IEC TS 62686-1:2012

(Main)Process management for avionics - Electronic components for aerospace, defence and high performance (ADHP) applications - Part 1: General requirements for high reliability integrated circuits and discrete semiconductors

Process management for avionics - Electronic components for aerospace, defence and high performance (ADHP) applications - Part 1: General requirements for high reliability integrated circuits and discrete semiconductors

IEC 62686-1:2012(E) defines the minimum requirements for general purpose "off the shelf" COTS (commercial off-the-shelf) integrated circuits and discrete semiconductors for ADHP (Aerospace, Defence and High Performance) applications. Applies to all components that can be operated in ADHP applications within the manufacturers' publicly available datasheet limits in conjunction with IEC/TS 62239-1. It may be used by other high performance and high reliability industries, at their discretion.

General Information

- Status

- Published

- Publication Date

- 17-Sep-2012

- Technical Committee

- TC 107 - Process management for avionics

- Drafting Committee

- WG 2 - TC 107/WG 2

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 22-Apr-2015

- Completion Date

- 13-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC TS 62686-1:2012 - Process management for avionics: Part 1 defines minimum requirements for high reliability integrated circuits and discrete semiconductors used in Aerospace, Defence and High Performance (ADHP) applications. The Technical Specification targets general-purpose COTS (commercial off‑the‑shelf) components operated within manufacturers’ published datasheet limits and used in conjunction with IEC/TS 62239-1. It can also be adopted by other high‑reliability industries seeking robust component process controls.

Keywords: IEC TS 62686-1:2012, ADHP, COTS components, high reliability integrated circuits, discrete semiconductors, process management for avionics.

Key Topics and Requirements

IEC TS 62686-1 sets out process, quality and documentation requirements to assure component performance and traceability for ADHP systems. Major technical topics include:

- Scope and applicability: Covers COTS ICs and discrete semiconductors suitable for ADHP use within datasheet limits.

- Product/process change notification (PCN): Procedures and required notification details for notifiable changes.

- Traceability and marking: Date‑code, shipping container, inner packaging and device marking requirements (including age-on-delivery controls).

- Shipment controls: ESD protection, moisture sensitivity level (MSL) handling, lead‑free marking, and packaging reuse rules.

- Electrical and mechanical controls: Electrical testing, parameter assessment, device termination finishes and hermetic seal robustness.

- Qualification and verification: Qualification methodology, test samples, similarity assessment and maintenance of qualification records.

- Quality assurance & audits: Internal audits, subcontract manufacturing oversight, outgoing/incoming quality sampling and failure analysis support.

- Reliability and product monitoring: Operating reliability metrics, failure criteria, product monitor program, accumulated test data and corrective actions.

- Environmental, health & safety (EHS): Device materials and handling, EHS compliance during manufacture and shipping.

- Annex and test references: Test code information and references to test methods (e.g., IEC 62416 and JP001.01 conditions referenced in Annex A).

Practical Applications

IEC TS 62686-1 is practical for organizations that need to manage risk when using commercial semiconductor devices in safety‑ or mission‑critical systems:

- Procurement teams specifying COTS components for avionics and defense platforms

- Component manufacturers implementing ADHP process controls for high‑reliability parts

- Quality, reliability and supply‑chain engineers establishing supplier audits, PCN workflows and traceability systems

- Test labs and qualification engineers performing acceptance and qualification testing

- Program managers requiring documented product monitor and corrective‑action processes

Who Would Use This Standard

- Avionics OEMs and subcontractors

- Defence contractors and integrators

- High‑reliability electronics manufacturers (space, rail, medical sectors where applicable)

- Component suppliers seeking compliance evidence for ADHP customers

Related Standards

- IEC/TS 62239-1 (referenced in scope)

- Test methods referenced in the TS (e.g., IEC 62416 and JP001.01 in Annex A)

IEC TS 62686-1:2012 provides a structured, auditable framework to reduce risk when applying COTS semiconductors in ADHP environments, emphasizing traceability, qualification and ongoing product monitoring.

IEC TS 62686-1:2012 - Process management for avionics - Electronic components for aerospace, defence and high performance (ADHP) applications - Part 1: General requirements for high reliability integrated circuits and discrete semiconductors Released:9/18/2012

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

Sponsored listings

Frequently Asked Questions

IEC TS 62686-1:2012 is a technical specification published by the International Electrotechnical Commission (IEC). Its full title is "Process management for avionics - Electronic components for aerospace, defence and high performance (ADHP) applications - Part 1: General requirements for high reliability integrated circuits and discrete semiconductors". This standard covers: IEC 62686-1:2012(E) defines the minimum requirements for general purpose "off the shelf" COTS (commercial off-the-shelf) integrated circuits and discrete semiconductors for ADHP (Aerospace, Defence and High Performance) applications. Applies to all components that can be operated in ADHP applications within the manufacturers' publicly available datasheet limits in conjunction with IEC/TS 62239-1. It may be used by other high performance and high reliability industries, at their discretion.

IEC 62686-1:2012(E) defines the minimum requirements for general purpose "off the shelf" COTS (commercial off-the-shelf) integrated circuits and discrete semiconductors for ADHP (Aerospace, Defence and High Performance) applications. Applies to all components that can be operated in ADHP applications within the manufacturers' publicly available datasheet limits in conjunction with IEC/TS 62239-1. It may be used by other high performance and high reliability industries, at their discretion.

IEC TS 62686-1:2012 is classified under the following ICS (International Classification for Standards) categories: 03.100.50 - Production. Production management; 31.020 - Electronic components in general; 47.020.60 - Electrical equipment of ships and of marine structures; 49.060 - Aerospace electric equipment and systems. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TS 62686-1:2012 has the following relationships with other standards: It is inter standard links to IEC PAS 62686-1:2011, IEC TS 62686-1:2015. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC TS 62686-1:2012 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC/TS 62686-1 ®

Edition 1.0 2012-09

TECHNICAL

SPECIFICATION

Process management for avionics – Electronic components for aerospace,

defence and high performance (ADHP) applications –

Part 1: General requirements for high reliability integrated circuits and discrete

semiconductors

IEC/TS 62686-1:2012(E)

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Useful links:

IEC publications search - www.iec.ch/searchpub Electropedia - www.electropedia.org

The advanced search enables you to find IEC publications The world's leading online dictionary of electronic and

by a variety of criteria (reference number, text, technical electrical terms containing more than 30 000 terms and

committee,…). definitions in English and French, with equivalent terms in

It also gives information on projects, replaced and additional languages. Also known as the International

withdrawn publications. Electrotechnical Vocabulary (IEV) on-line.

IEC Just Published - webstore.iec.ch/justpublished Customer Service Centre - webstore.iec.ch/csc

Stay up to date on all new IEC publications. Just Published If you wish to give us your feedback on this publication

details all new publications released. Available on-line and or need further assistance, please contact the

also once a month by email. Customer Service Centre: csc@iec.ch.

IEC/TS 62686-1 ®

Edition 1.0 2012-09

TECHNICAL

SPECIFICATION

Process management for avionics – Electronic components for aerospace,

defence and high performance (ADHP) applications –

Part 1: General requirements for high reliability integrated circuits and discrete

semiconductors

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

PRICE CODE

XB

ICS 03.100.50; 31.020; 49.060 ISBN 978-2-83220-345-3

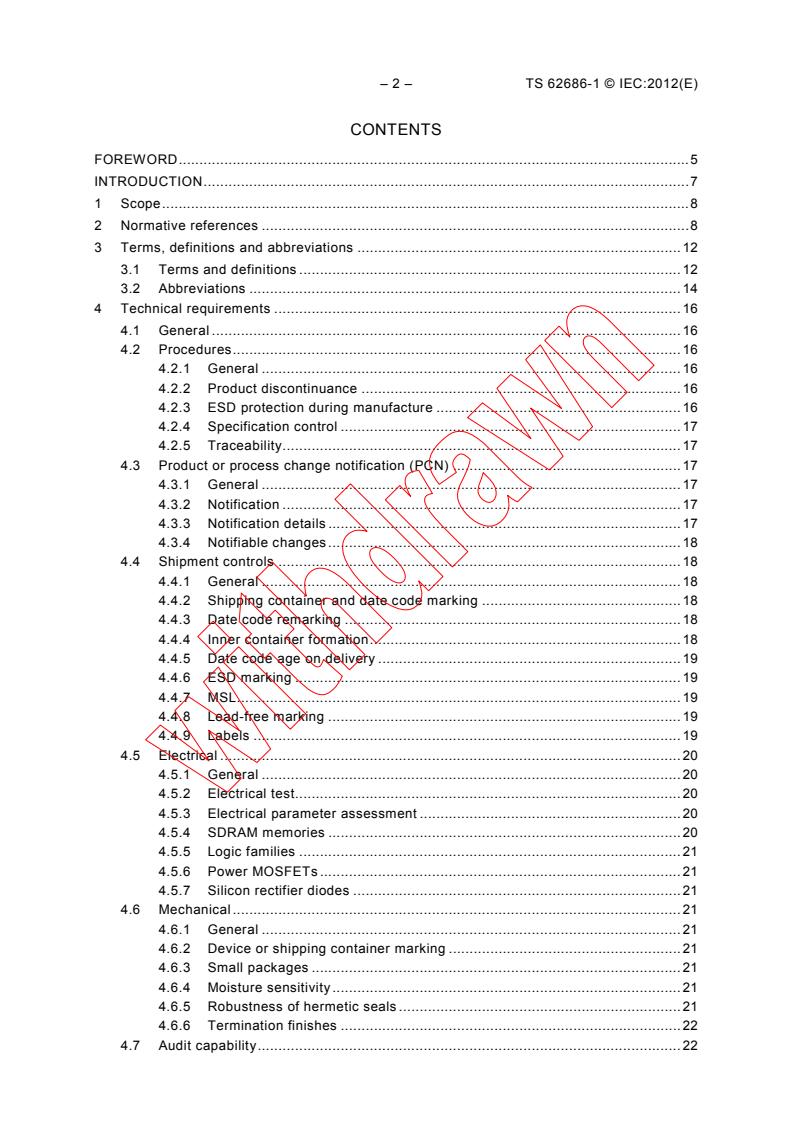

– 2 – TS 62686-1 © IEC:2012(E)

CONTENTS

FOREWORD . 5

INTRODUCTION . 7

1 Scope . 8

2 Normative references . 8

3 Terms, definitions and abbreviations . 12

3.1 Terms and definitions . 12

3.2 Abbreviations . 14

4 Technical requirements . 16

4.1 General . 16

4.2 Procedures . 16

4.2.1 General . 16

4.2.2 Product discontinuance . 16

4.2.3 ESD protection during manufacture . 16

4.2.4 Specification control . 17

4.2.5 Traceability . 17

4.3 Product or process change notification (PCN) . 17

4.3.1 General . 17

4.3.2 Notification . 17

4.3.3 Notification details . 17

4.3.4 Notifiable changes . 18

4.4 Shipment controls . 18

4.4.1 General . 18

4.4.2 Shipping container and date code marking . 18

4.4.3 Date code remarking . 18

4.4.4 Inner container formation . 18

4.4.5 Date code age on delivery . 19

4.4.6 ESD marking . 19

4.4.7 MSL . 19

4.4.8 Lead-free marking . 19

4.4.9 Labels . 19

4.5 Electrical . 20

4.5.1 General . 20

4.5.2 Electrical test. 20

4.5.3 Electrical parameter assessment . 20

4.5.4 SDRAM memories . 20

4.5.5 Logic families . 21

4.5.6 Power MOSFETs . 21

4.5.7 Silicon rectifier diodes . 21

4.6 Mechanical . 21

4.6.1 General . 21

4.6.2 Device or shipping container marking . 21

4.6.3 Small packages . 21

4.6.4 Moisture sensitivity . 21

4.6.5 Robustness of hermetic seals . 21

4.6.6 Termination finishes . 22

4.7 Audit capability . 22

TS 62686-1 © IEC:2012(E) – 3 –

4.7.1 General . 22

4.7.2 Internal quality audits . 22

4.7.3 Subcontract manufacturing . 22

4.8 Quality assurance . 23

4.8.1 General . 23

4.8.2 Quality system . 23

4.8.3 Sampling plans . 23

4.8.4 Failure analysis support . 23

4.8.5 Outgoing quality . 23

4.9 Supplier performance monitoring by the user . 24

4.9.1 General . 24

4.9.2 Lot acceptance . 24

4.9.3 Suspension of deliveries . 25

4.9.4 Loss of approval . 25

4.9.5 AQL figures . 25

4.9.6 100 % screening . 25

4.9.7 Termination determination . 25

4.10 Qualification . 25

4.10.1 General . 25

4.10.2 Methodology . 26

4.10.3 Test samples . 27

4.10.4 Qualification categories . 28

4.10.5 Maintenance of qualification standard . 28

4.10.6 In-process test results . 28

4.10.7 Product monitor results . 32

4.10.8 References . 32

4.10.9 Qualification report . 32

4.10.10 Archiving . 32

4.10.11 Qualification by similarity . 32

4.10.12 Similarity assessment . 32

4.11 Reliability . 33

4.11.1 General . 33

4.11.2 Operating reliability . 33

4.11.3 Failure criteria . 33

4.11.4 Corrective action . 34

4.11.5 Warranty . 34

4.11.6 Suspension of certification . 34

4.11.7 Single event effects (SEE) . 34

4.12 Product monitor . 34

4.12.1 General . 34

4.12.2 Monitor programme . 34

4.12.3 Problem notification . 35

4.12.4 Data reporting . 35

4.12.5 Samples . 35

4.12.6 Production maturity factors . 35

4.12.7 Device dissipation . 35

4.12.8 Corrective action . 36

4.12.9 Product monitor results . 36

4.12.10 Accumulated test data . 36

– 4 – TS 62686-1 © IEC:2012(E)

4.13 Environmental, health and safety (EHS) . 36

4.13.1 General . 36

4.13.2 EHS compliance . 37

4.13.3 Device handling . 37

4.13.4 Device materials . 37

4.14 Shipping container . 37

4.14.1 General . 37

4.14.2 ESD requirements . 37

4.14.3 Magazine reuse . 38

4.14.4 Tubes . 38

4.14.5 Trays . 39

4.15 Compliance with internal standards . 39

Annex A (informative) Test code (TC) information . 40

Annex B (informative) Cross-reference to STACK specification S/0001 revision 14 . 54

Bibliography . 61

Table 1 – Label requirements . 20

Table 2 – Internal quality audit requirements . 22

Table 3 – Outgoing quality . 24

Table 4 – Incoming test. 24

Table 5 – Technology/family qualification and device qualification . 29

Table 6 – Operating life failure rates . 34

Table 7 – Production maturity factors . 35

Table 8 – Product monitor tests . 36

Table A.1 – Conditions of the DC over voltage stress method of JP001.01 or

IEC 62416 test . 42

Table A.2 – Examples of temperature acceleration factors . 44

Table A.3 – Test conditions . 45

Table A.4 – Relationship between write/erase cycle and data retention. 47

TS 62686-1 © IEC:2012(E) – 5 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

PROCESS MANAGEMENT FOR AVIONICS –

ELECTRONIC COMPONENTS FOR AEROSPACE, DEFENCE

AND HIGH PERFORMANCE (ADHP) APPLICATIONS –

Part 1: General requirements for high reliability

integrated circuits and discrete semiconductors

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

The main task of IEC technical committees is to prepare International Standards. However, a

technical committee may propose the publication of a Technical Specification when

• the required support cannot be obtained for the publication of an International Standard,

despite repeated efforts, or

• the subject is still under technical development or where, for any other reason, there is the

future but no immediate possibility of an agreement on an International Standard.

Technical specifications are subject to review within three years of publication to decide

whether they can be transformed into International Standards.

IEC/TS 62686-1 which is a Technical Specification, has been prepared by IEC technical

committee 107: Process management for avionics.

– 6 – TS 62686-1 © IEC:2012(E)

This Technical Specification cancels and replaces IEC/PAS 62686-1. It includes the following

significant technical changes with respect to IEC/PAS 62686-1:

a) adoption and modification of STACK Specification S/0001 revision 14, General

requirements for integrated circuits and discrete semiconductors;

b) addition of alternative IEC semiconductor test methods;

c) update of JEDEC semiconductor test methods;

d) update of Annex A additional JEDEC and IEC test information;

e) certification of the OCM according to ISO 9001;

f) addition of lead-free termination finish requirements;

g) addition of request for OCMs to make the data for device lifetime calculations available;

h) update of the IEC and JEDEC test methods for the following semiconductor wear-out

mechanisms: TDDB, electro-migration, HCL and NBTI;

i) addition of request for OCMs to provide single event effects (SEE) data;

j) update of moisture sensitivity level (MSL) marking requirements.

The text of this Technical Specification is based on the following documents:

Enquiry draft Report on voting

107/167/DTS 107/184/RVC

Full information on the voting for the approval of this technical specification can be found in

the report on voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all the parts in the IEC 62686 series, published under the general title Process

management for avionics – Electronic components for aerospace, defence and high

performance (ADHP) applications, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• transformed into an International standard,

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

TS 62686-1 © IEC:2012(E) – 7 –

INTRODUCTION

This part of IEC 62686 includes all the requirements of STACK Specification S/0001 revision

14 and contains revisions for alternative IEC qualification test methods and additional test

information.

This Technical Specification complements IEC/TS 62564-1 which is used for ADHP

applications when additional manufacturer’s data is required beyond the publicly available

manufacturer published datasheets (e.g. when additional thermal performance data is

required for thermally challenging applications or when additional verification data are needed

for example to comply with the requirements of RTCA DO-254/EUROCAE ED-80 for complex

components for flight critical applications, etc.).

This Technical Specification can also be used to comply with the typical qualification

requirements of IEC/TS 62564-1. Further guidance is given in IEC/TS 62239-1.

NOTE With the adoption of the STACK Specification S/0001 revision 14 it will be possible for all existing STACK

certified manufacturers to be audited by IECQ under the new STACK-IECQ joint venture.

– 8 – TS 62686-1 © IEC:2012(E)

PROCESS MANAGEMENT FOR AVIONICS –

ELECTRONIC COMPONENTS FOR AEROSPACE, DEFENCE

AND HIGH PERFORMANCE (ADHP) APPLICATIONS –

Part 1: General requirements for high reliability

integrated circuits and discrete semiconductors

1 Scope

This part of IEC 62686 defines the minimum requirements for general purpose "off the shelf"

COTS (commercial off-the-shelf) integrated circuits and discrete semiconductors for ADHP

(Aerospace, Defence and High Performance) applications.

This Technical Specification applies to all components that can be operated in ADHP

applications within the manufacturers’ publicly available datasheet limits in conjunction with

IEC/TS 62239-1. It may be used by other high performance and high reliability industries, at

their discretion.

ADHP application requirements may not necessarily be fulfilled by this specification alone.

ADHP OEMs (original equipment manufacturers) may need to consider redesigning their

products or conducting further testing to verify suitability in ADHP applications using their

IEC/TS 62239-1 ECMP procedures. Alternatively a component in accordance with

IEC/TS 62564-1 may be more suitable.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60749-3, Semiconductor devices – Mechanical and climatic test methods – Part 3:

External visual inspection

IEC 60749-4, Semiconductor devices – Mechanical and climatic test methods – Part 4: Damp

heat, steady state, highly accelerated stress test (HAST)

IEC 60749-5, Semiconductor devices – Mechanical and climatic test methods – Part 5:

Steady-state temperature humidity bias life test

IEC 60749-6, Semiconductor devices – Mechanical and climatic test methods – Part 6:

Storage at high temperature

IEC 60749-7, Semiconductor devices – Mechanical and climatic test methods – Part 7:

Internal moisture content measurement and the analysis of other residual gases

IEC 60749-8, Semiconductor devices – Mechanical and climatic test methods – Part 8:

Sealing

IEC 60749-9, Semiconductor devices – Mechanical and climatic test methods – Part 9:

Permanence of marking

TS 62686-1 © IEC:2012(E) – 9 –

IEC 60749-14, Semiconductor devices – Mechanical and climatic test methods – Part 14:

Robustness of terminations (lead integrity)

IEC 60749-15, Semiconductor devices – Mechanical and climatic test methods – Part 15:

Resistance to soldering temperature for through hole mounted devices

IEC 60749-17, Semiconductors devices – Mechanical and climatic tests – Part 17: Neutron

irradiation

IEC 60749-19, Semiconductor devices – Mechanical and climatic test methods – Part 19: Die

shear strength

IEC 60749-20, Semiconductor devices – Mechanical and climatic test methods – Part 20:

Resistance of plastic encapsulated SMDs to the combined effects of moisture and soldering

heat

IEC 60749-20-1, Semiconductor devices – Mechanical and climatic test methods – Part 20-1:

Handling, packing, labelling and shipping of surface-mount devices sensitive to the combined

effect of moisture and soldering heat

IEC 60749-21, Semiconductor devices – Mechanical and climatic test methods – Part 21:

Solderability

IEC 60749-22, Semiconductor devices – Mechanical and climatic test methods – Part 22:

Bond strength

IEC 60749-23, Semiconductor devices – Mechanical and climatic test methods – Part 23: High

temperature operating life

IEC 60749-25, Semiconductor devices – Mechanical and climatic test methods – Part 25:

Temperature cycling

IEC 60749-26, Semiconductor devices – Mechanical and climatic test methods – Part 26:

Electrostatic discharge (ESD) sensitivity testing – Human body model (HBM)

IEC 60749-29, Semiconductor devices – Mechanical and climatic test methods – Part 29:

Latch-up test

IEC 60749-32, Semiconductor devices – Mechanical and climatic test methods – Part 32:

Flammability of plastic-encapsulated devices (externally induced)

IEC 60749-33, Semiconductor devices – Mechanical and climatic test methods – Part 33:

Accelerated moisture resistance – Unbiased autoclave

IEC 60749-34, Semiconductor devices – Mechanical and climatic test methods – Part 34:

Power cycling

IEC 60749-38, Semiconductor devices – Mechanical and climatic test methods – Part 38: Soft

error test method for semiconductor devices with memory

IEC 61340-5-1, Electrostatics – Part 5-1: Protection of electronic devices from electrostatic

phenomena – General requirements

IEC/TS 62239-1, Process management for avionics – Management plan – Part 1: Preparation

and maintenance of an electronic components management plan

– 10 – TS 62686-1 © IEC:2012(E)

IEC 62374, Semiconductor devices – Time dependent dielectric breakdown (TDDB) test for

gate dielectric films

IEC 62374-1, Semiconductor devices – Part 1: Time dependent dielectric breakdown (TDDB)

test for inter-metal layers

IEC 62415, Semiconductor devices – Constant current electromigration test

IEC 62416, Semiconductor devices – Hot carrier test on MOS transistors

IEC 62417, Semiconductor devices – Mobile ion tests for metal-oxide semiconductor field

effect transistors (MOSFETs)

IEC/PAS 62483, Test method for measuring whisker growth on tin and tin alloy finishes

ISO 9001, Quality management systems – Requirements

ISO 14001, Environmental management systems – Requirements with guidance for use

ISO/TS 16949, Quality management systems – Particular requirements for the application of

ISO 9001:2008 for automotive production and relevant service part organizations

AS/EN/JISQ 9100, Aerospace series – Quality management systems – Requirements for

aviation, space and defense organisations

TL 9000, Quality management system

STACK S/0001 revision 14, General requirements for integrated circuits and discrete

semiconductors

EIA-471, Symbol and label for electrostatic sensitive devices

EIA-541, Packaging material standards for ESD sensitive items

ANSI/EIA-556, Outer shipping container label standard

JP001.01, Foundry process qualification guidelines (Wafer fabrication manufacturing sites)

JEP130A, Guidelines for packing and labeling of integrated circuits in unit container packing

JEP119, A procedure for executing SWEAT

JEP154, Guideline for characterizing solder bump electromigration under constant current and

temperature stress

JESD6, Measurement of small values of transistor capacitance

JESD201, Environmental acceptance requirements for tin whisker susceptibility of tin and tin

alloy surface finishes

___________

For the telecommunications industry.

TS 62686-1 © IEC:2012(E) – 11 –

JESD202, Method for characterising the electromigration failure time distribution of

interconnects under constant-current and temperature stress

JESD22-A101, Steady state temperature humidity bias life test

JESD22-A102, Accelerated moisture resistance – Unbiased autoclave

JESD22-A103, High temperature storage life

JESD22-A104, Temperature cycling

JESD22-A108, Temperature bias and operating life

JESD22-A109, Hermeticity

JESD22-A110, Highly accelerated temperature and humidity stress test (HAST)

JESD22-A117, Electrically erasable programmable ROM (EEPROM) program/erase

endurance and data retention test

JESD22-B100, Physical dimension

JESD22-B101, External visual

JESD22-B102, Solderability

JESD22-B105, Lead integrity

JESD22-B106, Resistance to solder shock for through-hole mounted devices

JESD22-B107, Marking permanency

JESD22-B116, Wire bond shear test

JESD46, Customer notification of product/process changes by solid state suppliers.

JESD47, Stress test driven qualification of integrated circuits

JESD48, Product discontinuance

JESD78, IC Latchup test

JESD85, Methods for calculating failure rates in units of FITS

JESD86, Electrical parameters assessment

JESD89, Measurement and reporting of alpha particle and terrestrial cosmic ray-

induced soft errors in semiconductor devices

JESD94, Application specific qualification using knowledge based test methodology

JESD213, Standard test method utilizing X-RAY-Fluorescence (XRF) for analyzing component

finishes and solder alloys to determine Tin (Sn)-Lead (Pb) content

– 12 – TS 62686-1 © IEC:2012(E)

JESD625, Requirements for handling electrostatic discharge sensitive (ESDS) devices

J-STD-020, Moisture/reflow sensitivity classification for non-hermetic solid state surface

mount devices

J-STD-033, Handling, packing, shipping and use of moisture/reflow sensitive surface mount-

devices

J-STD-609A.01, Marking and labeling of components, PCBs and PCBAs to identify lead (Pb),

lead-free (Pb-Free) and other attributes

ANSI/ESDA/JEDEC JS-001, Electrostatic discharge sensitivity testing – Human body model

(HBM) – Component level

MIL-STD-1580, Destructive physical analysis (DPA) for electronic, electromagnetic and

electromechanical parts

UL94, Tests for flammability of plastic materials for parts in devices and appliances

AEC-Q100, Stress test qualification for integrated circuits

AEC-Q101, Stress test qualification for automotive grade discrete semiconductors

RTCA DO-254/EUROCAE ED-80, Design assurance guidance for airborne electronic

hardware

3 Terms, definitions and abbreviations

For the purposes of this document, the following terms, definitions and abbreviations apply.

3.1 Terms and definitions

3.1.1

calendar days

continuous days, including weekends and holidays

3.1.2

container

outer shipping container consisting of one or more inner containers

3.1.3

customer

user

original equipment manufacturer (OEM) who procures integrated circuits and/or

semiconductor devices compliant to this technical specification and uses them to design,

produce, and maintain systems

3.1.4

data sheet

document prepared by the manufacturer that describes the electrical, mechanical, and

environmental characteristics of the component

3.1.5

deviation

user agreement to allow the delivery of a shipping lot which does not fully meet the

requirements of this specification

TS 62686-1 © IEC:2012(E) – 13 –

Note 1 to entry: Considered equivalent to concession for the purposes of this document.

3.1.6

device specification

document written by a user and agreed by the supplier or OCM

3.1.7

form

shape, arrangement of parts, visible aspect, mode in which a part exists or manifests itself,

the material an item is constructed from

3.1.8

fit

qualified and competent, correct size and scale

3.1.9

function

work that an item is designed to do without degrading reliability

3.1.10

incoming lot

one or more shipments of a device, grouped together for the purpose of incoming inspection

3.1.11

inner container

box or bag containing devices, either in magazines or bulk packaged

3.1.12

magazine

shipping container that feeds into automatic placement machines

EXAMPLE Sticks, tubes, matrix trays, tape/reel, etc.

3.1.13

microcircuit

component

device

electrical or electronic device that is not subject to disassembly without destruction or

impairment of design use and is a small circuit having a high equivalent circuit element

density

Note 1 to entry: It is considered as a single part composed of interconnected elements on or within a single

substrate to perform an electronic circuit function.

Note 2 to entry: This excludes printed wiring boards/printed circuit boards, circuit card assemblies and modules

composed exclusively of discrete electronic components.

3.1.14

moisture sensitivity level

MSL

rating indicating a component’s susceptibility to damage due to absorbed moisture when

subjected to reflow soldering

3.1.15

original component manufacturer

OCM

company specifying and manufacturing the electronic component

– 14 – TS 62686-1 © IEC:2012(E)

3.1.16

room temperature

temperature identified at 25 °C ± 5 °C in a room

3.1.17

semiconductor device

electronic devices in which the characteristic distinguishing electronic conduction takes place

with a semiconductor

EXAMPLE 1 Semiconductor diodes which are semiconductor devices having two terminals and exhibiting a

nonlinear voltage-current characteristic.

EXAMPLE 2 Transistors which are active semiconductor devices capable of providing power amplification and

having three or more terminals.

3.1.18

shipping lot

single lot of one or more containers received by a user

3.1.19

supplier

company identified by the logo or name marked on the device typically referred to as the

original component manufacturer (OCM)

3.1.20

termination

element of a component that connects it electrically and mechanically to the next level of

assembly

3.1.21

triboelectric charge

electrical charge generated by frictional movement or separation of two surfaces

3.2 Abbreviations

AC alternating current

ADHP aerospace, defense and high performance

AOQ average out-going quality

AQEC aerospace qualified electronic component

AQL acceptable quality level

ASIC application specific integrated circuit

BGA ball grid array

BPSG borophosphosilicate glass

CB certifying body

CFC chlorofluorocarbon

COTS commercial off–the-shelf

CMOS complementary metal oxide semiconductor

D semiconductor device

DC direct current

DRAM dynamic random access memory

DLA Defense Logistics Agency (see http://www.dscc.dla.mil/)

DPM defects per million

ECMP electronic component management plan

EHS Environmental Health and Safety

TS 62686-1 © IEC:2012(E) – 15 –

EMAS Eco-Management and Audit Scheme (established by the European Union)

ESD electrostatic sensitive damage

FFF form, fit and function

FIT failures in time

h hour

HAST highly accelerated stress test

HCI hot carrier injection

HTOL high temperature operating life

IECQ International Electrotechnical Commission Quality Assessment System for

Electronic Components

IC integrated circuit

I/O input and output

IR infra-red

LTB last time buy

LTPD lot tolerance percent defective

min minute

MSL moisture sensitivity level

NBTI negative bias temperature Instability

NVL non-volatile memory operating life

OCM original component manufacturer

OEM original equipment manufacturer

PC preconditioning

PCB printed circuit board

PCN product or process change notification

Pkg package

QA quality assurance

SDRAM synchronous dynamic random access memory

SEE single event effect

SEFI single event functional interrupt

SEL single event latchup

SEU single event upset

SER soft error rate

SMD surface mount device

SRAM static random access memory

Tamb ambient temperature

TC test code

THB temperature humidity bias

Topmin minimum operating temperature

Topmax maximum operating temperature

UCL upper control limit

VPR vapour

– 16 – TS 62686-1 © IEC:2012(E)

4 Technical requirements

4.1 General

The supplier or original component manufacturer (OCM), as defined in 3.15 and 3.19, shall be

Third Party ISO 9001 certified and shall provide the following minimum technical

requirements. The OCM may use the test methods and methodologies specified herein which

are based on IEC semiconductor test methods or any other equivalent test method for

example JEDEC test methods (see 4.10.2.3 and Annex A). Proposed equivalent test methods,

rationale and supporting data shall be reviewed and shall achieve the same end objectives as

specified herein. Use of such equivalent tests shall not be considered to be deviations or

waivers to the requirements of this specification.

Informative annexes are provided at the end of this specification and their content is subject

to change. Users of this specification are encouraged to review the latest data available

whenever referencing the content of these annexes:

• Annex A: test code information summarises all semiconductor test methods discussed

herein;

• Annex B: cross-reference to STACK specification S/0001 revision 14;

• Annex C: Bibliography.

4.2 Procedures

4.2.1 General

The OCM shall have the following procedures:

• product discontinuance (4.2.2);

• ESD protection during manufacture (4.2.3);

• specification control (4.2.4);

• traceability (4.2.5).

4.2.2 Product discontinuance

Notification shall be in accordance with JESD48 or equivalent with the exception of timing as

described in a) and b) below:

a) the OCM shall provide to the user a minimum of 12 months’ notice of last order dates for

single-source devices and 6 months for multi-sourced devices;

b) the OCM may give less than the specified notice period provided a mutually acceptable

extension (up to the specification limit) is negotiated with any user needing a different

period;

c) for custom ASIC devices, the normal procedure is to include discontinuation notice in the

purchase contract.

4.2.3 ESD protection during manufacture

All integrated circuits and discrete semiconductors are considered to be static sensitive and

shall be protected through the OCM’s manufacturing operation. OCMs shall ensure that

devices are not exposed to static damage and are not degraded or damaged due to static

discharge. IEC 61340-5-1 and JESD625 are examples of suitable standards for ESD

precautions in wafer fabrication and probe. OCMs holding current IECQ Certification for

compliance with IEC 61340-5-1 shall be deemed to have satisfied this requirement.

TS 62686-1 © IEC:2012(E) – 17 –

4.2.4 Specification control

The OCM shall:

a) when applicable, have central or local record of the user’s part number and specification,

against the product to be delivered;

NOTE 1 This applies to direct sales and not to parts sold through distribution.

b) ensure the specifications on the purchase documents have been reviewed and accepted

by personnel authorized to do so.

NOTE 2 This applies to custom and special orders only.

4.2.5 Traceability

Traceability shall be managed as follows:

a) the OCM shall have traceability for any device in a shipping lot through a route code, lot

code or other marking on the device or magazine or inner container to identify the

manufacturing route, e.g. groups of wafer lots, wafer fabrication location, assembly

location, test location, date code and/or lot code;

b) the information needed to interpret the code shall be available;

c) the procedure shall be available for inspection during audit.

4.3 Product or process change notification (PCN)

4.3.1 General

The OCM shall provide th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...