IEC 61347-2-14:2018

(Main)Lamp controlgear - Part 2-14: Particular requirements for DC and/or AC supplied electronic controlgear for fluorescent induction lamps

Lamp controlgear - Part 2-14: Particular requirements for DC and/or AC supplied electronic controlgear for fluorescent induction lamps

IEC 61347-2-14:2018 specifies particular safety requirements for electronic controlgear for use on AC supplies up to 1 000 V at 50 Hz or 60 Hz and/or DC supplies with operating frequencies deviating from the supply frequency, associated with fluorescent induction lamps as specified in IEC 62532 and IEC 62639, for high-frequency operation.

Appareillages de lampes - Partie 2-14: Exigences particulières pour les appareillages électroniques alimentés en courant continu et/ou alternatif pour les lampes fluorescentes à induction

L'IEC 61347-2-14:2018 spécifie les exigences particulières de sécurité applicables aux appareillages électroniques destinés à être alimentés en courant alternatif jusqu’à 1 000 V à 50 Hz ou 60 Hz et/ou à courant continu avec des fréquences de fonctionnement différentes de la fréquence du réseau d’alimentation, associés aux lampes fluorescentes à induction spécifiées dans l’IEC 62532 et l’IEC 62639, pour un fonctionnement à haute fréquence.

Merjenje nizkofrekvenčnih elektromagnetnih polj z vidika izpostavljenosti ljudi – Posebne zahteve za instrumente in napotki za merjenje

General Information

- Status

- Published

- Publication Date

- 26-Feb-2018

- Technical Committee

- SC 34C - Auxiliaries for lamps

- Drafting Committee

- PT 61347-2-14 - TC 34/SC 34C/PT 61347-2-14

- Current Stage

- PPUB - Publication issued

- Start Date

- 27-Feb-2018

- Completion Date

- 23-Mar-2018

Overview

IEC 61347-2-14:2018 is an International Electrotechnical Commission standard that specifies particular safety requirements for electronic lamp controlgear intended for use with fluorescent induction lamps. It applies to controlgear powered from AC supplies up to 1 000 V at 50 Hz or 60 Hz and/or DC supplies where the controlgear’s operating frequencies may deviate from the supply frequency. The standard is specifically intended for high‑frequency operation and references lamp characteristics defined in IEC 62532 and IEC 62639.

Key Topics

- Scope of application - controlgear for fluorescent induction lamps operating at high frequencies and on AC (≤1 000 V, 50/60 Hz) and/or DC supplies.

- Particular safety requirements - requirements focused on ensuring safe function of electronic controlgear in the specified electrical environments.

- High-frequency operation considerations - provisions addressing behavior and safety when controlgear operates at frequencies different from the supply frequency.

- Interoperability with lamp standards - requirements aligned with lamp definitions and performance characteristics in IEC 62532 and IEC 62639.

- Verification and testing - provisions to demonstrate compliance through appropriate tests and assessments (electrical and functional checks relevant to high-frequency controlgear).

Note: IEC 61347-2-14 is a part-specific document and complements general requirements found in the broader lamp controlgear series.

Applications

Who uses IEC 61347-2-14:2018 and why:

- Lighting and ballast manufacturers - to design and certify electronic controlgear for fluorescent induction lamps that meet international safety expectations.

- Product development engineers - to ensure electronic controlgear operates safely at high frequencies on intended AC/DC supply configurations.

- Test laboratories and certification bodies - to evaluate conformity of controlgear with the particular safety requirements for induction-lamp applications.

- Procurement and compliance teams - to specify products that meet recognized safety and interoperability criteria in lighting projects.

- Consultants and specifiers - to recommend compliant controlgear solutions for commercial and industrial lighting using induction lamps.

Related Standards

- IEC 62532 - lamp characteristics and terminology for fluorescent induction lamps (referenced in the scope).

- IEC 62639 - additional lamp/fixture definitions related to induction lamps (referenced in the scope).

- IEC 61347-1 - general requirements for lamp controlgear (part 1 of the series); consult this for overarching safety and testing principles.

Keywords: IEC 61347-2-14:2018, lamp controlgear, electronic controlgear, fluorescent induction lamps, safety requirements, AC up to 1000 V, DC supplies, high-frequency operation, IEC 62532, IEC 62639.

Buy Documents

IEC 61347-2-14:2018 - Lamp controlgear - Part 2-14: Particular requirements for DC and/or AC supplied electronic controlgear for fluorescent induction lamps Released:2/27/2018 Isbn:9782832254486

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 61347-2-14:2018 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Lamp controlgear - Part 2-14: Particular requirements for DC and/or AC supplied electronic controlgear for fluorescent induction lamps". This standard covers: IEC 61347-2-14:2018 specifies particular safety requirements for electronic controlgear for use on AC supplies up to 1 000 V at 50 Hz or 60 Hz and/or DC supplies with operating frequencies deviating from the supply frequency, associated with fluorescent induction lamps as specified in IEC 62532 and IEC 62639, for high-frequency operation.

IEC 61347-2-14:2018 specifies particular safety requirements for electronic controlgear for use on AC supplies up to 1 000 V at 50 Hz or 60 Hz and/or DC supplies with operating frequencies deviating from the supply frequency, associated with fluorescent induction lamps as specified in IEC 62532 and IEC 62639, for high-frequency operation.

IEC 61347-2-14:2018 is classified under the following ICS (International Classification for Standards) categories: 17.220.20 - Measurement of electrical and magnetic quantities; 29.140.99 - Other standards related to lamps. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61347-2-14:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI SIST IEC 61786:2005

STANDARD

junij 2005

Merjenje nizkofrekvenčnih elektromagnetnih polj z vidika izpostavljenosti ljudi

– Posebne zahteve za instrumente in napotki za merjenje

Measurement of low-frequency magnetic and electric fields with regard to exposure

of human beings – Special requirements for instruments and guidance for

measurements

ICS 17.220.20 Referenčna številka

© Standard je založil in izdal Slovenski inštitut za standardizacijo. Razmnoževanje ali kopiranje celote ali delov tega dokumenta ni dovoljeno

NORME

CEI

INTERNATIONALE

IEC

INTERNATIONAL

Première édition

STANDARD

First edition

1998-08

Mesure de champs magnétiques et électriques

à basse fréquence dans leur rapport à l’exposition

humaine – Prescriptions spéciales applicables

aux instruments et recommandations

pour les procédures de mesure

Measurement of low-frequency magnetic

and electric fields with regard to exposure

of human beings – Special requirements for

instruments and guidance for measurements

© IEC 1998 Droits de reproduction réservés ⎯ Copyright - all rights reserved

Aucune partie de cette publication ne peut être reproduite ni No part of this publication may be reproduced or utilized in

utilisée sous quelque forme que ce soit et par aucun any form or by any means, electronic or mechanical,

procédé, électronique ou mécanique, y compris la photo- including photocopying and microfilm, without permission in

copie et les microfilms, sans l'accord écrit de l'éditeur. writing from the publisher.

International Electrotechnical Commission 3, rue de Varembé Geneva, Switzerland

Telefax: +41 22 919 0300 e-mail: inmail@iec.ch IEC web site http: //www.iec.ch

CODE PRIX

Commission Electrotechnique Internationale

XC

PRICE CODE

International Electrotechnical Commission

Pour prix, voir catalogue en vigueur

For price, see current catalogue

61786 © IEC:1998 – 3 –

CONTENTS

Page

FOREWORD . 5

INTRODUCTION . 7

Clause

1 Scope. 9

2 Normative references. 9

3 Definitions. 11

4 Symbols. 21

5 Measurement of alternating magnetic fields . 23

5.1 Instrumentation specifications. 23

5.2 Calibration. 31

5.3 Measurement uncertainty. 39

5.4 Recording and reporting measurement results. 41

5.5 Measurement procedure. 43

6 Measurement of alternating electric fields . 45

6.1 Instrumentation specifications. 45

6.2 Calibration. 49

6.3 Measurement uncertainty. 55

6.4 Recording and reporting measurement results. 55

6.5 Measurement procedure. 57

Annexes

A (normative) Calibration methods. 61

B (normative) Sources of measurement uncertainty . 83

C (informative) General characteristics of quasi-static magnetic

and electric fields . 105

D (informative) Magnetic flux density meters (magnetic field meters) –

Guidance for measurements . 113

E (informative) Electric field strength meters (electric field meters) –

Guidance for measurements . 143

F (informative) Static magnetic field-measuring instrumentation . 165

G (informative) Units . 167

H (informative) Bibliography . 169

61786 © IEC:1998 – 5 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

MEASUREMENT OF LOW-FREQUENCY MAGNETIC AND ELECTRIC FIELDS

WITH REGARD TO EXPOSURE OF HUMAN BEINGS –

SPECIAL REQUIREMENTS FOR INSTRUMENTS AND

GUIDANCE FOR MEASUREMENTS

FOREWORD

1) The IEC (International Electrotechnical Commission) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of the IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, the IEC publishes International Standards. Their preparation is

entrusted to technical committees; any IEC National Committee interested in the subject dealt with may

participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. The IEC collaborates closely with the International Organization

for Standardization (ISO) in accordance with conditions determined by agreement between the two

organizations.

2) The formal decisions or agreements of the IEC on technical matters express, as nearly as possible, an

international consensus of opinion on the relevant subjects since each technical committee has representation

from all interested National Committees.

3) The documents produced have the form of recommendations for international use and are published in the form

of standards, technical reports or guides and they are accepted by the National Committees in that sense.

4) In order to promote international unification, IEC National Committees undertake to apply IEC International

Standards transparently to the maximum extent possible in their national and regional standards. Any

divergence between the IEC Standard and the corresponding national or regional standard shall be clearly

indicated in the latter.

5) The IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with one of its standards.

6) Attention is drawn to the possibility that some of the elements of this International Standard may be the subject

of patent rights. The IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61786 has been prepared by IEC technical committee 85:

Measuring equipment for electromagnetic quantities.

The text of this standard is based on the following documents:

FDIS Report on voting

85/191/FDIS 85/193/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

Annexes A and B form an integral part of this standard.

Annexes C, D, E, F, G and H are for information only.

Words in bold in the text are defined in clause 3.

61786 © IEC:1998 – 7 –

INTRODUCTION

The increasing interest in characterizing human exposure to quasi-static magnetic and electric

fields in a number of environments has led to the development and marketing of many field

meters with a range of specifications. Sources of quasi-static fields include devices that

operate at power frequencies (50/60 Hz) and produce power frequency and power frequency

harmonic fields, as well as devices which produce fields that are independent of the power

frequency. Examples in the latter category include video display terminals (vertical scan

/

magnetic field), electric railroads (16 Hz and 25 Hz), mass transportation systems (0 Hz to

3 kHz depending on characteristics of adjustable speed drive), commercial airplanes (400 Hz),

induction heaters (50 Hz to 9 kHz), and electric automobiles. Because of differences in the

characteristics of the fields from sources in the various environments, e.g. frequency content,

temporal and spatial variations, polarization, and magnitude, the instrumentation requirements

and measurement procedures will be different in the various environments. Commercially

available instrumentation exists to measure human exposure to the field levels as well as to

other parameters that characterize the fields. The instrumentation and measurement methods,

as they may pertain to human exposure, are the focus of this document. It should be noted that

the parameters that describe quasi-static fields and the mechanisms for their interaction with

humans during magnetic and electric field exposure are still unknown.

The intended users of this International Standard include manufacturers of instrumentation and

groups or individuals interested in characterizing quasi-static magnetic and electric fields as

they relate to human exposure. It is assumed that users intending to perform measurements

have some knowledge of the instrumentation as well as field sources and their characteristics.

In the absence of such knowledge, it is strongly advised that some training be received. This

standard may serve as a textbook for the training process because of the technical information

provided in the annexes.

61786 © IEC:1998 – 9 –

MEASUREMENT OF LOW-FREQUENCY MAGNETIC AND ELECTRIC FIELDS

WITH REGARD TO EXPOSURE OF HUMAN BEINGS –

SPECIAL REQUIREMENTS FOR INSTRUMENTS AND

GUIDANCE FOR MEASUREMENTS

1 Scope

This International Standard provides guidance for measuring the steady-state root-mean-

square (r.m.s.) values of quasi-static magnetic and electric fields which have a frequency

content in the range 15 Hz to 9 kHz. Sources of quasi-static fields include devices that

operate at power frequencies and produce power frequency and power frequency harmonic

fields, as well as devices that produce fields independent of the power frequency. The

magnitude ranges covered by this standard are 100 nT to 100 mT and 1 V/m to 50 kV/m for

magnetic fields and electric fields, respectively. When measurements outside this range are

performed, most of the provisions of this standard will still apply, but certain provisions such as

specified uncertainty and calibration procedure may need modification. Specifically, this

standard

– defines terminology;

– identifies requisite field meter specifications;

– indicates methods of calibration;

– defines requirements on instrumentation uncertainty;

– describes general characteristics of fields;

– surveys operational principles of instrumentation;

– describes measurement methods that achieve defined goals pertaining to human exposure.

Sources of uncertainty during calibration and measurements are also identified and guidance is

provided on how they should be combined to determine total measurement uncertainty. In

regard to electric field measurements, this standard considers only the measurement of the

unperturbed electric field strength at a point in space (i.e. the electric field prior to the

introduction of the field meter and operator) or on conducting surfaces.

NOTE – Some separation between the normative measurement requirements in clauses 5 and 6 and the example

measurement protocols and guidance for measurements in annexes D and E is unavoidable because of format

requirements.

2 Normative references

The following normative documents contain provisions which, through reference in this text,

constitute provisions of this International Standard. At the time of publication, the editions

indicated were valid. All normative documents are subject to revision, and parties to

agreements based on this International Standard are encouraged to investigate the possibility

of applying the most recent editions of the normative documents indicated below. Members of

IEC and ISO maintain registers of currently valid International Standards.

IEC 61000-3-2:1995, Electromagnetic compatibility (EMC) – Part 3: Limits – Section 2: Limits

for harmonic current emissions (equipment input current ≤16 A per phase)

61786 © IEC:1998 – 11 –

IEC 61000-4-2:1995, Electromagnetic compatibility (EMC) – Part 4: Testing and measurement

techniques – Section 2: Electrostatic discharge immunity test – Basic EMC Publication

IEC 61000-4-3:1995, Electromagnetic compatibility (EMC) – Part 4: Testing and measurement

techniques – Section 3: Radiated, radio-frequency, electromagnetic field immunity test

IEC 61000-4-4:1995, Electromagnetic compatibility (EMC) – Part 4: Testing and measurement

techniques – Section 4: Electrical fast transient/burst immunity test – Basic EMC publication

IEC 61000-4-6:1996, Electromagnetic compatibility (EMC) – Part 4: Testing and measurement

techniques – Section 6: Immunity to conducted disturbances, induced by radio-frequency fields

IEC 61000-4-8:1993, Electromagnetic compatibility (EMC) – Part 4: Testing and measurement

techniques – Section 8: Power frequency magnetic field immunity test – Basic EMC Publication

CISPR 11:1990, Limits and methods of measurement of electromagnetic disturbance

characteristics of industrial, scientific and medical (ISM) radio-frequency equipment

ISBN 92-67-01075-1:1993, International vocabulary of basic and general terms in metrology,

International Organization for Standardization.

ISBN 92-67-10188-9:1995, ISO TAG, ISO Technical Advisory Group on Metrology, Working

Group 3, Guide to the expression of uncertainty in measurement.

IEEE Std 539:1990, IEEE Standard Definitions of Terms Relating to Corona and Field Effects of

Overhead Power Lines.

3 Definitions

For the purposes of this International Standard, the following definitions apply.

NOTE – Throughout this standard, the words "magnetic flux density" and "magnetic field" will be considered

synonymous.

3.1 Tests

3.1.1

acceptance tests

contractual test to prove to the customer that the device meets certain conditions of its

specifications

3.1.2

type test

test of one or more devices made to a certain design to show that the design meets certain

specifications

NOTE – This test is normally performed by the designer/manufacturer of the device.

61786 © IEC:1998 – 13 –

3.2 Meters

3.2.1

alternating electric field strength meter

meter designed to measure alternating electric fields. Three types of electric field strength

meters are available: free-body meter, ground reference meter, electro-optic meter.

NOTE – Electric field meters consist of two parts: the probe or field-sensing element, and the detector which

processes the signal from the probe and indicates the r.m.s. value of the electric field with an analogue or digital

display.

3.2.2

electro-optic meter

meter that measures the electric field strength by changes in the transmission of light through a

fibre or crystal which are due to the influence of the electric field

NOTE – While there are several electro-optic methods that can be used for measuring electric fields, e.g. the

Pockels effect, the Kerr effect, and interferometric techniques, this standard only considers electro-optic field

meters that utilize the Pockels effect.

3.2.3

free-body meter

meter that measures the electric field strength at a point above the ground and is supported in

space without conductive contact to earth

NOTE – are commonly constructed to measure the induced current between two isolated parts

Free-body meters

of a conductive body. Since the induced current is proportional to the time derivative of the electric field strength,

the meter's detector circuit often contains an integrating stage in order to recover the waveform of the electric field.

The integrated current waveform also coincides with that of the induced charge. The integrating stage is also

desirable, particularly for the measurement of electric fields with harmonic content, because this stage (i.e. its

integrating property) eliminates the excessive weighting of the harmonic components in the induced current signal.

3.2.4

fluxgate magnetometer

instrument designed to measure magnetic fields by making use of the non-linear magnetic

characteristics of a probe or sensing element that has a ferromagnetic core

3.2.5

ground reference meter

meter that measures the electric field at or close to the surface of the ground, frequently

implemented by measuring the induced current or charge oscillating between an isolated

electrode and ground. The isolated electrode is usually a plate located level with or slightly

above the ground surface.

NOTE – Ground reference meters measuring the induced current often contain an integrator circuit to compensate

for the derivative relationship between the induced current and the electric field.

3.2.6

magnetic flux density meter

meter designed to measure the magnetic flux density

NOTE 1 – Magnetic field meters consist of two parts: the probe or field-sensing element, and the detector which

processes the signal from the probe and indicates the r.m.s. value of the magnetic field with an analogue or digital

display.

NOTE 2 – Several types of meters are in common use, e.g. field meters with coil probes, meters with Hall-effect

probes, and meters that combine two coils with a ferromagnetic core as in a fluxgate magnetometer.

3.2.7

survey meter

lightweight battery-operated meter that gives a real time read-out and that can be held

conveniently by hand in order to conduct survey type measurements in different locations

61786 © IEC:1998 – 15 –

3.2.8

coil probe

magnetic flux density sensor comprised of a coil of wire that produces an induced voltage

proportional to the time derivative of the magnetic field

NOTE 1 – Since the induced voltage is proportional to the time derivative of the magnetic flux density, the detector

circuit of the sensor requires an integrating stage to recover the waveform of the magnetic flux density.

NOTE 2 – This probe can also be used to measure static (d.c.) magnetic flux density if the probe is rotated.

3.2.9

Hall effect probe

magnetic flux density sensor containing an element exhibiting the Hall effect to produce a

voltage proportional to the magnetic flux density

NOTE – Hall effect probes respond to static as well as time-varying magnetic flux densities. Due to limited

sensitivity and saturation problems sometimes encountered when attempting to measure small power frequency flux

densities in the presence of the substantial static geomagnetic flux of the earth, Hall-effect probes have seldom

been used to measure magnetic fields of a.c. power lines.

3.3 Meter characteristics

3.3.1

crest factor

for periodic functions, the ratio of the waveform crest (peak, maximum) value to its r.m.s. value

3.3.2

crosstalk

noise or extraneous signal caused by a.c. or pulse-type signals in adjacent circuits

3.3.3

frequency response

response (reading) of a field meter to a field of constant amplitude but different frequencies

3.3.4

pass-band

(1) (data transmission) a range of frequency spectra which can pass at low attenuation

(2) (circuits and systems) a band of frequencies that pass through a filter with little attenuation

(relative to other frequency bands such as a stop-band)

3.3.5

rectified average (calibrated in r.m.s.) detector (see 3.3.6)

detector circuit that rectifies the signal from the probe and is calibrated to give the correct

r.m.s. value of a sinusoidal field at a given frequency

NOTE – If there are harmonics in the field, a field meter with a rectified average (r.m.s.) detector will not indicate

the true r.m.s. value of the field if the signal from the probe is proportional to the time derivative of the field. If the

detector contains a stage of integration, the error is reduced. The error will also be a function of the phase relation

between the harmonic and fundamental field components [36], [61].

3.3.6

true r.m.s. detector (see rectified average (calibrated in r.m.s.) detector)

detector that contains a circuit component that performs the mathematical operation

61786 © IEC:1998 – 17 –

T

[(vt) dt (1)

]

∫

T

to a periodic signal v(t), where T is the period of the signal.

NOTE 1 – If v(t) is proportional to the time-derivative of the field, the detector circuit also requires a stage of

integration prior to the r.m.s. operation in order to recover the waveform of the magnetic flux density [25], [61]. This

type of detector gives the true r.m.s. value of a field containing harmonics provided that the frequency response of

the detector is flat over the frequency range of interest.

NOTE 2 – If significant levels of harmonics are present in v(t), particular attention should be given to the possibility

of amplifier saturation effects if the integration follows one or more stages of amplification.

3.4 Field characteristics

3.4.1

maximum r.m.s. value of electric field (maximum electric field)

measurement of elliptically polarized quasi-static electric and magnetic fields. At a given point,

the root-mean-square (r.m.s.) value of the semi-major axis of the electric field ellipse

3.4.2

maximum r.m.s. value of magnetic field (maximum magnetic field)

measurement of power frequency electric and magnetic fields. At a given point, the root-mean-

square (r.m.s.) value of the semi-major axis of the magnetic field ellipse

3.4.3

perturbed field

field that is changed in magnitude or direction, or both, by the introduction of an object

NOTE – The electric field at the surface of the object is, in general, strongly perturbed by the presence of the

object. At power frequencies, the magnetic flux density is not, in general, greatly perturbed by the presence of

objects that are free of magnetic materials. Exceptions to this include regions near the surface of thick electrical

conductors and regions far from thick conductors, if the conductor is close to the magnetic field source. The

perturbation in these instances is due to opposing magnetic fields produced by eddy currents in the conductors.

3.4.4

unperturbed field

field at a point that would exist in the absence of persons or movable objects

3.4.5

quasi-static field

field that satisfies the condition f << c÷l, where f is the frequency of the field, c is the speed of

light, and l is a characteristic dimension of the measurement geometry, e.g. the distance

between the field source and the measurement point

NOTE – Power frequency magnetic and electric fields near power lines and appliances are examples of quasi-

static fields.

3.4.6

resultant electric field

electric field given by the expression

22 2

= + + (2)

EE E E

R xy z

where E , E , and E are the r.m.s. values of the three orthogonal field components

x y z

61786 © IEC:1998 – 19 –

The resultant electric field is also given by the expression

2 2

E=+ (3)

EE

max

min

R

where E and E are the r.m.s. values of the semi-major and semi-minor axes of the

max min

electric field ellipse, respectively. The resultant E is always ≥E . If the electric field is

R max

linearly polarized, E = 0 and E = E . If the electric field is circularly polarized, E = E

min R max max min

and E ≈ 1,41 E .

R max

NOTE – The definition of "effective field strength" in CENELEC prestandard ENV 50166-1 [5] is equivalent to the

resultant magnetic field or resultant electric field, as the case may be.

3.4.7

resultant magnetic field

magnetic field given by the expression

22 2

B= + + (4)

B B B

R xy z

where B , B , and B are the r.m.s. values of the three orthogonal field components

x y z

The resultant magnetic field is also given by the expression

2 2

B= + (5)

B B

R max

min

where B and B are the r.m.s. values of the semi-major and semi-minor axes of

max min

the magnetic field ellipse, respectively. The resultant B is always ≥B . If the magnetic field

R max

is linearly polarized, B = 0 and B = B . If the magnetic field is circularly polarized,

min R max

B = B and B ≈ 1,41 B .

max min R max

NOTE – The definition of "effective field strength" in CENELEC prestandard ENV 50166-1 [5] is equivalent to the

resultant magnetic field or resultant electric field, as the case may be.

3.5 Measurements

3.5.1

correction factor

numerical factor by which the uncorrected result of a measurement is multiplied to compensate

for a known error

NOTE – Since the known error cannot be determined perfectly, the compensation cannot be complete.

3.5.2

coverage factor

numerical factor used as a multiplier of the combined standard uncertainty in order to obtain

an expanded uncertainty

NOTE – For a quantity z described by a normal distribution with expectation µ and standard deviation σ, the

z

interval µ ± kσ encompasses 68,27, 95,45, and 99,73 percent of the distribution for a coverage factor k = 1, 2,

z

and 3, respectively.

3.5.3

scale factor

factor by which the instrument reading is multiplied to obtain its input quantity

61786 © IEC:1998 – 21 –

3.5.4

spot measurement (point-in-time measurement)

measurement that is performed at some instant and point in space, that does not provide

information regarding temporal or spatial variations of the field

3.5.5

standard uncertainty

uncertainty of the result of a measurement expressed as a standard deviation

3.5.6

uncertainty of measurement

parameter, associated with the result of a measurement, that characterizes the dispersion of

the values that could reasonably be attributed to the measurand

NOTE – Uncertainty of measurement generally comprises many components. Some of these components may be

estimated on the basis of the statistical distribution of the results of series of measurements, and can be

characterized by experimental standard deviations. Estimates of other components can be based on experience or

other information.

4 Symbols

a = radius of coil probe; radius of spherical electric field probe

2a, 2b = side dimensions of rectangular coil

B = magnetic flux density vector

B = magnetic flux density (fundamental frequency)

f

B = magnetic flux density at jth frequency (j = 1 for fundamental frequency)

j

B = CENELEC magnetic flux density reference level at jth frequency

RLj

B = amplitude of alternating magnetic field

B = resultant magnetic field

R

B = axial magnetic flux density

z

B = r.m.s. values of orthogonal components of magnetic flux density

x,y,z

B , B = r.m.s. values of semi-major and semi-minor axes of magnetic field ellipse

max min

C = stray capacitance of coil probe

c = electro-optic coefficient of Pockels crystal

e

d = spacing of parallel plates; distance from electromagnetic field source

D = electric displacement vector

E = electric field strength

E = electric field at ith frequency (i = 1 for fundamental frequency)

i

E = CENELEC electric field reference level at ith frequency

i

RL

E = resultant electric field

R

E = uniform electric field strength

E′ = electric field in Pockels crystal

E = r.m.s. values of orthogonal components of electric field

x,y,z

E , E = r.m.s. values of semi-major and semi-minor axes of electric field ellipse

max min

61786 © IEC:1998 – 23 –

I = current to magnetic field coils

I = incident light (electro-optic field meter)

i

I = transmitted light (electro-optic field meter)

t

l = Pockels crystal thickness

L = inductance of coil probe

n = index of refraction

N = number of turns of wire (magnetic field coil system)

Q = induced charge

r = distance between magnetic field source and measurement location; resistance

of coil probe and leads

R = approximate input impedance of detector circuit (magnetic field meter)

S = electrode surface area (electric field meter)

t= time

T = period of periodic signal

V = voltage

v(t) = periodic electrical signal

v = coil probe voltage

p

W = ratio of coil probe voltage to induced voltage

Z = impedance in current injection circuit

α = fraction of ith harmonic in magnetic field

i

∆B = largest difference in percentage between magnetic field at centre of single-axis

max1

probe and average field (across area of probe) at maximum reading in dipole

magnetic field

∆B = largest difference in percentage between average resultant magnetic field and

max3

magnetic field at centre of three-axis probe in dipole magnetic field

ε = permittivity of free space

λ = wavelength of light

µ = permeability of free space

φ = magnetic flux

ω = angular frequency of alternating field

5 Measurement of alternating magnetic fields

5.1 Instrumentation specifications

The various types of instrumentation available for characterizing quasi-static magnetic fields

are described in D.1. Sufficient information shall be provided with the instrumentation, including

instrument specifications and a clearly written instruction manual, to enable users to determine

compliance with this standard, to aid them in the proper operation of the field meter, and to

assess the usefulness of the device for the user's application. Complicated operating

61786 © IEC:1998 – 25 –

procedures should be avoided. The instrument specifications that should be provided and/or

satisfied are given below.

NOTE – Instruments not complying with the specifications below may be used if it can be demonstrated that, under

the conditions the instrument is used, the results obtained will not differ significantly from those obtained with a

meter which is in compliance with this standard. For example, a meter with a rectified average detector with or

without an integrating stage may be used if it can be shown that the harmonics in the field are negligible, and if the

instrument has been calibrated for the fundamental frequency in the field.

5.1.1 Instrumental uncertainty

The measuring system for alternating magnetic fields should indicate the r.m.s. value of

uniform magnetic fields with an uncertainty of less than ±(10 % of reading +20 nT) after

correction factors have been applied, if appropriate.

NOTE 1 – The uncertainty of the instrument is determined from several components such as the calibration

uncertainty, temperature drift of the electronics, stability and external noise sources. The above uncertainty is

associated with the design and functioning of the magnetic flux density meter in a nearly uniform field. The 10 %

element refers to the uncertainty during calibration over the frequency range (pass-band) specified for the

instrument and includes uncertainties in the value of the magnetic flux density and additional uncertainties during

the calibration process (see 5.2.2). The coverage factor is 2. The inclusion of 20 nT anticipates instrumental

uncertainties during the calibration of the most sensitive scales and when fields in the order of 0,1 µT are

measured.

NOTE 2 – Other sources of measurement uncertainty and guidelines on the treatment of uncertainties are given in

clause B.1 and 5.3, respectively.

5.1.2 Magnitude range

The magnitude range over which the instrument operates within the specified uncertainty shall

be clearly indicated.

5.1.3 Pass-band

The instrument shall be provided with calibration data or specifications that enable the user to

assess the uncertainty in determining field levels when using the instrument in fields containing

different frequencies. This information should also include the sensitivity of the instrument to

frequencies beyond the intended useful range, e.g. the –3 dB points. The frequency response

of the instrument shall be such that the requirement of the instrumental uncertainty (see 5.1.1)

is fulfilled over the frequency range for which it is intended.

NOTE – The permitted instrumental uncertainty associated with the frequency response is increased to ±20 %

(coverage factor 2) for small personal exposure meters, devices that can be worn, and which periodically record

the power frequency and power frequency harmonic resultant magnetic field (see clause D.1).

5.1.4 Operating temperature and humidity ranges

The temperature and relative humidity ranges over which the instrument operates within the

specified uncertainty should be no less than 0 °C to 45 °C and 5 % to 95 %, respectively.

Sudden temperature changes that can lead to condensation in the instrument should be

avoided (see clause B.1).

5.1.5 Power supplies

If batteries are used, provision should be made to indicate whether the battery condition is

adequate for proper operation of the field meter. Instruments used to record personal exposure

should be capable of at least 8 h operation within their rated uncertainty before replacement or

recharging of the batteries becomes necessary. If rechargeable batteries are used, it is

recommended that the instrumentation is not operated while connected to the mains voltage.

61786 © IEC:1998 – 27 –

When such connections are necessary, it should be demonstrated that stray fields from the

battery charger, conducted disturbances from the mains voltage, and electromagnetic coupling

via the connecting leads (to the battery charger) do not affect the measurement (see 5.1.8).

NOTE – If batteries with ferromagnetic jackets are used in exposure meters, care must be exercised that the

jackets do not significantly influence readings by the instrument (see clause B.1).

5.1.6 Readability of scale

The meter dial markings or digital displays of magnetic field survey meters should be large

enough to be easily read at arm's length. If more than one range of sensitivity is provided, the

full scale value of the selected range should be indicated, and the units should be readily

interpretable. For auto-ranging instrumentation, the magnitude range may be indicated

elsewhere, e.g. in the user manual. The instrumentation should provide a clear indication of the

units being displayed.

NOTE – To comply with this standard, instrumentation marketed prior to the issue of this standard, which does not

indicate the units, should be provided with an appropriate label indicating the units. This may be accomplished by

the user applying a label to the body of the field meter. Alternatively, a label provided by the manufacturer to the

user may be applied by the user.

5.1.7 Instrument dimensions

The dimensions of the enclosure containing the detector circuit and any connecting cables

should be provided. The size of the probes or sensing elements should be appropriate to the

spatial variation of the field measured (see clause B.1). The sensing elements should be of

area 0,01 m , or smaller. With three-axis instruments, the three sensing elements may be

concentric (i.e. coil probes that have a common central point) or, if the sensing elements are

no larger than 0,05 m, they should be as close together as possible (see clause B.1). The

maximum dimension of the volume containing the three coil probes combined should not

exceed 0,2 m. Coil probes should be either circular or square in cross-section; small

deviations from these shapes, for example where concentric coils cross each other, are

permitted.

The locations and orientations of probes that are contained within the housings of magnetic

field meters should be clearly indicated on the instrument or in the instruction manual.

5.1.8 Electromagnetic compatibility

5.1.8.1 Immunity

a) Power frequency electric field

Instrumentation intended for use in the vicinity of high-voltage equipment operating at

power frequencies should not be affected significantly by ambient electric fields as large as

20 kV/m, i.e. the influence of the electric field on the magnetic field reading should be less

than 20 nT. This immunity requirement may need to be increased for some extreme

environments where electric fields as large as 100 kV/m may exist, e.g. near high-voltage

transmission line conductors.

NOTE 1 – Tests for immunity to power frequency electric fields may be performed using the parallel plates

systems described in clause A.2.

NOTE 2 – The proximity effect of the instrument user (see clause B.2) can shield or enhance the electric field,

depending on the geometry of the field and the location of the magnetic field meter relative to the user.

61786 © IEC:1998 – 29 –

b) Radiated electromagnetic fields

The operation of instrumentation shall not be affected by electromagnetic radiation between

80 MHz and 1 GHz for an electric field level of 3 V/m r.m.s. Testing of instrumentation

should be in accord with the methods described in IEC 61000-4-3.

The operation of instrumentation shall not be affected by electromagnetic radiation between

150 kHz and 80 MHz. Tests should be conducted according to the methods described in

IEC 61000-4-6 at a voltage level of 3 V r.m.s. The instrumentation should continue to

operate normally during both of the above tests.

NOTE 1 – Battery-powered equipment (dimension <λ/4) which has no connection(s) to the ground nor to any

other (non-insulated) equipment, and which will not be used during battery charging, does not need to be tested

according to IEC 61000-4-6.

NOTE 2 – It is important to perform the radiated immunity tests over the entire frequency range from 26 MHz to

1 GHz. The lower frequency boundary is important because of the high probability that the instruments will

experience radiation in the 27 MHz citizen's band.

NOTE 3 – The immunity requirements may need to be increased under certain conditions, e.g. during

measurements near radio-broadcasting antennas and mobile telephones (see clause B.1, table B.2).

c) Immunity to transients

Specifications for instrumentation connected to the mains in order to carry out

measurements should also be tested at the a.c. power port (interface of field meter with

external power source or mains) for compliance with IEC 61000-4-4 (electrical fast

transient) for a peak voltage of 2 kV. A temporary degradation of performance during the

test which is self-recoverable is acceptable.

d) Electrostatic discharge (ESD)

During most measurement applications, electrostatic discharges to or from the

instrumentation are not anticipated. However, the enclosure port of the instrumentation

shall be immune to a contact or discharge voltage of at least 2 kV and tested in accordance

with the methods described in IEC 61000-4-2. No degradation of performance shall occur.

5.1.8.2 Emissions

a) Harmonic emissions

The harmonic emissions of instrumentation with a power rating of 50 W or greater shall be

restricted according to the requirements of IEC 61000-3-2.

b) Conducted disturbances – 0,15 MHz to 30 MHz (instrumentation connected to mains)

The limits for mains terminal disturbance voltages may be characterized using quasi-peak

or average detectors and are given below as a function of frequency (see CISPR 11,

class B).

Table 1 – Mains terminal disturbance voltage limits

Frequency band Quasi-peak Average

MHz

dB(µV) dB(µV)

0,15 – 0,50 66 56

Decreasing with logarithm of Decreasing with logarithm of

frequency to 56 frequency to 46

0,50 – 5 56 46

5 – 30 60 50

61786 © IEC:1998 – 31 –

Testing of instrumentation should be in accordance with the methods described in

CISPR 11.

c) Radiated disturbances – 30 MHz to 1 000 MHz

The electromagnetic emissions from instrumentation containing devices operating at

frequencies of 9 kHz or higher shall be limited to the values listed below (see CISPR 11,

class B).

30 dB (µV/m) at 10 m 30 MHz to 230 MHz

37 dB (µV/m) at 10 m 230 MHz to 1 000 MHz

Testing of instrumentation should be in accordance with the methods described in

CISPR 11.

NOTE – The above test requirements have been taken from CISPR 11 and are subject to revision. Tests should

be conducted according to the most recent edition of that standard.

5.1.9 Crest factor

The measuring system should measure correctly the true r.m.s. value of the field, even when

the crest factor of the magnetic field is 3 (see clause B.1).

NOTE – Many practical fields exhibit a large crest factor and the presence of a large crest factor may lead to

unwanted saturation in the amplifier stages of the detector.

5.1.10 Durability

The indicating meter and other system components should be rugged enough to withstand

vibration and shock resulting from transport. A carrying case is desirable.

5.1.11 Weight

The weight of the instrumentation should be provided. The weight of portable instrumentation

should be kept as low as is practical to permit hand-held operation under restrictive conditions,

e.g. in some industrial environments.

5.2 Calibration

5.2.1 General

Measurement systems are required to undergo calibration and verification of their calibration

throughout their service life. The calibration tests referred to in this standard are type tests

and acceptance tests. Type tests are normally performed by the manufacturer on one or

more devices. Acceptance tests are normally performed only once by the manufacturer on

each field meter. Acceptance tests need to be repeated if major changes or repairs of the

instrument have been made. Verification tests are performed at time intervals during use of the

instrument (see 5.2.4). All calibrations should be traceable to national and international

standards through an unbroken chain of calibrations, all having stated uncertainties.

The following three methods of calibration are covered by this standard:

a) calibration by introduction of the field meter probe into a calculated magnetic field (following

measurements of coil dimensions and current to the coil system);

b) calibration using a voltage injection technique, and

c) calibration by comparison with a reference measurement system (see clause A.1).

61786 © IEC:1998 – 33 –

5.2.2 Calibration procedure

Calibrations are required as part of type tests, acceptance tests (see 5.2.1), and periodic

verification tests (see 5.2.4). The procedures of this section should be followed, as appropriate,

in all cases. For calibration of the higher magnitude ranges (i.e. ranges not significantly

influenced by background magnetic fields), the magnetic field probe should be placed in a

nearly uniform field produced by a coil system (see clause A.1). The probe axis should coincide

with the axis of the coil system and the largest departure of the field from the central value

should be less than 1 % over the cross-sectional area of the probe.

NOTE 1 – Information on fields generated by rectangular, square, and circular loop systems (including Helmholtz

coils) is given in [17], [35], [56], [69] and A.1. For example, the magnetic flux density produced by a single square

loop (of many turns of wire) 1 m × 1 m will satisfy the uniformity requirement for a probe with a 0,10 m diameter

(see clause A.1). The loop size may be scaled upwards or downwards for larger or smaller probes, respectively, to

maintain the indicated level of uniformity across the probe. The calibration may also be performed using the voltage

injection technique or by comparison with a reference magnetic field meter (see clause A.1).

NOTE 2 – The field uniformity requirement during calibration may be relaxed for large probes that are used for

determining average values of non-uniform fields and, or for applications where spatial resolution requirements are

not considered important. In this case, the largest departure of the calibration field from the central value should be

≤1,5 % over the cross-sectional area of the probe. For example, the field produced by a square loop 1,3 m × 1,3 m

will satisfy this uniformity requirement for a probe with a 0,20 m diameter.

Calibrations of single-axis field meters and each axis of three-axis field meters should be

performed with

...

IEC 61347-2-14 ®

Edition 1.0 2018-02

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Lamp controlgear –

Part 2-14: Particular requirements for DC and/or AC supplied electronic

controlgear for fluorescent induction lamps

Appareillages de lampes –

Partie 2-14: Exigences particulières pour les appareillages électroniques

alimentés en courant continu et/ou alternatif pour les lampes fluorescentes à

induction

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 21 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - webstore.iec.ch/advsearchform IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 67 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient 21 000 termes et définitions en anglais

Spécifications techniques, Rapports techniques et autres

et en français, ainsi que les termes équivalents dans 16

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC -

Glossaire IEC - std.iec.ch/glossary

webstore.iec.ch/advsearchform

67 000 entrées terminologiques électrotechniques, en anglais

La recherche avancée permet de trouver des publications IEC et en français, extraites des articles Termes et Définitions des

en utilisant différents critères (numéro de référence, texte, publications IEC parues depuis 2002. Plus certaines entrées

comité d’études,…). Elle donne aussi des informations sur les antérieures extraites des publications des CE 37, 77, 86 et

projets et les publications remplacées ou retirées. CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just Si vous désirez nous donner des commentaires sur cette

Published détaille les nouvelles publications parues. publication ou si vous avez des questions contactez-nous:

Disponible en ligne et aussi une fois par mois par email. sales@iec.ch.

IEC 61347-2-14 ®

Edition 1.0 2018-02

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Lamp controlgear –

Part 2-14: Particular requirements for DC and/or AC supplied electronic

controlgear for fluorescent induction lamps

Appareillages de lampes –

Partie 2-14: Exigences particulières pour les appareillages électroniques

alimentés en courant continu et/ou alternatif pour les lampes fluorescentes à

induction

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 29.140.99 ISBN 978-2-8322-5448-6

– 2 – IEC 61347-2-14:2018 © IEC 2018

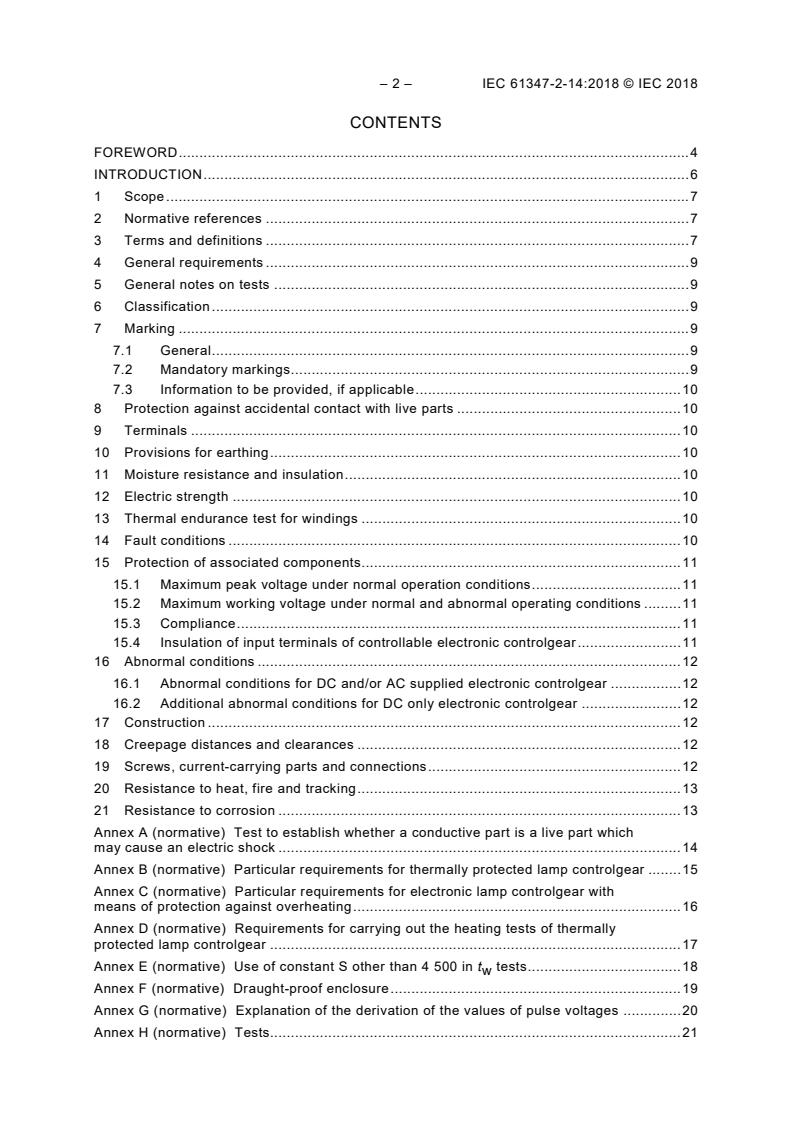

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 7

4 General requirements . 9

5 General notes on tests . 9

6 Classification . 9

7 Marking . 9

7.1 General . 9

7.2 Mandatory markings . 9

7.3 Information to be provided, if applicable . 10

8 Protection against accidental contact with live parts . 10

9 Terminals . 10

10 Provisions for earthing . 10

11 Moisture resistance and insulation . 10

12 Electric strength . 10

13 Thermal endurance test for windings . 10

14 Fault conditions . 10

15 Protection of associated components. 11

15.1 Maximum peak voltage under normal operation conditions . 11

15.2 Maximum working voltage under normal and abnormal operating conditions . 11

15.3 Compliance . 11

15.4 Insulation of input terminals of controllable electronic controlgear . 11

16 Abnormal conditions . 12

16.1 Abnormal conditions for DC and/or AC supplied electronic controlgear . 12

16.2 Additional abnormal conditions for DC only electronic controlgear . 12

17 Construction . 12

18 Creepage distances and clearances . 12

19 Screws, current-carrying parts and connections . 12

20 Resistance to heat, fire and tracking . 13

21 Resistance to corrosion . 13

Annex A (normative) Test to establish whether a conductive part is a live part which

may cause an electric shock . 14

Annex B (normative) Particular requirements for thermally protected lamp controlgear . 15

Annex C (normative) Particular requirements for electronic lamp controlgear with

means of protection against overheating . 16

Annex D (normative) Requirements for carrying out the heating tests of thermally

protected lamp controlgear . 17

Annex E (normative) Use of constant S other than 4 500 in t tests . 18

w

Annex F (normative) Draught-proof enclosure . 19

Annex G (normative) Explanation of the derivation of the values of pulse voltages . 20

Annex H (normative) Tests. 21

Annex I (normative) Additional requirements for built-in magnetic ballast with double

or reinforced insulation . 22

Annex J (normative) Particular additional safety requirements for DC and/or AC

supplied electronic controlgear for emergency lighting . 23

J.1 General . 23

J.2 Marking . 23

J.2.1 Mandatory markings . 23

J.2.2 Information to be provided if applicable . 23

J.3 General statement . 23

J.4 Starting conditions . 24

J.5 Operating conditions . 24

J.6 Current . 24

J.7 EMC immunity. 24

J.8 Pulse voltage from central battery systems . 24

J.9 Tests for abnormal conditions . 24

J.10 Temperature cycling test and endurance test . 25

J.11 Functional safety (EBLF) . 25

Annex K (informative) Conformity testing during manufacture . 26

Annex L (normative) Particular additional requirements for controlgear providing SELV . 27

Annex M (informative) Dielectric strength test voltages for controlgear intended for

the use in impulse withstand Category III . 28

Annex N (normative) Requirements for insulation materials used for double or

reinforced insulation . 29

Annex O (normative) Additional requirements for built-in electronic controlgear with

double or reinforced insulation . 30

Annex P (normative) Creepage distances and clearances and distance through

insulation (DTI) for lamp controlgear which are protected against pollution by the use

of coating or potting . 31

Annex Q (informative) Example for U calculation . 32

p

Annex R (informative) Concept of creepage distances and clearances . 33

Annex S (informative) Examples of controlgear insulation coordination . 34

Annex T (informative) Creepage distances and clearances for controlgear with a

higher degree of availability (impulse withstand category III) . 35

Bibliography . 36

Table 1 – Relation between RMS working voltage and maximum peak voltage . 11

Table J.1 – Pulse voltages . 24

– 4 – IEC 61347-2-14:2018 © IEC 2018

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

LAMP CONTROLGEAR –

Part 2-14: Particular requirements for DC and/or AC supplied

electronic controlgear for fluorescent induction lamps

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61347-2-14 has been prepared by subcommittee 34C: Auxiliaries

for lamps, of IEC technical committee 34: Lamps and related equipment.

The text of this International Standard is based on the following documents:

FDIS Report on voting

34C/1374/FDIS 34C/1383/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

This document is to be used in conjunction with IEC 61347-1:2015 and

IEC 61347-1:2015/AMD1:2017.

NOTE In this document, the following print types are used:

– Requirements proper: in roman type.

– Test specifications: in italic type.

– Explanatory matter: in smaller roman type.

A list of all parts in the IEC 61347 series, published under the general title Lamp controlgear,

can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – IEC 61347-2-14:2018 © IEC 2018

INTRODUCTION

This document specifies requirements for fluorescent induction lamp controlgear. The

formatting of IEC 61347-2 into separately published parts provides for ease of future

amendments and revisions. Additional requirements will be added as and when a need for

them is recognized.

This document, and the parts which make up IEC 61347-2, in referring to any of the clauses

of IEC 61347-1, specify the extent to which such a clause is applicable and the order in which

the tests are to be performed; they also include additional requirements, as necessary. All

parts which make up IEC 61347-2 are intended to be self-contained and, therefore, do not

include references to each other. However, for the case of emergency lighting lamp

controlgear, some cross-referencing has been used.

Where the requirements of any of the clauses of IEC 61347-1 are referred to in this document

by the phrase ”The requirements of clause n of IEC 61347-1 apply”, this phrase is interpreted

as meaning that all requirements of the clause in question of Part 1 apply, except any which

are clearly inapplicable to the specific type of lamp controlgear covered by this particular part

of IEC 61347-2.

LAMP CONTROLGEAR –

Part 2-14: Particular requirements for DC and/or AC supplied

electronic controlgear for fluorescent induction lamps

1 Scope

This part of IEC 61347 specifies particular safety requirements for electronic controlgear for

use on AC supplies up to 1 000 V at 50 Hz or 60 Hz and/or DC supplies with operating

frequencies deviating from the supply frequency, associated with fluorescent induction lamps

as specified in IEC 62532 and IEC 62639, for high-frequency operation.

For emergency lighting operation, particular requirements for controlgear operated from a

central supply are given in Annex J. Performance requirements appropriate to the safe

operation of emergency lighting are also contained in Annex J.

Requirements for emergency lighting controlgear operating from non-centralized power

supplies are given in IEC 61347-2-7.

NOTE Performance requirements detailed in Annex J are those considered to be safety related with respect to

reliable emergency operation.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60929:2011, AC and/or DC-supplied electronic control gear for tubular fluorescent lamps

– Performance requirements

IEC 61347-1:2015, Lamp controlgear – Part 1: General and safety requirements

IEC 61347-1:2015/AMD1:2017

IEC 61347-2-7:2011, Lamp controlgear – Part 2-7: Particular requirements for battery

supplied electronic controlgear for emergency lighting (self-contained)

IEC 61347-2-7:2011/AMD1:2017

IEC 61547, Equipment for general lighting purposes – EMC immunity requirements

IEC 62532:2011, Fluorescent induction lamps – Safety specifications

IEC 62639:2012, Fluorescent induction lamps – Performance specification

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 61347-1, IEC 62532

and IEC 62639 and the following apply.

– 8 – IEC 61347-2-14:2018 © IEC 2018

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

DC and/or AC supplied electronic controlgear

mains/battery-supplied DC only, AC/DC or AC only to AC invertor including stabilizing

elements for starting and operating one or more fluorescent induction lamps, generally at high

frequency

3.2

maximum allowed peak voltage

highest permitted peak voltage across any insulation under open-circuit condition and any

normal and abnormal operating conditions

Note 1 to entry: The maximum peak voltage is related to the declared RMS working voltage (see Table 1).

3.3

emergency lighting

lighting provided for use when the supply to the normal lighting fails

Note 1 to entry: Emergency lighting includes escape lighting and standby lighting.

3.4

rated battery voltage

voltage declared by the battery manufacturer

3.5

rated emergency power supply voltage

rated voltage of the emergency power supply claimed by the manufacturer

3.6

starting aid

device which facilitates the starting of the lamp

Note 1 to entry: A conductive strip affixed to the outer surface of the lamp and a conductive plate which is spaced

within an appropriate distance from a lamp are examples of starting aids.

3.7

ballast lumen factor

ratio of the luminous flux of a reference lamp when the controlgear under test is operated at

its rated voltage and frequency compared with the luminous flux of the same lamp operated

with the appropriate reference ballast supplied at its rated voltage and frequency

3.8

emergency ballast lumen factor

EBLF

ratio of the emergency luminous flux of the lamp supplied by the emergency controlgear to the

luminous flux of the same lamp operated with the appropriate reference ballast at its rated

voltage and frequency

Note 1 to entry: This note only applies to the French language.

3.9

total circuit power

total power dissipated by ballast and lamp in combination, at the rated voltage and frequency

of the ballast

3.10

reference lamp

lamp selected for testing controlgear which, when associated with a reference ballast, has

electrical characteristics which are close to the rated values as stated in the relevant lamp

standard

Note 1 to entry Relevant starting lamp data sheets are contained in IEC 62639.

[SOURCE: IEC 61347-1:2015, 3.3, modified – "ballasts" has been replaced with "controlgear"

and the note has been added.]

4 General requirements

The requirements of IEC 61347-1:2015 and IEC 61347-1:2015/AMD1:2017, Clause 4 apply,

together with the following additional requirement:

DC and/or AC supplied electronic controlgear for emergency lighting shall comply with the

requirements of Annex J.

5 General notes on tests

The requirements of IEC 61347-1:2015 and IEC 61347-1:2015/AMD1:2017, Clause 5 apply

together with the following additional requirement with regard to the number of specimens.

The following number of specimens shall be submitted for testing:

– one unit for the tests of Clauses 6 to 12 and 15 to 21;

– one unit for the test of Clause 14 (additional units or components, where necessary, may

be required in consultation with the manufacturer).

Tests to meet the safety requirements for DC and/or AC supplied electronic controlgear for

emergency lighting are made under the conditions specified in Annex J.

6 Classification

The requirements of IEC 61347-1:2015 and IEC 61347-1:2015/AMD1:2017, Clause 6 apply.

7 Marking

7.1 General

Controlgear which forms an integral part of the luminaire need not be marked.

7.2 Mandatory markings

In accordance with the requirements of IEC 61347-1:2015 and IEC 61347-1:2015/AMD1:2017,

7.2, controlgear, other than integral controlgear, shall be clearly and durably marked with the

following mandatory markings:

a) items a), b), c), d), e), k) and l) of IEC 61347-1:2015 and IEC 61347-1:2015/AMD1:2017,

7.1, together with

b) the symbol for earthing, as applicable;

c) for controllable controlgear, the control terminals shall be identified;

d) a declaration of the maximum working voltage (RMS) according to 15.3 between

– output terminals,

– any output terminal and earth.

– 10 – IEC 61347-2-14:2018 © IEC 2018

Marking for each of these two values shall be in steps of 10 V when the working voltage is

equal to, or less than, 500 V, and in steps of 50 V when the working voltage is higher than

500 V. The marking of maximum working voltage is referenced in two situations, the

maximum between output terminals and the maximum between any output terminal and

earth. It is acceptable for only the higher of these two voltages to be marked.

Marking shall be U-OUT = xx V, where xx is the marked working voltage value.

7.3 Information to be provided, if applicable

In addition to the above mandatory markings, the following information, if applicable, shall be

given either on the controlgear, or be made available in the manufacturer’s catalogue or

similar:

– items h), i), and j) given in IEC 61347-1:2015 and IEC 61347-1:2015/AMD1:2017, 7.1;

– information regarding voltage polarity reversal protection for DC supplied controlgear only.

8 Protection against accidental contact with live parts

The requirements of IEC 61347-1:2015 and IEC 61347-1:2015/AMD1:2017, Clause 10 apply.

9 Terminals

The requirements of IEC 61347-1:2015 and IEC 61347-1:2015/AMD1:2017, Clause 8 apply.

10 Provisions for earthing

The requirements of IEC 61347-1:2015 and IEC 61347-1:2015/AMD1:2017, Clause 9 apply.

11 Moisture resistance and insulation

The requirements of IEC 61347-1:2015 and IEC 61347-1:2015/AMD1:2017, Clause 11 apply.

12 Electric strength

The requirements of IEC 61347-1:2015 and IEC 61347-1:2015/AMD1:2017, Clause 12 apply.

13 Thermal endurance test for windings

The requirements of IEC 61347-1:2015 and IEC 61347-1:2015/AMD1:2017, Clause 13 do not

apply.

14 Fault conditions

The requirements of IEC 61347-1:2015 and IEC 61347-1:2015/AMD1:2017, Clause 14 apply.

For DC only electronic controlgear, the additional fault condition with reversed polarity of the

supply voltage shall be applied.

15 Protection of associated components

15.1 Maximum peak voltage under normal operation conditions

Under conditions of normal operation, verified using the appropriate circuit for ballast testing

in IEC 62639:2012, Clause D.4 and Figure D.3 and under conditions of abnormal operation,