IEC TS 62872-1:2019

(Main)Industrial-process measurement, control and automation - Part 1: System interface between industrial facilities and the smart grid

Industrial-process measurement, control and automation - Part 1: System interface between industrial facilities and the smart grid

IEC 62872-1:2019(E) defines the interface, in terms of information flow, between industrial facilities and the “smart grid”. It identifies, profiles and extends where required, the standards needed to allow the exchange of the information needed to support the planning, management and control of electric energy flow between the industrial facility and the smart grid.

The scope of this document specifically excludes the protocols needed for the direct control of energy resources within a facility where the control and ultimate liability for such control is delegated by the industrial facility to the external entity (e.g. distributed energy resource (DER) control by the electrical grid operator).

General Information

- Status

- Published

- Publication Date

- 25-Jun-2019

- Technical Committee

- TC 65 - Industrial-process measurement, control and automation

- Drafting Committee

- JWG 17 - TC 65/JWG 17

- Current Stage

- PPUB - Publication issued

- Start Date

- 26-Jun-2019

- Completion Date

- 23-Jul-2019

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC TS 62872-1:2019 - Industrial-process measurement, control and automation - Part 1: system interface between industrial facilities and the smart grid - defines the information-flow interface between industrial facilities and the smart grid. The Technical Specification identifies, profiles and, where necessary, extends existing standards to enable exchange of data required for planning, management and control of electrical energy flows between a facility and the grid. The document explicitly excludes protocols for direct control of on-site energy resources where control authority is delegated by the facility (e.g., DER control by the grid operator).

Key Topics and Requirements

- Information models and attributes: defines required data, data types and information attributes for facility–grid exchanges (see Tables and Annexes in the TS).

- Architecture and system models: architectural requirements for Facility Energy Management Systems (FEMS), network models and interfaces between enterprise, control and energy management layers.

- Demand response (DR) support: profiles use cases, user stories and incentive- and price-based DR mechanisms to manage facility-side responses to grid signals.

- Security and safety: security services, communication security requirements, audit logging and safety considerations for information exchange.

- Communications and timing: recommendations on communication technology use, network availability and time synchronization for reliable interaction with the smart grid.

- Use cases and normative examples: detailed normative annexes with user stories, sequence diagrams and exchanged-information tables; examples applying DR energy-management models.

- Standards profiling: analysis and mapping of existing standards to address information requirements (see Annex E).

Applications and Who Uses It

IEC TS 62872-1 is practical for organizations involved in integrating industrial sites with smart grid operations:

- Industrial automation and energy managers implementing Facility Energy Management Systems (FEMS).

- Utility and grid operators designing interfaces and programs for demand response and distributed energy resource coordination.

- System integrators and OEMs building gateways, EMS/FEMS products and communication adapters.

- Security and IT teams ensuring secure, auditable exchange of operational energy data. Practical uses include designing DR participation workflows, specifying data schemas for energy reports, and defining network/security requirements for facility–grid interfaces.

Related Standards

Annex E profiles and analyzes several complementary standards and specifications:

- OpenADR 2.0b (IEC 62746‑10‑1)

- OASIS Energy Interoperation 1.0

- NAESB Energy Services Provider Interface (ESPI)

- ISO 17800 Facility Smart Grid Information Model (FSGIM)

Keywords: IEC TS 62872-1:2019, smart grid, industrial facility, system interface, FEMS, demand response, energy management, information model, IEC standard.

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

Intertek Testing Services NA Inc.

Intertek certification services in North America.

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

Sponsored listings

Frequently Asked Questions

IEC TS 62872-1:2019 is a technical specification published by the International Electrotechnical Commission (IEC). Its full title is "Industrial-process measurement, control and automation - Part 1: System interface between industrial facilities and the smart grid". This standard covers: IEC 62872-1:2019(E) defines the interface, in terms of information flow, between industrial facilities and the “smart grid”. It identifies, profiles and extends where required, the standards needed to allow the exchange of the information needed to support the planning, management and control of electric energy flow between the industrial facility and the smart grid. The scope of this document specifically excludes the protocols needed for the direct control of energy resources within a facility where the control and ultimate liability for such control is delegated by the industrial facility to the external entity (e.g. distributed energy resource (DER) control by the electrical grid operator).

IEC 62872-1:2019(E) defines the interface, in terms of information flow, between industrial facilities and the “smart grid”. It identifies, profiles and extends where required, the standards needed to allow the exchange of the information needed to support the planning, management and control of electric energy flow between the industrial facility and the smart grid. The scope of this document specifically excludes the protocols needed for the direct control of energy resources within a facility where the control and ultimate liability for such control is delegated by the industrial facility to the external entity (e.g. distributed energy resource (DER) control by the electrical grid operator).

IEC TS 62872-1:2019 is classified under the following ICS (International Classification for Standards) categories: 25.040.40 - Industrial process measurement and control; 29.240.99 - Other equipment related to power transmission and distribution networks; 35.100.05 - Multilayer applications. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TS 62872-1:2019 has the following relationships with other standards: It is inter standard links to IEC TS 62872:2015. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC TS 62872-1:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC TS 62872-1 ®

Edition 1.0 2019-06

TECHNICAL

SPECIFICATION

colour

inside

Industrial-process measurement, control and automation –

Part 1: system interface between industrial facilities and the smart grid

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC TS 62872-1 ®

Edition 1.0 2019-06

TECHNICAL

SPECIFICATION

colour

inside

Industrial-process measurement, control and automation –

Part 1: system interface between industrial facilities and the smart grid

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 25.040.40; 29.240.99; 35.100.05 ISBN 978-2-8322-7084-4

– 2 – IEC TS 62872-1:2019 © IEC 2019

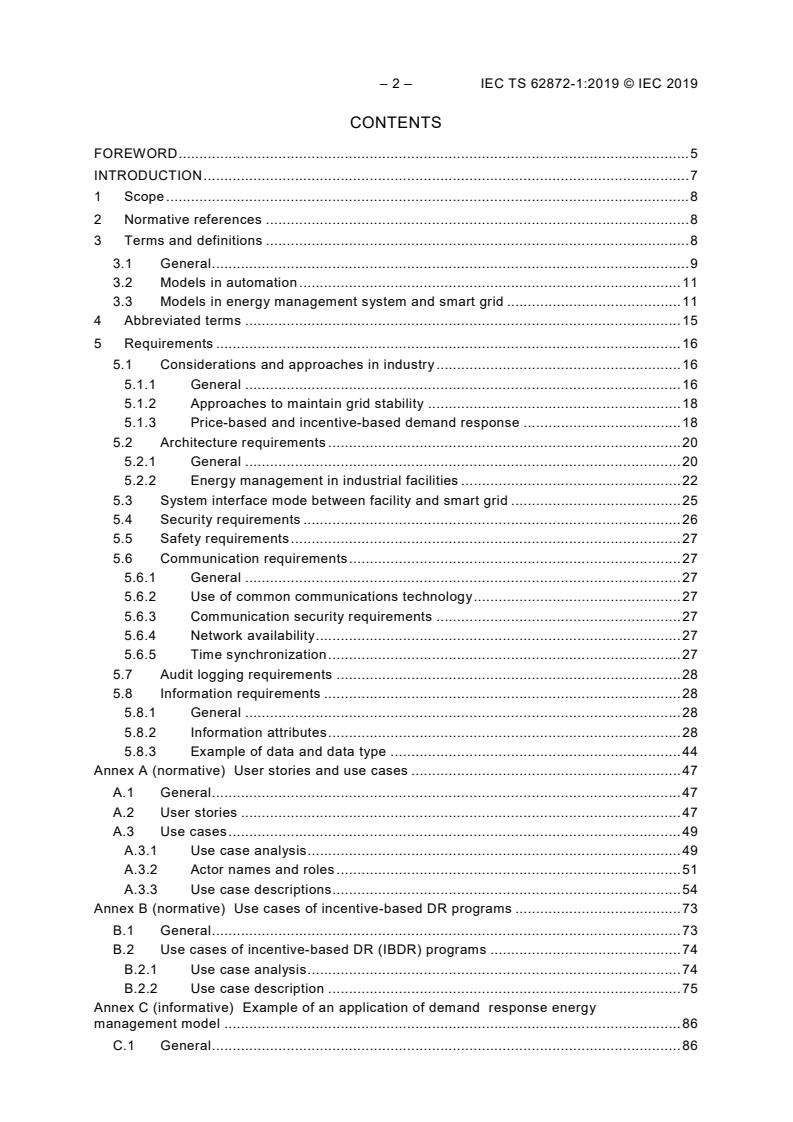

CONTENTS

FOREWORD . 5

INTRODUCTION . 7

1 Scope . 8

2 Normative references . 8

3 Terms and definitions . 8

3.1 General . 9

3.2 Models in automation . 11

3.3 Models in energy management system and smart grid . 11

4 Abbreviated terms . 15

5 Requirements . 16

5.1 Considerations and approaches in industry . 16

5.1.1 General . 16

5.1.2 Approaches to maintain grid stability . 18

5.1.3 Price-based and incentive-based demand response . 18

5.2 Architecture requirements . 20

5.2.1 General . 20

5.2.2 Energy management in industrial facilities . 22

5.3 System interface mode between facility and smart grid . 25

5.4 Security requirements . 26

5.5 Safety requirements . 27

5.6 Communication requirements . 27

5.6.1 General . 27

5.6.2 Use of common communications technology . 27

5.6.3 Communication security requirements . 27

5.6.4 Network availability . 27

5.6.5 Time synchronization . 27

5.7 Audit logging requirements . 28

5.8 Information requirements . 28

5.8.1 General . 28

5.8.2 Information attributes . 28

5.8.3 Example of data and data type . 44

Annex A (normative) User stories and use cases . 47

A.1 General . 47

A.2 User stories . 47

A.3 Use cases . 49

A.3.1 Use case analysis . 49

A.3.2 Actor names and roles . 51

A.3.3 Use case descriptions . 54

Annex B (normative) Use cases of incentive-based DR programs . 73

B.1 General . 73

B.2 Use cases of incentive-based DR (IBDR) programs . 74

B.2.1 Use case analysis . 74

B.2.2 Use case description . 75

Annex C (informative) Example of an application of demand response energy

management model . 86

C.1 General . 86

C.2 Main architecture . 86

C.3 Structure of a task . 87

C.4 Approaches of energy management . 87

C.4.1 General . 87

C.4.2 Approach 1 . 88

C.4.3 Approach 2 . 88

C.5 Mapping industrial demand response energy management model to use

cases . 88

Annex D (normative) Security services . 90

Annex E (informative) Solutions for information requirement . 91

E.1 General . 91

E.2 Existing standards . 91

E.3 Analysis for each use case . 93

E.3.1 General . 93

E.3.2 Analysis of "OpenADR2.0b" (IEC 62746-10-1:2018) . 93

E.3.3 Analysis of "OASIS Energy Interoperation 1.0" . 95

E.3.4 Analysis of "NAESB Energy Services Provider Interface (ESPI)". 97

E.3.5 Analysis of "ISO 17800:2017 Facility Smart Grid Information Model”

(FSGIM) . 98

Bibliography . 100

Figure 1 – Overview of interface between FEMS and smart grid . 17

Figure 2 – General approach common today for grid management of DR . 19

Figure 3 – Example facility electric power distribution . 20

Figure 4 – Facility enterprise and control systems . 21

Figure 5 – Model elements . 23

Figure 6 – Model architecture . 23

Figure 7 – Network architecture model . 26

Figure A.1 – Use case overview . 51

Figure A.2 – Generic communication diagram between the smart grid and the FEMS . 51

Figure A.3 – Actors in role hierarchy (IEC 62264-1) . 52

Figure A.4 – Sequence diagram for FG-100 . 56

Figure A.5 – Sequence diagram for FG-200 . 58

Figure A.6 – Sequence diagram for FG-300 . 60

Figure A.7 – Sequence diagram for FG-400 . 61

Figure A.8 – Sequence diagram for FG-500 . 63

Figure A.9 – Sequence diagram for FG-600 . 64

Figure A.10 – Sequence diagram for FG-710 . 66

Figure A.11 – Sequence diagram for FG-720 . 68

Figure A.12 – Sequence diagram for FG-810 . 70

Figure A.13 – Sequence diagram for FG-820 . 72

Figure B.1 – Role of incentive-based demand response in electric system planning

and operations . 74

Figure B.2 – Sequence diagram for IBDR-1 (DLC) . 76

Figure B.3 – Sequence diagram for IBDR-2 (I/C) . 78

Figure B.4 – Sequence diagram for IBDR-3 (EDRP) . 79

– 4 – IEC TS 62872-1:2019 © IEC 2019

Figure B.5 – Sequence diagram for IBDR-4 (DB) . 81

Figure B.6 – Sequence diagram for IBDR-5 (CMP). 83

Figure B.7 – Sequence diagram for IBDR-6 (ASM) . 85

Figure C.1 – An application example of demand response energy management model . 86

Figure C.2 – Structure of water cooling task . 87

Figure E.1 – Interaction to register report . 93

Figure E.2 – Interaction to request report . 94

Figure E.3 – Simple setup exchange . 94

Table 1 – Required information . 29

Table 2 – Example of data and data type . 45

Table A.1 – Facility user stories: facility operation view points . 48

Table A.2 – Utility user stories: utility operation view points . 49

Table A.3 – Dependency between user stories and use cases . 50

Table A.4 – Actors and roles . 53

Table A.5 – Exchanged information in FG-100 . 56

Table A.6 – Exchanged information in FG-200 . 58

Table A.7 – Exchanged information in FG-300 . 60

Table A.8 – Exchanged information in FG-400 . 61

Table A.9 – Exchanged information in FG-500 . 63

Table A.10 – Exchanged information in FG-600 . 64

Table A.11 – Exchanged information in FG-710 . 66

Table A.12 – Exchanged information in FG-720 . 68

Table A.13 – Exchanged information in FG-810 . 70

Table A.14 – Exchanged information in FG-820 . 72

Table B.1 – Dependency between user stories and use cases . 75

Table B.2 – Exchanged information in IBDR-1 (DLC) . 76

Table B.3 – Exchanged information in IBDR-2 (I/C) . 78

Table B.4 – Exchanged information in IBDR-3 (EDRP) . 80

Table B.5 – Exchanged information in IBDR-4 (DB) . 81

Table B.6 – Exchanged information in IBDR-5 (CMP). 83

Table B.7 – Exchanged information in IBDR-6 (ASM) . 85

Table E.1 – Overview of existing standard applicability . 92

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

INDUSTRIAL-PROCESS MEASUREMENT, CONTROL AND AUTOMATION –

Part 1: system interface between industrial facilities and the smart grid

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

The main task of IEC technical committees is to prepare International Standards. In

exceptional circumstances, a technical committee may propose the publication of a technical

specification when

• the required support cannot be obtained for the publication of an International Standard,

despite repeated efforts, or

• the subject is still under technical development or where, for any other reason, there is the

future but no immediate possibility of an agreement on an International Standard.

Technical specifications are subject to review within three years of publication to decide

whether they can be transformed into International Standards.

IEC TS 62872-1, which is a technical specification, has been prepared by IEC technical

committee 65: Industrial-process measurement, control and automation.

This first edition edition cancels and replaces IEC TS 62872, published in 2015. This edition

constitutes a technical revision.

– 6 – IEC TS 62872-1:2019 © IEC 2019

This edition includes the following significant technical changes with respect to IEC TS 62872:

• Normative references, Terms and definitions, and Abbreviations were updated;

• Subclause 5.1 was reformulated with price-based and incentive-based demand response;

• Subclause 5.8.3 “Example of data and data type” was added;

• New actors were added in Annex A;

• Use cases FG-7xx and FG-8xx were added in Annex A;

• Annex B “Use cases of incentive-based DR programs” was added.

The text of this Technical Specification is based on the following documents:

Enquiry draft Report on voting

65/731/DTS 65/743/RVDTS

Full information on the voting for the approval of this Technical Specification can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A review of this document will be carried out not later than 3 years after its publication with

the options of: extension for another 3 years; conversion into an International Standard; or

withdrawal.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

INTRODUCTION

The World Energy Outlook 2017 [19] reported that industry consumed over 40 % of world

electricity generation in 2015. Furthermore, industry itself is a significant generator of internal

power, with many facilities increasingly implementing their own generation, co-generation and

energy storage resources. As a major energy consumer, the ability of some industries to

schedule their consumption can be used to minimize peak demands on the electrical grid. As

an energy supplier, industries with in-house generation or storage resources can also assist

in grid load management. While some larger industrial facilities already manage their use and

supply of electric power, more widespread deployment, especially by smaller facilities, will

depend upon the availability of a readily available standard interface between industrial

automation equipment and the “smart grid”.

NOTE In this document “smart grid” is used to refer to the external-to-industry entity with which industry interacts

for the purpose of energy management. In other documents this term can be used to refer to all of the elements,

including internal industrial energy elements, which work together to optimize energy generation and use.

Industry is a major consumer of electric power and in many cases this consumption can be

scheduled to assist in minimizing overall peak demands on the smart grid. In addition, many

industrial facilities have in-house generation or storage resources. These facilities can assist

in smart grid load and supply management. For example, in-house generation can supply

energy to the smart grid and to the facility. Furthermore, storage resources can assist in smart

grid load management. While some larger industrial facilities already manage their use and

supply of electric power, more widespread deployment, especially by smaller facilities, will

depend upon the availability of readily available standard automated interfaces.

Standards are already being developed for home and building automation interfaces to the

smart grid; however, the requirements of industry differ significantly and are addressed in this

document. For industry, the planning of energy resources and production processes are under

the responsibility of the facility energy planner and production planner and the operations are

under the responsibility of the facility energy operator and production operator.

Incorrect operation of a resource could impact the safety of personnel, the facility, the

environment or lead to production failure and equipment damage. In addition, larger facilities

may have in-house production planning capabilities which might be co-ordinated with smart

grid planning, to allow longer term energy planning.

—————————

Numbers in square brackets refer to the Bibliography.

– 8 – IEC TS 62872-1:2019 © IEC 2019

INDUSTRIAL-PROCESS MEASUREMENT, CONTROL AND AUTOMATION –

Part 1: system interface between industrial facilities and the smart grid

1 Scope

This part of IEC 62872 defines the interface, in terms of information flow, between industrial

facilities and the “smart grid”. It identifies, profiles and extends where required, the standards

needed to allow the exchange of the information needed to support the planning, management

and control of electric energy flow between the industrial facility and the smart grid.

The scope of this document specifically excludes the protocols needed for the direct control of

energy resources within a facility where the control and ultimate liability for such control is

delegated by the industrial facility to the external entity (e.g. distributed energy resource

(DER) control by the electrical grid operator).

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 62264-1:2013, Enterprise-control system integration – Part 1: Models and terminology

IEC 62443 (all parts), Industrial communication networks – Network and system security

IEC TS 62443-1-1:2009, Industrial communication networks – Network and system security –

Part 1-1: Terminology, concepts and models

IEC 62443-2-1, Industrial communication networks – Network and system security – Part 2-1:

Establishing an industrial automation and control system security program

IEC TR 62443-3-1, Industrial communication networks – Network and system security –

Part 3-1: Security technologies for industrial automation and control systems

IEC 62443-3-3, Industrial communication networks – Network and system security – Part 3-3:

System security requirements and security levels

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1 General

3.1.1

profile

set of one or more base standards and/or other profiles and, where applicable, the

identification of chosen classes, conforming subsets, options and parameters of those base

standards, or profiles necessary to accomplish a particular function

[SOURCE: ISO/IEC TR 10000-1:1998, 3.1.4, modified – "ISPs" has been replaced by

"profiles".]

3.1.2

level

group of functions categorized with the functional hierarchy model of production systems

defined in IEC 62264-1

Note 1 to entry: The highest level, Level 4, typically includes enterprise resource planning and similar functions,

while the lowest level, Level 0, represents the physical industrial process itself.

3.1.3

level 4

functions involved in the business-related activities needed to manage a manufacturing

organization

[SOURCE: IEC 62264-1:2013, 3.1.16]

3.1.4

level 3

functions involved in managing the work flows to produce the desired end-products

[SOURCE: IEC 62264-1:2013, 3.1.17]

3.1.5

level 2

functions involved in monitoring and controlling of the physical process

[SOURCE: IEC 62264-1:2013, 3.1.17]

3.1.6

level 1

functions involved in sensing and manipulating the physical process

[SOURCE: IEC 62264-1:2013, 3.1.18]

3.1.7

level 0

actual physical process

[SOURCE: IEC 62264-1:2013, 3.1.19]

3.1.8

enterprise

one or more organizations sharing a definite mission, goals and objectives which provides an

output such as a product or service

[SOURCE: IEC 62264-1:2013, 3.1.10]

– 10 – IEC TS 62872-1:2019 © IEC 2019

3.1.9

area

physical, geographical or logical grouping of resources determined by the site

[SOURCE: IEC 62264-1:2013, 3.1.2, modified – The example has been removed.]

3.1.10

site

identified physical, geographical, and/or logical component grouping of a manufacturing

enterprise

[SOURCE: IEC 62264-1:2013, 3.1.39]

3.1.11

facility

industrial facility

site, or area within a site, that includes the resources within the site or area and includes the

activities associated with the use of the resources

[SOURCE: IEC 62264-1:2013, 3.1.20, modified – The preferred term facility and the admitted

term industrial facility have been replaced by facility.]

3.1.12

planner

facility energy planner

entity responsible for the advanced planning of facility energy use, storage and generation,

taking into account the requirements of future production and the overall operation of the

facility

Note 1 to entry: The facility energy planner is responsible for defining the overall future energy plan for the facility,

to include both the energy requirements of production and the overall needs and capabilities of the facility to

generate, store, and consume energy.

Note 2 to entry: Plans developed by the facility energy planner will typically be made at least a day prior to

intended use.

Note 3 to entry: The facility energy planner will assemble the overall energy plan based on the individual plans

developed by production planners and the non-production requirements and capabilities of the facility.

3.1.13

production planner

entity responsible for developing, monitoring and modifying the production plan based on

facility requirements and the availability of inputs

Note 1 to entry: Example of inputs are equipment, labour, raw materials and energy.

3.1.14

facility energy operator

entity responsible for the minute by minute supply of energy to support current production and

current facility operation

Note 1 to entry: The facility energy operator monitors facility energy use, generation and storage, and makes

adjustments in response to changes related to shifting energy supplies, material disruptions, and equipment

breakdowns.

3.1.15

production operator

entity responsible for the minute by minute use of energy to carry out production plans, and

authorized to respond to real-time changes based on feed-back from the process and other

internal or external event

Note 1 to entry: The production plan is given from production planner.

3.2 Models in automation

3.2.1

asset

physical or logical object owned by or under the custodial duties of an organization, having

either a perceived or actual value to the organization

Note 1 to entry: In the case of industrial automation and control systems the physical assets that have the largest

directly measurable value may be the equipment under control.

[SOURCE: IEC TS 62443-1-1:2009, 3.2.6]

3.2.2

automation asset

asset with a defined automation role in a manufacturing or process plant

Note 1 to entry: It would include structural, mechanical, electrical, electronics and software elements (e.g.

controllers, switches, network, drives, motors, pumps). These elements cover components, devices but not the

plant itself (machine, systems). It would not include human resources, process materials (e.g. raw, in-process,

finished), or financial assets.

3.2.3

process

set of interrelated or interacting activities that transforms inputs into outputs

[SOURCE: ISO 14040:2006, 3.11]

3.2.4

product

result of labour or of a natural or industrial process

Note 1 to entry: This term is defined by "any goods or service" in IEC 62430 [11] and ISO 20140-1 [18]. The

European Commission adopts a similar understanding in the directive "Ecodesign requirements for energy-related

products". In the context of this document, the term "product" does not cover the automation assets but only the

output of the manufacturing or process plant.

[SOURCE: IEC TR 62837:2013, 3.7.7]

3.3 Models in energy management system and smart grid

3.3.1

smart grid

SG

electric power system that utilizes information exchange and control technologies, distributed

computing and associated sensors and actuators, for purposes such as to integrate the

behaviour and actions of the network users and other stakeholders, and to efficiently deliver

sustainable, economic and secure electricity supplies

Note 1 to entry: In this document, smart grid is the counterpart system to which FEMS is connected.

[SOURCE: IEC 60050-617:2011, 617-04-13, modified by adding abbreviation and Note 1 to

entry]

3.3.2

smart meter

SM

embedded-computer-based energy meter with a communication link

Note 1 to entry: In this document smart meters are used to measure both the consumption and supply of energy

by the facility. They may also be deployed within the facility to measure internal energy flows.

– 12 – IEC TS 62872-1:2019 © IEC 2019

3.3.3

utility smart meter

USM

smart meter deployed by the utility company to measure energy consumption and supply by

the facility

Note 1 to entry: This meter typically forms part of the advanced metering infrastructure of smart grid.

3.3.4

facility smart meter

FSM

smart meter deployed and used by the facility to measure energy flows

Note 1 to entry: This meter will normally communicate with the FEMS.

3.3.5

distributed energy resource

DER

energy resource, often of a small size, operated by the utility to augment the local supply of

energy

Note 1 to entry: In this document, DER, in contrast to FER, is used to refer to resources under the direct control

of the utility. Such resources may include generation and/or storage capabilities.

3.3.6

facility energy resource

FER

energy resource, operated by the facility, which is used to supply energy to the facility and

which may also be used to provide energy to the grid

Note 1 to entry: This terminology, rather than distributed energy resource (DER) terminology, is used to

emphasize that the FER is operated by the facility and not under the direct control of the utility. Such resources

may include generation and/or storage capabilities.

3.3.7

demand response

DR

mechanism to manage customer load demand in response to supply conditions, such as

prices or availability signals

3.3.8

price-based demand response

PBDR

mechanism that give customers time-varying rates that reflect the value and cost of electricity

in different time periods

Note 1 to entry: Armed with this information, customers tend to use less electricity at times when electricity prices

are high.

3.3.9

time of use

TOU

rate with different unit prices for usage during different blocks of time, usually defined for a

24-hour day

Note 1 to entry: TOU rates reflect the average cost of generating and delivering power during those time periods.

3.3.10

day-ahead price

DAP

rate notified on a day-ahead basis, in which the price for electricity fluctuates hourly reflecting

changes in the wholesale price of electricity

3.3.11

real-time price

RTP

rate notified on hourly-ahead basis, in which the price for electricity fluctuates hourly

reflecting changes in the wholesale price of electricity

3.3.12

incentive-based demand response

IBDR

mechanism supported by soliciting demand response behaviour, commitment to agreed

demand response and programs that pay participating customers to reduce their loads at

times requested by the program sponsor

Note 1 to entry: The no-participation in solicited demand response behaviour does not incur any penalty;

examples are DLC and EDRP.

Note 2 to entry: The no-participation in committed agreed demand response behaviour entails a penalty;

examples are I/C, DB, CMP and ASM.

3.3.13

direct load control

DLC

one of IBDR programs, in which the SG operator remotely shuts down the load of a facility to

address system reliability contingencies, in exchange of paying the facility participation

payment in advance

3.3.14

interruptible/curtailable load

I/C

one of IBDR programs, in which the SG operator issues “incentive” to a facility for agreeing to

reduce load during system contingencies, a facility will be penalized if it does not reduce load

3.3.15

emergency demand response program

EDRP

one of IBDR programs, in which the SG operator provides incentive payment to a facility for

measured load reduction during a reliability-triggered event, no penalty is imposed if the

facility does not respond

3.3.16

demand bidding

DB

one of IBDR programs, in which the SG operator allows a facility to bid load reduction into the

energy market, a facility with accepted bid shall reduce load as contracted, otherwise it faces

a penalty

3.3.17

capacity market program

CMP

one of IBDR programs, in which the SG operator provides a facility with guaranteed payment

for committing to provide predefined load reduction as the system capacity, a facility will face

a penalty if it does not reduce load during a DR event

3.3.18

ancillary service market

ASM

one of IBDR programs, in which the SG operator allows a qualified facility to bid load

reduction into the ancillary market as operating reserves, a facility with accepted bid shall

curtail load when called by the SG operator, otherwise it faces a penalty

– 14 – IEC TS 62872-1:2019 © IEC 2019

3.3.19

facility energy management system

FEMS

system providing the functionality needed for the effective and efficient operation of energy

generation, storage and consumption within the industrial facility, and which provides the

necessary information interface with the smart grid

[SOURCE: IEC TS 61968-2:2011, 2.101, modified – The definition has been rewritten]

3.3.20

utility gateway

UG

function within FEMS responsible for the connection with the smart grid

Note 1 to entry: It is a function within FEMS.

3.3.21

energy generation system

EGS

energy resource capable of creating electric energy from other sources of energy or process

wastes

EXAMPLE Combined heat and power systems, photo-voltaic cells, wind power generators.

3.3.22

energy storage system

ESS

energy resource capable of storing energy for later use

EXAMPLE Batteries, flywheels, pumped hydro storage, electrical vehicles, fuel cells.

3.3.23

facility power line

FPL

network, which distributes energy to individual industrial equipment within a facility

3.3.24

schedulable processing task

ST

task for which energy demand can be scheduled among multiple operating modes, where

each mode has a different production rate and energy demand, such as heating, cooling,

packaging, etc.

3.3.25

non-schedulable processing task

NST

task for which energy demand shall be satisfied immediately, such as rolling in steel

manufacturing, assembling in automobile industry, etc.

3.3.26

monitor and control agent

MCA

agent that monitors and controls processing operations of a task

3.3.27

energy management agent

EMA

agent that monitors the energy consumption and controls the electric load of a task

3.3.28

power source switch

switch which selects the energy source of a task

3.3.29

non-shiftable equipment

NSE

equipment whose operation cannot be re-scheduled

3.3.30

controllable equipment

CE

equipment whose energy demand can be controlled among multiple operating levels, each of

which has a different energy demand

3.3.31

shiftable equipment

SE

equipment that can be operated at an earlier or later time

3.3.32

firewall

inter-network connection device that restricts data communication traffic between two

connected networks

4 Abbreviated terms

APO Advanced Planning and Optimization

ASM Ancillary Service Market

CE Controllable Equipment

CHP Combined Heat and Power (co-generation) Equipment

CMM Computerized Maintenance Management

CMP Capacity Market Program

DAP Day-ahead Price

DB Demand Bidding

DCS Distributed Control System

DER Distributed Energy Resource

DLC Direct Load Control

DR Demand Response

EDRP Emergency Demand Response Program

EGS Energy Generation System

EMA Energy Management Agent

EMS Energy Management System

ERP Enterprise Resource Planning

ESS Energy Storage System

FEMS Facility Energy Management System

FER Facility Energy Resource

FG Facility-Grid (Use Case)

FSM Facility Smart Meter

FUS Facility User Story

– 16 – IEC TS 62872-1:2019 © IEC 2019

GW Utility Gateway

HMI Human Machine Interface

IBDR Incentive-based Demand Response

I/C Interruptible/curtailable Load

I/O Input Output

ICT Information and Communications Technology

LAN Local Area Network

LIMS Laboratory Information Management System

MCA Monitor and Control Agent

MES Manufacturing Execution System

NSE Non-shiftable Equipment

NST Non-schedulable Processing Task

PBDR Price-based Demand Response

PLC Programmable Logic Controller

PV Photo Voltaic

RTP Real-time price

SCADA Supervisory Control and Data Acquisition

SE Shiftable Equipment

SG Smart Grid

SM Smart Meter

ST Schedulable Processing

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...