IEC 61788-24:2018

(Main)Superconductivity - Part 24: Critical current measurement - Retained critical current after double bending at room temperature of Ag-sheathed Bi-2223 superconducting wires

Superconductivity - Part 24: Critical current measurement - Retained critical current after double bending at room temperature of Ag-sheathed Bi-2223 superconducting wires

IEC 61788-24:2018 describes a test method for determining the retained critical current after double bending at room temperature of short and straight Ag- and/or Ag alloy-sheathed Bi-2223 superconducting wires that have the shape of a flat or square tape containing mono- or multicores of oxides. The wires can be laminated with copper alloy, stainless steel or Ni alloy tapes.

The test method is intended for use with superconductors that have a critical current less than 300 A and an n-value larger than 5.

Supraconductivité - Partie 24: Mesurage du courant critique - Courant critique retenu après double flexion à température ambiante des fils supraconducteurs Bi-2223 avec gaine Ag

IEC 61788-24:2018 décrit une méthode d’essai permettant de déterminer le courant critique retenu après double flexion à température ambiante de fils supraconducteurs rectilignes courts Bi-2223 avec gaine Ag et/ou en alliage d’Ag, ayant la forme d’une bande plate ou carrée et contenant des noyaux simples ou plusieurs noyaux d’oxydes. Les fils peuvent être stratifiés avec des bandes en alliage de cuivre, en acier inoxydable ou en alliage de Ni.

La méthode d’essai est destinée à être utilisée avec des supraconducteurs ayant un courant critique inférieur à 300 A et une valeur n supérieure à 5.

General Information

- Status

- Published

- Publication Date

- 17-Jun-2018

- Technical Committee

- TC 90 - Superconductivity

- Drafting Committee

- WG 3 - TC 90/WG 3

- Current Stage

- PPUB - Publication issued

- Start Date

- 18-Jun-2018

- Completion Date

- 06-Jul-2018

Overview

IEC 61788-24:2018 is an international standard developed by the International Electrotechnical Commission (IEC) that specifies a standardized test method for assessing the retained critical current after double bending at room temperature of silver (Ag)-sheathed Bi-2223 superconducting wires. This part of the IEC 61788 series addresses critical current measurement specifically for short and straight Bi-2223 oxide superconducting wires, sheathed in silver or silver alloys, and optionally laminated with copper alloy, stainless steel, or nickel alloy tapes. The standard focuses on wires shaped as flat or square tapes containing mono- or multi-core superconducting oxide structures.

This standard applies to superconductors with critical currents under 300 A and an n-value (a measure of the steepness of the voltage-current curve near critical current) greater than 5. It is designed to support quality control and performance verification in the production and application of Bi-2223 superconducting wires, especially in environments where mechanical deformations such as bending might occur.

Key Topics

Critical Current Measurement

IEC 61788-24 defines the procedure and requirements for measuring the critical current (Ic) of Bi-2223 superconducting wires after mechanical deformation. The method establishes how much of the critical current is retained after the superconducting wire undergoes double bending at room temperature.Double Bending Test Method

This standard specifies the apparatus and test setup for applying double bending to the superconducting wire to simulate mechanical stress, and details how to measure the Ic post-bending. The test uses a bending mandrel to ensure consistent and repeatable deformation.Specimen Preparation and Setup

It outlines protocols for specimen length, mounting, and handling to eliminate test variability – including the use of specialized sample holders and electrically precise measurement systems.Data Analysis and Reporting

Guidelines are provided for calculating results, such as the retained critical current ratio (Ic after bending/Ic before bending), and measurement of the n-value. Detailed instructions for test reporting ensure consistent documentation of test conditions, specimen identification, and measurement outcomes.Uncertainty Evaluation

Annexes provide informative guidance on uncertainty evaluation related to critical current measurement. This covers instrumentation precision, voltage tap placement, current measurement, and combined standard uncertainty calculation.

Applications

Quality Control in Superconducting Wire Manufacturing

Manufacturers of Ag-sheathed Bi-2223 superconducting wires use IEC 61788-24 test methods to verify mechanical durability and electrical performance after bending deformations typical in wire handling and winding processes.Superconductor Development and Research

Researchers developing new superconducting wires can benchmark mechanical and electrical resilience to bending strains using this standard, facilitating material innovation and performance optimization.Industrial Cable Production and Integration

This standard supports the validation of superconducting wires used in superconducting cables and devices, ensuring they maintain critical current capabilities after mechanical manipulations during installation or operation.Electric and Magnetic Equipment

Applications including magnets, transformers, and power devices rely on reliable critical current capacities under mechanical stress; IEC 61788-24 ensures these superconducting components meet rigorous bending performance criteria.

Related Standards

IEC 61788 Series

IEC 61788 encompasses test methods and performance specifications for superconductors including critical current measurement protocols for differing materials and geometries.IEC 60404 Series

This series covers magnetic materials standards, sometimes intersecting with superconducting wire applications regarding magnetic characteristics.ISO/IEC Directives

The procedural guidelines for preparation and publication of IEC standards-ensuring consistency and reliability.Material-Specific Test Norms

Related protocols for high-temperature superconductors (HTS), including Bi-2212 and YBCO conductors, which may require alternative or complementary mechanical and electrical testing standards.

By adhering to IEC 61788-24:2018, organizations ensure standardized, repeatable, and accurate measurements of the retained critical current in Ag-sheathed Bi-2223 superconducting wires after mechanical bending stress. This contributes to enhanced reliability, safety, and performance in superconducting technology applications worldwide.

Get Certified

Connect with accredited certification bodies for this standard

Element Materials Technology

Materials testing and product certification.

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

Sponsored listings

Frequently Asked Questions

IEC 61788-24:2018 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Superconductivity - Part 24: Critical current measurement - Retained critical current after double bending at room temperature of Ag-sheathed Bi-2223 superconducting wires". This standard covers: IEC 61788-24:2018 describes a test method for determining the retained critical current after double bending at room temperature of short and straight Ag- and/or Ag alloy-sheathed Bi-2223 superconducting wires that have the shape of a flat or square tape containing mono- or multicores of oxides. The wires can be laminated with copper alloy, stainless steel or Ni alloy tapes. The test method is intended for use with superconductors that have a critical current less than 300 A and an n-value larger than 5.

IEC 61788-24:2018 describes a test method for determining the retained critical current after double bending at room temperature of short and straight Ag- and/or Ag alloy-sheathed Bi-2223 superconducting wires that have the shape of a flat or square tape containing mono- or multicores of oxides. The wires can be laminated with copper alloy, stainless steel or Ni alloy tapes. The test method is intended for use with superconductors that have a critical current less than 300 A and an n-value larger than 5.

IEC 61788-24:2018 is classified under the following ICS (International Classification for Standards) categories: 17.220 - Electricity. Magnetism. Electrical and magnetic measurements; 29.050 - Superconductivity and conducting materials; 77.040.10 - Mechanical testing of metals. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61788-24:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61788-24 ®

Edition 1.0 2018-06

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Superconductivity –

Part 24: Critical current measurement – Retained critical current after double

bending at room temperature of Ag-sheathed Bi-2223 superconducting wires

Supraconductivité –

Partie 24: Mesurage du courant critique – Courant critique retenu après double

flexion à température ambiante des fils supraconducteurs Bi-2223 avec gaine Ag

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 21 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - webstore.iec.ch/advsearchform IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 67 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient 21 000 termes et définitions en anglais

Spécifications techniques, Rapports techniques et autres

et en français, ainsi que les termes équivalents dans 16

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC -

Glossaire IEC - std.iec.ch/glossary

webstore.iec.ch/advsearchform

67 000 entrées terminologiques électrotechniques, en anglais

La recherche avancée permet de trouver des publications IEC et en français, extraites des articles Termes et Définitions des

en utilisant différents critères (numéro de référence, texte, publications IEC parues depuis 2002. Plus certaines entrées

comité d’études,…). Elle donne aussi des informations sur les antérieures extraites des publications des CE 37, 77, 86 et

projets et les publications remplacées ou retirées. CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just Si vous désirez nous donner des commentaires sur cette

Published détaille les nouvelles publications parues. publication ou si vous avez des questions contactez-nous:

Disponible en ligne et aussi une fois par mois par email. sales@iec.ch.

IEC 61788-24 ®

Edition 1.0 2018-06

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Superconductivity –

Part 24: Critical current measurement – Retained critical current after double

bending at room temperature of Ag-sheathed Bi-2223 superconducting wires

Supraconductivité –

Partie 24: Mesurage du courant critique – Courant critique retenu après double

flexion à température ambiante des fils supraconducteurs Bi-2223 avec gaine Ag

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 17.220; 29.050; 77.040.10 ISBN 978-2-8322-5801-9

– 2 – IEC 61788-24:2018 © IEC 2018

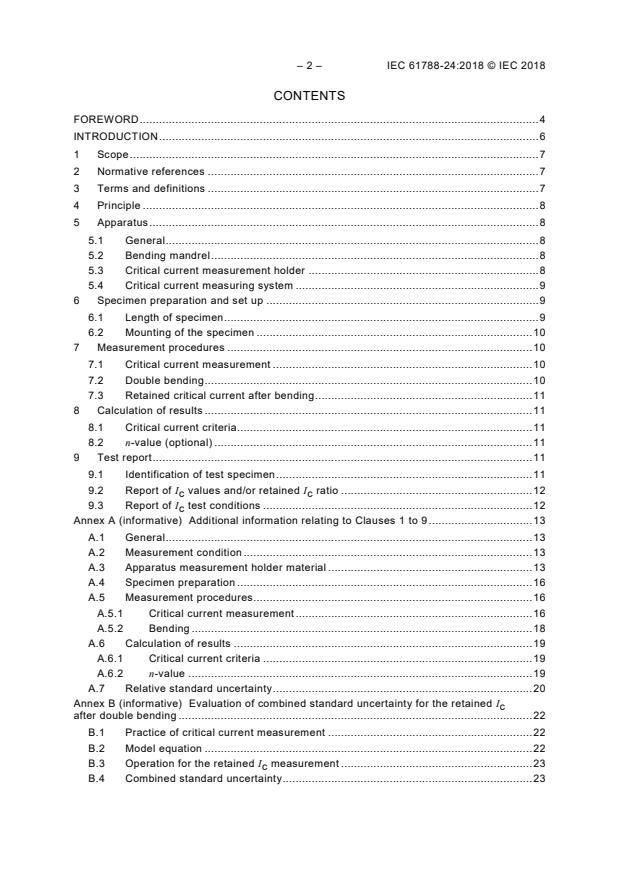

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 7

4 Principle . 8

5 Apparatus . 8

5.1 General . 8

5.2 Bending mandrel . 8

5.3 Critical current measurement holder . 8

5.4 Critical current measuring system . 9

6 Specimen preparation and set up . 9

6.1 Length of specimen . 9

6.2 Mounting of the specimen . 10

7 Measurement procedures . 10

7.1 Critical current measurement . 10

7.2 Double bending . 10

7.3 Retained critical current after bending . 11

8 Calculation of results . 11

8.1 Critical current criteria. 11

8.2 n-value (optional) . 11

9 Test report . 11

9.1 Identification of test specimen . 11

9.2 Report of I values and/or retained I ratio . 12

c c

9.3 Report of I test conditions . 12

c

Annex A (informative) Additional information relating to Clauses 1 to 9 . 13

A.1 General . 13

A.2 Measurement condition . 13

A.3 Apparatus measurement holder material . 13

A.4 Specimen preparation . 16

A.5 Measurement procedures . 16

A.5.1 Critical current measurement . 16

A.5.2 Bending . 18

A.6 Calculation of results . 19

A.6.1 Critical current criteria . 19

A.6.2 n-value . 19

A.7 Relative standard uncertainty . 20

Annex B (informative) Evaluation of combined standard uncertainty for the retained I

c

after double bending . 22

B.1 Practice of critical current measurement . 22

B.2 Model equation . 22

B.3 Operation for the retained I measurement . 23

c

B.4 Combined standard uncertainty . 23

B.5 Evaluation of standard uncertainty (SU) for each measurand . 24

B.5.1 Voltage tap length (L) . 24

B.5.2 Voltage (U) . 24

B.5.3 Current (I) . 25

B.6 Evaluation of combined standard uncertainty . 26

Bibliography . 29

Figure 1 – Sample holder . 9

Figure 2 – Intrinsic U-I characteristic . 12

Figure 3 – U-I characteristic with a current transfer component . 12

Figure A.1 – Measurement configuration for a few hundred ampere class conductor . 15

Figure A.2 – Clips . 15

Figure A.3 – Additional strain caused by voltage tap wires and solders . 16

Figure A.4 – Boiling temperature of liquid nitrogen versus atmospheric pressure . 17

Figure A.5 – Critical current versus temperature for a typical Bi-2223 wire . 18

Figure A.6 – Bending process . 19

Figure B.1 – U-I diagram . 22

Figure B.2 – Bending diameter dependence of the retained I and , where the

c COV

calculated curve of I /I gives Equation (B.24). 28

c c0

Table A.1 – Thermal expansion data of Bi-2223 superconductors and selected

materials . 14

Table A.2 – Average of the degree of retained critical current (I /I ), their relative

c c0

standard uncertainty and coefficient of variance. 21

Table B.1 – Precondition for evaluating standard uncertainty . 22

Table B.2 – Partial sum (Equation (B.17) of standard uncertainty as related to the

current measurement) . 26

Table B.3 – Budget table of standard uncertainty for each component . 27

Table B.4 – Combined standard uncertainty . 27

– 4 – IEC 61788-24:2018 © IEC 2018

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

SUPERCONDUCTIVITY –

Part 24: Critical current measurement –

Retained critical current after double bending at room

temperature of Ag-sheathed Bi-2223 superconducting wires

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61788-24 has been prepared by IEC technical committee 90:

Superconductivity:

The text of this standard is based on the following documents:

FDIS Report on voting

90/402/FDIS 90/406/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 6 – IEC 61788-24:2018 © IEC 2018

INTRODUCTION

In 1988, a new class of high critical temperature (T ) copper oxide superconductors,

c

Bi-Sr-Ca-Cu-O, was discovered. After nearly three decades, (Bi,Pb) Sr Ca Cu O (Bi-2223)

2 2 2 3 x

is now being utilized as a commercial high-T superconducting wire.

c

Superconducting wires are often subjected to bending deformation during production and

application, e.g. during wire processing, magnet construction, cable fabrication, etc. The wire

is bent towards both the upper and lower directions as it passes through several pulleys.

These production processes are carried out at room temperature. Critical current of the wire is

likely influenced through such bending, and may be accompanied by irreversible degradation

in case of large deformation. The easiest way to evaluate the influence of bending on critical

current is to carry out comparative measurement with the wire in the straight form before and

after bending to a specific diameter.

After a wire is made into a coil or a cable, critical current is often measured under bending

conditions or a more complex deformation state. In these cases, change in critical current

may include both reversible and irreversible contributions depending on the amount of

deformation. Irreversible degradation usually originates from a fracture in the superconducting

component. In order to evaluate only irreversible contributions, measuring the retained critical

current after the wire is straightened back from its deformed shape is necessary.

The critical bending diameter below which wire performance degrades significantly is typically

specified for use of commercial superconducting wire. Thus, it is important to standardize

measurement methods for the retained critical current after double bending. This document

can be applied to other similar bending tests such as single bending, cyclic bending, etc.

This document consists of two fundamental technologies of the critical current measurement

and the double bending process.

SUPERCONDUCTIVITY –

Part 24: Critical current measurement –

Retained critical current after double bending at room

temperature of Ag-sheathed Bi-2223 superconducting wires

1 Scope

This part of IEC 61788 describes a test method for determining the retained critical current

after double bending at room temperature of short and straight Ag- and/or Ag alloy-sheathed

Bi-2223 superconducting wires that have the shape of a flat or square tape containing mono-

or multicores of oxides. The wires can be laminated with copper alloy, stainless steel or Ni

alloy tapes.

The test method is intended for use with superconductors that have a critical current less than

300 A and an n-value larger than 5. The test to determine the retained critical current is

carried out without an applied magnetic field, with the test specimen immersed in a liquid

nitrogen open bath.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60050-815:2015, International Electrotechnical Vocabulary – Part 815: Superconductivity

(available at http://www.electropedia.org/)

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60050-815 and the

following apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

double bending

bending in one direction to a certain diameter followed by the subsequent bending in the

opposite direction to the same diameter

Note 1 to entry: Bending diameter is defined as the diameter of the bending mandrel.

Note 2 to entry: The definition of bending diameter is in principle the sum of the mandrel diameter and

superconductor thickness. In the engineering process, however, the minimum diameter of the pulleys through

which the wire is passed should also be considered.

– 8 – IEC 61788-24:2018 © IEC 2018

3.2

constant sweep rate method

voltage-current data (U-I data) acquisition method where a current is swept at a constant rate

from zero to a value above critical current (I ) while continuously or frequently and

c

periodically acquiring U-I data

3.3

ramp-and-hold method

U-I data acquisition method where a current is ramped to a number of appropriately

distributed points along the U-I curve and held constant at each of these points while

acquiring a number of voltages and current readings

4 Principle

The principle of the double bending method is described as follows. Critical current at 77 K

under self-field shall be measured in a straight configuration with no mechanical strain. After

measurement the specimen shall be warmed up to room temperature.

Hereafter, the specimen shall be bent in one direction to the specified diameter and then

returned to the straight configuration. Successively, the specimen shall be bent in the

opposite direction to the same diameter and returned to the straight configuration again.

Critical current of the specimen at 77 K under self-field shall be measured after double

bending and straightening. The time interval between critical current measurements before

and after bending should be as short as possible.

Critical current is determined from voltage-current (U-I) characteristic measured in a liquid

nitrogen open bath under a constant pressure. Critical current is determined as the current at

a specific electric field strength criterion (electric field criterion) (E ), which corresponds to the

c

voltage criterion (U ) for a specified voltage tap separation.

c

5 Apparatus

5.1 General

The apparatuses required for the present test methods include the following:

• mandrels with necessary bending diameters;

• critical current measuring system.

5.2 Bending mandrel

Bending diameter shall be defined as the diameter of the bending mandrel. Bendable length

shall be longer than the distance between the voltage taps.

5.3 Critical current measurement holder

The measurement holder is constructed from an insulating material.

Critical current may inevitably depend on the measurement holder material due to specimen

strain induced by the difference of thermal contraction between specimen and holder.

The structure of the measurement holder shall be one which does not induce a local excess

strain. The specimen strain induced by the difference of thermal contraction between

specimen and holder during cooling from room temperature to 77 K shall be minimized to

within ± 0,1 %. This thermal strain can be evaluated in cases where the thermal expansion

coefficients of constituent materials are known. To minimize the thermal strain, the holder

shall be constructed from material which has a thermal contraction similar to the specimen.

NOTE Recommended measurement holder materials are described in A.3.

5.4 Critical current measuring system

The apparatus to measure U-I characteristics consists of a specimen probe, an open bath of

liquid nitrogen and a U-I measurement system.

The specimen probe, which consists of a specimen, a measurement holder and a specimen

support structure, is inserted in the open bath filled with liquid nitrogen. The U-I measurement

system consists of a direct current source, a recorder and necessary preamplifiers, filters or

voltmeters, or a combination thereof.

A computer-assisted data acquisition system is recommended.

6 Specimen preparation and set up

6.1 Length of specimen

The length (L) of the specimen to be measured shall be determined as follows (see Figure 1):

L = 2 × L + 2 × L + L + 2 × L > 5 × W (1)

2 4 1 3

L ≥ W, L ≥ W, L ≥ W (2)

1 2 3

where

L is the distance between the voltage taps;

L is the length of the current contact;

L is the shortest distance from the current contact to the voltage tap;

L is the width of the voltage tap;

W is the width of the specimen to be measured.

L L L L L L L

2 3 4 1 4 3 2

Current

Current Voltage

Voltage

IEC

Figure 1 – Sample holder

For a specimen with a larger current-carrying capacity/width, L shall be longer than 3W. In

cases where the specimen is laminated with stainless steel or laminated with another highly

resistive material, L shall be larger. For measurement which requires higher voltage

sensitivity, L shall be larger. In cases where current transfer voltage cannot be ignored, L shall

1 3

be larger.

– 10 – IEC 61788-24:2018 © IEC 2018

In Table 2 of [1] , five successful double bend test conditions are shown. Typically, specimen

length L ranges from 90 mm to 150 mm, L from 18,25 mm to 50 mm, L from 10 mm to

1 2

20 mm, L from 12,5 mm to 20 mm, and L from 1,75 mm to 11 mm. When testing Bi-2223

3 4

wire with a stainless steel or nickel alloy laminate, L should be sufficiently large to avoid

local heating.

6.2 Mounting of the specimen

The specimen shall be mounted on the flat surface of the holder and both ends shall be

fastened to the current contact blocks without solder, as described in A.3. As long as the

current pad areas of the wire are not located within the area to be bent, they can also be

soldered, if desired.

Voltage taps shall be placed in the central section of the specimen, without any material

which cannot be removed.

NOTE The recommended voltage tap method is described in A.3.

The voltage leads shall be twisted as close to the voltage taps as possible.

7 Measurement procedures

7.1 Critical current measurement

Critical current shall be measured under conditions that avoid any extra mechanical strain.

The specimen shall be slowly immersed in the liquid nitrogen bath. The specimen shall be

cooled from room temperature to the temperature of the liquid nitrogen over a time period of

at least a few tens of seconds.

When using the constant sweep rate method, ramp rate shall be set so that I and n-value are

c

not ramp rate dependent.

When using the ramp-and-hold method, current sweep rate between current set points shall

be set lower than the equivalent ramping from zero current to I in 3 s. Data acquisition at

c

each set point shall begin as soon as the flow/creep voltage generated by the current ramp

can be disregarded. Current drift during each current set point shall be less than 1 % of I .

c

U-I characteristics are measured and recorded at increasing current values.

Baseline voltage of the U-I characteristic shall be determined as the recorded voltage at zero

current for the ramp-and-hold method or the average voltage at approximately 0,1 I for the

c

constant sweep rate method.

After measurement, the specimen shall be warmed up to room temperature.

7.2 Double bending

At room temperature, one end of the specimen shall be affixed to a mandrel of a specific

diameter and the specimen bent along the mandrel from the fixed end to the free end, as

shown in A.5.2. The bending section shall include the entire length between the voltage taps.

Hereafter, the specimen shall be free of bending.

___________

Numbers in square brackets refer to the Bibliography.

The specimen shall be turned over and reaffixed to the mandrel with the same diameter and

bent along the mandrel from the fixed end to the free end of specimen.

Finally, the specimen shall be straightened.

7.3 Retained critical current after bending

Critical current shall be measured in a straight configuration with no mechanical strain other

than straightening from the plastic deformation caused by the previous bending.

Critical current measurement shall be carried out using the same procedure as in 7.1.

Measurement shall be carried out in a liquid nitrogen open bath with a time interval between

critical current measurements before and after bending treatment as short as possible. Since

critical current is strongly dependent on temperature, attention shall be given to avoid

variation in temperature before and after bending. A detailed discussion is provided in A.5.1.

8 Calculation of results

8.1 Critical current criteria

Critical current I shall be determined using electric field criterion E .

c c

The value of I shall be determined under criteria of 100 μV/m and/or 10 μV/m.

c

I shall be determined to be the current corresponding to the point on the U-I curve where

c

voltage U is measured relative to the baseline voltage (see Figure 2 and Figure 3):

c

U = L E (3)

c 1 c

where

U is the voltage criterion in microvolts (μV);

c

L is the voltage tap separation in metres (m);

E is the electric field criterion in microvolts per metre (μV/m);

c

where U and I are the corresponding voltage and current values at the intersecting point of

c c

the straight lines with the U-I curve as shown in Figure 2.

A straight line shall be drawn from the baseline voltage to the average voltage near 0,5 I

c

(see Figure 3). The finite slope of this line shall be due to current transfer and/or local sample

damage. Valid determination of I requires that the slope of the line be less than 0,3 U /I ,

c c c

where U and I are determined under the criteria of 100 μV/m and/or 10 μV/m.

c c

8.2 n-value (optional)

n-value shall be calculated as the slope of the plot of log U versus log I in the region between

100 μV/m and 10 μV/m.

9 Test report

9.1 Identification of test specimen

The test specimen shall be identified by the following:

a) name of the manufacturer of the specimen;

– 12 – IEC 61788-24:2018 © IEC 2018

b) classification and/or symbol;

c) lot number.

9.2 Report of I values and/or retained I ratio

c c

I values before and after bending and/or the retained I ratio, together with their

c c

corresponding criteria and n-values (optional), shall be reported.

9.3 Report of I test conditions

c

The following test conditions shall be reported as needed:

a) bending diameter (D);

b) fixing method of the current and voltage taps (for example, clip, crimping using Cu block,

solder (for currents) or another connecting method);

c) length of specimen (L);

d) distance between voltage taps (L );

e) the shortest distance from a current contact to a voltage tap (L );

f) length of the current contacts (L );

g) sweep rate when using the constant sweep rate method;

h) ramp pitch, ramping time and holding time when using the ramp-and-hold method.

U = LE

c

0 I

c

DC current, I (arbitrary units)

IEC

Figure 2 – Intrinsic U-I characteristic

U = LE

c

Current transfer line

I

c

DC current, I (arbitrary units)

IEC

Figure 3 – U-I characteristic with a current transfer component

Voltage U (arbitrary units) Voltage U (arbitrary units)

U = LE

U = LE c c

c c

Annex A

(informative)

Additional information relating to Clauses 1 to 9

A.1 General

Many different variables have a significant effect on the critical current measurement value for

Ag- and/or Ag alloy-sheathed Bi-2223 superconductor wires. However, significant portions of

the test method covered in this document are common or similar to those for Bi-based oxide

superconductors (IEC 61788-3 [2]). Only some of these variables are addressed in Annex A.

For variables that are not mentioned here, refer to IEC 61788-3.

Special features of oxide superconductors can be classified into two groups. The first group is

specific to oxide composite superconductors, including mechanical fragility, electromagnetic

weak links, cryogen gas bubble formation, aging degradation, magnetic flux flow and creep,

large anisotropy, hysteresis in critical current with magnetic field sweep, etc. The second

group is related to the short length of the specimen used in the standard. Critical current

measurement of such a specimen may easily pick up varying voltage signals due to thermal

electromotive force, inductive voltage, thermal noise, current redistribution, specimen motion

relative to the holder, etc. Current transfer voltages may be present due to the short distance

from a current contact to the voltage tap.

Superconductors with critical currents above 300 A can be measured using this document

with an anticipated reduction both in accuracy and precision and a more significant self-field

effect.

Restrictions in this test method have been added in order to obtain the required precision in

the final definitive phase of long conductor qualification.

A.2 Measurement condition

The minimum total length of the tape specimen is five times the tape width (W) plus two times

the voltage tap width (L ), which represents the sum of the following:

– the minimum voltage tap separation (L ≥ W);

– the length of the current contacts (L ≥ W);

– the shortest distance between the current and voltage contacts (L ≥ W).

A.3 Apparatus measurement holder material

In this method, the specimen strain is kept to a minimum (less than 0,1 %). A thermal

contraction of less than 0,1 % does not result in an appreciable deviation of I at 0 T, near

c

77 K. One significant source of strain is the mismatch of thermal contraction rates between

the measurement holder and the specimen when cooled to liquid nitrogen temperature.

Based on the typical thermal contractions shown in Table A.1, the following materials are

recommended for the measurement holder material. For alternative holder materials, a

carefully prepared qualification study should precede routine tests.

The recommended holder material is fibreglass epoxy composite, with the specimen lying in

the plane of the fabric warp.

– 14 – IEC 61788-24:2018 © IEC 2018

Table A.1 – Thermal expansion data of Bi-2223 superconductors

and selected materials

Material ∆L/L [%]

293K-77K

Ag-sheathed Bi-2223 [3] 0,274

Ag,Au-sheathed Bi-2223 [3] 0,293

Copper alloy laminated Bi-2223 0,275

Stainless steel laminated Bi-2223 0,265

Nickel alloy laminated Bi-2223 0,227

Silver [4] 0,370

Copper [5] 0,302

GFRP G10, warp [6][7] 0,21

GFRP G10, normal [6][7] 0,64

An example of a measurement holder is shown in Figure A.1.

As shown in Figure A.1 (a), the sample holder is constructed by four contact blocks made of

silver tape (2) attached to the fibreglass epoxy base (1). The braided wires (3) are soldered to

the silver tapes in the opposite surface as current and voltage taps.

As shown in Figure A.1 (b), the tape specimen (4) is set on the sample holder by contacting

the silver tapes and lapped by the braided wires. The lapped surface is then tightly gripped

with the clips ((5) in Figure A.1 (c)). Examples of the clips are shown in Figure A.2.

L L

2 4

L

L

3 1

3 4

(4)

IEC IEC

(a) Measurement holder (b) Specimen laid on the holder

(5)

1 2 4

IEC IEC

(d) All contacts clipped on to the specimen

(c) Current contact clipped on to the specimen

Key

current contacts

voltage taps

Figure A.1 – Measurement configuration for a few hundred ampere class conductor

IEC IEC

Figure A.2 – Clips

– 16 – IEC 61788-24:2018 © IEC 2018

Additional strain

Solder

Wire

Wire

Solder

IEC IEC

Bending in one direction Bending in the opposite direction

Figure A.3 – Additional strain caused by voltage tap wires and solders

A critical current measurement standard (IEC 61788-3) exists for BSCCO wire. IEC 61788-3

uses soldering to affix the voltage taps. However, if IEC 61788-3 is used, additional strain is

induced on the wire at the soldered position, when the wire is bent and the solder and voltage

taps are caught between the wire and the bending mandrel. This document for critical current

measurement is an exception in order to avoid additional strain-induced degradation of the

wire.

A.4 Specimen preparation

The distance between the voltage taps is defined as the smallest distance between the

voltage contacts, irrespective of size.

A.5 Measurement procedures

A.5.1 Critical current measurement

To reduce thermoelectric potential on the specimen voltage leads, copper voltage leads are

used continuously from the cryogen bath until room temperature, where an isothermal

environment for all room temperature joints or connections is provided. It should be noted that

the joints or connections immersed in the cryogen bath are isothermal.

The rate of cooling may affect the results of critical current measurement due to differential

cooling rates and differential thermal contraction causing excessive strain of the specimen.

Atmospheric pressure causes variation in the boiling temperature of liquid nitrogen filled in the

open bath. Figure A.4 shows the correlation between boiling temperature (T ) and

b

atmospheric pressure (P).

78,5

77,5

y = 0,084 8x + 68,745

R = 0,999 4

76,5

85 90 95 100 105 110 115

P (kPa)

IEC

Figure A.4 – Boiling temperature of liquid nitrogen

versus atmospheric pressure

The critical current of Bi-2223 wires depends on temperature as shown in Figure A.5.

In this document, the objective is to obtain the ratio of critical currents before and after the

bending treatment. In order to avoid a significant temperature change from atmospheric

pressure variation over time, the duration between two critical current measurements shall be

as short as possible.

If system noise is significant compared to the prescribed value of voltage, i.e. U , increasing

c

the time for the ramp progress from zero current to I to more than 150 s is desirable. In this

c

case, care should be taken to sufficiently increase the heat capacity and/or to sufficiently cool

the surface of the current contacts to suppress the influence of heat generation due to the

longer time required for measurement. It should be noted that the ramp-and-hold method

allows for averaging data which can be appropriately distributed along the U-I characteristics.

T (K)

b

– 18 – IEC 61788-24:2018 © IEC 2018

y = –9,131 8x + 885,58

77 77,2 77,4 77,6 77,8

Temperature (K)

IEC

Figure A.5 – Critical current versus temperature for a typical Bi-2223 wire

Ramping the specimen current can induce a positive or negative voltage on the voltage taps

over time. This source of interference voltage during ramping can be identified by its

proportional dependence on ramp rate. If this voltage is significant compared to U , then

c

decreasing the ramp rate, decreasing the area of the loop formed by the voltage taps and the

specimen in between, or using the ramp-and-hold method is recommended.

Faster current ramp rates can be used for the ramp-and-hold method if the measurement

system proves to yield consistent results with a specific ramp rate equivalent to ramping from

zero to I in 3 s. It is possible to obtain consistent results with ramp rates as high as 500 A/s

c

on a conductor with critical current from 10 A to 200 A.

Baseline voltage may include thermoelectric, off-set, ground-loop and common-mode voltages.

It is assumed that these voltages remain relatively constant for the time it takes to record

each U-I characteristic. Small changes in thermoelectric and off-set voltages can be

approximately negated by measuring the baseline voltage before and after the U-I curve

measurement and assuming a linear change with time. If the change in the baseline voltage is

significant compared to U , then the experimental configuration should be corrected.

c

A.5.2 Bending

In these procedures, “double bending” re

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...