IEC 62908-12-10:2017

(Main)Touch and interactive displays - Part 12-10: Measurement methods of touch displays - Touch and electrical performance

Touch and interactive displays - Part 12-10: Measurement methods of touch displays - Touch and electrical performance

IEC 62908-12-10:2017(E) specifies the standard measuring conditions and methods for determining touch performance of a touch sensor module. This document is applicable to touch sensor modules, where the structural relationship between touch sensor, touch controller, touch sensor module, display panel, touch display panel, and touch display module is defined in IEC 62908-1-2.

The contents of the corrigendum of November 2018 have been included in this copy.

General Information

- Status

- Published

- Publication Date

- 07-Jun-2017

- Technical Committee

- TC 110 - Electronic displays

- Drafting Committee

- WG 9 - TC 110/WG 9

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 30-Jan-2023

- Completion Date

- 26-Nov-2021

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

Standard Reference: IEC 62908-12-10:2017

Title: Touch and interactive displays - Part 12-10: Measurement methods of touch displays - Touch and electrical performance (corrigendum Nov 2018 included)

IEC 62908-12-10:2017 specifies standard measuring conditions and methods for determining the touch performance and electrical performance of a touch sensor module. It applies to touch sensor modules whose structural relationship (sensor, controller, module, display panel, touch display panel, touch display module) is defined in IEC 62908-1-2. The standard defines environmental and positioning conditions, test tools, and repeatable procedures for laboratory and production test environments.

Key topics and technical requirements

The standard defines measurement methods and reporting for a comprehensive set of touch and electrical performance metrics, including:

Standard measuring conditions

- Environmental and atmospheric reference conditions

- Standard positioning equipment and a human-operator alternative

- Test bar size, shape and material parameters

Touch performance tests

- Accuracy - position error measurement and reporting

- Repeatability / jitter - short-term position stability

- Linearity - deviation along dragged lines

- Reproducibility - consistency across sessions and velocities

- Signal-to-noise ratio (SNR) - touch signal vs. background noise

- Report rate - reporting frequency under specified conditions

- Latency - time from physical event to reported touch

- Electrical noise immunity - response to external electrical interference

- Water droplet immunity - touch behavior in presence of droplets

- Optical noise immunity - behavior under ambient/LED lighting

- Power consumption - measurement procedures for power draw

- Perpendicular touch / hover distance - detection thresholds for proximity

Electrical performance (Annex A)

- Resistance measurements of sensor structures

- Trans-capacitance measurements and procedures

- Required test samples, measurement equipment (e.g., LCR meters), procedures and reporting formats

The document includes figures, test grids and reporting guidance to ensure reproducible, comparable results.

Applications and who uses it

This standard is essential for stakeholders involved in design, manufacture, integration and validation of touch-enabled displays:

- Display manufacturers and touch sensor vendors - for design verification and specification compliance

- Touch controller and module designers - to validate firmware/hardware performance

- Test laboratories and QA teams - to run repeatable production and acceptance tests

- System integrators and OEMs - to assess touch performance in final products

- Procurement and compliance teams - to specify measurable acceptance criteria

Using IEC 62908-12-10 helps reduce field failures, enable fair vendor comparisons, and support claims about accuracy, latency, robustness to water or electrical noise, and power efficiency.

Related standards

- IEC 62908-1-2 - defines structural relationships of touch sensor modules referenced by this part

- The document is part of the IEC 62908 series on touch and interactive displays.

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

Sponsored listings

Frequently Asked Questions

IEC 62908-12-10:2017 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Touch and interactive displays - Part 12-10: Measurement methods of touch displays - Touch and electrical performance". This standard covers: IEC 62908-12-10:2017(E) specifies the standard measuring conditions and methods for determining touch performance of a touch sensor module. This document is applicable to touch sensor modules, where the structural relationship between touch sensor, touch controller, touch sensor module, display panel, touch display panel, and touch display module is defined in IEC 62908-1-2. The contents of the corrigendum of November 2018 have been included in this copy.

IEC 62908-12-10:2017(E) specifies the standard measuring conditions and methods for determining touch performance of a touch sensor module. This document is applicable to touch sensor modules, where the structural relationship between touch sensor, touch controller, touch sensor module, display panel, touch display panel, and touch display module is defined in IEC 62908-1-2. The contents of the corrigendum of November 2018 have been included in this copy.

IEC 62908-12-10:2017 is classified under the following ICS (International Classification for Standards) categories: 11.040.10 - Anaesthetic, respiratory and reanimation equipment; 31.120 - Electronic display devices. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62908-12-10:2017 has the following relationships with other standards: It is inter standard links to IEC 62908-12-10:2017/COR1:2018, IEC 62908-12-10:2023. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 62908-12-10:2017 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62908-12-10 ®

Edition 1.0 2017-06

INTERNATIONAL

STANDARD

colour

inside

Touch and interactive displays –

Part 12-10: Measurement methods of touch displays – Touch and electrical

performance

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 20 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 65 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

IEC 62908-12-10 ®

Edition 1.0 2017-06

INTERNATIONAL

STANDARD

colour

inside

Touch and interactive displays –

Part 12-10: Measurement methods of touch displays – Touch and electrical

performance

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 31.120 ISBN 978-2-8322-4394-7

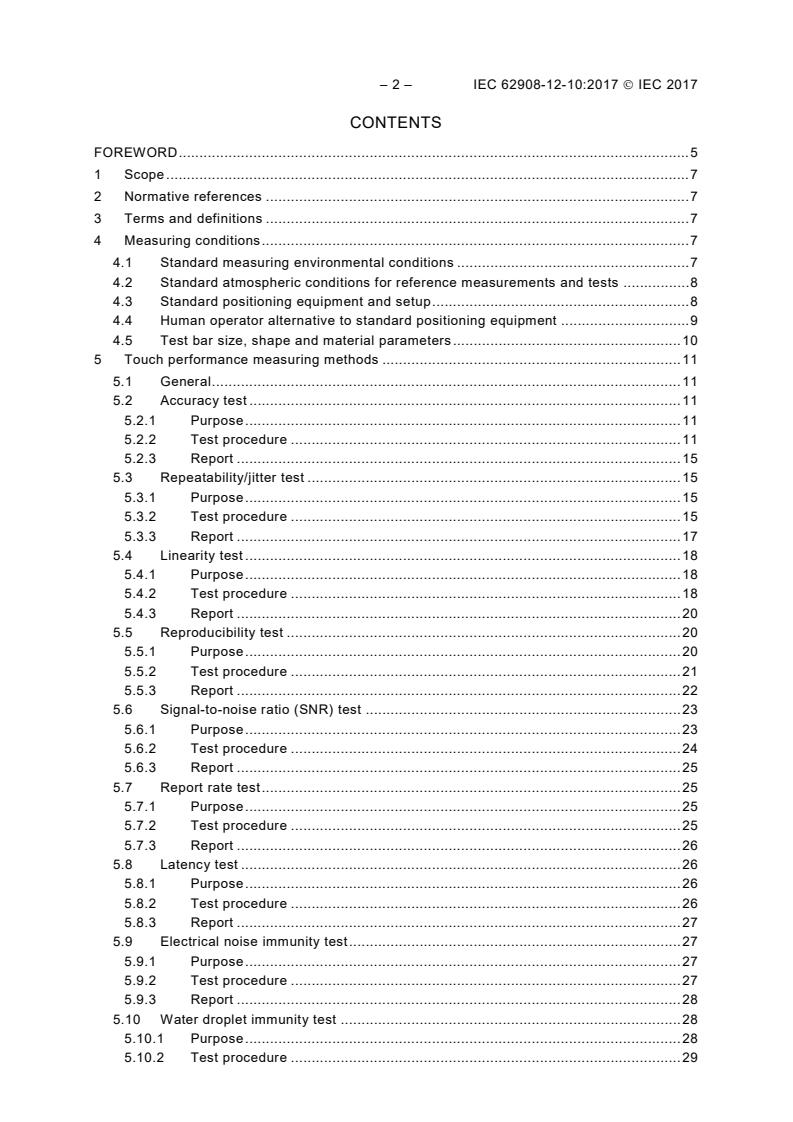

– 2 – IEC 62908-12-10:2017 IEC 2017

CONTENTS

FOREWORD . 5

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 7

4 Measuring conditions . 7

4.1 Standard measuring environmental conditions . 7

4.2 Standard atmospheric conditions for reference measurements and tests . 8

4.3 Standard positioning equipment and setup . 8

4.4 Human operator alternative to standard positioning equipment . 9

4.5 Test bar size, shape and material parameters . 10

5 Touch performance measuring methods . 11

5.1 General . 11

5.2 Accuracy test . 11

5.2.1 Purpose . 11

5.2.2 Test procedure . 11

5.2.3 Report . 15

5.3 Repeatability/jitter test . 15

5.3.1 Purpose . 15

5.3.2 Test procedure . 15

5.3.3 Report . 17

5.4 Linearity test . 18

5.4.1 Purpose . 18

5.4.2 Test procedure . 18

5.4.3 Report . 20

5.5 Reproducibility test . 20

5.5.1 Purpose . 20

5.5.2 Test procedure . 21

5.5.3 Report . 22

5.6 Signal-to-noise ratio (SNR) test . 23

5.6.1 Purpose . 23

5.6.2 Test procedure . 24

5.6.3 Report . 25

5.7 Report rate test . 25

5.7.1 Purpose . 25

5.7.2 Test procedure . 25

5.7.3 Report . 26

5.8 Latency test . 26

5.8.1 Purpose . 26

5.8.2 Test procedure . 26

5.8.3 Report . 27

5.9 Electrical noise immunity test . 27

5.9.1 Purpose . 27

5.9.2 Test procedure . 27

5.9.3 Report . 28

5.10 Water droplet immunity test . 28

5.10.1 Purpose . 28

5.10.2 Test procedure . 29

5.10.3 Report . 29

5.11 Optical noise immunity test . 29

5.11.1 Purpose . 29

5.11.2 Test procedure . 30

5.11.3 Report . 30

5.12 Power consumption test . 30

5.12.1 Purpose . 30

5.12.2 Test procedure . 30

5.12.3 Report . 30

5.13 Perpendicular touch/hover distance test . 30

5.13.1 Purpose . 30

5.13.2 Test procedure . 30

5.13.3 Report . 31

Annex A (informative) Electrical performance measuring methods of touch sensor . 32

A.1 Resistance . 32

A.1.1 General . 32

A.1.2 Test samples . 32

A.1.3 Measurement equipment . 32

A.1.4 Procedures . 32

A.1.5 Data analysis . 33

A.1.6 Report . 33

A.2 Trans-capacitance . 33

A.2.1 General . 33

A.2.2 Test samples . 33

A.2.3 Measurement equipment . 33

A.2.4 Procedure . 33

A.2.5 Data analysis . 34

A.2.6 Report . 34

Figure 1 – Composition of test equipment . 9

Figure 2 – Concept of performance measurement . 9

Figure 3 – Example of manual test tool (left), positioning without triggering a touch

event (middle) and recording a touch event (right) . 10

Figure 4 – Examples of test bars . 10

Figure 5 – Location of edge area and centre area . 12

Figure 6 – Point grid . 12

Figure 7 – Accuracy definition . 13

Figure 8 – Example of measurement result and calculation of accuracy . 15

Figure 9 – Repeatability in touch sensor module . 16

Figure 10 – Example of measurement result for repeatability . 17

Figure 11 – Dragging line for linearity test . 18

Figure 12 – Linearity definition . 19

Figure 13 – Example of measurement and calculation of linearity . 20

Figure 14 – Example of reproducibility test results . 21

Figure 15 – Reproducibility test procedure . 22

Figure 16 – Examples of measurements of reproducibility – Velocity dependence . 23

Figure 17 – SNR definition concept . 24

– 4 – IEC 62908-12-10:2017 IEC 2017

Figure 18 – Dragging direction for reporting time measurement . 25

Figure 19 – Reporting time interval measurement . 26

Figure 20 – Latency measurement . 26

Figure 21 – Example of the effect of external noise . 27

Figure 22 – External noise injection . 28

Figure 23 – Report of external noise immunity . 28

Figure 24 – Example of water drop effect . 29

Figure 25 – Water droplet test procedure . 29

Figure 26 – Perpendicular touch/hover distance measurement . 31

Figure A.1 – Diagrammatic representation of measurement of resistance . 33

Figure A.2 – Diagrammatic representation of measurement of capacitance . 34

Table 1 – Standard conditions for reference measurements and tests . 8

Table A.1 – Specification of LCR impedance meter . 32

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

TOUCH AND INTERACTIVE DISPLAYS –

Part 12-10: Measurement methods of touch displays –

Touch and electrical performance

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62908-12-10 has been prepared by IEC technical committee 110:

Electronic display devices.

The text of this International Standard is based on the following documents:

FDIS Report on voting

110/861/FDIS 110/872/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

– 6 – IEC 62908-12-10:2017 IEC 2017

A list of all parts in the IEC 62908 series, published under the general title Touch and

interactive displays, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

reconfirmed,

withdrawn,

replaced by a revised edition, or

amended.

A bilingual version of this publication may be issued at a later date.

The contents of the corrigendum of Novembre 2018 have been included in this copy.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

TOUCH AND INTERACTIVE DISPLAYS –

Part 12-10: Measurement methods of touch displays –

Touch and electrical performance

1 Scope

This part of IEC 62908 specifies the standard measuring conditions and methods for

determining touch performance of a touch sensor module. This document is applicable to

touch sensor modules, where the structural relationship between touch sensor, touch

controller, touch sensor module, display panel, touch display panel, and touch display module

is defined in IEC 62908-1-2.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60068-1, Environmental testing – Part 1: General and guidance

IEC 62908-1-2 , Touch and interactive displays – Part 1-2: Generic – Terminology and letter

symbols

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60068-1 and

IEC 62908-1-2 apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

4 Measuring conditions

4.1 Standard measuring environmental conditions

Measurements shall be carried out under the standard environmental conditions:

• temperature: 25 °C ± 3 °C,

• relative humidity: 25 % RH to 85 % RH,

• atmospheric pressure: 86 kPa to 106 kPa.

When different environmental conditions are used, they shall be noted in the measurement

report.

___________

Under preparation. Stage at the time of publication: IEC/AFDIS 62908-1-2:2017.

– 8 – IEC 62908-12-10:2017 IEC 2017

4.2 Standard atmospheric conditions for reference measurements and tests

If the parameters to be measured depend on temperature, pressure and humidity and their

dependence on temperature, pressure and humidity is unknown, the atmospheres to be

specified shall be selected from the following values, as shown in Table 1. The selected

values shall be noted in the relevant specifications.

Table 1 – Standard conditions for reference measurements and tests

a a, b a

Temperature Relative humidity Air pressure

°C % RH kPa

45 to 75 86 to 106

20, 25, 30, and 35 ± 3

a

Including extreme values.

b 3

Absolute humidity ≤ 22 g/m .

4.3 Standard positioning equipment and setup

Standard positioning equipment for touch performance shall be the positioning machine

equipped with a test bar, a moving arm, and a stage onto which the touch sensor module is

placed, as shown in Figure 1. The positioning machine shall move its arm and stage to place

the test bar on the touch sensor module.

There are three types of positions associated with a given test: target, actual and reported

positions. The target position is a desired measurement location in physical space referenced

to a fixed datum on the touch sensor module surface. The actual position is the actual

location of contact during test, referenced to the same fixed datum, which may differ from the

target position due to test bar placement error. The reported position is the location reported

by the touch controller.

As shown in Figure 2, the reported positions from the touch controller are analysed to define

performance measures with respect to the target positions.

The touch sensor module and the stage shall be aligned correctly while setting up the

measurement equipment, because a misalignment between them may introduce coordinate

shifts or rotation between the actual touch positions and target positions; each positioning

machine has its inherent accuracy, which means that an actual touched position does not

coincide with its target position. The performance measurements based on target positions

may include errors due to the accuracy of the positioning machine. The touch sensor module

under test shall be attached to the stage and connected to the electrical interface. The test

bar of the selected diameter shall be attached to the moving arm.

Moving arm

Test bar

Touch sensor

module

Stage

Electrical

interface

IEC

Figure 1 – Composition of test equipment

Positioning machine

Moving arm

Target

(Moving)

position

Stage

Test bar

Touch sensor module

Reported

Performance

position

Actual touched

measure calculation

position

Touch sensor

IEC

Figure 2 – Concept of performance measurement

4.4 Human operator alternative to standard positioning equipment

Under certain circumstances, for example if the display under test is too large for suitable

positioning equipment to be available, a suitably designed test arm may be manually

positioned to enable completion of a subset of the tests described in this document. In this

situation, the test arm needs to be designed carefully to minimise the reasonable achievable

error between actual and target positions when conducting measurements. An example of

such a test arm may consist of a rod with a sliding tip (Figure 3, left), whose materials are

chosen so that contact between the rod and the display does not trigger a touch event

(Figure 3, middle), whereas contact between the sliding tip and the display does trigger a

touch event (Figure 3, right). Such a test arm may be placed accurately and reliably by the

human operator with the sliding tip away from the display, subsequent to which a

measurement may be made by sliding the tip into contact with the display.

Touch

controller

– 10 – IEC 62908-12-10:2017 IEC 2017

IEC IEC IEC

Figure 3 – Example of manual test tool (left), positioning without triggering

a touch event (middle) and recording a touch event (right)

4.5 Test bar size, shape and material parameters

The parameters of the test bar shall be size, shape, and material. Examples of suitable sizes

and shapes of the test bar are shown in Figure 4. Care shall be taken to ensure that material

parameters for the test bar are appropriately chosen given the device category under test.

When the touch sensor module is a capacitive touch system, the test bar shall be electrically

conductive and shall additionally be grounded in order to avoid potential performance

degradation due to electrical noise, unless otherwise stated. A test bar may have an

insulating layer on the base to model the effect of a gloved finger.

For reflection-based optical systems, the reflectivity of the contact end of the test bar shall be

chosen to be spectrally representative of human skin.

In all cases, the appropriate properties (including size, shape and material) of the test bar

shall be reported.

Material: Brass

or

Conductive polyamide resin

Physical property

2 4

Electrical resistivity: < 10 to 10 Ω · cm

Hardness: > R119

Half-sphere type

Cylinder type

ø1,6

ø8 ø10

ø4 ø6

IEC

NOTE ø (test bar diameter) = 4 mm, 6 mm, 7 mm, 9 mm, or 12 mm.

Figure 4 – Examples of test bars

5 Touch performance measuring methods

5.1 General

Fundamental touch performance measuring methods are described in this clause. They shall

be taken into account during characterisation of a touch sensor module to realize a good user

experience.

5.2 Accuracy test

5.2.1 Purpose

The purpose of this test is to measure the ability of touch sensors and modules to indicate

how close touch positions are reported relative to their target positions.

5.2.2 Test procedure

5.2.2.1 General

For the accuracy measurement, one of the following two methods can be selected. The first

method is a straightforward method to evaluate the distance between each target point and its

corresponding reported point. The second method is an indirect method where target grid

points are estimated from reported points. This method can tolerate coordinate shifts which

are caused by a misalignment between the touch sensor module and the stage while setting

up the measurement equipment.

5.2.2.2 Method 1

The active area is defined as the area where touch is recognized. The centre area is defined

as the rest of the active area without the edge area as shown in Figure 5. The edge area is

defined as an area with the width of W from the edge of the active area. The origin and axis

direction shall be defined.

The touch sensor module under test shall be attached to the stage and connected to the

electrical interface.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...