IEC 62625-2:2016

(Main)Electronic railway equipment - On board driving data recording system - Part 2: Conformity testing

Electronic railway equipment - On board driving data recording system - Part 2: Conformity testing

IEC 62625-2:2016 covers the standardized test methods for verifying the compliance of an On board Driving Data Recording System implementation with the requirements specified by IEC 62625-1. It also covers the conformity testing criteria for designed and manufactured ODDRS. This part of IEC 62625 includes the list of the requirements specified by IEC 62625-1 and the relevant acceptance conditions for ODDRS at design review, type test and routine test phases. For the train level design review and train level test phases, this part provides guidelines for the conformity testing methods to be applied to the ODDRS installed on the train.

Matériel électronique ferroviaire - Système embarqué d'enregistrement de données de conduite - Partie 2: Essais de conformité

L'IEC 62625-2:2016 porte sur les méthodes d'essais normalisées pour la vérification de la conformité de la mise en oeuvre d'un système embarqué d'enregistrement des données de conduite aux exigences spécifiées dans l'IEC 62625-1. De plus, elle porte sur les critères d'essais de conformité des ODDRS conçus et fabriqués. La présente partie de l'IEC 62625 contient la liste des exigences spécifiées par l'IEC 62625-1, ainsi que les conditions d'acceptation correspondantes pour l'ODDRS lors des phases de revue de conception, d'essai de type et d'essai individuel de série. Pour les phases de revue de conception au niveau du train et d'essais au niveau du train, la présente partie donne les lignes directrices relatives aux méthodes d'essais de conformité à appliquer à l'ODDRS installé dans le train.

General Information

- Status

- Published

- Publication Date

- 26-Jan-2016

- Technical Committee

- TC 9 - Electrical equipment and systems for railways

- Drafting Committee

- WG 48 - TC 9/WG 48

- Current Stage

- PPUB - Publication issued

- Start Date

- 27-Jan-2016

- Completion Date

- 31-Jan-2016

Overview

IEC 62625-2:2016 is an international standard published by the International Electrotechnical Commission (IEC) that specifies conformity testing methods for On Board Driving Data Recording Systems (ODDRS) used in electronic railway equipment. This second part of the IEC 62625 series focuses on verifying that ODDRS implementations meet the stringent functional and system requirements outlined in IEC 62625-1. It provides a comprehensive framework for conformity testing during design review, type testing, and routine testing phases to ensure reliable performance and safety of onboard driving data recorders in railway operations.

Key Topics

Conformity Testing Methodology

IEC 62625-2 details standardized test procedures and methodologies for assessing compliance of ODDRS with IEC 62625-1 requirements. It covers testing at both system and train levels, including integrated type tests of ODDRS installed on trains.Functional Requirements Verification

The standard outlines testing for key functions such as recording train data, onboard data protection, data retrieval, and recorded data analysis. It also specifies how to verify optional functions provided by the ODDRS unit.System Requirements Evaluation

Essential system-level criteria such as ODDRS operating modes, recording performance, environmental resilience, availability, security of records, maintainability, data survivability, and power consumption are rigorously tested. The standard defines acceptance conditions tied to these aspects.Implementation Conformity Statements

IEC 62625-2 introduces tools including Functional Implementation Conformity Statements (FICS) and System Implementation Conformity Statements (SICS) to document and assess implementation compliance throughout the testing process.Test Environment and Type Test Arrangements

Requirements for the test setup, including the use of equivalent signal generators and power supplies, ensure repeatability and reliability of type testing. The standard provides guidelines on how to organize integrated ODDRS testing within a train environment.

Applications

Railway Equipment Manufacturers

Companies designing and manufacturing on-board driving data recorders rely on IEC 62625-2 to validate device compliance with international standards, ensuring their products meet strict safety and performance benchmarks before market release.Railway Operators and Regulators

Railway operators use this standard to verify onboard equipment conformity during procurement, installation, and routine maintenance phases. Regulatory bodies adopt the standard as part of certification processes for railway safety and interoperability.Testing Laboratories and Certification Bodies

Test centers performing conformity assessments of electronic railway equipment implement IEC 62625-2 procedures to provide credible and harmonized evaluation results that support international market access.Safety and Quality Assurance Teams

Engineering teams incorporate the IEC 62625-2 testing framework within their quality assurance processes to identify and mitigate risks associated with data recording reliability and integrity in railway systems.

Related Standards

IEC 62625-1: On Board Driving Data Recording System – Functional and System Requirements

Defines the fundamental requirements and performance specifications that IEC 62625-2 tests for conformity.IEC 62998: Electronic Railway Equipment – Data Communication Networks

Addresses communication aspects which may interface with data recorders and impact overall system compliance.IEC 61508: Functional Safety of Electrical/Electronic/Programmable Electronic Safety-related Systems

Provides broader principles on safety lifecycle and reliability applicable to railway equipment including ODDRS.EN 50155: Railway Applications – Electronic Equipment Used on Rolling Stock

Sets environmental and reliability criteria relevant to onboard data recording devices.

By adhering to the IEC 62625-2:2016 standard, stakeholders in the railway sector ensure that On Board Driving Data Recording Systems are rigorously tested for conformity-contributing to enhanced operational safety, system interoperability, and data integrity in modern railway transportation.

Get Certified

Connect with accredited certification bodies for this standard

Bureau Veritas Railway Certification

Railway and transportation certification.

Deutsch Quality Systems (India) Pvt. Ltd. (DQS India)

Subsidiary of DQS Holding GmbH, founding member of IQNet. CDSCO Notified Body.

Excellence Ireland Quality Association (EIQA)

Irish quality certification organization.

Sponsored listings

Frequently Asked Questions

IEC 62625-2:2016 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Electronic railway equipment - On board driving data recording system - Part 2: Conformity testing". This standard covers: IEC 62625-2:2016 covers the standardized test methods for verifying the compliance of an On board Driving Data Recording System implementation with the requirements specified by IEC 62625-1. It also covers the conformity testing criteria for designed and manufactured ODDRS. This part of IEC 62625 includes the list of the requirements specified by IEC 62625-1 and the relevant acceptance conditions for ODDRS at design review, type test and routine test phases. For the train level design review and train level test phases, this part provides guidelines for the conformity testing methods to be applied to the ODDRS installed on the train.

IEC 62625-2:2016 covers the standardized test methods for verifying the compliance of an On board Driving Data Recording System implementation with the requirements specified by IEC 62625-1. It also covers the conformity testing criteria for designed and manufactured ODDRS. This part of IEC 62625 includes the list of the requirements specified by IEC 62625-1 and the relevant acceptance conditions for ODDRS at design review, type test and routine test phases. For the train level design review and train level test phases, this part provides guidelines for the conformity testing methods to be applied to the ODDRS installed on the train.

IEC 62625-2:2016 is classified under the following ICS (International Classification for Standards) categories: 31.220.20 - Switches; 45.060.01 - Railway rolling stock in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62625-2:2016 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62625-2 ®

Edition 1.0 2016-01

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Electronic railway equipment – On board driving data recording system –

Part 2: Conformity testing

Matériel électronique ferroviaire – Système embarqué d'enregistrement de

données de conduite –

Partie 2: Essais de conformité

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 20 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 15 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 65 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient 20 000 termes et définitions en anglais

Spécifications techniques, Rapports techniques et autres

et en français, ainsi que les termes équivalents dans 15

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

La recherche avancée permet de trouver des publications IEC 65 000 entrées terminologiques électrotechniques, en anglais

en utilisant différents critères (numéro de référence, texte, et en français, extraites des articles Termes et Définitions des

comité d’études,…). Elle donne aussi des informations sur les publications IEC parues depuis 2002. Plus certaines entrées

projets et les publications remplacées ou retirées. antérieures extraites des publications des CE 37, 77, 86 et

CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 62625-2 ®

Edition 1.0 2016-01

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Electronic railway equipment – On board driving data recording system –

Part 2: Conformity testing

Matériel électronique ferroviaire – Système embarqué d'enregistrement de

données de conduite –

Partie 2: Essais de conformité

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 45.060 ISBN 978-2-8322-3106-7

– 2 – IEC 62625-2:2016 © IEC 2016

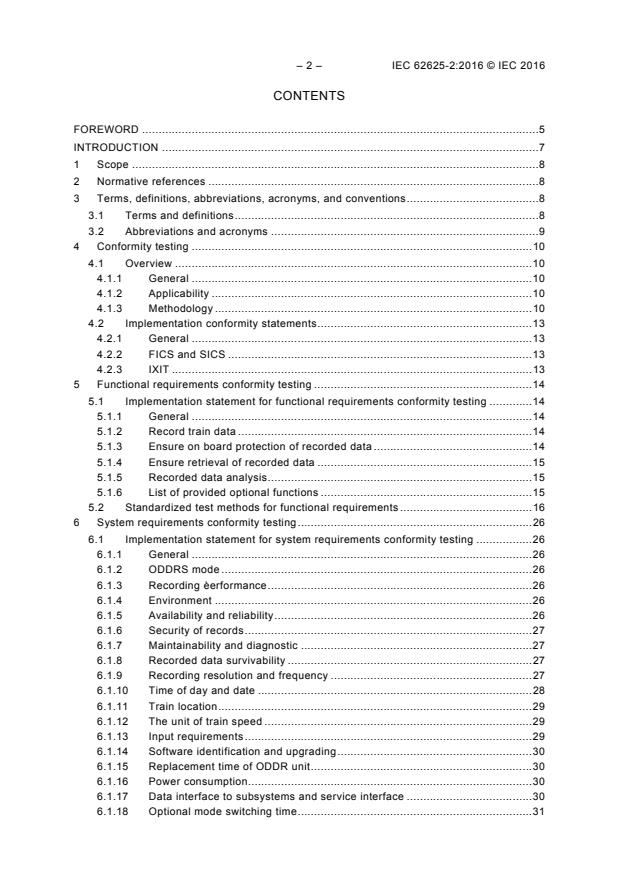

CONTENTS

FOREWORD .5

INTRODUCTION .7

1 Scope .8

2 Normative references .8

3 Terms, definitions, abbreviations, acronyms, and conventions .8

3.1 Terms and definitions .8

3.2 Abbreviations and acronyms .9

4 Conformity testing . 10

4.1 Overview . 10

4.1.1 General . 10

4.1.2 Applicability . 10

4.1.3 Methodology . 10

4.2 Implementation conformity statements . 13

4.2.1 General . 13

4.2.2 FICS and SICS . 13

4.2.3 IXIT . 13

5 Functional requirements conformity testing . 14

5.1 Implementation statement for functional requirements conformity testing . 14

5.1.1 General . 14

5.1.2 Record train data . 14

5.1.3 Ensure on board protection of recorded data . 14

5.1.4 Ensure retrieval of recorded data . 15

5.1.5 Recorded data analysis . 15

5.1.6 List of provided optional functions . 15

5.2 Standardized test methods for functional requirements . 16

6 System requirements conformity testing . 26

6.1 Implementation statement for system requirements conformity testing . 26

6.1.1 General . 26

6.1.2 ODDRS mode . 26

6.1.3 Recording èerformance . 26

6.1.4 Environment . 26

6.1.5 Availability and reliability . 26

6.1.6 Security of records . 27

6.1.7 Maintainability and diagnostic . 27

6.1.8 Recorded data survivability . 27

6.1.9 Recording resolution and frequency . 27

6.1.10 Time of day and date . 28

6.1.11 Train location . 29

6.1.12 The unit of train speed . 29

6.1.13 Input requirements . 29

6.1.14 Software identification and upgrading . 30

6.1.15 Replacement time of ODDR unit . 30

6.1.16 Power consumption . 30

6.1.17 Data interface to subsystems and service interface . 30

6.1.18 Optional mode switching time . 31

6.2 Standardized test methods for system requirements . 31

7 Arrangements for ODDR Unit type test . 44

7.1 Type test with the integrated ODDRS . 44

7.1.1 General . 44

7.1.2 Equivalent signal generator, power supply . 44

7.1.3 Setup of the test environment . 45

Annex A (informative) FICS and SICS structure and instruction . 46

A.1 FICS and SICS pro-forma. 46

A.1.1 General . 46

A.1.2 Abbreviations used in FICS and SICS tables . 46

A.2 FICS and SICS tables . 46

A.2.1 Identification of FICS and SICS . 46

A.2.2 Identification of the implementation under test . 46

A.2.3 Identification of the IUT supplier . 47

A.2.4 Identification of the standards . 47

A.2.5 Global statement of conformity . 48

A.2.6 Level of conformity . 48

A.2.7 FICS and SICS tables structure . 48

Annex B (informative) Methods for testing the parameter values of the protection

capability . 50

B.1 Overview . 50

B.2 General procedure . 50

B.3 Detailed procedure . 50

B.3.1 Protection capability code FA . 50

B.3.2 Protection capability code FB . 51

B.3.3 Protection capability code SA . 51

B.3.4 Protection capability code SB . 52

B.3.5 Protection capability code PA . 52

B.3.6 Protection capability code CA. 52

B.3.7 Protection capability code CB. 53

B.3.8 Protection capability code IA . 53

B.3.9 Protection capability code IB . 53

B.3.10 Protection capability code HA. 54

B.3.11 Protection capability code MA . 54

Bibliography . 55

Figure 1 – Conformity testing process . 11

Figure 2 – Test configurations at the integrated type test . 45

Figure B.1 – Impact shock waveform . 52

Table 1 – FICS pro-forma “Record train data” . 14

Table 2 – FICS pro-forma “Ensure on board protection of recorded data” . 15

Table 3 – FICS pro-forma “Ensure retrieval of recorded data” . 15

Table 4 – FICS pro-forma “Recorded data analysis” . 15

Table 5 – FICS pro-forma “List of provided optional functions” . 15

Table 6 – Standardized test methods for functional requirements . 17

Table 7 – SICS pro-forma “ODDRS mode” . 26

– 4 – IEC 62625-2:2016 © IEC 2016

Table 8 – SICS pro-forma “Recording performance” . 26

Table 9 – SICS pro-forma “Environment” . 26

Table 10 – SICS pro-forma “Availability and reliability” . 27

Table 11 – SICS pro-forma “Security of records” . 27

Table 12 – SICS pro-forma “Maintainability and diagnostic” . 27

Table 13 – SICS pro-forma “Recorded data survivability”. 27

Table 14 – SICS pro-forma “Recording resolution and frequency” . 28

Table 15 – SICS pro-forma “Time of day and date” . 29

Table 16 – SICS pro-forma “Train location” . 29

Table 17 – SICS pro-forma “The unit of train speed” . 29

Table 18 – SICS pro-forma “Input requirements” . 30

Table 19 – SICS pro-forma “Software identification and upgrading” . 30

Table 20 – SICS pro-forma “Replacement time of ODDR unit” . 30

Table 21 – SICS pro-forma “Power consumption” . 30

Table 22 – SICS pro-forma “Data interface to subsystems and service interface” . 31

Table 23 – SICS pro-forma “Optional mode switching time” . 31

Table 24 – Standardized test methods for system requirements . 32

Table A.1 – FICS and SICS identification table . 46

Table A.2 – IUT identification table . 47

Table A.3 – IUT supplier identification table . 47

Table A.4 – Applicable standards identification table . 47

Table A.5 – Global statement table . 48

Table A.6 – FICS and SICS tables format . 49

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTRONIC RAILWAY EQUIPMENT –

ON BOARD DRIVING DATA RECORDING SYSTEM –

Part 2: Conformity testing

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an

international consensus of opinion on the relevant subjects since each technical committee has representation

from all interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated

in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

Internationals Standard IEC 62625-2 has been prepared by IEC Technical Committee 9:

Electrical equipment and systems for railways.

The text of this standard is based on the following documents:

FDIS Report on voting

9/2081/FDIS 9/2118/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

– 6 – IEC 62625-2:2016 © IEC 2016

A list of all parts in the IEC 62625 series, published under the general title Electronic railway

equipment – On board driving data recording system, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC website under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

INTRODUCTION

In consideration that IEC 62625-1 specifies the ODDRS (On Board Driving Data Recording

System) requirements in terms of functional and system descriptions, a standardized

conformity testing approach was developed in this standard on the base of the ISO/IEC 9646

series standards.

The ISO/IEC 9646 series standards apply to the assessment of communication protocol and

are based on the concept of PICS (Protocol Implementation Conformity Statement) and PIXIT

(Protocol Implementation eXtra Information for Testing). This standard extends the concepts

to functional and system description introducing FICS (Function Implementation Conformity

Statement), SICS (System Implementation Conformity Statement) and IXIT (Implementation

eXtra Information for Testing).

The IEC 62625-1 requirements implementation, formally described by FICS, SICS and IXIT

are verified by design review and other test methods applied to ODDR Unit and ODDRS

installed on the train.

– 8 – IEC 62625-2:2016 © IEC 2016

ELECTRONIC RAILWAY EQUIPMENT –

ON BOARD DRIVING DATA RECORDING SYSTEM –

Part 2: Conformity testing

1 Scope

This part of IEC 62625 covers the standardized test methods for verifying the compliance of

an On board Driving Data Recording System implementation with the requirements specified

by IEC 62625-1.

Furthermore, it covers the conformity testing criteria for designed and manufactured ODDRS.

This part of IEC 62625 includes the list of the requirements specified by IEC 62625-1 and the

relevant acceptance conditions for ODDRS at design review, type test and routine test

phases. For the train level design review and train level test phases, this part provides

guidelines for the conformity testing methods to be applied to the ODDRS installed on the

train.

This part does not cover the conformity assessment schemes that, according to ISO/IEC

Directives Part 2, are the responsibility of ISO policy committee “Committee on conformity

assessment” (ISO/CASCO). Consequently, this part does not include elements related to

conformity assessment aspects other than design review and testing provisions for the

products, processes or services which implements the requirements specified in IEC 62625-1.

This part does not delete, change or interpret the general requirements for conformity

assessment procedures and vocabulary detailed in ISO/IEC 17000.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document

and are indispensable for its application. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60571, Railway applications – Electronic equipment used on rolling stock

IEC 61375 (all parts), Electronic railway equipment – Train communication network (TCN)

IEC 62498-1, Railway applications – Environmental conditions for equipment – Part 1:

Equipment on board rolling stock

IEC 62625-1:2013, Electronic railway equipment – On board driving data recording system –

Part 1: System specification

ISO/IEC 8824 (all parts), Information technology – Abstract Syntax Notation One (ASN.1)

3 Terms, definitions, abbreviations, acronyms, and conventions

3.1 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1.1

accident

unintended event or series of events that results in death, injury, loss of a system or service,

or environmental damage

Note 1 to entry: Accidents are divided into the following categories: collisions, derailments, level crossing

accidents, accidents to persons caused by rolling stock in motion, fires and others.

3.1.2

consist

single vehicle or a group of vehicles which are not separated during normal operation

EXAMPLE The vehicles of a consist are steadily connected in a workshop, and automatic couplers are mounted

at both ends of the consist to facilitate the coupling and de-coupling of complete consists in the workshop or

during operation.

Note 1 to entry: A consist may contain one or more traction units.

3.1.3

incident

any occurrence, other than accident or serious accident, associated with the operation of

trains and affecting the safety of operation

3.1.4

non-volatile storage medium

memory and the relevant interface circuitry, which store the data for investigative use in case

of accidents and incidents

Note 1 to entry: The non-volatile storage medium may be protected.

3.1.5

ODDR unit

physical unit which implements the ODDRS

Note 1 to entry: ODDRS may be implemented by one or more ODDR units.

3.1.6

resolution

smallest change in the measurand, or stored quantity, which causes a perceptible change in

the indication

[SOURCE: IEC 60050-311:2001, 311-03-10, modified – ‘stored quantity’ instead of ‘quantity

supplied’ has been used]

3.1.7

test verdict

statement of “pass”, “fail”, or “inconclusive”, as specified in an abstract test case, concerning

conformity of an IUT with respect to the test case when it is executed

3.1.8

train safety function

technical barrier to prevent a hazard to become an accident during the train operation

3.2 Abbreviations and acronyms

CSV Comma Separated Values

DR Design Review

EMC Electromagnetic Compatibility

FICS Function Implementation Conformity Statement

GPS Global Positioning System

– 10 – IEC 62625-2:2016 © IEC 2016

IDRR Integration DR Report

ITTR Integration Type Test Report

IUT Implementation Under Test

IXIT Implementation eXtra Information for Testing

LSB Least Significant Bit

NTP Network Time Protocol

ODDR On Board Driving Data Recording

ODDRS On Board Driving Data Recording System

RAL Colour Standard

SICS System Implementation Conformity Statement

TCMS Train Control and Monitoring System

TCN Train Communication Network

TLDR Train Level Design Review

TLDRR Train Level Design Review Report

TLT Train Level Test

TLTR Train Level Test Report

TT Type Test

USB Universal Serial Bus

UTC Universal Time, Coordinated

XML eXtensible Markup Language

4 Conformity testing

4.1 Overview

4.1.1 General

Clause 4 specifies the process and methodology for the conformity testing, in terms of

procedures, design review requirements, testing requirements, and conformity testing

documentation requirements.

4.1.2 Applicability

This standard is applicable to verify and test ODDRS at sub-system level or at unit level. The

conformity testing shall be performed and concluded for units carrying any function covered

by 4.2 of IEC 62625-1:2013 and respecting the requirements specified by 4.3 of IEC 62625-

1:2013.

4.1.3 Methodology

4.1.3.1 General

The ODDRS conformity testing process shall follow the phases listed below, see Figure 1.

The relevant documentation shall be part of the conformity testing and documentation folder.

Phases of the conformity testing process:

a) Device/function conformity checking

b) Subsystem integration Design Review (DR)

c) Subsystem integration Type Test (TT)

d) Subsystem type and traction unit type – Train Level Design Review (TLDR)

e) Subsystem type and traction unit type – Train Level Type Test (TLTT)

Device/Function

Dev/Funct

Devices /

Device/Function

D B C Test

Function

a) A E Device/Function

test suite

Report

Test procedure

Conformity

Acceptance process

Testing

Documentation

Subsystem

A C

System

B Review the design IDDR

Requirements

b)

of the ODDR Unit Integration

E DR Report

D Test methods DR

in Table 6 and

Integration Design Review

Table 24

Subsystem Type

Integration Test

C

A

Procedure

B

Perform the type test ITTR integration

c)

of the ODDR Unit Type Test Report

Test methods TT

E

D

in Table 6 and

Table 24

Integration Type Test

Subsystem Type + Traction unit type

Type System

A

Requirements

B C

TLDRR Train

Review the integration

d) Conformity testing

Level Design

E design of the ODDRS

D

Test methods

and

on the train Review Report

TLDR in Table 6

Document Folder

and Table 24

Train Level Design Review

Subsystem Type + Traction unit type

Installation Test

procedure

A

B C

Perform tests of the

e) TLTR Train Level

E Test methods TLT ODDRS on the train

D

Test Report

in Table 6 and

Table 24

IEC

Train Level Test

Figure 1 – Conformity testing process

4.1.3.2 Device/function conformity checking

The compliance to the requirements specified by IEC 62625-1:2013 is mandatory for all the

functions/devices composing the ODDR unit. Each device/function shall be verified according

to the provided test procedure.

Considering that the user of this standard is free, at design level, to choose the functions

mapping over devices, several situations may apply:

• One complete function is carried and executed by one device.

• More than one function is carried and executed by one device.

• One function is carried and executed by more devices, each one executing a part (sub-

function) of the complete function.

Following this consideration, the device/function conformity checking is only covering the

capability of the device to execute the functions/sub-functions which are carried by such

device.

The test procedures are defined by the designer. The passing of such test procedure are a

prerequisite to run the tests specified by 4.1.3.4 and 4.1.3.6.

Specific requirements related to practices necessary to assure the integration at ODDR unit

and at train level are to be determined in accordance with relevant railway standards during

the following phases.

– 12 – IEC 62625-2:2016 © IEC 2016

4.1.3.3 Subsystem integration design review

The design review evaluates the design of an ODDR Unit against the requirements specified

by IEC 62625-1:2013, through examination of technical documentation for the IUT together

with any supporting evidence.

The functional and system requirements of ODDR unit shall be listed and described

according to the FICS and SICS specified by the Clauses 5 and 6.

The design review shall also include documentation on reliability, availability, maintainability,

interfaces, installation requirements and constraints.

If there are any changes to the ODDR unit, an evaluation shall be performed in order to

identify if its functionality has been affected and which impact exists on the system. If so, the

relevant test methods shall be applied in order to verify that the ODDR unit still complies with

the requirements of IEC 62625-1:2013.

The Design Review test methods are specified in Table 6 and Table 24 (phase DR).

4.1.3.4 Subsystem integration type test

The aim of the type test of the ODDR Unit is to verify that the functional and system

requirements specified by IEC 62625-1:2013 are met by the ODDR Unit.

The description of functional and system requirements which are implemented by the design

of IUT and are submitted to type test shall be listed and described by the FICS and SICS

specified by the Clauses 5 and 6.

Type test shall be performed on one or more unit of a given design and manufacturing

procedure to ensure the full coverage of the specified requirements.

If there is any change to a previously tested unit, the type test shall repeat at least those test

cases which are affected by the change.

The type test methods are specified in Table 6 and Table 24 (phase TT).

4.1.3.5 Subsystem type and traction unit type – Train level design review

The train level design review verifies the integration of an ODDRS in the train, through

examination of technical documentation together with any supporting evidence.

The train level design review shall include documentation on reliability, availability,

maintainability, interfaces, installation requirements and constraints.

The Train Level Design Review test methods are specified in Table 6 and Table 24 (phase

TLDR).

4.1.3.6 Subsystem type and traction unit type – Train level test

The aim of train level test is to verify some functional and system requirements of the

ODDRS after the installation in the train, in order to assure that the installation has not

affected the fulfilment of those requirements.

The test cases, to be carried out during the train level test, are listed in Table 6 and Table 24.

The Train Level Test methods are specified in Table 6 and Table 24 (phase TLT).

4.2 Implementation conformity statements

4.2.1 General

The functional requirements are verified according to the declaration statements called FICS

which are relevant to 4.2 of IEC 62625-1:2013.

The system requirements are verified according to the declaration statements called SICS

which are relevant to 4.3 of IEC 62625-1:2013.

The supplier shall determine which extra IUT specific information is necessary for testing the

functional and system requirements. The IUT supplier shall complete an IXIT pro-forma with

the necessary information, and make it available.

4.2.2 FICS and SICS

To evaluate the conformity of a particular implementation, it is necessary to have a statement

of the capabilities and options that have been implemented with reference to the

requirements and any features which have been omitted, so that the implementation can be

checked for acceptance against the requirements specified respectively in 4.2 and in 4.3 of

IEC 62625-1:2013, and against those requirements only. Such statements are called

respectively:

• Function Implementation Conformity Statement (FICS).

• System Implementation Conformity Statement (SICS).

The structure and instructions for completion of the FICS and SICS are given in the

informative Annex A.

4.2.3 IXIT

In order to test a function implementation, the test authority needs information relating to the

IUT and its testing environment in addition to that provided by the FICS and SICS. This

"Implementation eXtra Information for Testing" (IXIT) will be provided by the supplier and

system integrator submitting the implementation for testing, as a result of consultation with

the test authority.

The IXIT may contain the following information:

a) information needed by the test authority in order to be able to run the appropriate test

suite on the specific system (e.g. information related to the test method to be used to run

the test cases, addressing information);

b) information already mentioned in the FICS and which needs to be made precise (e.g. a

timer value range which is declared as a parameter in the FICS should be specified in the

IXIT);

c) information to help determine which capabilities stated in the FICS as being supported

are testable and which are not testable;

d) other administrative matters (e.g. the IUT identifier, reference to the related FICS).

The IXIT shall not conflict with the appropriate FICS or SICS.

– 14 – IEC 62625-2:2016 © IEC 2016

5 Functional requirements conformity testing

5.1 Implementation statement for functional requirements conformity testing

5.1.1 General

The following subclauses specify the FICS pro-forma relevant to the functional requirements

which shall be filled by the IUT supplier and provided as part of input documentation to the

verification. Column 2 of Tables 1 to 5 is the reference to the IEC 62625-1:2013 subclause.

For an explanation of the abbreviations used in the tables, refer to A.1.2.

5.1.2 Record train data

The Table 1 shall be filled by the IUT supplier.

Table 1 – FICS pro-forma “Record train data”

Ref. No. Subclause Capability Requirement Value Implementation

class

4.2.1 Protected storage medium m 24 h minimum

capacity

4.2.1 Storage medium capacity m 8 days minimum

At minimum:

4.2.1 Recorded data list m

– Time of day and

date

– Train speed

– Train location

– Driver’s command

relevant to safe

operation

– Actions of safety

functions related

to train operation

NOTE 1 The value of the capabilities “Protected storage medium capacity” and “Storage medium capacity”

depend on, among other things, the capability “Recorded data list” and on the maximum amount of data be

recorded during full train operations.

NOTE 2 For the implementation of the “Recorded data list” refer to Table 2 in IEC 62625-1:2013. The format of

the data is described by the party who submits the IUT to the conformity testing.

5.1.3 Ensure on board protection of recorded data

The Table 2 shall be filled by the IUT supplier.

Table 2 – FICS pro-forma “Ensure on board protection of recorded data”

Ref. No. Subclause Capability Requirement Value Implementation

class

4.2.2 Protection capability m See Table 1 in

IEC 62625-1:2013

4.2.2 Date and time entry by an o n/a Yes / No

authorised personnel

4.2.2 Data retention after loss of m At least one month

power

NOTE According to 4.2.2, the IUT implementation description is clarified: safeguarding against unauthorized

data access and software update, means of preventing, modifying and deleting the recorded data.

5.1.4 Ensure retrieval of recorded data

The Table 3 shall be filled by the IUT supplier.

Table 3 – FICS pro-forma “Ensure retrieval of recorded data”

Ref. No. Subclause Capability Requirement Value Implementation

class

4.2.3 m Removable storage

1 Data extraction means

medium

and/or

Communication

interface

4.2.3 o n/a Yes / No

2 No overwrite mode

4.2.3 o n/a Yes / No

3 Downloading and

recording in parallel

5.1.5 Recorded data analysis

The Table 4 shall be filled by the IUT supplier.

Table 4 – FICS pro-forma “Recorded data analysis”

Ref. No. Subclause Capability Requirement Value Implementation

class

1 4.2.4 Data exchange format m Standard format

(e.g. CSV, XML)

5.1.6 List of provided optional functions

The Table 5 shall be filled by the IUT supplier.

Table 5 – FICS pro-forma “List of provided optional functions”

Ref. No. Subclause Capability Requirement Value Implementation

class

1 4.2.5.1 Display ODDRS status to o n/a Yes / No

the driver

2 4.2.5.2 Make easy the recognition o Orange RAL 2003

of the protected storage

medium

3 4.2.5.3 Provide on-board o n/a Yes / No

communication

– 16 – IEC 62625-2:2016 © IEC 2016

Ref. No. Subclause Capability Requirement Value Implementation

class

4 4.2.5.3 Provide on-board to ground o n/a Yes / No

communication

5 4.2.5.4 Provide low power o n/a Yes / No

management

6 4.2.5.5 Support digital signature o n/a Yes / No

and driver identification

7 4.2.5.6 Provide remote status o n/a Yes / No

information

8 4.2.5.6 Provide remote o n/a Yes / No

initialization function

9 4.2.5.6 Upload new software o n/a Yes / No

10 4.2.5.6 Download diagnostic o n/a Yes / No

logging files

11 4.2.5.6 Provide download tool for o n/a Yes / No

recorded data

5.2 Standardized test methods for functional requirements

The following Table 6 lists all the functional requirements which shall be verified. The table

includes the following columns:

1) reference No;

2) subclause;

3) requirement description;

4) verification context;

5) phase;

6) acceptance criteria;

7) note, if applicable.

Column 1 is an incremental number which identifies the row in the table.

Column 2 is the reference to the IEC 62625-1:2013 subclause listing the requirement which

the IUT shall be verified against.

Column 3 is a brief description of the requirement.

Column 4 describes the context for the verifica

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...