3: Umroller und RollenschneiderSécurité de machines - Exigences techniques de sécurité pour la conception et la construction de machines de fabrication et de finition du papier - Partie 3 : Visiteuses et bobineusesSafety of machinery - Safety requirements for the design and construction of paper making and finishing machines - Part 3: Rereelers and winders85.100Oprema za papirno industrijoEquipment for the paper industry21.020Characteristics and design of machines, apparatus, equipment13.110Varnost strojevSafety of machineryICS:Ta slovenski standard je istoveten z:EN 1034-3:2011SIST EN 1034-3:2012en,de01-februar-2012SIST EN 1034-3:2012SLOVENSKI

STANDARDSIST EN 1034-3:2000+A1:20101DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1034-3

December 2011 ICS 85.100 Supersedes EN 1034-3:1999+A1:2009English Version

Safety of machinery - Safety requirements for the design and construction of paper making and finishing machines - Part 3: Rereelers and winders

Sécurité de machines - Exigences techniques de sécurité pour la conception et la construction de machines de fabrication et de finition du papier - Partie 3 : Visiteuses et bobineuses

Sicherheit von Maschinen - Sicherheitsanforderungen an Konstruktion und Bau von Maschinen der Papierherstellung und Ausrüstung - Teil 3: Umroller und Rollenschneider This European Standard was approved by CEN on 29 October 2011.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2011 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1034-3:2011: ESIST EN 1034-3:2012

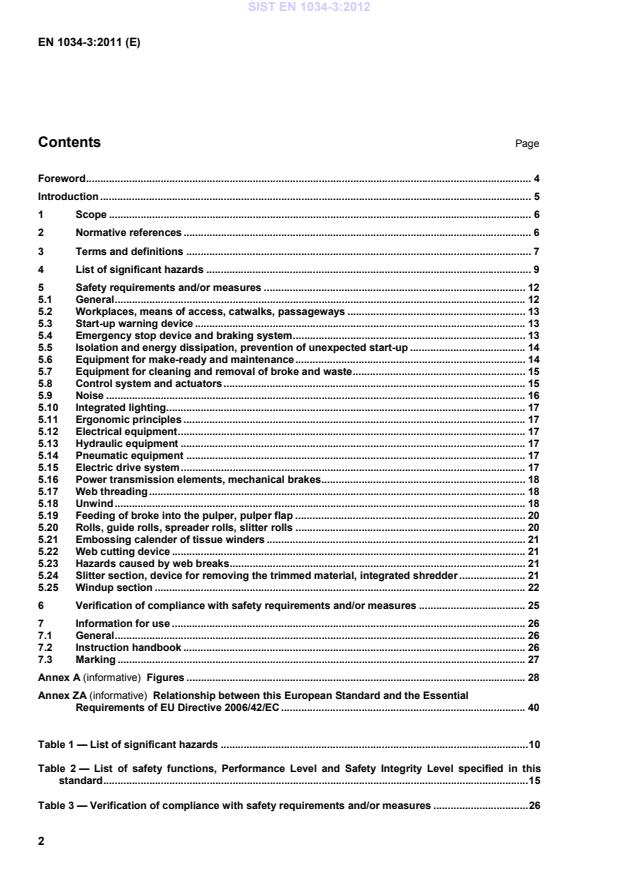

Figures . 28Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC . 40 Table 1 — List of significant hazards . 10Table 2 — List of safety functions, Performance Level and Safety Integrity Level specified in this standard . 15Table 3 — Verification of compliance with safety requirements and/or measures . 26SIST EN 1034-3:2012

Figure A.1 — Principle of a rereeler . 28Figure A.2 — Principle of a two-drum winder . 29Figure A.3 — Principle of a two-drum winder for narrow slitting width . 30Figure A.4 — Principle of a two-drum winder . 31Figure A.5 — Principle of a two-drum winder with an integrated pulper and reel spool storage . 32Figure A.6 — Principle of a single-drum bobbin winder with centre-surface drive . 33Figure A.7 — Principle of a single-drum winder with centre-drive . 34Figure A.8— Principle of a centre driven winder with single contact rolls . 35Figure A.9 — Principle of a winder with machine reel- and reel spool storage . 36Figure A.10 — Principle of a single-drum centre-driven winder . 37Figure A.11 — Principle of a tissue winder (plying machine) . 38Figure A.12 — Example for a tool for changing slitter knives . 39Figure A.13 — Examples for shell and bearing supports, a) without locking arm, b) with locking arm39

EN 1034-1:2000+A1:2010. It deals with all significant hazards, hazardous situations and hazard events relevant to rereelers and winders, when used as intended and under the conditions foreseen by the manufacturer (see Clause 4). This European Standard does not apply to machines used in paper converting. This European Standard is not applicable to rereelers and winders which are manufactured before the date of publication as an EN. 2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 349, Safety of machinery — Minimum gaps to avoid crushing of parts of the human body EN 953:1997+A1:2009, Safety of machinery — Guards — General requirements for the design and construction of fixed and movable guards EN 1034-1:2000+A1:2010, Safety of machinery — Safety requirements for the design and construction of paper making and finishing machines — Part 1: Common requirements EN 1034-4:2005+A1:2009, Safety of machinery — Safety requirements for the design and construction of paper making and finishing machines — Part 4: Pulpers and their loading facilities EN 1034-6, Safety of machinery — Safety requirements for the design and construction of paper making and finishing machines — Part 6: Calender EN 1037, Safety of machinery — Prevention of unexpected start-up EN 1088, Safety of machinery — Interlocking devices associated with guards — Principles for design and selection EN 1760-1, Safety of machinery — Pressure sensitive protective devices — Part 1: General principles for the design and testing of pressure sensitive mats and pressure sensitive floors EN 1760-2, Safety of machinery — Pressure sensitive protective devices — Part 2: General principles for the design and testing of pressure sensitive edges and pressure sensitive bars EN 1837, Safety of machinery — Integral lighting of machines EN 13023, Noise measurement methods for printing, paper converting, paper making machines and auxiliary equipment — Accuracy grades 2 and 3 EN 60204-1:2006, Safety of machinery — Electrical equipment of machines — Part 1: General requirements (IEC 60204-1:2005, modified) EN 60204-11, Safety of machinery — Electrical equipment of machines — Part 11: Requirements for HV equipment for voltages above 1 000 V a.c. or 1 500 V d.c. and not exceeding 36 kV (IEC 60204-11:2000) EN 60529:1999, Degrees of protection provided by enclosures (IP code) SIST EN 1034-3:2012

3.10 chain-type threading system threading system using synchronously revolving chains on both tending and drive side. For threading, a rod equalling in length the width of the machine is connected to the chains with the machine in standstill. The web end is then fixed to the rod and the rod pulls the web through the machine 3.11 paper rolls rolls, made in the wind up section of a winder, by winding up the paper webs onto cores or onto a winding shaft or by winding up the paper web in the wind up section of a rereeler onto a reel spool 3.12 reel spool drum with shaft and clutch, for wind up and unwind the paper web

4 List of significant hazards This clause contains all significant hazards, hazardous situations and hazard events, as far as they are dealt with in this standard, which are identified by risk assessment as significant for this type of machinery and which require action to eliminate or reduce the risk.

HazardSubclause of this standard Subclause of EN 1034-1:2000+A1:2010 No. Kind or group Origin (sources) Potential consequences 1 Mechanical hazards Inadequate design of workplaces, means of access, catwalks, passageways, fall-off protection Slipping, tripping and falling 5.2.1; 5.2.2; 5.2.3; 5.19.1; 5.20.4 5.5 Less clear passage height over platforms and walkways Impact hazards for the head, contusion 5.2.2 5.5.9 Ingoing nips and wrapping points on rotating drums, rolls, machine reels and paper rolls, power transmission elements, chains, belts; unwind, windup section, embossing calender Drawing-in or trapping 5.4; 5.16.1; 5.17.2; 5.17.2; 5.18.1; 5.18.2; 5.18.3; 5.20.1; 5.20.2; 5.20.3; 5.21; 5.24.4; 5.25.1; 5.25.13 5.1; 5.2; 5.4; 5.7 Running rolls Falling onto running rolls5.20.4 5.5 Linear and swivelling movements of machinery parts Crushing and shearing of hands, arms or legs 5.4; 5.17.3; 5.18.2; 5.18.3; 5.18.4; 5.18.8; 5.18.9; 5.19.2; 5.24.3; 5.25.1; 5.25.2; 5.25.3; 5.25.4; 5.25.7; 5.25.8; 5.25.9; 5.25.10; 5.25.12; 5.25.13 5.1; 5.3; 5.7 Slitter knives, shredder, sharp edge of the frame, web cutting device Cutting 5.1; 5.6.2; 5.22; 5.24.1; 5.24.2; 5.24.5; 5.24.6; 5.25.12 5.1; 5.11; 5.12 Hydraulic equipment

Ejection of high-pressure fluids 5.13 5.24 SIST EN 1034-3:2012

HazardSubclause of this standard Subclause of EN 1034-1:2000+A1:2010 No. Kind or group Origin (sources)Potential consequences

Pneumatic equipment Ejection of high-pressure fluids 5.14 5.25 Unwind, ejection of machine reels Impact and crushing persons 5.18.5; 5.18.6; 5.18.10

Windup section, ejection of paper rolls Impact and crushing persons 5.25.5; 5.25.6; 5.25.11; 5.25.12

Reel spool change by crane Overload, damage, falling of machinery parts 5.18.6; 5.18.7

Ejection of disengaged slitter or pieces of shattered slitter Impact and cutting persons Clause 7

Ejection of damaged core in shaftless unwind section

Impact

5.18.11

Ejection of cores in shaftless windup section Impact 5.25.3

2 Electrical hazards Electrical equipment

Electric shock, death by electric shock, fire, outside effects on electrical equipment 5.12.1; 5.12.2 5.23 3 Thermical hazards Hot surfaces Burning by contact 5.16.2 5.17 4 Noise hazards Drives, power transmissions elements, unwind, slitter section, wind up, trim removal devices, shredder, hydraulic aggregate Hearing loss or other physical disorders, interference with speech communication and acoustic signals 5.9 5.15 5 Material and substances hazards

Paper Fire

5.10.2 5.19 Paper dust Fire and explosion 5.10.2 5.13; 5.16; 5.19

Web break Impact persons, head, eyes 5.23

Dust from brake pads Illness by dust 5.16.3

Wrapping points of strong web on rolls

Drawing in of hands 5.20.2

HazardSubclause of this standard Subclause of EN 1034-1:2000+A1:2010 No. Kind or group Origin (sources) Potential consequences 6 Hazards generated by neglecting ergonomic principles Neglecting ergonomic principles in the design of workplaces e.g.: placing of reels into unwind stands; threading of the web; placing of cores into windup units; removal of shafts/cores from unwind stands; removal of broke Discomfort, fatigue, stress, overload 5.11 5.22 Inadequate lighting of the workplace Slipping, tripping, falling, blinding, stress 5.10 5.18 7 Hazards generated by failure of energy supply, control system and other functional disorders Unexpected start-up Impact of person, drawing-in or trapping, crushing and/or shearing of body parts 5.3.1; 5.3.2; 5.5; 5.13; 5.14 5.6; 5.8 Malfunction in the control system

Impact of person, drawing-in or trapping, crushing and/or shearing of body parts, overturn 5.3.2; 5.4.4; 5.4.5; 5.5.3; 5.6.3; 5.8.1; 5.8.2; 5.15.1; 5.15.2; 5.17.3; 5.18.1; 5.18.3; 5.18.4; 5.18.5; 5.18.8; 5.18.9; 5.18.10; 5.19.2; 5.22; 5.24.3; 5.24.6; 5.25.1; 5.25.2; 5.25.3; 5.25.4; 5.25.5; 5.25.6; 5.25.7; 5.25.9; 5.25.10; 5.25.11; 5.25.12 5.14 8 Combination of hazards Make-ready, maintenance, cleaning, removal of broke Slipping, tripping and falling, drawing in, cutting 5.6; 5.7; 5.17.1; 5.25.12 5.6; 5.7

5 Safety requirements and/or measures 5.1 General The machine shall comply with the safety requirements and/or protective measures of Clause 5 and the requirements of EN 1034-1:2000+A1:2010. For guidance in connection with risk reduction, see EN ISO 12100:2010, 6.2, and for safeguarding measures, see EN ISO 12100:2010, 6.3.

5.2.2 The clear passage height over platforms and walkways shall be at least 2,10 m, in deviation from 5.5.9 of EN 1034-1:2000+A1:2010. Where this requirement can exceptionally not be satisfied for constructional reasons, the resultant danger points shall be provided with padding with black/yellow danger marking. 5.2.3 The clear walking width of walkways and working platforms shall when possible be at least 0,80 m in accordance with EN ISO 14122-2:2001. If this is not achievable, the clear walking width shall be at least 0,60 m. Where this requirement cannot be complied with for design or constructional reasons, 5.5.6 of EN 1034-1:2000+A1:2010 shall be satisfied. 5.3 Start-up warning device 5.3.1 A start-up warning device shall be provided. It shall comply with category B specified in 5.6 of EN 1034-1:2000+A1:2010. 5.3.2 The safety-related control system connecting the actuator and the sounder shall comply with at least Performance Level PL c of EN ISO 13849-1:2008 or Safety Integrity Level SIL 1 according to EN 62061:2005.

5.4 Emergency stop device and braking system 5.4.1 An emergency stop device shall be provided. It shall comply with the requirements of EN ISO 13850, 5.7 of EN 1034-1:2000+A1:2010 and 10.7 of EN 60204-1:2006. The emergency stop function shall act on all hazards of the machine including the integrated conveyors and integrated pulpers. 5.4.2 The emergency stop function shall be available and operational at all times, regardless of the operating mode.

5.4.3 Machines shall be fitted with braking devices for the rolls and drums which operate on the actuation of the emergency stop device, for example mechanical or electro-dynamic brakes. Braking devices shall operate in such a way that the stopping time following actuation of the emergency stop is as short as possible without causing additional hazards. On electrical braking systems, the emergency stop function shall comply with stop category 1 in accordance with 9.2.2 of EN 60204-1:2006. Emergency stop principles shall be made in accordance with 9.2.5.4.2 of EN 60204-1:2006.

5.4.4 Those parts of the control system used for the emergency stop function of the roll and drum drives shall comply with at least Performance Level PL d of EN ISO 13849-1:2008 or Safety Integrity Level SIL 2 according to EN 62061:2005.

5.4.5 Those parts of the control system used for the emergency stop function for linear or swivelling movements of machinery parts with hydraulic, pneumatic or electrical drives, e.g.: machine reel handling devices in the unwind section or in the near vicinity (automatic crane, lifting table, integrated conveyor, reel pusher), positioning system for the slitting knives, feeding system for the cores, rider roll, SIST EN 1034-3:2012

5.4.6 For placement of emergency stop actuators, the requirements of 5.7 of EN 1034-1:2000+A1:2010 shall be complied with. 5.4.7 Emergency stop actuators shall be designed in accordance with 4.4.1 and 4.4.2 of EN ISO 13850:2008. The requirements of 10.7.3 of EN 60204-1:2006 shall be satisfied. 5.5 Isolation and energy dissipation, prevention of unexpected start-up 5.5.1 For isolation and energy dissipation of electric, pneumatic and hydraulic equipment from their respective power source the devices specified in 5.8 of EN 1034-1:2000+A1:2010 and in EN 1037 shall be provided. 5.5.2 Where the supply disconnecting device according to 5.3 of EN 60204-1:2006 is not arranged in the immediate vicinity of the machine, the main control panel shall be equipped with a device ensuring prevention of unexpected start-up. 5.5.3 Devices for the prevention of unexpected start-up of the roll, drum and reel drives shall be in compliance with 5.8.2 of EN 1034-1:2000+A1:2010. The related control system shall comply with at least Performance Level PL d of EN ISO 13849-1:2008 or Safety Integrity Level SIL 2 of EN 62061:2005. The safety stop with prevention of unexpected start up shall be indicated on the control panel e.g. with a display "drive safe" or with a signal lamp. The light “on” means safe status. The part of the control system, which give the feedback from the "off-position" of the power circuit (main contactor, DC-AC-Converter) in accordance with 5.8.2 b) or 5.8.2 c) of EN 1034-1:2000+A1:2010, shall comply with at least Performance Level PL c of EN ISO 13849-1:2008 or Safety Integrity Level SIL 1 of EN 62061:2005. 5.5.4 For prevention of unexpected start-up following return of power after disruption of supply voltage, the requirements of 7.5 of EN 60204-1:2006 shall be satisfied. 5.5.5 When a part of the machinery has been stopped, any drift away from the stopping position, for whatever reason other than action on the control devices, shall be prevented or the machine shall be designed and constructed in such way that the drift away does not present a hazard. To fulfil this requirement e.g. brakes, self arresting gears or automatic retaining pawls shall be used. 5.6 Equipment for make-ready and maintenance 5.6.1 The requirements laid down in 5.9 of EN 1034-1:2000+A1:2010 shall be satisfied where applicable. 5.6.2 For changing circular knives, tools shall be provided to avoid operator contact. Figure A.12 in Annex A shows an example of a tool for changing slitter knives. 5.6.3 If for make-ready or maintenance movements of machinery parts are required hold-to-run controls shall be provided. Hold-to-run devices shall be located in such a way that the operator has full sight of the danger point. EN ISO 13855 and 5.9.5 of EN 1034-1:2000+A1:2010 shall be applied. The related control system shall comply with at least Performance Level PL c of EN ISO 13849-1:2008 or Safety Integrity Level SIL 1 of EN 62061:2005. SIST EN 1034-3:2012

The requirements of 5.10 of EN 1034-1:2000+A1:2010 shall be satisfied. 5.8 Control system and actuators 5.8.1 The requirements of 5.14 of EN 1034-1:2000+A1:2010 shall be satisfied. Actuators provided for starting hazardous movements shall be safeguarded against inadvertent actuation. Control devices shall be clearly visible and identifiable, using pictograms where appropriate, for example using marking in accordance to 10.2.2 of EN 60204-1:2006. Safety-related parts of the control system shall satisfy the requirements of the following standards: • EN ISO 13849-1 and EN ISO 13849-2 or - for electric/electronic control systems; • EN 62061. For the recommended application of EN 13849-1 and EN 62061 to hydraulic, pneumatic, electric, electronic and complex electronic systems, see Table 1 of EN ISO 13849-1:2008 and Table 1 of EN 62061:2005. Safety related parts of the control system used to implement the safety functions listed in Table 2 shall comply with the performance levels and safety integrity levels given at Table 2 for each function. Table 2 — List of safety functions, Performance Level and Safety Integrity Level specified in this standard Safety function Clause of this standardPerformance Level (at least) Safety Integrity Level (at least) start-up warning (interlocking function) 5.3.2 PL c SIL 1 emergency stop roll drives 5.4.4 PL d SIL 2 emergency stop linear and swivelling movements 5.4.5 PL c SIL 1 prevention of unexpected start-up of the roll drives 5.5.3 PL d SIL 2 feedback-function of the device for prevention of unexpected start-up 5.5.3 PL c SIL 1 hold to run control for make-ready and maintenance 5.6.3 PL c SIL 1 limiting maximum speed 5.15.1 PL c SIL 1 limiting crawl speed 5.15.2 PL c SIL 1 hold to run control for chain-type threading device 5.17.3

PL

c SIL 1 interlocking of guards on unwind units 5.18.1 PL d SIL 2 hold to run control for positioning the machine roll in crawl speed 5.18.1 PL b SIL 1 interlocking of guards on unwinds tissue winders 5.18.3 PL d SIL 2 interlocking guards and trip devices for in automatic-modus controlled equipment in the unwind 5.18.4 PL d SIL 2 safe guiding of the reels 5.18.5 PL d SIL 2 safeguarding of crushing points (e.g. hold to run control) for core chucks 5.18.8 PL c SIL 1 hold to run control for winding arms 5.18.9 PL c SIL 1 interlocking on shaftless unwinds 5.18.10 PL d SIL 2 SIST EN 1034-3:2012

movement of the pulper flap 5.19.2 PL c SIL 1 safeguarding of web cutting device 5.22 PL c SIL 1 safeguarding of crushing points, created by positioning systems for slitter knives 5.24.3 PL d SIL 2 interlocking of guards on the shredder

5.24.6 PL d SIL 2 interlocking of guards for inrunning nips in the windup section5.25.1 PL d SIL 2 stop function of trip devices and hold to run control for inrunning nips in the windup section 5.25.1 PL d SIL 2 limiting crawl speed 10 m/min (see 5.15.2) 5.25.1 PL c

SIL 1 safeguarding of crushing points created by power driven movable guards on the wind up section 5.25.1 PL c SIL 1 safeguarding of crushing points, created by positioning the windup stations of centre driven winders 5.25.2 PL c SIL 1 safeguarding for engaging core chucks on shaftless windup 5.25.3 PL c SIL 1 limiting of the force for engaging core chucks on shaftless windup 5.25.3 PL b SIL 1 hold to run control for movement of winding arms 5.25.4 PL c SIL 1 interlocking for moving apart of core chucks on rewinding units with shaftless windup 5.25.5 PL d SIL 2 interlocking the containement device on double-drum slitters with shaftless windup 5.25.6 PL d SIL 2 hold to run control for the

movement of the rider roll 5.25.7 PL c SIL 1 trip devices preventing crushing hazards between the paper roll lowering device and floor 5.25.9 PL d SIL 2 interlocking guards and trip devices preventing crushing hazards between the paper roll lowering device and the wind up 5.25.10 PL d SIL 2 interlocking for prevent ejection of paper rolls 5.25.11 PL d SIL 2 safeguarding automatic controlled equipment in the windup section 5.25.12 PL d SIL 2

5.8.2 The validation of safety functions shall be made in accordance with EN ISO 13849-2 or Clause 8 of EN 62061:2005. 5.9 Noise 5.9.1 The requirements of 5.15 of EN 1034-1:2000+A1:2010 shall be satisfied. 5.9.2 Examples of noise reduction measures and points to be considered are: SIST EN 1034-3:2012

5.16 Power transmission elements, mechanical brakes 5.16.1 Safety devices for power transmission elements between motors and rolls, unwind-unit, rewind-unit etc. shall be selected and designed as specified in 5.2 of EN 1034-1:2000+A1:2010. Fixed guards that have to removed periodically for maintenance shall be constructed in such way that their fixing systems remain attached to the guards or to the machinery when the guards are removed. An example is shown in Figure 11 of EN 953:1997+A1:2009. 5.16.2 Hot surfaces of mechanical brakes shall be safeguarded in accordance to 5.17 of

EN 1034-1:2000+A1:2010. 5.17 Web threading 5.17.1 Threading devices such as belt conveyor, compressed air and vacuum-threading systems or chain-type threading systems, shall be provided for safe threading of the web. NOTE Manual guiding of the web with the machine in crawl mode is allowed in areas, where no drawing-in, falling or cutting hazards exist e.g. manually guiding the web from the parent roll in the unwind to the guide and spreader roll and into the threading device situated in the slitter- and upwind-section. 5.17.2 Wrapping points on belts of web threading systems shall be safeguarded in accordance with 5.4.2 of EN 1034-1:2000+A1:2010 and 5.1 of EN 1034-1:2000+A1:2010. Crushing points on adjustable web threading systems shall be avoided in accordance with 5.3 of

EN 1034-1:2000+A1:2010. 5.17.3 The following measures are required on chain-type threading systems: a) All points where chains are wrapped onto drive gearwheels and guide pulleys or rolls shall be safeguarded by fixed guards, for example filler pieces, b) Crushing and shearing points which may be created during threading by the threading rod and fixed machine parts and rolls shall be avoided as far as possible or be safeguarded by safety distances according to EN 349 or guards with safety distances according Table 1 and Table 4 of EN ISO 13857:2008. Where this requirement cannot be satisfied, hold-to-run control shall be provided. Danger points shall be within the operator’s sight. The related control system complying with at least Performance Level PL c of EN ISO 13849-1:2008 or Safety Integrity Level SIL 1 of EN 62061:2005.

5.18 Unwind

5.18.1 On the unwind unit drawing-in hazards between the rotating machine reel and fixed machine parts, the floor, guide rolls and other machine reels shall be avoided by safety-distances according to 5.4.1 of EN 1034-1:2000+A1:2010.

If this requirement cannot be fulfilled the danger area shall be safeguarded by one or a combination of the following safety measures: guards according to 5.4.1 of EN 1034-1:2000+A1:2010, fixed guards, e.g. fence-type enclosures, in accordance with EN 953 and Table 2 and Table 4 of EN ISO 13857:2008, if frequent access is required - movable guards with guard locking and interlocking devices according to EN 1088 interlocked with the energy supply of the unwind drive and in accordance with 5.1.3 of EN 1034-1:2000+A1:2010. Access gates shall be designed and located so that safe access to workplaces is ensured for threading the web. The related control system shall comply with at least Performance Level PL d of EN ISO 13849-1:2008 or Safety Integrity Level SIL 2 of EN 62061:2005, SIST EN 1034-3:2012

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...