IEC 62951-6:2019

(Main)Semiconductor devices - Flexible and stretchable semiconductor devices - Part 6: Test method for sheet resistance of flexible conducting films

Semiconductor devices - Flexible and stretchable semiconductor devices - Part 6: Test method for sheet resistance of flexible conducting films

IEC 62951-6:2019 specifies terms, as well as the test method and report of sheet resistance of the flexible conducting film under bending and folding tests. The measurement methods include the 2-point probe, 4-point probe and Montgomery method, which can be applied to in-situ and ex-situ measurement and the measurements of anisotropic sheet resistance.

Dispositifs à semiconducteurs - Dispositifs à semiconducteurs souples et extensibles - Partie 6: Méthode d’essai pour la résistance de couche des couches conductrices souples

L’IEC 62951-6:2019 spécifie les termes, ainsi que la méthode et le rapport d’essai de la résistance de couche d’une couche conductrice souple soumise à des essais de courbure et de pliage. Les méthodes de mesurage comprennent la méthode de la sonde 2 points, la méthode de la sonde 4 points et la méthode de Montgomery, qui peuvent être appliquées à un mesurage sur site ou hors site et aux mesurages de résistance de couche anisotrope.

General Information

- Status

- Published

- Publication Date

- 05-May-2019

- Technical Committee

- TC 47 - Semiconductor devices

- Drafting Committee

- WG 6 - TC 47/WG 6

- Current Stage

- PPUB - Publication issued

- Start Date

- 06-May-2019

- Completion Date

- 24-May-2019

Overview

IEC 62951-6:2019 is an international standard published by the International Electrotechnical Commission (IEC) that specifies test methods for measuring the sheet resistance of flexible conducting films used in semiconductor devices. This part of the IEC 62951 series focuses on flexible and stretchable semiconductor devices and provides standardized procedures for evaluating sheet resistance under bending and folding conditions. The standard covers different measurement techniques, including the 2-point probe, 4-point probe, and Montgomery methods, applicable for both in-situ and ex-situ testing. It further addresses measurements of anisotropic sheet resistance, ensuring comprehensive characterization of flexible conducting films.

Key Topics

Scope and Purpose: Standardizes terminology, testing procedures, and result reporting related to sheet resistance of flexible conducting films subjected to mechanical stresses such as bending and folding.

Measurement Methods:

- 2-Point Probe Method: Suitable for in-situ testing; involves applying current and measuring voltage across two probes to calculate sheet resistance.

- 4-Point Probe Method: Provides uniformity measurements with minimized contact resistance influences by using separate pairs of current and voltage probes.

- Montgomery Method: Ideal for evaluating anisotropic sheet resistance, accounting for directional electrical properties in the film.

Test Conditions: Includes conditioning and evaluation under standardized atmospheric conditions and mechanical deformation to simulate real operational stresses.

Data Analysis and Reporting: Specifies how to measure, analyze, and document results ensuring consistent and reproducible testing outcomes.

Correction Factors: The standard details necessary corrections for finite sample sizes, probe tip dimensions, and measurement positions, enhancing accuracy in practical applications.

Applications

IEC 62951-6:2019 is vital for industries developing or utilizing flexible and stretchable semiconductor devices, including:

Flexible Electronics: Validation of conductive films used in bendable displays, wearable devices, and flexible circuits to guarantee performance under mechanical strain.

Medical Devices: Testing of bio-compatible flexible sensors and conductive films for wearable health monitoring systems.

Automotive and Aerospace: Reliable characterization of conductive films in flexible electronics integrated into vehicle interiors and aircraft for enhanced durability.

Research and Development: Providing standardized evaluation methods that support innovation in flexible semiconductor materials and devices.

This standard enables manufacturers, testing laboratories, and researchers to deliver improved product reliability and quality assurance for next-generation flexible semiconductor technologies.

Related Standards

IEC 62951 Series: This part 6 complements other parts of the IEC 62951 series, which cover broader aspects of flexible and stretchable semiconductor devices.

ISO 291:2008: Specifies standard atmospheres for conditioning and testing plastics, referenced for conditioning flexible films before resistance testing.

IEC 60050 Series: Provides definitions and terms related to resistivity and resistance, supporting the terminology used in IEC 62951-6:2019.

Professionals working with flexible conducting films should consult these standards in conjunction with IEC 62951-6:2019 for comprehensive compliance and testing strategies.

Keywords: IEC 62951-6:2019, flexible conducting films, sheet resistance test, 2-point probe method, 4-point probe method, Montgomery method, flexible semiconductor devices, bending tests, anisotropic sheet resistance, flexible electronics standards, semiconductor device testing.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 62951-6:2019 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Semiconductor devices - Flexible and stretchable semiconductor devices - Part 6: Test method for sheet resistance of flexible conducting films". This standard covers: IEC 62951-6:2019 specifies terms, as well as the test method and report of sheet resistance of the flexible conducting film under bending and folding tests. The measurement methods include the 2-point probe, 4-point probe and Montgomery method, which can be applied to in-situ and ex-situ measurement and the measurements of anisotropic sheet resistance.

IEC 62951-6:2019 specifies terms, as well as the test method and report of sheet resistance of the flexible conducting film under bending and folding tests. The measurement methods include the 2-point probe, 4-point probe and Montgomery method, which can be applied to in-situ and ex-situ measurement and the measurements of anisotropic sheet resistance.

IEC 62951-6:2019 is classified under the following ICS (International Classification for Standards) categories: 29.060.20 - Cables; 31.080.99 - Other semiconductor devices. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62951-6:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62951-6 ®

Edition 1.0 2019-05

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Semiconductor devices – Flexible and stretchable semiconductor devices –

Part 6: Test method for sheet resistance of flexible conducting films

Dispositifs à semiconducteurs – Dispositifs à semiconducteurs souples

et extensibles –

Partie 6: Méthode d’essai pour la résistance de couche des couches

conductrices souples

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - Electropedia - www.electropedia.org

webstore.iec.ch/advsearchform Le premier dictionnaire d'électrotechnologie en ligne au

La recherche avancée permet de trouver des publications IEC monde, avec plus de 22 000 articles terminologiques en

en utilisant différents critères (numéro de référence, texte, anglais et en français, ainsi que les termes équivalents dans

comité d’études,…). Elle donne aussi des informations sur les 16 langues additionnelles. Egalement appelé Vocabulaire

projets et les publications remplacées ou retirées. Electrotechnique International (IEV) en ligne.

IEC Just Published - webstore.iec.ch/justpublished Glossaire IEC - std.iec.ch/glossary

Restez informé sur les nouvelles publications IEC. Just 67 000 entrées terminologiques électrotechniques, en anglais

Published détaille les nouvelles publications parues. et en français, extraites des articles Termes et Définitions des

Disponible en ligne et une fois par mois par email. publications IEC parues depuis 2002. Plus certaines entrées

antérieures extraites des publications des CE 37, 77, 86 et

Service Clients - webstore.iec.ch/csc CISPR de l'IEC.

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 62951-6 ®

Edition 1.0 2019-05

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Semiconductor devices – Flexible and stretchable semiconductor devices –

Part 6: Test method for sheet resistance of flexible conducting films

Dispositifs à semiconducteurs – Dispositifs à semiconducteurs souples

et extensibles –

Partie 6: Méthode d’essai pour la résistance de couche des couches

conductrices souples

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 31.080.99 ISBN 978-2-8322-6871-1

– 2 – IEC 62951-6:2019 © IEC 2019

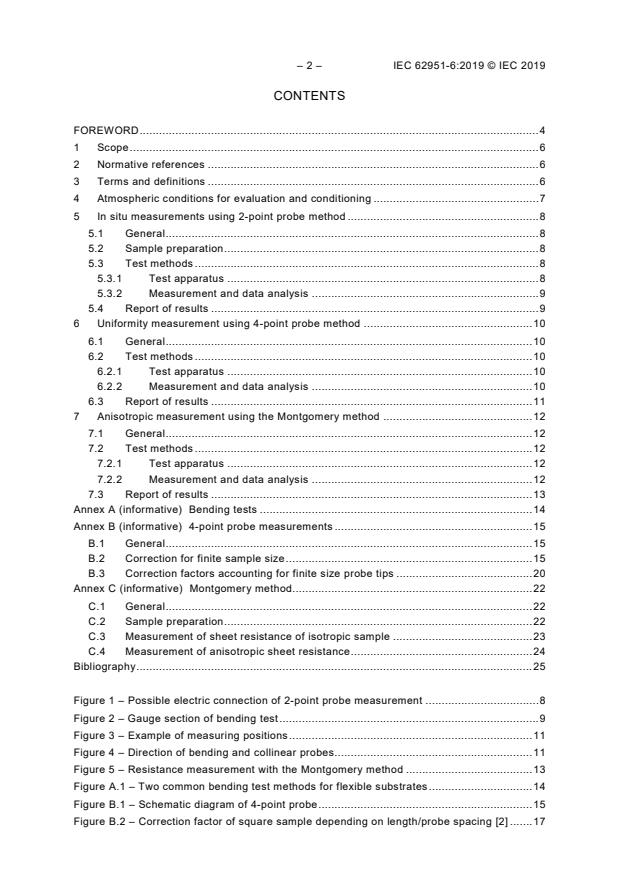

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Atmospheric conditions for evaluation and conditioning . 7

5 In situ measurements using 2-point probe method . 8

5.1 General . 8

5.2 Sample preparation . 8

5.3 Test methods . 8

5.3.1 Test apparatus . 8

5.3.2 Measurement and data analysis . 9

5.4 Report of results . 9

6 Uniformity measurement using 4-point probe method . 10

6.1 General . 10

6.2 Test methods . 10

6.2.1 Test apparatus . 10

6.2.2 Measurement and data analysis . 10

6.3 Report of results . 11

7 Anisotropic measurement using the Montgomery method . 12

7.1 General . 12

7.2 Test methods . 12

7.2.1 Test apparatus . 12

7.2.2 Measurement and data analysis . 12

7.3 Report of results . 13

Annex A (informative) Bending tests . 14

Annex B (informative) 4-point probe measurements . 15

B.1 General . 15

B.2 Correction for finite sample size . 15

B.3 Correction factors accounting for finite size probe tips . 20

Annex C (informative) Montgomery method. 22

C.1 General . 22

C.2 Sample preparation . 22

C.3 Measurement of sheet resistance of isotropic sample . 23

C.4 Measurement of anisotropic sheet resistance . 24

Bibliography . 25

Figure 1 – Possible electric connection of 2-point probe measurement . 8

Figure 2 – Gauge section of bending test . 9

Figure 3 – Example of measuring positions . 11

Figure 4 – Direction of bending and collinear probes . 11

Figure 5 – Resistance measurement with the Montgomery method . 13

Figure A.1 – Two common bending test methods for flexible substrates . 14

Figure B.1 – Schematic diagram of 4-point probe . 15

Figure B.2 – Correction factor of square sample depending on length/probe spacing [2] . 17

Figure B.3 – Correction factor depending on measuring position when collinear probes

are directed vertically . 18

Figure B.4 – Correction factor depending on measuring position when collinear probes

are directed horizontally . 18

Figure B.5 – Correction factor, f depending on measuring positions and direction of

collinear probes . 19

Figure B.6 – Example of probe with a finite contact diameter (e.g. 2mm) comparable to

inter-distance between probes (e.g. 5 mm) . 20

Figure B.7 – Dimensional sketch of probe with a finite contact diameter . 21

Figure C.1 – Possible contact placements of square or rectangular sample . 22

Figure C.2 – Correction factors for finite contact size on resistivity measurement [4] . 23

Figure C.3 – Resistance measurement of Montgomery method . 24

– 4 – IEC 62951-6:2019 © IEC 2019

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

SEMICONDUCTOR DEVICES –

FLEXIBLE AND STRETCHABLE SEMICONDUCTOR DEVICES –

Part 6: Test method for sheet resistance of flexible conducting films

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62951-6 has been prepared by IEC technical committee 47:

Semiconductor devices.

The text of this International Standard is based on the following documents:

FDIS Report on voting

47/2547/FDIS 47/2566/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 62951 series, published under the general title Semiconductor

devices – Flexible and stretchable semiconductor devices, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 6 – IEC 62951-6:2019 © IEC 2019

SEMICONDUCTOR DEVICES –

FLEXIBLE AND STRETCHABLE SEMICONDUCTOR DEVICES –

Part 6: Test method for sheet resistance of flexible conducting films

1 Scope

This part of IEC 62951 specifies terms, as well as the test method and report of sheet

resistance of the flexible conducting film under bending and folding tests. The measurement

methods include the 2-point probe, 4-point probe and Montgomery method, which can be

applied to in-situ and ex-situ measurement and the measurements of anisotropic sheet

resistance.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

ISO 291:2008, Plastics – Standard atmospheres for conditioning and testing

3 Terms and definitions

For the purpose of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

resistivity

inverse of the conductivity when this inverse exists

[SOURCE: IEC 60050-121:1998, 121-12-04]

3.2

R

s

sheet resistance

resistance of thin films that are nominally uniform in thickness, which is the resistivity divided

by the thickness of conducting film

3.3

resistance

for a resistive two-terminal element or two-terminal circuit with terminals A and B, quotient of

the voltage (IEC 60050-131:2008, 131-11-56) u between the terminals by the electric

AB

current i in the element or circuit

𝑢𝑢

𝐴𝐴𝐴𝐴

𝑅𝑅=

𝑖𝑖

where the electric current is taken positive if its direction is from A to B and negative if its

direction is from B to A

Note 1 to entry: A resistance cannot be negative.

Note 2 to entry: The term "resistance" is also a short term for “resistance to alternating current”

(IEC 60050-131:2013, 131-12-45).

Note 3 to entry: In French, the term "résistance" also denotes a device, in English "resistor" (see

IEC 60050-151:2001, 151-13-19).

Note 4 to entry: The coherent SI unit of resistance is ohm, Ω.

[SOURCE: IEC 60050-131:2013, 131-12-04]

3.4

contact resistance

resistance between the surface of a material and the electric contact made to the surface

3.5

radius

distance from the centre of a circle to the circumference

Note 1 to entry: The radius of a sphere is the radius of a great circle.

[SOURCE: IEC 60050-113:2011, 113-01-25]

3.6

radius of curvature

at a point of a curve, radius of the osculating circle

Note 1 to entry: The osculating circle is the circle tangent to a curve at a point that approaches at best the curve

in the vicinity of the point.

[SOURCE: IEC 60050-113:2011, 113-01-30]

3.7

2-point probe method

method for measuring the resistivity of a material, using two electric contacts to the material

Note 1 to entry: The measured value is dependent on the probe resistance.

3.8

4-point probe method

method for measuring the resistivity of a material, using four electric contacts to the material

Note 1 to entry: This avoids many contact resistance problems.

3.9

Montgomery method

technique used to measure the resistivity of two-dimensional sample by placing the electrodes

on its perimeter

4 Atmospheric conditions for evaluation and conditioning

The standard atmosphere for evaluation (test and measurement) and storage of the specimen

shall be a temperature of 23°C ± 2°C and relative humidity of (50 ± 10) %, conforming to

standard atmosphere class 2 specified in ISO 291:2008. If a polymer substrate is used for a

test piece coated with a conductive layer, the standard atmosphere for evaluation shall be a

temperature of 23°C ± 1°C and relative humidity of (50 ± 5) %, conforming to standard

atmosphere class 1 specified in ISO 291:2008.

– 8 – IEC 62951-6:2019 © IEC 2019

If conditioning is necessary, the same standard atmosphere as specified above shall apply.

5 In situ measurements using 2-point probe method

5.1 General

The 2-point probe method for measuring the sheet resistance of a conductive film uses two

electric contacts. It is well known that the measured value includes the error caused by the

probe resistance and the contact resistance. However, other methods (i.e. 4-point probe and

Montgomery method) are not convenient or impossible to use for in-situ measurement during

the bending or folding test. Consequently, the 2-point probe method is often necessary for in-

situ measurements.

5.2 Sample preparation

To minimize the error caused by the probe resistance and the contact resistance, the

following should be satisfied.

• The sample resistance should be 20 times larger than the probe resistance to guarantee

the error within 5 % (e.g. if the sheet resistance is about 50 ohms/square and the probe

resistance is about 5 Ω, the ratio of length to width, L/W can be larger than 2).

• The probe electric contact should be made securely using highly conductive adhesive,

such as silver paste.

• When the width W is comparable or larger than the length L, of the sample, the conducting

bar (using highly conductive adhesive, such as silver paste) should be securely attached

to the sample to minimize the spreading resistance in the width direction. (see Figure 1)

L

L

W W

B

W ≥ L W << L

IEC

Key

W width of the sample

L length of the sample

B conductive bar

Figure 1 – Possible electric connection of 2-point probe measurement

5.3 Test methods

5.3.1 Test apparatus

The appropriate evaluation for flexible electronics is bending the sample to a given radius. For

this, either the collapsing radius test (see IEC 62951-1) or the X–Y–θ test can be used

(refer to Annex A). It is noted that the gauge section (where the bending radius r is observed)

should be measured in the collapsing radius test.

It is noted that the folding test is also similar to the bending test. The difference is the fact

that the permanent deformation occurs in folding due to the relatively small radius of

curvature.

5.3.2 Measurement and data analysis

Acquisition of temporal resistance data requires digital multimeter, whose reading rate should

be 10 times faster than the bending frequency to measure the resistance change during one

cyclic bending. It is noted that the applied current can cause heating of the material, which

can change its resistivity. To avoid this problem, make sure the measured resistance is

constant with time (the average resistance should not drift more than 10 % in a few minutes).

For the 2-point probe method, the sheet resistance, R can be calculated from the measured

s

resistance, R, as shown by Formula (1):

W

RR= (1)

s

L

In addition, the bending radius should be measured by fitting circles to optical images of

curvature (especially when collapsing radius test is used). When the whole area of sample

does not experience the same bending radius (Figure 2), the sheet resistance at the gauge

section can be obtained from the initial resistance, R as shown by Formula (2):

i

LL− W

bend

R R− R

(2)

si

LL

bend

After the bending test, it is recommended to measure the sheet resistance of the sample

using a 4-point probe. The comparison of measurements between the 2-point and 4-point

probe can ascertain the secure electrical connection of the 2-point probe after the bending

test and can further reduce the measurement error by the 2-point probe. For the same reason,

it is also recommended to measure the sheet resistance using a 4-point probe before the

bending test.

L

bend

L

bend

r

r

L

L

IEC

Figure 2 – Gauge section of bending test

5.4 Report of results

The report shall include the following items:

a) specimen identification;

b) date of test;

=

– 10 – IEC 62951-6:2019 © IEC 2019

c) atmospheric conditions of test;

d) bending radius;

e) sample dimension and the actual bending area (gauge section);

f) frequency of bending;

g) temporal sheet resistance curve (or equivalent sheet resistance over bending area);

h) optical observation permanent deformation;

i) (optional) 4-point probe measurement before and after the bending test.

6 Uniformity measurement using 4-point probe method

6.1 General

The 4-point probe method is an electrical measuring technique that uses separate pairs of

current-carrying and voltage-sensing electrodes to make more accurate measurements than

the simpler 2-point probe sensing. Separation of current and voltage electrodes eliminates the

lead and contact resistance from the measurement. 4-point probes can accurately measure a

resistance below 100 Ω, and therefore it is a suitable technique to evaluate the sheet

resistance uniformity of thin films.

6.2 Test methods

6.2.1 Test apparatus

The sheet resistances are measured by pressing collinear 4-point probes against the surface

of the film. A current is applied between the outer two points, while the voltage is measured

across the inner two points.

For the soft conducting film on flexible substrate, the use of the special collinear probe with a

finite contact area equipped with internal springs is recommended. An example of this probe

pin is shown in Figure B.6.

6.2.2 Measurement and data analysis

From the induced current, I and the measured voltage, V, the sheet resistance is calculated

as:

πV V

R f,4 5324 f

(3)

s

ln2 II

Here, f is the correction factor considering the finite size of the sample and the finite size of

the probe contact area and is detailed in Annex B. See Figure B.1 and Figure B.7.

To evaluate the uniformity of the sheet resistance of the conductive film, many measurement

points are required. There is not a preferred map for measuring positions, but it is

recommended that the positions are located 10 % inside from the edge. An example of

measuring positions is shown in Figure 3.

In the case of a long roll of flexible conductive film, it is recommended to acquire the samples

from both ends, but not the extremities of the roll and to evaluate the uniformity.

==

0,2W 0,15W 0,15W 0,15W 0,15W 0,2W

W

IEC

Figure 3 – Example of measuring positions

In the case of a sample after the bending test, anisotropic resistivity may appear. Therefore, it

is recommended that the sheet resistance is measured with the collinear probe placed in both

directions, parallel and perpendicular to the bending direction, as depicted in Figure 4.

IEC

Key

1 direction of collinear probes

2 bending direction

Figure 4 – Direction of bending and collinear probes

6.3 Report of results

The report shall include the following items:

a) specimen identification;

L

0,2W 0,15W 0,15W 0,15W 0,15W 0,2W

– 12 – IEC 62951-6:2019 © IEC 2019

b) date of test;

c) atmospheric conditions of test;

d) sample history;

e) sample dimension and measuring positons;

f) direction of collinear probes;

g) sheet resistance data and its statistical uniformity information;

h) (optional) data of correction factor.

7 Anisotropic measurement using the Montgomery method

7.1 General

The Montgomery method is a technique used to measure the sheet resistance of a sample. Its

advantage lies in its ability to accurately measure the sheet resistance of a sample and to

measure an anisotropic resistivity as well. However, for this method, electrodes should be

placed on the perimeter of the sample, so that it only provides the average value. See

Annex C.

7.2 Test methods

7.2.1 Test apparatus

An electric equipment similar to that used for the 4-point probe method can be used. Since

the current source and voltmeter shall be switched to all terminals of the sample, equipment

with switching matrix to automate measurements is recommended. The electric contacts

should be made on the four corners of the rectangular sample and the size of contact should

be 10 times smaller than the sample dimension to guarantee an error within 1 %.

7.2.2 Measurement and data analysis

To make a measurement, a current should flow along one edge of the sample (for instance,

I and I ) and the voltage across the opposite edge (in this case, V and V , respectively)

12 23 34 41

is measured (refer to Figure 5). From these values, a resistance (for this example, R and

12,34

R ) can be found using Ohm's law:

23,41

V

R =

(4)

12,34

I

V

R =

23,41

I

(5)

These measurements are repeated to improve the accuracy of the resistance values and the

vertical and horizontal resistance can be obtained as follows:

RR+ + RR+

12,34 21,43 34,12 43,21

(6)

R =

vertical

R + R + R + R

23,41 32,14 41,23 14,32

R =

horizontal

(7)

If any of the reversed polarity measurements do not agree, to a sufficient degree of accuracy

(usually within 3 %), with the corresponding standard polarity measurement, then there is

probably a source of error somewhere in the setup, which should be investigated before

continuing. The same principle applies to the reciprocal measurements.

In the case of an anisotropic sample, both the respective sheet resistances for both vertical

and horizontal directions can be calculated as follows:

π L

R = RFsinh πF

( ) (8)

s,vertical horizontal

8 L

sinh πF

L ( )

π

RR= (9)

s,horizontal horizontal

8 LF

where

2

11 RR1

vertical vertical

F≈+ln ln + 4

(10)

2 π R π R

horizontal horizontal

L and L are vertical and horizontal lengths of the sample, respectively.

12 23

V

V 14

A

V

V

I

1 4

1 4

A

I

2 2

IEC IEC

R = V /I R = V /I

12,34 43 12 23,41 41 23

Figure 5 – Resistance measurement with the Montgomery method

7.3 Report of results

The report shall include the following items:

a) specimen identification;

b) date of test;

c) atmospheric conditions of test;

d) sample dimension;

e) directional sheet resistance data;

f) (optional) data of correction factor;

g) (optional) sample history (direction of bending).

– 14 – IEC 62951-6:2019 © IEC 2019

Annex A

(informative)

Bending tests

The appropriate evaluation for flexible electronics is bending the sample to a given radius. For

this, the most common technique is the collapsing radius test detailed in IEC 62951-1

(Figure A.1 (left)). In the collapsing radius test, the sample is subjected to a bending radius r

(shown in Figure A.1 (left)) in the gauge section only, while other areas are subjected to a

bending radius other than r. In the X-Y-θ test (Figure A.1 (right), also mentioned in

IEC 62951-1), the end of the sample is positioned on the coordinates of the circumference, so

that the whole area of the sample is subjected to the same bending radius r. Therefore, the X-

Y-θ test can provide a larger area for the electrical measurement given the same sample size

and it also allows to measure sheet resistance variation depending on the radius of curvature

during the bending test.

(x , y , 0°) (x , y , 0°)

1 1 2 1

2r

(x , y ,θ)

i i

(x , y ,180°)

1 2

Fixed Moving

IEC

Figure A.1 – Two common bending test methods for flexible substrates

Annex B

(informative)

4-point probe measurements

B.1 General

With the probes centered on a very wide (lateral dimension >> s) and very thin

(thickness << s) sample, with s the probe spacing, the sheet resistance is given by:

πV V

R,4 5324

(B.1)

s

ln2 II

where

I is the current between probe A and D;

V is the potential difference measured between probe B and C.

D

C

B

A

–b/2 b/2

y

s

x

A

s

a

y

A

x IEC

Figure B.1 – Schematic diagram of 4-point probe

B.2 Correction for finite sample size

For a sample of finite width, this should be multiplied by a finite size correction factor f:

πV V

R f,4 5324 f (B.2)

s

ln2 II

where

f is the finite width correction factor.

The correction factor f can be expressed by the following formula:

==

==

– 16 – IEC 62951-6:2019 © IEC 2019

∞

y − y

2 bb b

−1 C

B

F(+ cos ξx )cosh ξ y+− cos( ξx )cosh ξ y+ ×cos( ξx )cosh ξ y−

∑ BB C C A A

aaξsinh( bξ ) 2 2 2

m=1

b bb

− cos( ξx )cosh ξ y − − cos( ξx )cosh ξ y −×cos( ξx )cosh ξ y +

BB C C DD

2 22

∞

2 bb b

+ × cosh ηy + − cosh ηy + ×cosh ηy −

BC A

∑

aηsinh( bη ) 2 2 2

n=1

(B.3)

bb b

− cosh ηy −− cosh ηy − ×cosh ηy +

BC D

22 2

∞∞

4 b bb

+ × cos(ξx )cosh ζ y + − cos(ξx )cosh ζ y +×cos(ξx )cosh ζ y −

∑∑ BB CC A A

aζ sinh( bζ ) 2 22

mn11

b b b

− cos ξx cosh ζ y −− cos ξx cosh ζ y − ×cos ξx cosh ζ y +

( ) ( ) ( )

B B C C DD

22 2

where

π

F f,4 532 4 f

(B.4)

ln2

( x ,y ) are the x, y coordinates of probe A (cm);

AA

( x ,y ) are the x, y coordinates of probe B (cm);

BB

( x ,y ) are the x, y coordinates of probe C (cm);

CC

( x ,y ) are the x, y coordinates of probe D (cm);

DD

a, b are the length of the conductive layer;

ξ= mπ / a (m represents an integral number);

η= nπ / t (n represents an integral number, t represents the thickness of the conductive

layer);

12/

ζ ξη+

.

( )

If t << s and collinear probes are oriented parallel to the y axis (i.e. ),

x xx x

A B CD

Formula (B.3) simplifies to:

∞ 2

s 2cos ( ξx ) b b b

− A

F =+ cosh ξ y+ − cosh ξ y+ ×cosh ξ y−

∑ BC A

aaξsinh( bξ ) 2 2 2

m=1

bb b

(B.5)

− cosh ξ y −− cosh ξ y − ×+cosh ξ y

BC D

22 2

∞ ∞∞

2 4cos ξx

−−sη 22sη A −sζ − sζ

+ (e −+e ) (e − e )

∑ ∑∑

aη aζ

n 1 mn11

Representative correction factors are shown hereafter. When a 4-point probe is placed at the

centre of a square sample, the correction factor, f is calculated using Formula (B.6) resulting

in Figure B.2.

Figure B.3 and Figure B.4 show the variation of the correction factor for long samples

depending on measuring positions as well as the orientation of collinear probes.

Figure B.5 shows the variation of correction for rectangular samples.

= = =

===

=

==

= =

=

It is noted that the correction factor is closer to 1 when the collinear probes are oriented

parallel to the short side. However, in this case, it decreases earlier when the measuring

position approaches the edge of samples.

0,95

0,9

0,85

0,8

0,75

0,7

0,65

0,6

0,55

0,5

0 5 10 15 20 25 30 35 40

a/s (length of square sample/probe spacing)

IEC

Figure B.2 – Correction factor of square sample depending on length/probe spacing [2]

f (correction factor)

– 18 – IEC 62951-6:2019 © IEC 2019

a/s = 12

0,95

0,9

a/s = 6

0,85

0,8

a/s = 4

0,75

0,7

0,65

b/s = 60

0,6

–30 –25 –20 –15 –10 –5 0 5 10 15 20 25 30

x/s

IEC

Figure B.3 – Correction factor depending on measuring position when

collinear probes are directed vertically

0,95

a/s = 12

0,9

0,85

a/s = 6

0,8

s

0,75

0,7

a/s = 4

0,65

b/s = 60

0,6

–30 –25 –20 –15 –10 –5 0 5 10 15 20 25 30

x/s

IEC

Figure B.4 – Correction factor depending on measuring position when

collinear probes are directed horizontally

f (correction factor)

f (correction factor)

s

a/s

a/s

Measurement position

Direction of

collinear probes

s

Measurement position

Direction of collinear probes

W/s = 40

W/s = 40

W/s = 20 W/s = 20

0,2W 0,15W 0,15W

0,2W 0,15W 0,15W

W/s = 10

W/s = 10

IEC

Figure B.5 – Correction factor, f depending on measuring positions and

direction of collinear probes

L/s = 30 L/s = 60

L/s = 15

0,2L 0,15L 0,15L

0,2L 0,15L 0,15L 0,2L 0,15L 0,15L

s

L/s = 60

L/s = 30

L/s = 15

– 20 – IEC 62951-6:2019 © IEC 2019

B.3 Correction factors accounting for finite size probe tips

The sharp probe tip often scratches the soft conducting film (e.g. nanoparticle conducting film,

nanowire coated film), which may result in inconsistent measurements of sheet resistance. To

prevent this, a probe with a finite contact area equipped with internal springs is used. An

example of this probe pin for the soft conducting film is shown in Figure B.6. In this case, the

contact diameter is comparable to the inter-distance between probes and the additional

correction factor for sheet resistance is required.

The finite diameter of the probe tips results in under-estimation of the measured sheet

resistance for small electrode pitch, since it leads to an injection of the current over the whole

contact area instead of a point-like injection.

The additional correction factor including the effect of finite contact diameter can be

expressed as follows [2] :

πV V

R ff× 4,532 4 ff×

(B.6)

s probe probe

ln2 II

where

d

11+−d / a

( )

s

f =

;

probe

d

1− A

s

0,77+<0,074log( a / d ) for a / d 1000

A≈

(when s/ d> 2 ).

1 for a / d≥ 1000

2

IEC

Figure B.6 – Example of probe with a finite contact diameter (e.g. 2mm) comparable

to inter-distance between probes (e.g. 5 mm)

___________

Numbers in square brackets refer to the bibliography.

= =

b

a

d

IEC

s

Figure B.7 – Dimensional sketch of probe with a finite contact diameter

– 22 – IEC 62951-6:2019 © IEC 2019

Annex C

(informative)

Montgomery method

C.1 General

The Montgomery method is a technique used to measure the sheet resistance of a sample [3]

Its power lies in its ability to accurately measure the properties of a sample of any arbitrary to

dimensional shape. The electrodes are placed on its perimeter and an anisotropic resistivity

can be measured as well.

C.2 Sample preparation

In order to reduce errors in the calculations, it is preferable that the sample is symmetrical.

The measurements require that four small ohmic contacts be placed on the boundary of the

sample (or as close to it as possible). See Figure C.1.

Here, any errors given by their non-zero size will be of the order D/L, where D is the average

size of the contact and L is the distance between the contacts. As shown in Figure C.2, if D/L

is less than 0,15, the sheet resistance can be measured within the error of 1 %.

Contacts at Contacts at the edges

the corners or inside the perimeter

L

IEC IEC

Acceptable Not recommended

Figure C.1 – Possible contact placements of square or rectangular sample

1,1

Square contact

Theory

Experiment

Triangular contact

1,08

Theory

Experiment

l

1,06

δ

1,04

1,02

0 0,05 0,1 0,15 0,2 0,25

δ/l

IEC

Figure C.2 – Correction factors for finite contact size on resistivity measurement [4]

C.3 Measurement of sheet resistance of isotropic sample

To make a measurement, a current is caused to flow along one edge of the sample (for

instance, I ) and the voltage across the opposite edge (in this case, V ) is measured (refer

12 34

to Figure C.3). From these two values, a resistance (for this example, R ) can be found

12,34

using Ohm's law:

V

RR (C.1)

12,34 vertical

I

V

R R (C.2)

23,41 horizontal

I

The van der Pauw formula showed that the sheet resistance of samples with arbitrary shapes

can be determined from two of these resistances: one measured along a vertical edge, such

as R and a corresponding one measured along a horizontal edge, such as R . The

12,34 23,41

actual sheet resistance, R , is related to these resistances by the van der Pauw formula:

s

exp −πR / R +−exp πR / R =1

( ) ( ) (C.3)

vertical s horizontal s

A further improvement in the accuracy of the resistance values can be obtained by both

reciprocal measurements and switching polarities.

Resistivity correction factor

==

==

– 24 – IEC 62951-6:2019 © IEC 2019

RR+ + RR+

12,34 21,43 34,12 43,21

R =

(C.4)

vertical

R + R + R + R

23,41 32,14 41,23 14,32

R =

(C.5)

horizontal

The sheet resistance, R can be obtained from the above van der Pauw formula, again.

s

V

V 14

A

V

34 V

I

1 4

1 4

A

I

2 2

IEC IEC

R = V /I R = V /I

12,34 43 12 23,41 41 23

Figure C.3 – Resistance measurement of Montgomery method

If any of the reversed polarity measurements do not agree to a sufficient degree of accuracy

(usually within 3 %) with the corresponding standard polarity measurement, then there is

probably a source of error within the setup, which should be investigated before continuing.

The same principle applies to the reciprocal measurements.

C.4 Measurement of anisotropic sheet resistance

In the case of an anisotropic sample, both the respective sheet resistances for both vertical

and horizontal directions can be approximated as follows [5]:

π L

R = RFsinh πF (C.6)

( )

s,vertical horizontal

8 L

sinh πF

π L ( )

RR=

(C.7)

s,horizontal horizontal

8 LF

where

2

11 RR1

vertical vertical

F≈+ln ln + 4

2 π R π R

horizontal horizontal

L and L are the vertical and horizontal lengths of the sample, respectively.

12 23

Bibliography

[1] IEC 62951-1:2017, Semiconductor devices – Fle

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...