IEC TR 61916:2017

(Main)Electrical accessories - Harmonization of general rules

Electrical accessories - Harmonization of general rules

IEC TR 61916:2017(E) provides guidance on requirements and tests for subjects applicable to electrical accessories that are within the scope of IEC TC 23 and its subcommittees.

This fourth edition cancels and replaces the third edition published in 2014 and constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition:

a) clarification of the introduction and the scope;

b) clarification of subclause 6.3;

c) modification of Clause 7;

d) modification of Clause 10;

e) addition of Annex B for temperature selection for GWEPT.

General Information

- Status

- Published

- Publication Date

- 27-Mar-2017

- Technical Committee

- TC 23 - Electrical accessories

- Drafting Committee

- MT 11 - TC 23/MT 11

- Current Stage

- PPUB - Publication issued

- Start Date

- 28-Mar-2017

- Completion Date

- 10-Apr-2017

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC TR 61916:2017 - "Electrical accessories - Harmonization of general rules" - is a Technical Report published by the IEC (Edition 4.0, 2017). It provides guidance on harmonized requirements and tests for electrical accessories covered by IEC TC 23 and its subcommittees. This edition updates and clarifies scope, several clauses (notably 6.3, Clause 7 and Clause 10) and adds Annex B with suggested temperatures for the Glow-Wire End-Product Test (GWEPT).

Key topics and technical requirements

The report consolidates general rules and recommendations used across accessory-specific standards. Major technical topics include:

- General requirements and standard conditions for operation (ambient temperature, altitude, humidity, magnetic field, orientation).

- Resistance to heat and resistance to abnormal heat and fire, including guidance on the glow-wire flammability test (IEC 60695-2-11) and selection of GWEPT temperatures (Annex B).

- Screws, current-carrying parts and connections - types of screws (thread-forming/cutting), torque guidance, and test criteria for electrical and mechanical connections.

- Insulation and clearances - dimensioning of clearances, creepage distances, solid and functional insulation with reference to the IEC 60664 family.

- Insulating material performance - tracking resistance (IEC 60112), flammability considerations, arc ignition guidance and material selection processes (Annex A).

- Mechanical strength - impact and free-fall guidance for accessory components.

- Resistance to UV, rusting, and durability of markings - tests and relevance for in-service performance.

- Legibility, durability and indelibility of marking, and criteria for tests to be applied in accessory standards.

Practical applications and users

IEC TR 61916 is a practical harmonization guide used by:

- Design engineers and product developers of switches, sockets, connectors and other electrical accessories - to align designs with harmonized general rules.

- Standards writers and technical committees (IEC TC 23) - to ensure accessory-specific standards apply consistent test methods and requirements.

- Test laboratories and certification bodies - to interpret and apply recommended tests (e.g., glow-wire, tracking index) when assessing accessories.

- Regulatory bodies and procurement teams - to reference harmonized criteria for safety, marking and environmental performance.

Using IEC TR 61916 helps reduce duplication across accessory standards, improves comparability between products, and supports safer, more reliable electrical accessories in global markets.

Related standards and references

- IEC 60695-2-11 (glow-wire flammability testing)

- IEC 60112 (tracking index test)

- IEC 60664 series (insulation coordination - clearances and creepage)

- Other accessory-specific IEC standards developed by IEC TC 23

Keywords: IEC TR 61916, electrical accessories, harmonization of general rules, glow-wire, GWEPT, insulation distances, tracking index, IEC TC 23, accessory testing.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC TR 61916:2017 is a technical report published by the International Electrotechnical Commission (IEC). Its full title is "Electrical accessories - Harmonization of general rules". This standard covers: IEC TR 61916:2017(E) provides guidance on requirements and tests for subjects applicable to electrical accessories that are within the scope of IEC TC 23 and its subcommittees. This fourth edition cancels and replaces the third edition published in 2014 and constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) clarification of the introduction and the scope; b) clarification of subclause 6.3; c) modification of Clause 7; d) modification of Clause 10; e) addition of Annex B for temperature selection for GWEPT.

IEC TR 61916:2017(E) provides guidance on requirements and tests for subjects applicable to electrical accessories that are within the scope of IEC TC 23 and its subcommittees. This fourth edition cancels and replaces the third edition published in 2014 and constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) clarification of the introduction and the scope; b) clarification of subclause 6.3; c) modification of Clause 7; d) modification of Clause 10; e) addition of Annex B for temperature selection for GWEPT.

IEC TR 61916:2017 is classified under the following ICS (International Classification for Standards) categories: 01.040.17 - Metrology and measurement. Physical phenomena (Vocabularies); 17.220.01 - Electricity. Magnetism. General aspects; 29.020 - Electrical engineering in general; 29.120.01 - Electrical accessories in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TR 61916:2017 has the following relationships with other standards: It is inter standard links to IEC TR 61916:2014. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC TR 61916:2017 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC TR 61916 ®

Edition 4.0 2017-03

TECHNICAL

REPORT

colour

inside

Electrical accessories – Harmonization of general rules

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 20 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 65 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

IEC TR 61916 ®

Edition 4.0 2017-03

TECHNICAL

REPORT

colour

inside

Electrical accessories – Harmonization of general rules

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 29.120.01 ISBN 978-2-8322-4117-2

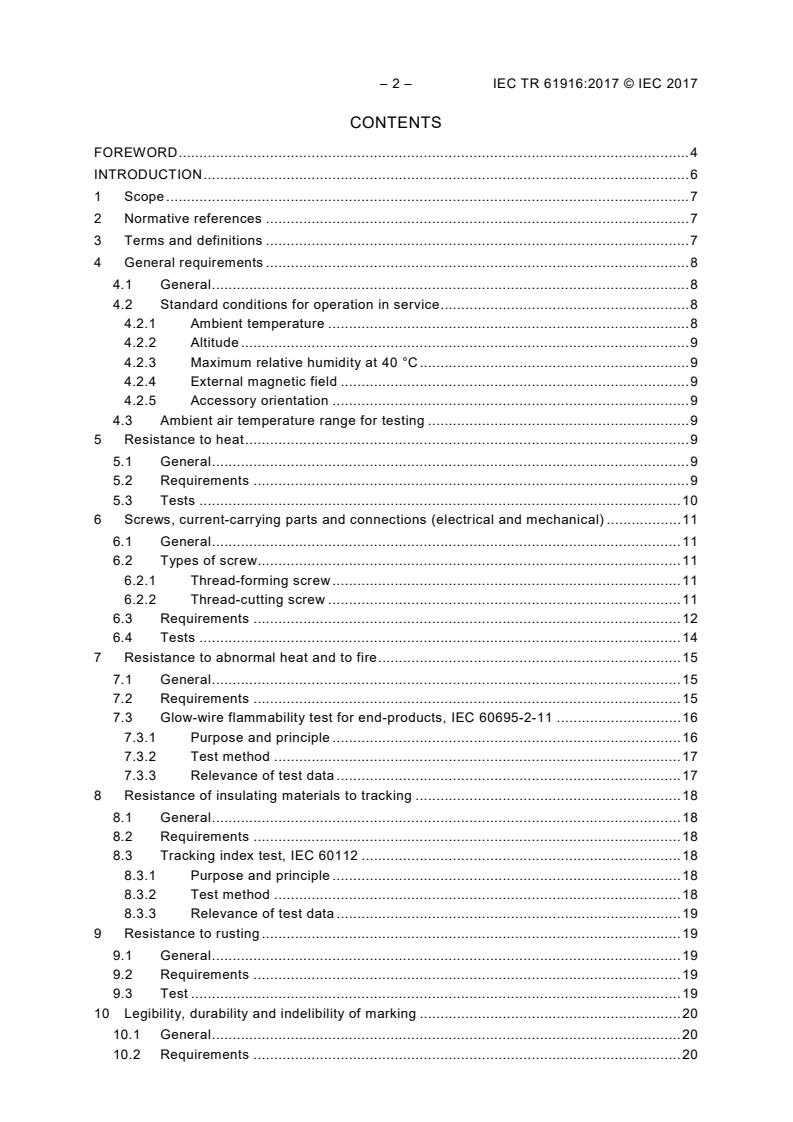

– 2 – IEC TR 61916:2017 © IEC 2017

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 7

4 General requirements . 8

4.1 General . 8

4.2 Standard conditions for operation in service . 8

4.2.1 Ambient temperature . 8

4.2.2 Altitude . 9

4.2.3 Maximum relative humidity at 40 °C . 9

4.2.4 External magnetic field . 9

4.2.5 Accessory orientation . 9

4.3 Ambient air temperature range for testing . 9

5 Resistance to heat . 9

5.1 General . 9

5.2 Requirements . 9

5.3 Tests . 10

6 Screws, current-carrying parts and connections (electrical and mechanical) . 11

6.1 General . 11

6.2 Types of screw . 11

6.2.1 Thread-forming screw . 11

6.2.2 Thread-cutting screw . 11

6.3 Requirements . 12

6.4 Tests . 14

7 Resistance to abnormal heat and to fire . 15

7.1 General . 15

7.2 Requirements . 15

7.3 Glow-wire flammability test for end-products, IEC 60695-2-11 . 16

7.3.1 Purpose and principle . 16

7.3.2 Test method . 17

7.3.3 Relevance of test data . 17

8 Resistance of insulating materials to tracking . 18

8.1 General . 18

8.2 Requirements . 18

8.3 Tracking index test, IEC 60112 . 18

8.3.1 Purpose and principle . 18

8.3.2 Test method . 18

8.3.3 Relevance of test data . 19

9 Resistance to rusting . 19

9.1 General . 19

9.2 Requirements . 19

9.3 Test . 19

10 Legibility, durability and indelibility of marking . 20

10.1 General . 20

10.2 Requirements . 20

10.3 Test . 20

11 Screw-type terminals for connecting conductors . 21

12 Criteria for tests in accessory standards . 21

13 Tolerances . 21

14 Mechanical strength . 22

14.1 Impact. 22

14.2 Free fall . 22

15 Appropriate dimensioning of insulation distances . 22

15.1 General . 22

15.2 General information . 22

15.3 Dimensioning of clearances . 23

15.4 Dimensioning of creepage distances . 23

15.5 Dimensioning of solid insulation . 25

15.6 Dimensioning of functional insulation . 25

15.7 Practical application of the IEC 60664 series with regards to particular

questions . 25

15.8 Other information useful for TC 23 and its subcommittees . 25

16 Resistance to UV . 26

16.1 General . 26

16.2 Basic principles . 27

16.3 Tests . 27

16.3.1 General . 27

16.3.2 UV test . 27

16.3.3 Mechanical test . 28

Annex A (informative) Material selection process . 29

A.1 General . 29

A.2 Requirements for material selection process . 29

A.3 Material selection process. 30

A.3.1 Material selection based on flammability classifications . 30

A.3.2 Arc ignition test . 30

Annex B (informative) Suggested GWEPT temperatures . 32

Bibliography . 33

Figure 1 – Thread-forming screw . 11

Figure 2 – Thread-cutting screw . 12

Figure 3 – Small parts . 17

Figure 4 – Test piston dimensions. 21

Table 1 – Torque per thread diameter . 14

Table A.1 – Minimum glow-wire ignition temperature (GWIT) of insulating materials

required for the flammability classification of the selected material . 30

Table A.2 – Minimum glow-wire ignition temperature (GWIT) of insulating materials

required for the GWFI classification of the selected material . 30

Table A.3 – Minimum number of arcs required for the flammability classification of the

selected material . 30

Table A.4 – Minimum number of arcs required for the GWFI classification of the

selected material . 30

– 4 – IEC TR 61916:2017 © IEC 2017

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTRICAL ACCESSORIES –

HARMONIZATION OF GENERAL RULES

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

The main task of IEC technical committees is to prepare International Standards. However, a

technical committee may propose the publication of a Technical Report when it has collected

data of a different kind from that which is normally published as an International Standard, for

example "state of the art".

IEC TR 61916, which is a Technical Report, has been prepared by IEC technical committee

23: Electrical accessories.

This fourth edition cancels and replaces the third edition published in 2014 and constitutes a

technical revision. This edition includes the following significant technical changes with

respect to the previous edition:

a) clarification of the introduction and the scope;

b) clarification of subclause 6.3;

c) modification of Clause 7;

d) modification of Clause 10;

e) addition of Annex B for temperature selection for GWEPT.

The text of this Technical Report is based on the following documents:

Enquiry draft Report on voting

23/742/DTR 23/766/RVDTR

Full information on the voting for the approval of this Technical Report can be found in the

report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

In this Technical Report, the following print types are used:

• requirements proper: in roman type;

• test specifications: in italic type;

• Explanatory matter: in smaller roman type.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 6 – IEC TR 61916:2017 © IEC 2017

INTRODUCTION

The purpose of this document is to have harmonized rules on the same subjects in all the

standards published by IEC TC 23 and its subcommittees, in order to give coordinated

indications to subcommittees when developing their standards.

These recommendations are meant as a guide. Consequently, subcommittees, according to

their own particularities, can use whole or part of the document, which is not meant to be

compulsory.

In this document, the word “shall” is used only to illustrate how the relevant requirement

should be implemented in a product standard and does not itself imply a product requirement

within this document.

In publishing these recommendations, IEC TC 23 wishes to spread the information so that

other committees of the IEC can use these recommendations, if necessary.

ELECTRICAL ACCESSORIES –

HARMONIZATION OF GENERAL RULES

1 Scope

This document, which is a Technical Report, provides guidance on requirements and tests for

subjects applicable to electrical accessories that are within the scope of IEC TC 23 and its

subcommittees.

2 Normative references

There are no normative references in this document.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

tracking

progressive formation of conductive paths, which are produced on the surface of or within a

solid insulating material, due to the combined effects of electric stress and electrolytic

contamination

[SOURCE: IEC 60050-212:2010, 212-11-56, modified – The note has been deleted.]

3.2

electric erosion

wearing away of insulating material by the action of electric discharges

[SOURCE: IEC 60050-212:2010, 212-11-55]

3.3

comparative tracking index

CTI

numerical value of the maximum voltage in volts at which a material withstands 50 drops

without tracking

Note 1 to entry: The value of each test voltage and the CTI should be divisible by 25.

[SOURCE: IEC 60050-212:2010, 212-11-59, modified – In the definition, the number of drops

is specified and the text "and without a persistent flame occurring under specified test

conditions" has been removed at the end of the definition. Note 1 to entry has been added.]

– 8 – IEC TR 61916:2017 © IEC 2017

3.4

proof tracking index

PTI

numerical value of the proof voltage in volts at which an insulating material withstands 50

drops without tracking

[SOURCE: IEC 60050-212:2010, 212-11-60, modified – In the definition, the number of drops

is specified. As a consequence, the words “can withstand in a specified tracking test without

tracking failure and without a persistent flame occurring” have been deleted.]

3.5

material selection

process of assessing and choosing candidate materials for parts of components or

subassemblies during the design stage of a product

4 General requirements

4.1 General

Before tests, the specimen is stored for at least 24 h in an atmosphere having a temperature

between 15 °C and 35 °C and relative humidity between 45 % and 75 %, except for the test of

Clause 7 where IEC 60112 applies.

Accessories within the scope of TC 23 standards, and those of its subcommittees, shall be

designed and constructed so that, in normal use, their performance is reliable and safe for the

user and the surroundings.

Standard conditions for operation in service for electrical accessories complying with the

existing standards should be suitable for use at ambient temperatures not normally exceeding

40 °C, and whose average over a period of 24 h does not exceed 35 °C, with a lower limit of

the ambient air temperature of −5 °C.

4.2 Standard conditions for operation in service

4.2.1 Ambient temperature

4.2.1.1 General

Unless covered by a temperature classification, accessories within the scope of TC 23

standards, and those of its subcommittees, should be at least capable of operating under the

following standard conditions.

4.2.1.2 Ambient air temperature range in normal use

Electrical accessories complying with the existing standards are suitable for normal use at

ambient temperatures not normally exceeding 40 °C, but their average over a period of 24 h

does not exceed 35 °C, with a lower limit of the ambient air temperature of −5 °C.

NOTE This temperature range corresponds to AA4 of IEC 60364-5-51:2005, Table 51A. Part of the temperature

range of IEC 60721-3-3, class 3K5, with the high air temperature restricted to 40 °C.

Accessories intended to be used in ambient air temperatures outside the above mentioned

conditions permanently or during a long period shall be covered by special requirements or

tests, if necessary, to be decided by each product committee.

4.2.1.3 Ambient air temperature range in cold climate

In areas where electrical accessories are to be used in cold or arctic climate, any tests may

need to be performed in a suitable cold ambient temperature.

Product committees have the responsibility to evaluate if the accessories intended to be used

in ambient air temperatures in cold climate permanently or during a long period shall be

tested in a temperature corresponding to the climate area, for example AA3 or AA2 of

IEC 60364-5-51:2005, Table 51A.

4.2.2 Altitude

Unless otherwise specified, the accessories are intended to be installed at an altitude not

higher than 2 000 m.

4.2.3 Maximum relative humidity at 40 °C

Unless otherwise specified, the maximum relative humidity at the temperature of 40 °C is

50 %.

Higher relative humidity values are admitted at lower temperature (for example 90 % at

20 °C).

4.2.4 External magnetic field

Unless otherwise specified, the external magnetic field is considered not exceeding five times

the Earth’s magnetic field in any direction.

NOTE When an equipment is installed in proximity to a strong magnetic field, supplementary requirements can be

necessary.

4.2.5 Accessory orientation

Unless otherwise specified, the mounting coordinates of the accessories with respect to the

horizontal or vertical are as stated by the manufacturer, with a tolerance of 2° in any direction.

4.3 Ambient air temperature range for testing

Unless otherwise specified, the tests are carried out at an ambient temperature of (20 ± 5) °C.

5 Resistance to heat

5.1 General

This guidance is applicable to the relevant clause(s) of TC 23 standards, and those of its

subcommittees, covering requirements and tests to determine the resistance to heat of

accessories.

These recommendations are in accordance with IEC 60669-1.

The text includes two subclauses.

• Requirements (5.2).

• Tests (5.3).

For editing purposes, the order and the numbers may be altered if necessary.

5.2 Requirements

Accessories including enclosures, if any, shall be sufficiently resistant to heat.

Compliance is checked by the tests of 5.3.

– 10 – IEC TR 61916:2017 © IEC 2017

5.3 Tests

5.3.1 Verification of resistance to heat:

a) for surface mounting boxes, separable covers, separable cover plates and separable

frames, by the test of 5.3.4;

b) for accessories, with the exception of the parts, if any, covered by a), by the tests of 5.3.2,

5.3.3 and, with the exception of the accessories made from natural or synthetic rubber or

a mixture of both, by the test of 5.3.4.

5.3.2 The specimens are kept for 1 h in a heating cabinet at a temperature of

100 °C ± 2 °C.

During the test, they shall not undergo any change impairing their further use, and sealing

compound, if any, shall not flow to such an extent that live parts are exposed.

After the test and after the specimens have been allowed to cool down to approximately room

temperature, there shall be no access to live parts which are normally not accessible when

the specimens are mounted as in normal use, even if probe B of IEC 61032 is applied with a

force not exceeding 5 N.

After the test, markings shall still be legible.

Discoloration, blisters or slight displacement of the sealing compound is disregarded provided

that safety is not impaired within the meaning of the relevant standard.

5.3.3 Parts of insulating material necessary to retain current-carrying parts and parts of the

earthing circuit in position are subjected to a ball-pressure test according to

IEC 60695-10-2:2014, except that the insulating parts necessary to retain the earthing

terminals in a box shall be tested instead to the test as specified in 5.3.4.

A current-carrying part or a part of the earthing circuit retained by a mechanical means is

considered to be retained in position. The use of grease or the like is not considered to be

mechanical means.

In case of doubt, to determine whether an insulating material is necessary to retain current-

carrying parts and parts of the earthing circuit in position, the specimen is examined without

conductors while held in all positions with the insulating material in question removed.

Before the test is started, the ball and the support on which the specimen shall be placed, are

brought to the temperature specified. The part under test shall be placed on a 3 mm thick

steel plate in direct contact with it, so as to be supported to withstand the test force.

When it is not possible to carry out the test on the specimens, the test shall be carried out on

a piece at least 2 mm thick which is cut out of the specimen. If this is not possible, up to and

including four layers, each cut out of the same specimen, may be used, in which case the

total thickness of the layers should be not less than 2,5 mm.

The test load and the supporting means shall be placed within the heating cabinet for a

sufficient time to ensure that they have attained the stabilized testing temperature before the

test commences.

The test is made in a heating cabinet at a temperature of 125 °C ± 2 °C.

+2

After min, the ball is removed from the specimen which is then cooled and treated

according to Clause 7 of IEC 60695-10-2:2014.

The diameter of the impression caused by the ball is measured in accordance with

IEC 60695-10-2:2014 and shall not exceed 2 mm.

5.3.4 Parts of insulating material not necessary to retain current-carrying parts and parts of

the earthing circuit in position, even though they are in contact with them, are subjected to a

ball pressure test in accordance with 5.3.3, but the test is made at a temperature of

70 °C ± 2 °C or 40 °C ± 2 °C plus the highest temperature rise determined for the relevant

part during the test of clause “Temperature rise test”, whichever is the higher.

6 Screws, current-carrying parts and connections (electrical and mechanical)

6.1 General

This guidance is applicable to the relevant clause(s) of TC 23 standards, and those of its

subcommittees, covering the requirements and tests of screws, current-carrying parts and

connections (electrical and mechanical) of accessories.

These recommendations are in accordance with IEC 60669-1.

The text includes three subclauses as follows.

• Definitions (6.2).

• Requirements (6.3).

• Tests (6.4).

For editing purposes, the order and numbers may be altered, if necessary.

6.2 Types of screw

6.2.1 Thread-forming screw

A tapping screw having an uninterrupted thread which by screwing-in forms a thread by

displacing material in the cavity.

An example of a thread-forming screw is shown in Figure 1.

IEC

Figure 1 – Thread-forming screw

6.2.2 Thread-cutting screw

A screw having an interrupted thread which, by screwing-in, makes a thread by removing

material from the cavity.

An example of thread-cutting screw is shown in Figure 2.

– 12 – IEC TR 61916:2017 © IEC 2017

IEC

Figure 2 – Thread-cutting screw

6.3 Requirements

6.3.1 Connections, electrical or mechanical, using screws and nuts, shall withstand the

mechanical stresses occurring in normal use.

Screws and nuts which transmit mechanical contact pressure for electrical continuity and

conductor retention shall be of metal and shall be in engagement with a metal thread.

Screws for connecting external conductors shall be neither thread-cutting screws nor thread-

forming screws.

Screws and nuts which are operated when mounting an accessory during installation, and/or

which are likely to be operated during the life of the accessory, shall be in engagement with a

metal thread or appropriate requirements shall be considered to ensure that they withstand

the mechanical stresses occurring in normal use.

NOTE Screws and nuts which are operated when mounting the accessory include screws for fixing the cover of

cover plates, etc., but not connecting means for screwed conduits and screws for fixing the base of the accessory.

Compliance is checked by inspection and by the test of 6.4.

6.3.2 For screws in engagement with a thread of insulating material and screws of

insulating material, which are used for the installation of the accessory and/or which are likely

to be operated during the life of the accessory, correct introduction of the screw into the screw

hole or nut shall be ensured.

Screws of insulating materials shall not be used in cases when the replacement with metal

screws could impair the insulation of the accessory.

Compliance is checked by inspection and by manual test.

The requirements with regard to correct introduction are met if introduction of the screw in a

slanting manner is prevented, for example by guiding the screw by the part to be fixed, by a

recess in the female thread or by the use of a screw with the leading thread removed.

6.3.3 Screws and rivets intended to be used for electrical connections and screws and

rivets intended to be used for mechanical connection shall be locked against loosening or

turning.

NOTE Spring washers can provide satisfactory locking. For rivets, a non-circular shank or an appropriate notch

can be sufficient. Sealing compound which softens on heating provides satisfactory locking only for screw

connections not subjected to torsion in normal use.

Compliance is checked by inspection and manual test.

6.3.4 Electrical connections shall be so designed that contact pressure is not transmitted

through insulating material other than ceramic, pure mica or other material with characteristics

no less suitable, unless there is sufficient resiliency in the metallic parts to compensate for

any possible shrinkage or yielding of the insulating material.

Compliance is checked by inspection.

NOTE The suitability of the material is considered with regard to the stability of the dimensions.

6.3.5 Current-carrying parts, including those of terminals (also earthing terminals), shall be

of a metal having, under the conditions occurring in the equipment, mechanical strength,

electrical conductivity and resistance to corrosion adequate for their intended use.

Compliance is checked by inspection and, if necessary, by chemical analysis.

Examples of suitable metals, when used within a permissible temperature range and under

normal conditions of chemical pollution, are:

– copper;

– an alloy containing at least 58 % copper for parts that are worked cold or at least 50 %

copper for other parts;

– stainless steel containing at least 13 % chromium and not more than 0,09 % carbon;

– steel provided with an electroplated coating of zinc according to ISO 2081, the coating

having a thickness of at least

• 5 µm (ISO service condition 1) for ordinary equipment,

• 8 µm (ISO service condition 2) for drip-proof and splash-proof equipment,

• 12 µm (ISO service condition 3) for jet-proof and watertight equipment;

– steel provided with an electroplated coating of nickel and chromium according to

ISO 1456, the coating having a thickness of at least

• 10 µm (ISO service condition 1) for ordinary equipment,

• 20 µm (ISO service condition 2) for drip-proof and splash-proof equipment,

• 30 µm (ISO service condition 3) for jet-proof and watertight equipment;

– steel provided with an electroplated coating of tin, according to ISO 2093, the coating

having a thickness equal to at least that specified for

• 12 µm (ISO service condition 1) for ordinary equipment,

• 20 µm (ISO service condition 2) for drip-proof and splash-proof equipment,

• 30 µm(ISO service condition 3) for jet-proof and watertight equipment;

Parts which may be subjected to mechanical wear, shall not be made of steel provided with

an electroplated coating.

– steel provided with an electroplated coating of zinc: only permitted for prime current-

carrying parts if no fixed connection is intended to be made. For connection, an

electroplated coating of zinc is permissible only on parts which do not participate directly

in current transmission, such as screws or washers used for certain types of terminals in

which they transmit only the contact pressure.

This requirement is not intended to apply to contacts, magnetic circuits, heating elements,

bimetallic components, shunts, parts of electronic devices, etc.

NOTE Screws, nuts, washers, clamping plates and similar parts of terminals are not regarded as current-carrying

parts.

Under moist conditions, metals having a great difference of electrochemical potential with

respect to each other shall not be used in contact with each other.

Compliance is checked by inspection.

– 14 – IEC TR 61916:2017 © IEC 2017

6.3.6 Thread-forming screws and thread-cutting screws shall not be used for the

connection of current-carrying parts. Thread-forming screws and thread-cutting screws may

be used to provide earthing continuity, provided that it is not necessary to disturb the

connection in normal use and at least two screws are used for each connection.

Compliance is checked by inspection.

NOTE The use of thread-forming screws without displacement of material which are operated when mounting the

accessory is under consideration.

6.4 Tests

Compliance with the requirements of 6.3.1 is checked by inspection and by the following test.

The screws and nuts are tightened and loosened:

• 10 times for metal screws in engagement with a thread of insulating material and for

screws of insulating material;

• 5 times in all other cases.

Screws or nuts in engagement with a thread of insulating material and screw of insulating

material are completely removed and re-inserted each time.

The test is made by means of a suitable test screwdriver or spanner applying a torque as

shown in Table 1.

The shape of the blade of the test screwdriver shall suit the head of the screw for screws and

nuts which are operated when mounting and connecting up the device by the following test.

The screws and nuts shall be tightened smoothly. In the case of a test on terminals, the

conductor is moved each time the screw or nut is loosened.

Table 1 – Torque per thread diameter

Torque

Nominal diameter of thread

Nm

mm

I II III IV V

Up to and including 2,8 0,2 – 0,4 0,4 –

over 2,8 up to and including 3,0 0,25 – 0,5 0,5 –

over 3,0 up to and including 3,2 0,3 – 0,6 0,6 –

over 3,2 up to and including 3,6 0,4 – 0,8 0,8 –

over 3,6 up to and including 4,1 0,7 1,2 1,2 1,2 1,2

over 4,1 up to and including 4,7 0,8 1,2 1,8 1,8 1,8

over 4,7 up to and including 5,3 0,8 1,4 2,0 2,0 2,0

over 5,3 up to and including 6,0 1,2 1,8 2,5 3,0 3,0

over 6,0 up to and including 8,0 2,5 2,5 3,5 6,0 4,0

over 8,0 up to and including 10,0 – 3,5 4,0 10,0 6,0

over 10,0 up to and including 12,0 – 4,0 – – 8,0

over 12,0 up to and including 15,0 – 5,0 – – 10,0

Column I applies to screws without head if the screw when tightened does not protrude from

the hole, and to other screws which cannot be tightened by means of a screwdriver with a

blade wider than the diameter of the screw.

Column II applies to nuts of mantle terminals which are tightened by means of a screwdriver.

Column III applies to other screws which are tightened by means of a screwdriver.

Column IV applies to screws and nuts other than nuts of mantle terminals which are tightened

by means other than a screwdriver.

Column V applies to nuts of mantle terminals which are tightened by means other than a

screwdriver.

NOTE For mantle screws, the specific nominal diameter is that of the slotted stud.

For screws with a nominal diameter over 5,3 mm and having a head with a slot, the test is

made twice, first applying to the hexagonal head the torque specified in column IV, and then

on another set of specimens applying the torque specified in column III by means of a

screwdriver.

For smaller screws having a hexagonal head with a slot, only the test with the screwdriver is

made.

During the test, the screwed connection shall not work loose and there shall be no damage,

such as breakage of screws or damage to the head slots, threads, washers or stirrups, that

will impair the further use of the accessory.

7 Resistance to abnormal heat and to fire

7.1 General

Clause 7 is applicable to the relevant clause(s) of TC 23 standards, and those of its

subcommittees, covering requirements and tests to determine the resistance to abnormal heat

and to fire of combustible parts of electrotechnical equipment.

Subclauses 7.2 and 7.3 are meant to give to TC 23 and its subcommittees information on how

to use IEC 60695-2-10:2013 and IEC 60695-2-11:2014.

NOTE IEC 60695-2-11:2014, Annex A gives guidance to assist TC 23 and its subcommittees to select the

appropriate glow-wire temperature.

7.2 Requirements

Parts of insulating material of electrotechnical equipment which might be exposed to

excessive thermal stress due to electric effects and the deterioration of which might impair the

safety of the equipment shall not be unduly affected by heat and by fire generated within the

equipment.

For certain accessories (e.g. switches, plugs, or others) the requirements apply to all parts of

the insulating material, whereas for other accessories (e.g. circuit breakers), which have their

insulating material submitted to severe resistance to fire tests, the requirements apply only to

the external parts of the insulating material.

Parts of insulating material or of other solid combustible material which are liable to propagate

flames inside the equipment may be ignited by glowing wires or glowing elements. Under

certain conditions, for example a fault current flowing through a wire, overloading of

components, and bad connections, certain elements may attain a temperature such that they

will ignite parts in their vicinity.

NOTE In some subcommittees, only external parts are taken into account.

Compliance is checked by the glow-wire test according to 7.3.

– 16 – IEC TR 61916:2017 © IEC 2017

7.3 Glow-wire flammability test for end-products, IEC 60695-2-11

7.3.1 Purpose and principle

7.3.1.1 General

The glow-wire is a specified loop of resistance wire, which is electrically heated to a specified

temperature. The test apparatus is described in IEC 60695-2-10.

When selecting test temperatures, product committees should consider Annex B, which gives

suggested glow-wire end-product test (GWEPT) temperatures.

The purpose of IEC 60695-2-11 is to ensure that, under defined conditions, the glow-wire

does not cause ignition of parts, and that a part, if ignited, has a limited duration of burning

without spreading fire by flames or by burning or glowing particles falling from the test

specimen.

The glow-wire end-product test (GWEPT) shall be conducted on a complete end-product

chosen so that the conditions of the test will not be significantly different from those occurring

in normal use.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...