IEC 63145-20-20:2019

(Main)Eyewear display - Part 20-20: Fundamental measurement methods - Image quality

Eyewear display - Part 20-20: Fundamental measurement methods - Image quality

IEC 63145-20-20:2019 (E) specifies the standard measurement conditions and measurement methods for determining the image quality of eyewear displays. This document is applicable to non-see-through type (virtual reality “VR” goggle) and see-through type (augmented reality “AR” glasses) eyewear displays using virtual image optics.

Contact-lens type displays and retina direct projection displays are out of the scope of this document.

General Information

- Status

- Published

- Publication Date

- 12-Sep-2019

- Technical Committee

- TC 110 - Electronic displays

- Drafting Committee

- WG 12 - TC 110/WG 12

- Current Stage

- PPUB - Publication issued

- Start Date

- 13-Sep-2019

- Completion Date

- 27-Sep-2019

Overview

IEC 63145-20-20:2019 - "Eyewear display - Part 20-20: Fundamental measurement methods - Image quality" defines standardized measurement conditions and methods for assessing image quality of eyewear displays. It applies to both non-see-through (VR goggles) and see-through (AR glasses) that use virtual-image optics. Contact‑lens type displays and retina direct‑projection systems are explicitly out of scope.

This standard sets out how to measure optical performance reproducibly: environmental and warm‑up conditions, power supply considerations, measurement geometry, test patterns, measurement points and reporting formats for key image‑quality metrics.

Key Topics and Requirements

- Standard measurement conditions

- Environmental limits (temperature, humidity, pressure) and warm‑up procedures to ensure repeatable results.

- Stable power-supply and dark‑room conditions for optics and luminance tests.

- Measurement systems and geometry

- Defined coordinate systems (spherical and Cartesian) for mapping measurements across the field of view (FOV).

- Specification of measurement equipment such as LMD (light measuring device) and stage/setup requirements.

- Test patterns and measurement points

- Use of checkerboard, solid‑colour and Michelson contrast patterns for systematic evaluation.

- Prescribed centre and multi‑point layouts to capture spatial variation across the display.

- Image quality metrics and methods

- Distortion: procedures, calculation and reporting for spatial distortion across the FOV.

- Colour registration error: measurement of misalignment among primary colour channels.

- Michelson contrast: method for contrast measurement and use in defining perceptual FOV and eye‑box.

- Focal distance / Dioptre: procedures to determine focal distance at measurement points.

- FOV and Eye‑box definitions based on Michelson contrast thresholds.

- Reporting

- Standardized calculation steps and reporting templates for consistent documentation.

Practical Applications and Users

IEC 63145-20-20 is intended for:

- Display manufacturers (VR/AR headset designers) seeking objective image‑quality validation.

- Test and calibration laboratories performing product compliance, benchmarking and QA.

- Systems integrators and OEMs verifying optical performance for integration into consumer or enterprise devices.

- Researchers and optical engineers developing virtual‑image optics or comparing imaging trade‑offs.

Typical uses: product development, acceptance testing, competitive comparison, and documented verification for procurement or certification.

Related Standards (if applicable)

- IEC 63145-20-10 - Eyewear display: Fundamental measuring methods - Optical properties (related optical metrics).

- ISO 9241‑302:2008 - Ergonomics of human‑system interaction - Terminology for electronic visual displays.

Keywords: IEC 63145-20-20, eyewear display, image quality, VR goggle, AR glasses, measurement methods, Michelson contrast, distortion, colour registration, FOV, eye-box, light measuring device.

Get Certified

Connect with accredited certification bodies for this standard

BSMI (Bureau of Standards, Metrology and Inspection)

Taiwan's standards and inspection authority.

Sponsored listings

Frequently Asked Questions

IEC 63145-20-20:2019 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Eyewear display - Part 20-20: Fundamental measurement methods - Image quality". This standard covers: IEC 63145-20-20:2019 (E) specifies the standard measurement conditions and measurement methods for determining the image quality of eyewear displays. This document is applicable to non-see-through type (virtual reality “VR” goggle) and see-through type (augmented reality “AR” glasses) eyewear displays using virtual image optics. Contact-lens type displays and retina direct projection displays are out of the scope of this document.

IEC 63145-20-20:2019 (E) specifies the standard measurement conditions and measurement methods for determining the image quality of eyewear displays. This document is applicable to non-see-through type (virtual reality “VR” goggle) and see-through type (augmented reality “AR” glasses) eyewear displays using virtual image optics. Contact-lens type displays and retina direct projection displays are out of the scope of this document.

IEC 63145-20-20:2019 is classified under the following ICS (International Classification for Standards) categories: 01 - GENERALITIES. TERMINOLOGY. STANDARDIZATION. DOCUMENTATION; 17.180.99 - Other standards related to optics and optical measurements; 31.120 - Electronic display devices. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 63145-20-20:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 63145-20-20 ®

Edition 1.0 2019-09

INTERNATIONAL

STANDARD

Eyewear display –

Part 20-20: Fundamental measurement methods – Image quality

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 63145-20-20 ®

Edition 1.0 2019-09

INTERNATIONAL

STANDARD

Eyewear display –

Part 20-20: Fundamental measurement methods – Image quality

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 17.180.99; 31.120 ISBN 978-2-8322-7352-4

– 2 – IEC 63145-20-20:2019 © IEC 2019

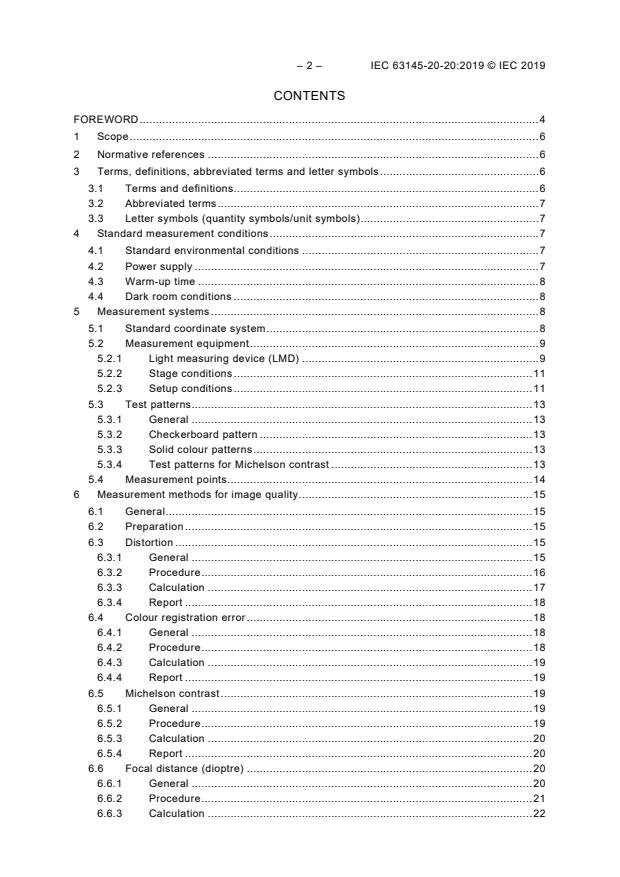

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms, definitions, abbreviated terms and letter symbols . 6

3.1 Terms and definitions . 6

3.2 Abbreviated terms . 7

3.3 Letter symbols (quantity symbols/unit symbols) . 7

4 Standard measurement conditions . 7

4.1 Standard environmental conditions . 7

4.2 Power supply . 7

4.3 Warm-up time . 8

4.4 Dark room conditions . 8

5 Measurement systems . 8

5.1 Standard coordinate system . 8

5.2 Measurement equipment . 9

5.2.1 Light measuring device (LMD) . 9

5.2.2 Stage conditions . 11

5.2.3 Setup conditions . 11

5.3 Test patterns. 13

5.3.1 General . 13

5.3.2 Checkerboard pattern . 13

5.3.3 Solid colour patterns . 13

5.3.4 Test patterns for Michelson contrast . 13

5.4 Measurement points . 14

6 Measurement methods for image quality . 15

6.1 General . 15

6.2 Preparation . 15

6.3 Distortion . 15

6.3.1 General . 15

6.3.2 Procedure . 16

6.3.3 Calculation . 17

6.3.4 Report . 18

6.4 Colour registration error . 18

6.4.1 General . 18

6.4.2 Procedure . 18

6.4.3 Calculation . 19

6.4.4 Report . 19

6.5 Michelson contrast . 19

6.5.1 General . 19

6.5.2 Procedure . 19

6.5.3 Calculation . 20

6.5.4 Report . 20

6.6 Focal distance (dioptre) . 20

6.6.1 General . 20

6.6.2 Procedure . 21

6.6.3 Calculation . 22

6.6.4 Report . 22

6.7 FOV based on Michelson contrast . 22

6.7.1 General . 22

6.7.2 Procedure . 22

6.7.3 Calculation . 23

6.7.4 Report . 23

6.8 Eye-box based on Michelson contrast . 23

6.8.1 General . 23

6.8.2 Procedure . 23

6.8.3 Calculation . 24

6.8.4 Report . 25

Bibliography . 26

Figure 1 – Spherical coordinate system . 9

Figure 2 – Three-dimensional Cartesian coordinate system . 9

Figure 3 – Example of LMD structure . 10

Figure 4 – Examples of measurement setup. 12

Figure 5 – Example of 5 x 5 checkerboard pattern . 13

Figure 6 – Example of Michelson contrast test pattern . 14

Figure 7 – Measuring points for the centre- and multi-point measurement . 14

Table 1 – Letter symbols (symbols for quantities, and units) . 7

– 4 – IEC 63145-20-20:2019 © IEC 2019

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

EYEWEAR DISPLAY –

Part 20-20: Fundamental measurement methods –

Image quality

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 63145-20-20 has been prepared by IEC technical committee

TC 110: Electronic displays.

The text of this International Standard is based on the following documents:

FDIS Report on voting

110/1110/FDIS 110/1139/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 63145 series, published under the general title Eyewear display,

can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

– 6 – IEC 63145-20-20:2019 © IEC 2019

EYEWEAR DISPLAY –

Part 20-20: Fundamental measurement methods –

Image quality

1 Scope

This part of IEC 63145 specifies the standard measurement conditions and measurement

methods for determining the image quality of eyewear displays. This document is applicable

to non-see-through type (virtual reality “VR” goggle) and see-through type (augmented reality

“AR” glasses) eyewear displays using virtual image optics.

Contact-lens type displays and retina direct projection displays are out of the scope of this

document.

NOTE See IEC TR 63145-1-1 [1] for eyewear displays, ISO 9241-302:2008, 3.5.45, for see-through types.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 63145-20-10:– , Eyewear display – Part 20-10: Fundamental measuring methods –

Optical properties

ISO 9241-302:2008, Ergonomics of human-system interaction – Part 302: Terminology for

electronic visual displays

3 Terms, definitions, abbreviated terms and letter symbols

3.1 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 63145-20-10 and

ISO 9241-302 apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

NOTE 1 Terms related to eyewear displays will be defined in specific projects.

NOTE 2 Some terms relating to eyewear displays are given in IEC TR 63145-1-1 [1].

____________

Numbers in square brackets refer to the Bibliography.

Under preparation. Stage at the time of publication: IEC FDIS 63145-20-10:2019.

3.2 Abbreviated terms

AR augmented reality

CCD charge-coupled device detector

CPD cycles per degree

DUT device under test

FOV field of view

LMD light measuring device

VR virtual reality

3.3 Letter symbols (quantity symbols/unit symbols)

The letter symbols for eyewear displays are shown in Table 1

Table 1 – Letter symbols (symbols for quantities, and units)

Quantities Symbols and units

Measuring point (i = 0: centre) P

i

Luminance at P L (cd/m )

i vi

Distortion at the corner

δ (%)

vh

Colour registration error for primary colour ε (degree)

vh, colour

Michelson contrast C

m

Maximum luminance L (cd/m )

vM

Minimum luminance L (cd/m )

vm

Spatial frequency (CPD) f (1/degree)

CPD

Focal distance at P γ (m)

i i

Dioptre at P D (1/m)

i i

4 Standard measurement conditions

4.1 Standard environmental conditions

Unless otherwise specified, all tests and measurements for eyewear displays shall be carried

out after sufficient warm-up time for the illumination sources and DUT (see 4.3), under the

following standard environmental conditions:

• temperature 22 °C to 28 °C,

• relative humidity 25 % to 85 %, and

• atmospheric pressure 86 kPa to 106 kPa.

When different environmental conditions are used, they shall be reported in detail in the

specification.

4.2 Power supply

In order to stabilize the performances of the DUT, the power supply for driving the DUT shall

be adjusted according to the specification of the DUT.

NOTE When the DUT is driven by a battery, it is less susceptible to power supply fluctuations.

– 8 – IEC 63145-20-20:2019 © IEC 2019

4.3 Warm-up time

The optical performances of DUTs are affected by the transient temperature behaviour of the

device. It takes a certain time for the luminance output of the DUT to reach the steady state. If

the luminance output is not within a ±3 % variation, it shall be reported. All measuring

conditions shall be kept constant during the measurements.

NOTE If the measuring result does not become a steady state, it might be influenced by the output fluctuation of

the DUT and/or the fluctuation of the LMD such as noise.

4.4 Dark room conditions

The luminance contribution from the background of the test room reflected off the

measurement space shall be less than 1/20 of the minimum luminance output from the DUT. If

this condition is not satisfied, then background luminance can be subtracted and it shall be

reported.

5 Measurement systems

5.1 Standard coordinate system

To indicate the size and position of a virtual image, a spherical coordinate system of elevation

(latitude) and azimuth (longitude) shall be used in the measurements; the polar axis is

vertically oriented as shown in Figure 1. The angles measured in the vertical half plane of

data are elevation angles, denoted as α, and the horizontal angles to the half plane are

azimuth angles, denoted as Ψ. The origin direction (α = 0, Ψ = 0) of the spherical coordinate

system shall be coincident with the optical axis of the DUT.

To indicate the positional relationship among the eye-box, reference point on the DUT, eye

point and eye relief of the DUT, entrance pupil of the LMD and so on, a three-dimensional

Cartesian coordinate system (x, y, z) shall be used, as shown in Figure 2. Unless specified

otherwise, the eye point of the DUT is placed in the centre of the entrance pupil of the eye,

which is in the centre of the iris. The eye point defines the origin of the coordinate system.

The manufacturer or supplier of the DUT shall specify the distance between a reference point

on the DUT and the eye point. The eye relief is defined as the distance from the cornea of the

eye to the closest optical element of the DUT.

The origins of both the spherical coordinate system and the Cartesian coordinate system shall

be located at the eye point.

NOTE In the case of a binocular eyewear display, the left eye can be used as the origin of the Cartesian

coordinate system.

Figure 1 – Spherical coordinate system

NOTE This figure is an example of the eye pupil adjusting to the eye point, which is the origin position.

Figure 2 – Three-dimensional Cartesian coordinate system

5.2 Measurement equipment

5.2.1 Light measuring device (LMD)

5.2.1.1 General

The configurations and operating conditions of the equipment should comply with the

structures specified in each item. To ensure accurate measurements, the following

requirements shall be applied. Otherwise, the differences shall be noted in the report.

ISO/CIE 19476 [4] describes the LMD evaluation procedures.

The optics of an LMD (a spot LMD or a 2D imaging LMD) shall be equivalent to the human

eye, as shown in Figure 3. The LMD shall be equipped with an optical finder or a digital

viewfinder. The position of the entrance pupil (aperture) of the LMD shall be provided by the

manufacturer or the supplier. The entrance pupil size of the LMD should be set between 2 mm

and 5 mm, and shall be smaller than the light ray of the DUT. The LMD to measure the optical

characteristics such as luminance and colour shall be calibrated with the appropriate

photometric or spectrometric standards. The LMD should be carefully checked before

measurements, considering the following points:

• sensitivity of the measured quantity to the measuring light;

• errors caused by the veiling glare and lens flare (i.e., stray light in the optical system);

• timing of data-acquisition, low-pass filtering and aliasing-effects;

• linearity of detection and data conversion;

• measurement field size.

– 10 – IEC 63145-20-20:2019 © IEC 2019

NOTE See IEC TR 63145-1-1:2018, 6.2 [1].

Figure 3 – Example of LMD structure

5.2.1.2 Spectrometer-type LMD

When a spectrometer-type LMD such as a spectroradiometer is used, the wavelength range

shall be at least 380 nm to 780 nm, the spectral bandwidth shall be 5 nm or smaller, and the

wavelength accuracy shall be 0,3 nm or smaller.

5.2.1.3 Filter-type LMD for measuring luminance

When a filter-type LMD such as a luminance meter is used, to ensure the luminance accuracy

for the intended DUT light sources, its spectral responsivity should comply with the spectral

luminous efficiency for CIE photopic vision or it should be compared with a calibrated

spectrometer. The spectral mismatch correction factor can be applied, if necessary.

NOTE CIE-f ’ indicates the spectral mismatch function between the spectral responsivity of the filter-type LMD

and the CIE photopic luminous efficiency function. Details of the spectral mismatch correction factor are given in

ISO19476 [4].

5.2.1.4 Filter-type LMD for measuring colour

When a filter-type LMD such as a colorimeter is used to ensure the colour accuracy for the

intended DUT light sources, its spectral responsivity should comply with the CIE colour-

matching functions for the CIE 1931 standard colorimetric observer (see ISO 11664-1 [3]) or it

should be compared with a calibrated spectrometer. The colour correction factors can be

applied, if necessary. The filter-type LMD shall not be used for absolute colour quantities, but

for relative colour quantities such as colour uniformity.

5.2.1.5 2D imaging LMD

The 2D imaging LMD (using a two-dimensional sensor such as a CCD) is a kind of a filter-

type LMD. The performances of the 2D imaging LMD shall comply with 5.2.1.3 and 5.2.1.4.

The valid measurement field angle of the 2D imaging LMD shall be confirmed and the

peripheral image of the 2D imaging LMD shall confirm the absence of vignetting. The number

of pixels of the 2D imaging LMD should not be less than four times the sub-pixels number

within the measurement field.

NOTE 1 The measurement field of some 2D imaging LMDs is affected by the smaller entrance aperture.

NOTE 2 The 2D imaging LMD using a colour filter array might cause moiré.

5.2.2 Stage conditions

5.2.2.1 General

The stage shall be used to realize the coordinate system specified in 5.1. The stage should be

constructed with the equivalent of a biaxial goniometer and an orthogonal three-axis

translation stage.

5.2.2.2 Goniometer

A biaxial goniometer shall be assembled to be capable of measuring the azimuth (horizontal)

and elevation (vertical) angles in the spherical coordinate system as shown in Figure 1.

Examples of a five-axis stage are shown in Figure 4. The angular accuracy should be no less

than 0,1°. The goniometer can be pivoted at the centre of the entrance pupil of the LMD or

10 mm behind the entrance pupil.

5.2.2.3 Translation stage

An orthogonal three-axis translation stage is assembled with an adequate range to cover the

measuring distance such as the eye-box volume, and, if necessary, to cover the interpupillary

distance for binocular DUTs, as in the examples shown in Figure 4. The translation accuracy

should be no less than 0,05 mm.

5.2.3 Setup conditions

The DUT shall be mounted on a stable platform to ensure image stability. The LMD position

relative to the DUT shall be moved, and it can use a five-axis system (a biaxial goniometer

and orthogonal three-axis translation stage). Examples of a measuring setup are shown in

Figure 4. The eye point of the DUT shall match the origin of the biaxial goniometer. The

optical axis of the DUT which is decided by the manufacturer or a supplier shall be adjusted to

the optical axis of the LMD and shall be aligned with the z-axis of the orthogonal three-axis

translation stage. The aspect of the virtual image of the DUT shall be adjusted to the x- and y-

axes of the orthogonal three-axis translation stage.

To measure the conditions viewed from the front side, when the DUT does not suppose a

change of gaze angle (eye rotation), the origin of a biaxial goniometer shall be assumed as

the entrance pupil of the eye (eye point), not the rotation centre of the eyeball (eye

movement). When the origin of the biaxial goniometer does not match the eye point of the

DUT, the coordinate correction shall be required and shall be reported. When the DUT

supposes a change of the gaze angle, the detailed information such as the position of the

rotation centre shall be specified by the manufacturer or the supplier and shall be reported.

NOTE 1 The cornea position is about 3 mm in front of the iris position. Some optical designs are used based on

the cornea position.

NOTE 2 The rotation centre of the eyeball is located about 10 mm behind the iris.

– 12 – IEC 63145-20-20:2019 © IEC 2019

a) LMD mounted on a biaxial goniometer and orthogonal three-axis translation stage

b) DUT mounted on a biaxial goniometer and an orthogonal three-axis translation stage

NOTE 1 When the LMD is installed on the biaxial goniometer, the elevation stage is set on the azimuth stage.

NOTE 2 Some eyewear displays change their virtual image depending on their orientation.

Figure 4 – Examples of measurement setup

5.3 Test patterns

5.3.1 General

The following test patterns shall be specified by the manufacturer or the supplier, and the

applied test pattern shall be noted in the report. When other test patterns are applied, they

shall be noted in the report.

NOTE Unlike a conventional display, the boundary of the display area is not clear, and the choice of test pattern

might affect the measurement results.

5.3.2 Checkerboard pattern

The checkerboard pattern as shown in Figure 5 should be used to measure the applicable

properties, and can be used for alignment of the DUT and LMD optics. The checkerboard

pattern with crosses whose example is specified in ISO 9241-305 [2], should also be used for

alignment of the DUT and LMD optics. Both patterns of white and black at the centre can be

used. Usually, a white and black checkerboard pattern is used, but a checkerboard pattern of

another colour (red, green, blue and so on) and black can be used if necessary.

NOTE The 5 x 5 checkerboard pattern is helpful in navigating across the virtual image and focusing

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...