IEC 62841-2-14:2015

(Main)Electric motor-operated hand-held tools, transportable tools and lawn and garden machinery - Safety - Part 2-14: Particular requirements for hand-held planers

Electric motor-operated hand-held tools, transportable tools and lawn and garden machinery - Safety - Part 2-14: Particular requirements for hand-held planers

IEC 62841-2-14:2015 applies to hand-held planners the rated voltage is not more than 250 V for single-phase a.c. or d.c. tools, and 480 V for three-phase a.c. tools. The rated input is not more than 3 700 W. The limits for the applicability of this standard for battery tools is given in Annex K. This standard deals with the hazards presented by tools which are encountered by all persons in the normal use and reasonably foreseeable misuse of the tools. Hand-held electric tools, which can be mounted on a support or working stand for use as fixed tools without any alteration of the tool itself, are within the scope of this standard and such combination of a hand-held tool and a support is considered to be a transportable tool and thus covered by the relevant Part 3. The attention of National Committees is drawn to the fact that equipment manufacturers and testing organizations may need a transitional period following publication of a new, amended or revised IEC publication in which to make products in accordance with the new requirements and to equip themselves for conducting new or revised tests. It is the recommendation of the committee that the content of this publication be adopted for implementation nationally not earlier than 36 months from the date of publication. Key words: Planner, Hand held, Cutting head

This publication is to be read in conjunction with IEC 62841-1:2014.

Outils électroportatifs à moteur, outils portables et machines pour jardins et pelouses – sécurité – Partie 2-14: Exigences particulières pour les rabots portatifs

IEC 62841-2-14:2015 s’applique aux rabots portatifs, la tension assignée est inférieure à 250 V pour les outils à courant monophasé alternatif ou continu, et inférieure à 480 V pour les outils à courant alternatif triphasé. La tension assignée est inférieure à 3 700 W. Les limites d'application de la présente Norme aux outils fonctionnant sur batterie sont indiquées en K. La présente Norme traite des dangers présentés par les outils, encourus par tous les individus dans l'utilisation normale et dans l'utilisation impropre raisonnablement prévisible de ces outils. Les outils comportant des éléments chauffants électriques entrent dans le domaine d'application de la présente Norme. Les outils électroportatifs, qui peuvent être montés sur un support de travail pour être utilisés comme outils installés à poste fixe sans aucune modification de l'outil lui-même, sont compris dans le domaine d'application de la présente Norme et la combinaison d'un outil portatif et d'un support est considérée comme un outil portable, donc couvert par la Partie 3 applicable. L’attention des Comités Nationaux est attirée sur le fait que les fabricants d’appareils et les organismes d’essai peuvent avoir besoin d’une période transitoire après la parution d’une nouvelle publication IEC, ou d’une publication amendée ou révisée, pour fabriquer des produits conformes aux nouvelles exigences et pour adapter leurs équipements aux nouveaux essais ou aux essais révisés. Le comité recommande que le contenu de cette publication soit entériné au niveau national au plus tôt 36 mois après la date de publication.

La présente Partie 2-14 doit être utilisée conjointement avec la première édition de l’IEC 62841-1:2014.

Mots clés: rabots, portatif, tête de coupe

General Information

- Status

- Published

- Publication Date

- 24-Jun-2015

- Technical Committee

- TC 116 - Safety of motor-operated electric tools

- Drafting Committee

- WG 8 - TC 116/WG 8

- Current Stage

- PPUB - Publication issued

- Start Date

- 25-Jun-2015

- Completion Date

- 31-Jul-2015

Relations

- Effective Date

- 08-Dec-2023

Overview

IEC 62841-2-14:2015 (with Amendment 1) is the IEC safety standard that specifies particular requirements for hand-held planers - electric motor‑operated tools intended for removing surface material with a rotating cutting head. It applies to single‑phase a.c. or d.c. tools with rated voltage not more than 250 V, three‑phase a.c. tools up to 480 V, and tools with rated input not more than 3 700 W. Battery tool applicability and limits are covered in Annex K. This Part 2-14 is to be read in conjunction with IEC 62841‑1:2014 (general requirements for powered hand tools).

Key topics and technical requirements

- Scope & definitions: Clear definitions for planer, cutting head, and lift‑off device (device preventing blade contact when placing the base on a flat surface).

- Marking & instructions:

- Required markings include rated no‑load speed and direction of rotation (arrow or equivalent).

- Additional user instructions specific to planers (e.g., waiting for cutter to stop, insulated grip recommendations, securing the workpiece).

- Guidance on depth‑of‑cut adjustment, dust collection use, cutting head types, blade changing and blade adjustment, and chip‑ejection cleaning.

- Mechanical and electrical safety: Supplements the general clauses in Part 1 covering protection against live parts, starting, input/current limits, heating, moisture and fire resistance, earthing, internal wiring and component integrity.

- Testing & performance:

- General test conditions and mass definition (tool mass includes cutting head, blades and any dust adapter).

- Annex I addresses noise and vibration measurement; Annexes K and L cover battery tools and battery packs (normative).

- Requirements on mechanical strength, endurance, abnormal operation and overload protection.

- Special features: Requirements for planers that can be mounted on a support (considered transportable tools) and for lift‑off devices where provided.

Practical applications - who uses this standard

- Tool manufacturers and product designers - to design safe hand‑held planers, select/verify cutting heads, and prepare compliant instructions and markings.

- Test labs and certification bodies - to carry out performance, electrical and mechanical safety tests and noise/vibration measurements.

- Regulators and procurement - to specify compliance in safety regulations, tenders and product approval.

- Safety engineers and trainers - to develop safe work procedures, user manuals and training materials based on standardized safety instructions.

Related standards

- IEC 62841‑1:2014 - General requirements for electric motor‑operated hand‑held and transportable tools (read together with Part 2‑14).

- Other parts of the IEC 62841 series cover additional tool types and transportable/fixed tool configurations.

This standard is essential for ensuring the safe design, testing and use of hand‑held planers, addressing hazards from cutting heads, electrical systems, mechanical integrity, and user interaction.

Buy Documents

IEC 62841-2-14:2015 - Electric motor-operated hand-held tools, transportable tools and lawn and garden machinery - Safety - Part 2-14: Particular requirements for hand-held planers Released:6/25/2015 Isbn:9782832227701

IEC 62841-2-14:2015+AMD1:2025 CSV - Electric motor-operated hand-held tools, transportable tools and lawn and garden machinery - Safety - Part 2-14: Particular requirements for hand-held planers Released:2/27/2025 Isbn:9782832702895

IEC 62841-2-14:2015 - Electric motor-operated hand-held tools, transportable tools and lawn and garden machinery - Safety - Part 2-14: Particular requirements for hand-held planers Released:12/12/2017 Isbn:9782832249390

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

UL Solutions

Global safety science company with testing, inspection and certification.

Sponsored listings

Frequently Asked Questions

IEC 62841-2-14:2015 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Electric motor-operated hand-held tools, transportable tools and lawn and garden machinery - Safety - Part 2-14: Particular requirements for hand-held planers". This standard covers: IEC 62841-2-14:2015 applies to hand-held planners the rated voltage is not more than 250 V for single-phase a.c. or d.c. tools, and 480 V for three-phase a.c. tools. The rated input is not more than 3 700 W. The limits for the applicability of this standard for battery tools is given in Annex K. This standard deals with the hazards presented by tools which are encountered by all persons in the normal use and reasonably foreseeable misuse of the tools. Hand-held electric tools, which can be mounted on a support or working stand for use as fixed tools without any alteration of the tool itself, are within the scope of this standard and such combination of a hand-held tool and a support is considered to be a transportable tool and thus covered by the relevant Part 3. The attention of National Committees is drawn to the fact that equipment manufacturers and testing organizations may need a transitional period following publication of a new, amended or revised IEC publication in which to make products in accordance with the new requirements and to equip themselves for conducting new or revised tests. It is the recommendation of the committee that the content of this publication be adopted for implementation nationally not earlier than 36 months from the date of publication. Key words: Planner, Hand held, Cutting head This publication is to be read in conjunction with IEC 62841-1:2014.

IEC 62841-2-14:2015 applies to hand-held planners the rated voltage is not more than 250 V for single-phase a.c. or d.c. tools, and 480 V for three-phase a.c. tools. The rated input is not more than 3 700 W. The limits for the applicability of this standard for battery tools is given in Annex K. This standard deals with the hazards presented by tools which are encountered by all persons in the normal use and reasonably foreseeable misuse of the tools. Hand-held electric tools, which can be mounted on a support or working stand for use as fixed tools without any alteration of the tool itself, are within the scope of this standard and such combination of a hand-held tool and a support is considered to be a transportable tool and thus covered by the relevant Part 3. The attention of National Committees is drawn to the fact that equipment manufacturers and testing organizations may need a transitional period following publication of a new, amended or revised IEC publication in which to make products in accordance with the new requirements and to equip themselves for conducting new or revised tests. It is the recommendation of the committee that the content of this publication be adopted for implementation nationally not earlier than 36 months from the date of publication. Key words: Planner, Hand held, Cutting head This publication is to be read in conjunction with IEC 62841-1:2014.

IEC 62841-2-14:2015 is classified under the following ICS (International Classification for Standards) categories: 19.020 - Test conditions and procedures in general; 25.140.20 - Electric tools; 29.035.01 - Insulating materials in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62841-2-14:2015 has the following relationships with other standards: It is inter standard links to IEC 62841-2-14:2015/AMD1:2025. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 62841-2-14:2015 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62841-2-14 ®

Edition 1.0 2015-06

INTERNATIONAL

STANDARD

Electric motor-operated hand-held tools, transportable tools and lawn and

garden machinery – Safety –

Part 2-14: Particular requirements for hand-held planers

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing more than 30 000 terms and

Technical Specifications, Technical Reports and other definitions in English and French, with equivalent terms in 15

documents. Available for PC, Mac OS, Android Tablets and additional languages. Also known as the International

iPad. Electrotechnical Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a More than 60 000 electrotechnical terminology entries in

variety of criteria (reference number, text, technical English and French extracted from the Terms and Definitions

committee,…). It also gives information on projects, replaced clause of IEC publications issued since 2002. Some entries

and withdrawn publications. have been collected from earlier publications of IEC TC 37,

77, 86 and CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

IEC 62841-2-14 ®

Edition 1.0 2015-06

INTERNATIONAL

STANDARD

Electric motor-operated hand-held tools, transportable tools and lawn and

garden machinery – Safety –

Part 2-14: Particular requirements for hand-held planers

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 25.140.20 ISBN 978-2-8322-2770-1

– 2 – IEC 62841-2-14:2015 © IEC 2015

CONTENTS

FOREWORD . 3

1 Scope . 5

2 Normative references. 5

3 Terms and definitions . 5

4 General requirements . 5

5 General conditions for the tests . 5

6 Radiation, toxicity and similar hazards . 6

7 Classification . 6

8 Marking and instructions . 6

9 Protection against access to live parts . 6

10 Starting . 6

11 Input and current . 7

12 Heating . 7

13 Resistance to heat and fire . 7

14 Moisture resistance . 7

15 Resistance to rusting . 7

16 Overload protection of transformers and associated circuits . 7

17 Endurance . 7

18 Abnormal operation . 7

19 Mechanical hazards . 8

20 Mechanical strength . 10

21 Construction . 10

22 Internal wiring . 11

23 Components . 11

24 Supply connection and external flexible cords . 11

25 Terminals for external conductors . 11

26 Provision for earthing . 11

27 Screws and connections . 11

28 Creepage distances, clearances and distances through insulation . 11

Annexes . 14

Annex I (informative) Measurement of noise and vibration emissions . 14

Annex K (normative) Battery tools and battery packs . 18

Annex L (normative) Battery tools and battery packs provided with mains connection

or non-isolated sources . 19

Bibliography . 20

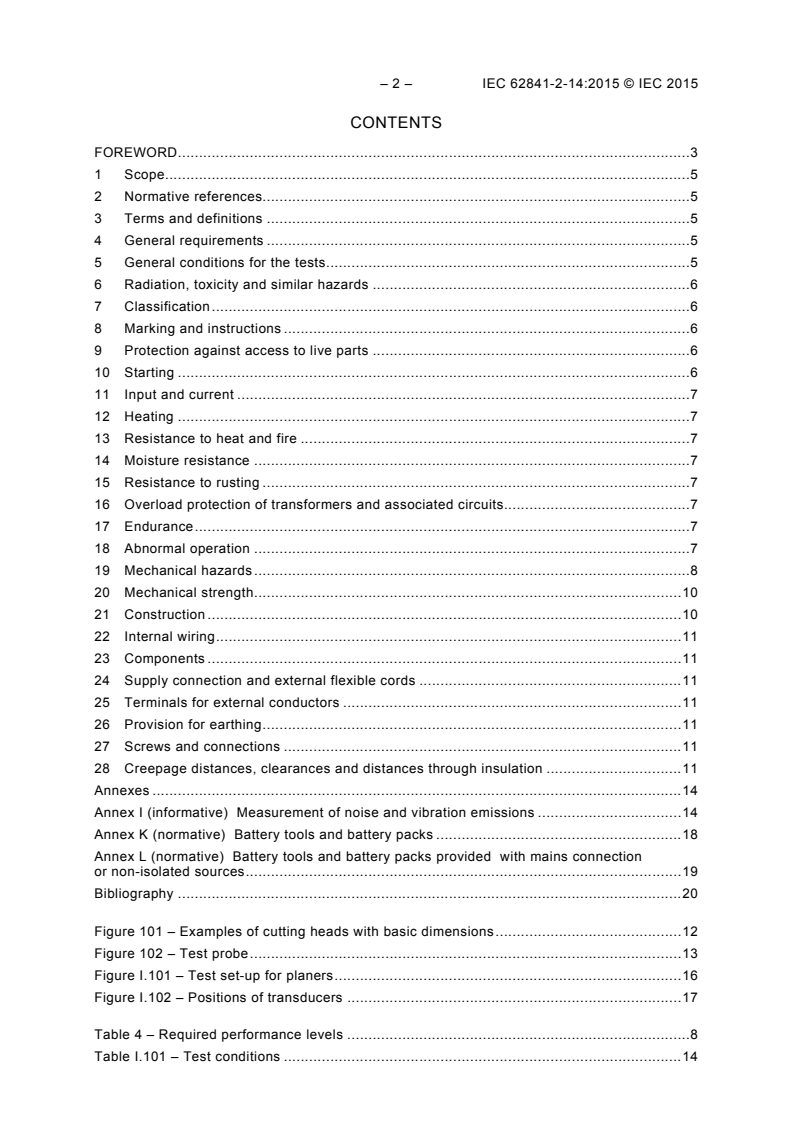

Figure 101 – Examples of cutting heads with basic dimensions . 12

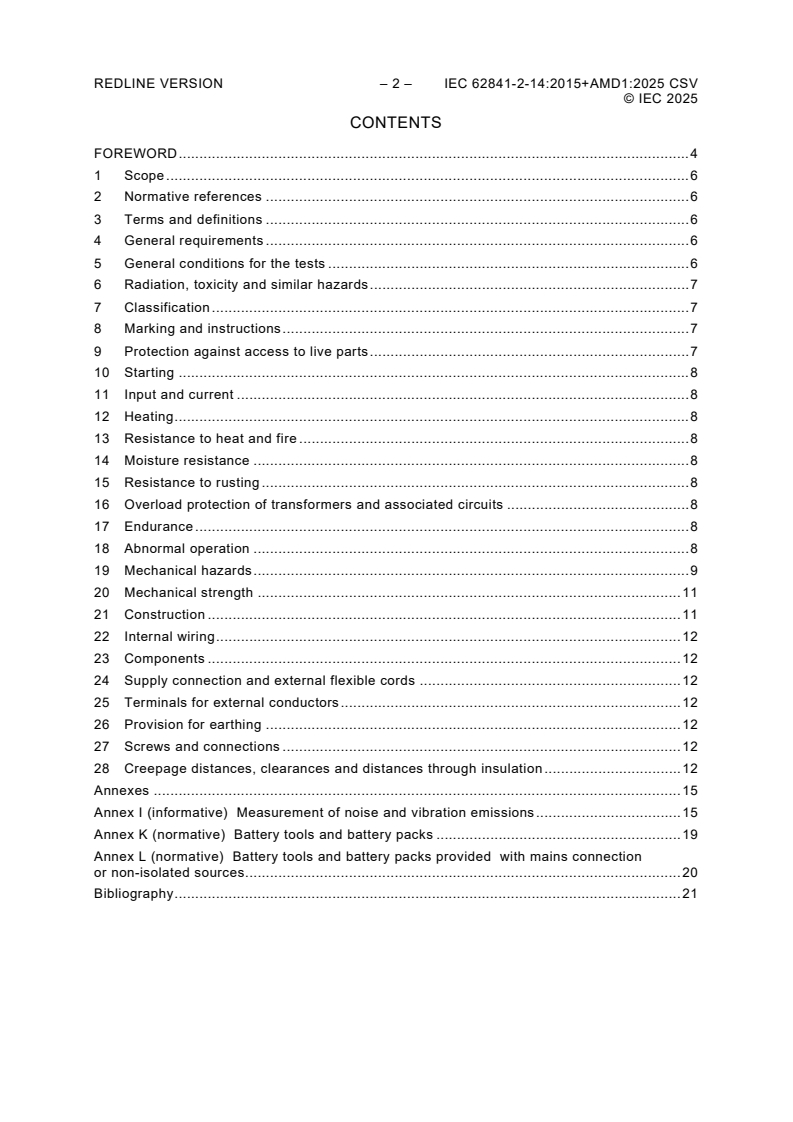

Figure 102 – Test probe . 13

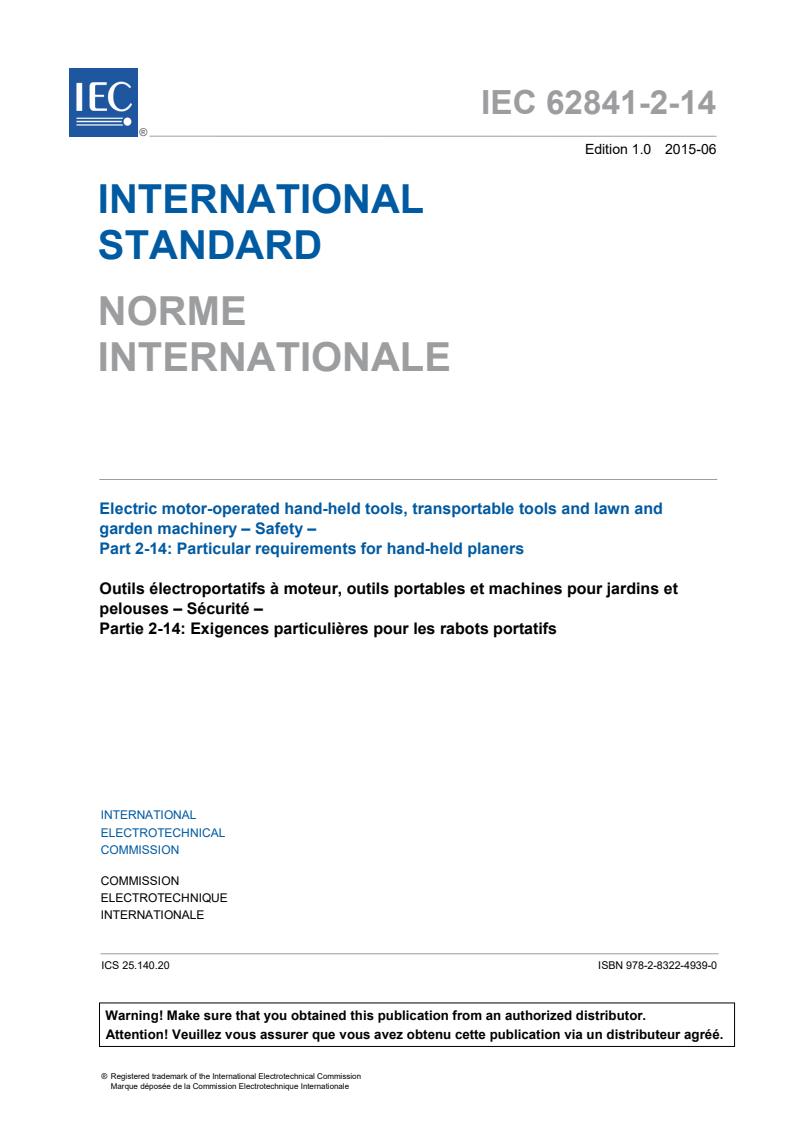

Figure I.101 – Test set-up for planers . 16

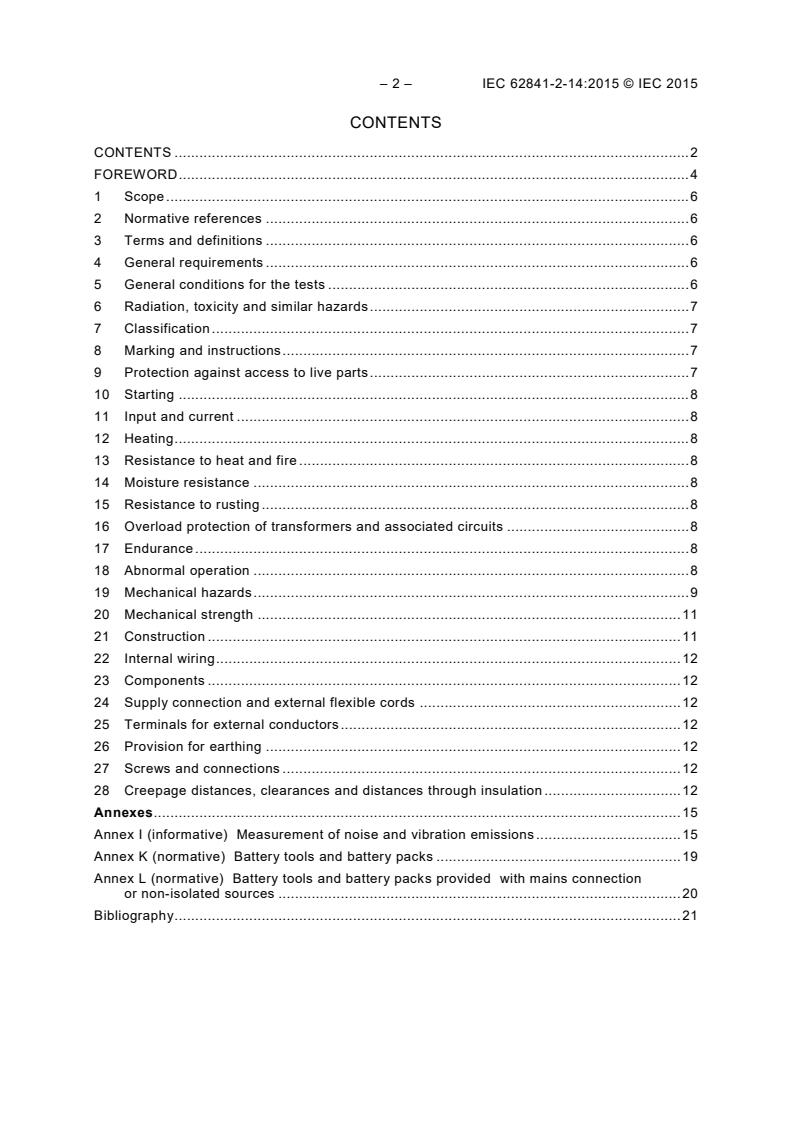

Figure I.102 – Positions of transducers . 17

Table 4 – Required performance levels . 8

Table I.101 – Test conditions . 14

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTRIC MOTOR-OPERATED HAND-HELD TOOLS, TRANSPORTABLE

TOOLS AND LAWN AND GARDEN MACHINERY – SAFETY –

Part 2-14: Particular requirements for hand-held planers

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62841-2-14 has been prepared by IEC technical committee 116:

Safety of motor-operated electric tools.

The text of this standard is based on the following documents:

FDIS Report on voting

116/222/FDIS 116/236/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

This Part 2-14 is to be used in conjunction with the first edition of IEC 62841-1 (2014).

– 4 – IEC 62841-2-14:2015 © IEC 2015

This Part 2-14 supplements or modifies the corresponding clauses in IEC 62841-1, so as to

convert it into the IEC standard: Particular requirements for hand-held planers.

Where a particular subclause of Part 1 is not mentioned in this Part 2-14, that subclause

applies as far as relevant. Where this standard states “addition”, “modification” or

“replacement”, the relevant text in Part 1 is to be adapted accordingly.

The following print types are used:

– requirements: in roman type;

– test specifications: in italic type;

– notes: in small roman type.

The terms defined in Clause 3 are printed in bold typeface.

Subclauses, notes and figures which are additional to those in Part 1 are numbered starting

from 101.

A list of all parts of the IEC 62841 series, under the general title: Electric motor-operated

hand-held tools, transportable tools and lawn and garden machinery – Safety, can be found

on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC website under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

NOTE The attention of National Committees is drawn to the fact that equipment manufacturers and testing

organizations may need a transitional period following publication of a new, amended or revised IEC publication in

which to make products in accordance with the new requirements and to equip themselves for conducting new or

revised tests.

It is the recommendation of the committee that the content of this publication be adopted for implementation

nationally not earlier than 36 months from the date of publication.

ELECTRIC MOTOR-OPERATED HAND-HELD TOOLS, TRANSPORTABLE

TOOLS AND LAWN AND GARDEN MACHINERY – SAFETY –

Part 2-14: Particular requirements for hand-held planers

1 Scope

This clause of Part 1 is applicable, except as follows:

Addition:

This part of IEC 62841 applies to planers.

2 Normative references

This clause of Part 1 is applicable.

3 Terms and definitions

This clause of Part 1 is applicable, except as follows:

Additional definitions:

3.101

planer

tool intended for removing surface material, equipped with a rotating cutting head where the

axis of rotation of the cutting head is parallel to the plane of the base plate, which is the part

supporting the planer on the workpiece

Note 1 to entry: The base plate consists of a fixed shoe and an adjustable shoe that determines the depth of cut.

3.102

lift-off device

device which keeps the blade(s) from making contact with a flat surface when the base plate

of the planer is attempted to be placed on the flat surface

3.103

cutting head

assembly of blades, cutter block, blade fixing elements, relevant screws and spindle, the

whole being ready for working

4 General requirements

This clause of Part 1 is applicable.

5 General conditions for the tests

This clause of Part 1 is applicable, except as follows:

5.17 Addition:

The mass of the tool includes the cutting head including blades and the dust extraction

adapter, if any.

– 6 – IEC 62841-2-14:2015 © IEC 2015

6 Radiation, toxicity and similar hazards

This clause of Part 1 is applicable.

7 Classification

This clause of Part 1 is applicable.

8 Marking and instructions

This clause of Part 1 is applicable, except as follows:

8.1 Addition:

– rated no-load speed.

8.3 Addition:

– direction of rotation of the working spindle. This shall be indicated by an arrow, raised or

sunk, or by other means no less visible and indelible.

8.14.1 Addition:

For planers, the additional safety instructions as specified in 8.14.1.101 shall be given. This

part may be printed separately from the “General power tool safety warnings”.

8.14.1.101 Safety instructions for planers

a) Wait for the cutter to stop before setting the tool down. An exposed rotating cutter

may engage the surface leading to possible loss of control and serious injury.

b) Hold the power tool by insulated gripping surfaces, because the cutter may contact

its own cord. Cutting a "live" wire may make exposed metal parts of the power tool "live"

and could give the operator an electric shock.

c) Use clamps or another practical way to secure and support the workpiece to a stable

platform. Holding the workpiece by your hand or against the body leaves it unstable and

may lead to loss of control.

8.14.2 b) Addition:

101) instructions on how to adjust the entire range of the depth of cut;

102)

...

IEC 62841-2-14 ®

Edition 1.1 2025-02

CONSOLIDATED VERSION

INTERNATIONAL

STANDARD

Electric motor-operated hand-held tools, transportable tools and lawn and

garden machinery – Safety –

Part 2-14: Particular requirements for hand-held planers

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews, graphical symbols and the glossary.

committee, …). It also gives information on projects, replaced With a subscription you will always have access to up to date

and withdrawn publications. content tailored to your needs.

IEC Just Published - webstore.iec.ch/justpublished

Electropedia - www.electropedia.org

Stay up to date on all new IEC publications. Just Published

The world's leading online dictionary on electrotechnology,

details all new publications released. Available online and once

containing more than 22 500 terminological entries in English

a month by email.

and French, with equivalent terms in 25 additional languages.

Also known as the International Electrotechnical Vocabulary

IEC Customer Service Centre - webstore.iec.ch/csc

(IEV) online.

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 62841-2-14 ®

Edition 1.1 2025-02

CONSOLIDATED VERSION

INTERNATIONAL

STANDARD

Electric motor-operated hand-held tools, transportable tools and lawn and

garden machinery – Safety –

Part 2-14: Particular requirements for hand-held planers

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 25.140.20 ISBN 978-2-8327-0289-5

REDLINE VERSION – 2 – IEC 62841-2-14:2015+AMD1:2025 CSV

© IEC 2025

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 General requirements . 6

5 General conditions for the tests . 6

6 Radiation, toxicity and similar hazards . 7

7 Classification . 7

8 Marking and instructions . 7

9 Protection against access to live parts . 7

10 Starting . 8

11 Input and current . 8

12 Heating . 8

13 Resistance to heat and fire . 8

14 Moisture resistance . 8

15 Resistance to rusting . 8

16 Overload protection of transformers and associated circuits . 8

17 Endurance . 8

18 Abnormal operation . 8

19 Mechanical hazards . 9

20 Mechanical strength . 11

21 Construction . 11

22 Internal wiring . 12

23 Components . 12

24 Supply connection and external flexible cords . 12

25 Terminals for external conductors . 12

26 Provision for earthing . 12

27 Screws and connections . 12

28 Creepage distances, clearances and distances through insulation . 12

Annexes . 15

Annex I (informative) Measurement of noise and vibration emissions . 15

Annex K (normative) Battery tools and battery packs . 19

Annex L (normative) Battery tools and battery packs provided with mains connection

or non-isolated sources . 20

Bibliography . 21

© IEC 2025

Figure 101 – Examples of cutting heads with basic dimensions . 13

Figure 102 – Test probe . 14

Figure I.101 – Test set-up for planers . 17

Figure I.102 – Positions of transducers . 18

Table 4 – Required performance levels . 9

Table I.101 – Test conditions . 15

REDLINE VERSION – 4 – IEC 62841-2-14:2015+AMD1:2025 CSV

© IEC 2025

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTRIC MOTOR-OPERATED HAND-HELD TOOLS, TRANSPORTABLE

TOOLS AND LAWN AND GARDEN MACHINERY – SAFETY –

Part 2-14: Particular requirements for hand-held planers

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) IEC draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). IEC takes no position concerning the evidence, validity or applicability of any claimed patent rights in

respect thereof. As of the date of publication of this document, IEC had not received notice of (a) patent(s),

which may be required to implement this document. However, implementers are cautioned that this may not

represent the latest information, which may be obtained from the patent database available at

https://patents.iec.ch. IEC shall not be held responsible for identifying any or all such patent rights.

This consolidated version of the official IEC Standard and its amendment has been

prepared for user convenience.

IEC 62841-2-14 edition 1.1 contains the first edition (2015-06) [documents 116/222/FDIS

and 116/236/RVD] and its amendment 1 (2025-02) [documents 116/857/FDIS and

116/882/RVD].

In this Redline version, a vertical line in the margin shows where the technical content

is modified by amendment 1. Additions are in green text, deletions are in strikethrough

red text. A separate Final version with all changes accepted is available in this

publication.

© IEC 2025

International Standard IEC 62841-2-14 has been prepared by IEC technical committee 116:

Safety of motor-operated electric tools.

This bilingual version (2017-12) corresponds to the monolingual English version, published in

2015-06.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The French version of this standard has not been voted upon.

This Part 2-14 is to be used in conjunction with the first edition of IEC 62841-1 (2014).

This Part 2-14 supplements or modifies the corresponding clauses in IEC 62841-1, so as to

convert it into the IEC standard: Particular requirements for hand-held planers.

Where a particular subclause of Part 1 is not mentioned in this Part 2-14, that subclause

applies as far as relevant. Where this standard states “addition”, “modification” or

“replacement”, the relevant text in Part 1 is to be adapted accordingly.

The following print types are used:

– requirements: in roman type;

– test specifications: in italic type;

– notes: in small roman type.

The terms defined in Clause 3 are printed in bold typeface.

Subclauses, notes and figures which are additional to those in Part 1 are numbered starting

from 101.

A list of all parts of the IEC 62841 series, under the general title: Electric motor-operated

hand-held tools, transportable tools and lawn and garden machinery – Safety, can be found

on the IEC website.

The committee has decided that the contents of this document and its amendment will remain

unchanged until the stability date indicated on the IEC website under webstore.iec.ch in the

data related to the specific document. At this date, the document will be

• reconfirmed,

• withdrawn, or

• revised.

NOTE The attention of National Committees is drawn to the fact that equipment manufacturers and testing

organizations may need a transitional period following publication of a new, amended or revised IEC publication in

which to make products in accordance with the new requirements and to equip themselves for conducting new or

revised tests.

It is the recommendation of the committee that the content of this publication be adopted for implementation

nationally not earlier than 36 months from the date of publication.

REDLINE VERSION – 6 – IEC 62841-2-14:2015+AMD1:2025 CSV

© IEC 2025

ELECTRIC MOTOR-OPERATED HAND-HELD TOOLS, TRANSPORTABLE

TOOLS AND LAWN AND GARDEN MACHINERY – SAFETY –

Part 2-14: Particular requirements for hand-held planers

1 Scope

This clause of Part 1 is applicable, except as follows:

Addition:

This part of IEC 62841 applies to planers.

2 Normative references

This clause of Part 1 is applicable.

3 Terms and definitions

This clause of Part 1 is applicable, except as follows:

Additional definitions:

3.101

planer

tool intended for removing surface material, equipped with a rotating cutting head where the

axis of rotation of the cutting head is parallel to the plane of the base plate, which is the part

supporting the planer on the workpiece

Note 1 to entry: The base plate consists of a fixed shoe and an adjustable shoe that determines the depth of cut.

3.102

lift-off device

device which keeps the blade(s) from making contact with a flat surface when the base plate

of the planer is attempted to be placed on the flat surface

3.103

cutting head

assembly of blades, cutter block, blade fixing elements, relevant screws and spindle, the

whole being ready for working

4 General requirements

This clause of Part 1 is applicable.

5 General conditions for the tests

This clause of Part 1 is applicable, except as follows:

© IEC 2025

5.17 Addition:

The mass of the tool includes the cutting head including blades and the dust extraction

adapter, if any.

6 Radiation, toxicity and similar hazards

This clause of Part 1 is applicable.

7 Classification

This clause of Part 1 is applicable.

8 Marking and instructions

This clause of Part 1 is applicable, except as follows:

8.1 Addition:

– rated no-load speed.

8.3 Addition:

– direction of rotation of the working spindle. This shall be indicated by an arrow, raised or

sunk, or by other means no less visible and indelible.

8.14.1 Addition:

For planers, the additional safety instructions as specified in 8.14.1.101 shall be given. This

part may be printed separately from the “General power tool safety warnings”.

8.14.1.101 Safety instructions for planers

a) Wait for the cutter to stop before setting the tool down. An exposed rotating cutter

may engage the surface leading to possible loss of control and serious injury.

b) Hold the power tool by insulated gripping surfaces, because the cutter may contact

its own cord. Cutting a "live" wire may make exposed metal parts of the power tool "live"

and could give the operator an electric shock.

c) Use clamps or another practical way to secure and support the workpiece to a stable

platform. Holding the workpiece by your hand or against the body leaves it unstable and

may lead to loss of control.

8.14.2 b) Addition:

101) instructions on how to adjust the entire range of the depth of cut;

102) instruction on the correct use of the dust collection system.

8.14.2 c) Addition:

101) information about types of cutting heads which can be used, if applicable;

102) instructions for the changing of the blades and their adjustment to the correct position;

103) instruction on how to properly clean/clear the chip ejection opening.

9 Protection against access to live parts

This clause of Part 1 is applicable.

REDLINE VERSION – 8 – IEC 62841-2-14:2015+AMD1:2025 CSV

© IEC 2025

10 Starting

This clause of Part 1 is applicable.

11 Input and current

This clause of Part 1 is applicable.

12 Heating

This clause of Part 1 is applicable.

13 Resistance to heat and fire

This clause of Part 1 is applicable.

14 Moisture resistance

This clause of Part 1 is applicable.

15 Resistance to rusting

This clause of Part 1 is applicable.

16 Overload protection of transformers and associated circuits

This clause of Part 1 is applicable.

17 Endurance

This clause of Part 1 is applicable, except as follows:

17.101 If a lift-off device is provided to meet the requirements of 18.8 or 21.18.1.1, it shall

be sufficiently durable.

Compliance is checked by a new tool sample completing the following test.

The planer is to be set in horizontal position. The lift-off device is cycled through its

intended range of operation for 50 000 cycles. This sequence is repeated at a rate not less

than 10 cycles per minute.

After completion of the cycling test as specified above, the planer shall then comply with

19.111.

18 Abnormal operation

This clause of Part 1 is applicable, except as follows:

18.8 Replacement of Table 4 by the following:

© IEC 2025

Table 4 – Required performance levels

Type and purpose of SCF Minimum Performance

Level (PL)

Power switch – prevent unwanted switch-on c

Power switch – provide desired switch-off for planers with lift-off device a

Power switch – provide desired switch-off for planers without lift-off device b

Any electronic control to pass the test of 18.3 a

Overspeed prevention to prevent output speed above 130 % of rated no-load speed b

Provide desired direction of rotation a

Prevent exceeding thermal limits as in Clause 18.4 and 18.5.3 a

Prevent self-resetting as required in 23.3 b

Lock-off function as required by 21.18.1.2 b

19 Mechanical hazards

This clause of Part 1 is applicable, except as follows:

19.1 Addition:

For the requirements given in 19.107, 19.108 and 19.109, only the test probe shown in

Figure 102 is used.

19.6 This subclause of Part 1 is applicable.

19.4.101 Planers with a mass according to 5.17 exceeding 3 kg shall have at least two

handles. The auxiliary handle, if any, may also be used for the depth-of-cut setting, provided

the adjustment of depth of cut is achieved by a rotary action.

Compliance is checked by inspection and by measurement.

19.101 The cutting head shall be cylindrically shaped except for the blades, the gullet and

the blade clamping means.

The maximum gullet width s shall be

s = 0,235 d + 7,2 mm

max

where d is the diameter of the rotating circle of the cutting edges. See Figure 101.

Compliance is checked by inspection and by measurement.

19.102 The blades when aligned with the fixed shoe shall not project by more than 1,1 mm

radially beyond the cutter block (as per dimension “a” in Figure 101).

Compliance is checked by measurement.

19.103 At any depth of cut, the distance “b” (see Figure 101) between the rotating circle of

the cutting edges and the trailing edge on the adjustable shoe shall not exceed 5 mm

measured radially.

Compliance is checked by inspection and by measurement.

REDLINE VERSION – 10 – IEC 62841-2-14:2015+AMD1:2025 CSV

© IEC 2025

19.104 The blades shall be secured in the cutter block in such a way that friction alone is not

relied upon to prevent the radial ejection of the blades.

Compliance is checked by inspection.

19.105 Cutting heads shall be designed and made of such materials that they withstand the

forces and loads expected in normal use.

Compliance is checked by the following test:

An overspeed test shall be made on a sample cutting head, equipped with blades for the

largest cutting diameter and the largest cutting edge width, the test speed being 1,5 times the

rated no-load speed. If applicable, tension elements such as clamping screws shall be

tightened in accordance with the instructions required by 8.14.2 b).

After the test, the cutting head shall not be deformed or cracked, no screws shall be

loosened and displacements of separable parts shall be less than specified in the test

procedure.

The test procedure is as follows:

1) Measure the cutting head dimensions.

2) Bring the cutting head to the rated no-load speed, for 1 min.

3) Stop and re-measure the cutting head; measured displacements of the separable parts of

the cutting head shall not be greater than 0,15 mm.

4) Bring the cutting head to the test speed, for 1 min.

5) Stop and re-measure the cutting head and compare the results with those obtained from

step 3. The compared displacements shall not exceed 0,15 mm.

19.106 Clamping screws or bolts shall not project beyond the cutter block as shown in

Figure 101.

Compliance is checked by inspection.

19.107 It shall not be possible to inadvertently touch rotating parts from the sides of the

planer, except for the cases covered by 19.108.

Compliance is checked by the following test:

The planer is set to minimum depth of cut and is positioned with the shoes resting on a flat

surface that extends beyond the planer by at least 100 mm in all directions. Any lift-off

device is disabled. The accessibility is checked by means of the test probe shown in

Figure 102 with a force not exceeding 5 N.

19.108 Planers with rabbeting facilities shall be provided with a guard that avoids

inadvertent contact at the sides with the blades.

NOTE Rabbeting is also known as rebating.

Compliance is checked by inspection and by the following test:

The planer is set to minimum depth of cut and is positioned with the shoes resting on a flat

surface that extends beyond the planer by at least 100 mm in all directions. Any lift-off

device is disabled. The accessibility is checked by means of the test probe shown in

Figure 102 without any force.

© IEC 2025

19.109 It shall not be possible to touch the blades through the chip ejection opening.

Compliance is checked by testing all apertures for chip ejection with the test probe of

Figure 102. It shall not be possible to touch the blades in the cutting head at any angle of the

probe.

19.110 Planers shall stop within 10 s after switching off.

Compliance is checked by inspection and by measurement.

19.111 Lift-off device

19.111.1 If a lift-off device is provided to meet the requirements of 18.8 or 21.18.1.1, it

shall meet the requirements of 19.111.2 and 19.111.3, which are checked only after

completing the endurance test of 17.101.

19.111.2 If a lift-off device is provided, it shall be designed so that

– it is automatically activated, when the planer is lifted up from a horizontal surface; and

– the blade(s) do not make contact, when the planer is set at maximum depth of cut in

accordance with 8.14.2 b) 101) and placed on a horizontal surface.

Compliance is checked by inspection.

19.111.3 A lift-off device shall provide sufficient stability.

Compliance is checked by the following test:

The planer is set to maximum depth of cut in accordance with 8.14.2 b) 101) and with the

supply cord, if any, removed. The planer is then placed on a flat board of medium density

3 3

to 850 kg/m that is inclined at an angle of

fibreboard (MDF) having a density of 650 kg/m

10°, such that the rear of the planer is nearest to the high side of the board and allowed to

rest freely for 10 s to 12 s. During the test, the planer is permitted to slide, however, the lift-

off device shall not collapse such that the planer blades come into contact with the board.

20 Mechanical strength

This clause of Part 1 is applicable.

21 Construction

This clause of Part 1 is applicable, except as follows:

21.18.1.1 Addition:

Planers whose blade(s) make contact with a flat surface when the base plate is placed on the

flat surface and without a lift-off device are regarded as tools having a risk associated with

continued locked-on operation.

NOTE In Europe (EN 62841-2-14), the above text is replaced by the following:

For planers, the switch shall not have any locking device to lock it in the “on” position.

21.18.1.2 Addition:

Planers are regarded as tools having a risk associated with inadvertent starting.

REDLINE VERSION – 12 – IEC 62841-2-14:2015+AMD1:2025 CSV

© IEC 2025

21.35 This subclause of Part 1 is applicable.

22 Internal wiring

This clause of Part 1 is applicable.

23 Components

This clause of Part 1 is applicable, except as follows:

23.3 Replacement of the first paragraph:

Protection devices or circuits shall be of the non-self-resetting type unless the tool is

equipped with a momentary power switch with no provision for being locked in the "on"

position.

24 Supply connection and external flexible cords

This clause of Part 1 is applicable.

25 Terminals for external conductors

This clause of Part 1 is applicable.

26 Provision for earthing

This clause of Part 1 is applicable.

27 Screws and connections

This clause of Part 1 is applicable.

28 Creepage distances, clearances and distances through insulation

This clause of Part 1 is applicable.

© IEC 2025

IEC

a) Example 1 and explanation of basic dimensions

IEC

b) Example 2

Key

1 fixed shoe

2 adjustable shoe

3 trailing edge

a radial projection of the blades beyond the cutter block

b distance between the rotating circle of the cutting edges and the trailing edge of the adjustable shoe

d diameter of the rotating circle of the cutting edges

s gullet width

Figure 101 – Examples of cutting heads with basic dimensions

REDLINE VERSION – 14 – IEC 62841-2-14:2015+AMD1:2025 CSV

© IEC 2025

Dimensions in millimetres

1 3 2

+0

R6

−0,05

30 5 50±0,2

IEC

Key

1 handle section

2 test section

3 probe’s flange

Figure 102 – Test probe

∅35±0,2

∅8

+0

∅12

−0,05

© IEC 2025

Annexes

The annexes of Part 1 are applicable except as follows.

Annex I

(informative)

Measurement of noise and vibration emissions

NOTE In Europe (EN 62841-2-14), Annex I is normative.

I.2 Noise test code (grade 2)

This clause of Part 1 is applicable except as follows:

I.2.4 Installation and mounting conditions of the power tools during noise tests

Addition:

Planers are held and used as specified in I.2.5.

I.2.5 Operating conditions

Addition:

Planers are tested under load observing the conditions shown in Table I.101.

The temperature requirements of 5.6 are not applicable.

Table I.101 – Test conditions

Orientation Planing along a horizontal surface of a softwood workpiece free of knots and having a

residual moisture not exceeding 14 %.

The workpiece shall have a minimum length of 600 mm, a minimum height of 90 mm and

a width B, where B is the maximum planing width of the tool minus (15 ± 2) mm.

The workpiece shall be supported on resilient material and fixed vertically by screws,

clamps, air cylinders or the like to a test bench of Figure I.1, see Figure I.101. For the

fixing, the workpiece may have recesses or the like; an example is shown in Figure I.101.

The resilient material shall be mounted so that it does not have any significant resonance

in the frequency range that can influence the test result.

To prevent absorption of airborne noise, the resilient material shall either

– not extend the contact area between workpiece and test bench; or

– be of non airborne-sound absorbing material, such as rubber.

If a parallel guide is provided, this may be used.

NOTE Examples of softwood are pine and fir.

Tool bit Blade as specified for planing softwood. The depth of cut shall be set to maximum

capacity.

Feed force As necessary to achieve a constant feed rate resulting in 10 s to 15 s planing time for one

test cycle (600 mm). Equal forces are applied to the main handle and the auxiliary

handle, if applicable, avoiding excessive gripping forces.

However, if it is not possible to plane the whole surface length within the given time,

because the planer may stall, a longer test cycle time is permitted using a feed force as

high as possible without stalling the planer.

Test cycle Planing the complete length of 600 mm at maximum depth of cut.

The measurement takes place over a length of approximately 400 mm that does not

include the ends of the workpiece.

REDLINE VERSION – 16 – IEC 62841-2-14:2015+AMD1:2025 CSV

© IEC 2025

I.3 Vibration

This clause of Part 1 is applicable except as follows:

I.3.3.2 Location of measurement

Addition:

Figure I.102 shows the positions on the main handle and the auxiliary handle, if applicable.

I.3.5.1 General

Addition:

For battery operated tools, the tests are conducted with the lightest battery in accordance

with K.8.14.2 e) 2) of Part 1 that has sufficient capacity to complete the 15 measurements as

specified in I.3.6.1 of Part 1, under the operating conditions described in Table I.101.

I.3.5.3 Operating conditions

Addition:

Planers are tested under load according to the conditions shown in Table I.101.

I.3.6.2 Declaration of the vibration total value

Addition:

of the handle with the highest emission and the uncertainty K shall

The vibration total value a

h

be declared.

© IEC 2025

IEC

a) Side view

IEC

b) Front view

Key

1 test bench of Figure I.1

2 resilient material

3 workpiece

4 fixing means (e.g. clamps)

Figure I.101 – Test set-up for planers

REDLINE VERSION – 18 – IEC 62841-2-14:2015+AMD1:2025 CSV

© IEC 2025

IEC

Figure I.102 – Positions of transducers

© IEC 2025

Annex K

(normative)

Battery tools and battery packs

K.1 Scope

Addition:

All clauses of this Part 2-14 apply unless otherwise specified in this annex.

K.8.14.1.101 Item b) is not applicable.

K.12.2.1 This subclause is not applicable.

K.20.5 This subclause is not applicable.

K.21.18.1.2 Addition:

Two separate and dissimilar actions shall be necessary before the motor is switched on (e.g.

a power switch which has to be pushed in before it can be moved laterally to close the

contacts to start the motor). It shall not be possible to achieve these two actions with a single

grasping motion or a straight line motion.

Compliance is checked by inspection and by manual test.

K.21.30 This subclause is not applicable.

NOTE In Europe (EN 62841-2-14), the following additional subclause applies:

K.21.18.Z101 Isolation device

Planers with an integral battery shall be equipped with an isolation device to prevent the risk of injury from

mechanical hazards during user maintenance that

– ensures a reliable disconnection of at least one pole of the battery from the relevant load(s);

– has a reliable mechanical link between the manual control and the disconnecting element(s);

– is equipped with an unambiguous indication of the state of the disconnection device which corresponds to each

position of its manual control (actuator);

– protects against accidental reconnection.

NOTE 1 Examples of methods to achieve this disconnection include removable jumpers, removable batteries or a

electromechanical power switch with a direct mechanical link between the actuator and the contact.

NOTE 2 The risk of accidental reconnection for a power switch is addressed by the requirement of 21.18.1.2.

The other examples in Note 1 achieve this by the necessary actions for reconnection.

Compliance is checked by inspection.

REDLINE VERSION – 20 – IEC 62841-2-14:2015+AMD1:2025 CSV

© IEC 2025

Annex L

(normative)

Battery tools and battery packs provided

with mains connection or non-isolated sources

L.1 Scope

Addition:

All clauses of this Part 2-14 apply unless otherwise specified in this annex.

L.21.18.1.2 Addition:

Two separate and dissimilar actions shall be necessary before the motor is switched on (e.g.

a power switch which has to be pushed in before it can be moved laterally to close the

contacts to start the motor). It shall not be possible to achieve these two actions with a single

grasping motion or a straight line motion.

Compliance is checked by inspection and by manual test.

NOTE In Europe (EN 62841-2-14), the following additional subclause applies:

L.21.18.Z101 Isolation device

Planers with an integral battery shall be equipped with an isolation device to prevent the risk of injury from

mechanical hazards during user maintenance that

– ensures a reliable disconnection of at least one pole of the battery from the relevant load(s);

– has a reliable mechanical link between the manual control and the disconnecting element(s);

– is equipped with an unambiguous indication of the state of the disconnection device which corresponds to each

position of its manual control (actuator);

– protects against accidental reconnection.

NOTE 1 Examples of methods to achieve this disconnection include removable jumpers, removable batteries or a

electromechanical power switch with a direct mechanical link between the actuator and the contact.

NOTE 2 The risk of accidental reconnection for a power switch is addressed by the requirement of 21.18.1.2.

The other examples in Note 1 achieve this by the necessary actions for reconnection.

Compliance is checked by inspection.

© IEC 2025

Bibliography

The bibliography of Part 1 is applicable.

___________

FINAL VERSION – 2 – IEC 62841-2-14:2015+AMD1:2025 CSV

© IEC 2025

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 General requirements . 6

5 General conditions for the tests . 6

6 Radiation, toxicity and similar hazards . 7

7 Classification . 7

8 Marking and instructions . 7

9 Protection against access to live parts . 7

10 Starting . 8

11 Input and current . 8

12 Heating . 8

13 Resistance to heat and fire . 8

14 Moisture resistance . 8

15 Resistance to rusting . 8

16 Overload protection of transformers and associated circuits . 8

17 Endurance . 8

18 Abnormal operation . 8

19 Mechanical hazards . 9

20 Mechanical strength . 11

21 Construction . 11

22 Internal wiring . 12

23 Components . 12

24 Supply connection and external flexible cords . 12

25 Terminals for external conductors . 12

26 Provision for earthing . 12

27 Screws and connections . 12

28 Creepage distances, clearances and distances through insulation . 12

Annexes . 15

Annex I (informative) Measurement of noise and vibration emissions . 15

Annex K (normative) Battery tools and battery packs . 19

Annex L (normative) Battery tools and battery packs provided with mains connection

or non-isolated sources . 20

Bibliography . 21

© IEC 2025

Figure 101 – Examples of cutting heads with basic dimensions . 13

Figure 102 – Test probe . 14

Figure I.101 – Test set-up for planers . 17

Figure I.102 – Positions of transducers . 18

Table 4 – Required performance levels . 9

Table I.101 – Test conditions . 15

FINAL VERSION – 4 – IEC 62841-2-14:2015+AMD1:2025 CSV

© IEC 2025

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTRIC MOTOR-OPERATED HAND-HELD TOOLS, TRANSPORTABLE

TOOLS AND LAWN AND GARDEN MACHINERY – SAFETY –

Part 2-14: Particular requirements for hand-held planers

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is acc

...

IEC 62841-2-14 ®

Edition 1.0 2015-06

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Electric motor-operated hand-held tools, transportable tools and lawn and

garden machinery – Safety –

Part 2-14: Particular requirements for hand-held planers

Outils électroportatifs à moteur, outils portables et machines pour jardins et

pelouses – Sécurité –

Partie 2-14: Exigences particulières pour les rabots portatifs

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 20 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 65 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient 20 000 termes et définitions en anglais

Spécifications techniques, Rapports techniques et autres

et en français, ainsi que les termes équivalents dans 16

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

65 000 entrées terminologiques électrotechniques, en anglais

La recherche avancée permet de trouver des publications IEC

en utilisant différents critères (numéro de référence, texte, et en français, extraites des articles Termes et Définitions des

comité d’études,…). Elle donne aussi des informations sur les publications IEC parues depuis 2002. Plus certaines entrées

projets et les publications remplacées ou retirées. antérieures extraites des publications des CE 37, 77, 86 et

CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 62841-2-14 ®

Edition 1.0 2015-06

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Electric motor-operated hand-held tools, transportable tools and lawn and

garden machinery – Safety –

Part 2-14: Particular requirements for hand-held planers

Outils électroportatifs à moteur, outils portables et machines pour jardins et

pelouses – Sécurité –

Partie 2-14: Exigences particulières pour les rabots portatifs

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 25.140.20 ISBN 978-2-8322-4939-0

– 2 – IEC 62841-2-14:2015 © IEC 2015

CONTENTS

CONTENTS . 2

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 General requirements . 6

5 General conditions for the tests . 6

6 Radiation, toxicity and similar hazards . 7

7 Classification . 7

8 Marking and instructions . 7

9 Protection against access to live parts . 7

10 Starting . 8

11 Input and current . 8

12 Heating . 8

13 Resistance to heat and fire . 8

14 Moisture resistance . 8

15 Resistance to rusting . 8

16 Overload protection of transformers and associated circuits . 8

17 Endurance . 8

18 Abnormal operation . 8

19 Mechanical hazards . 9

20 Mechanical strength . 11

21 Construction . 11

22 Internal wiring . 12

23 Components . 12

24 Supply connection and external flexible cords . 12

25 Terminals for external conductors . 12

26 Provision for earthing . 12

27 Screws and connections . 12

28 Creepage distances, clearances and distances through insulation . 12

Annexes . 15

Annex I (informative) Measurement of noise and vibration emissions . 15

Annex K (normative) Battery tools and battery packs . 19

Annex L (normative) Battery tools and battery packs provided with mains connection

or non-isolated sources . 20

Bibliography . 21

Figure 101 – Examples of cutting heads with basic dimensions . 13

Figure 102 – Test probe . 14

Figure I.101 – Test set-up for planers . 17

Figure I.102 – Positions of transducers . 18

Table 4 – Required performance levels . 9

Table I.101 – Test conditions . 15

– 4 – IEC 62841-2-14:2015 © IEC 2015

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTRIC MOTOR-OPERATED HAND-HELD TOOLS, TRANSPORTABLE

TOOLS AND LAWN AND GARDEN MACHINERY – SAFETY –

Part 2-14: Particular requirements for hand-held planers

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62841-2-14 has been prepared by IEC technical committee 116:

Safety of motor-operated electric tools.

This bilingual version (2017-12) corresponds to the monolingual English version, published in

2015-06.

The text of this standard is based on the following documents:

FDIS Report on voting

116/222/FDIS 116/236/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The French version of this standard has not been voted upon.

This Part 2-14 is to be used in conjunction with the first edition of IEC 62841-1 (2014).

This Part 2-14 supplements or modifies the corresponding clauses in IEC 62841-1, so as to

convert it into the IEC standard: Particular requirements for hand-held planers.

Where a particular subclause of Part 1 is not mentioned in this Part 2-14, that subclause

applies as far as relevant. Where this standard states “addition”, “modification” or

“replacement”, the relevant text in Part 1 is to be adapted accordingly.

The following print types are used:

– requirements: in roman type;

– test specifications: in italic type;

– notes: in small roman type.

The terms defined in Clause 3 are printed in bold typeface.

Subclauses, notes and figures which are additional to those in Part 1 are numbered starting

from 101.

A list of all parts of the IEC 62841 series, under the general title: Electric motor-operated

hand-held tools, transportable tools and lawn and garden machinery – Safety, can be found

on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC website under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

NOTE The attention of National Committees is drawn to the fact that equipment manufacturers and testing