IEC 61189-5-601:2021

(Main)Test methods for electrical materials, printed boards and other interconnection structures and assemblies - Part 5-601: General test methods for materials and assemblies - Reflow soldering ability test for solder joint, and reflow heat resistance test for printed boards

Test methods for electrical materials, printed boards and other interconnection structures and assemblies - Part 5-601: General test methods for materials and assemblies - Reflow soldering ability test for solder joint, and reflow heat resistance test for printed boards

IEC 61189-5-601:2021 specifies the reflow soldering ability test method for components mounted on organic rigid printed boards, the reflow heat resistance test method for organic rigid printed boards, and the reflow soldering ability test method for the lands of organic rigid printed boards in applications using solder alloys, which are eutectic or near-eutectic tin-lead (Pb), or lead-free alloys.

The printed boards materials for this organic rigid printed boards are epoxide woven E-glass laminated sheets that are specified in IEC 61249-2 (all parts).

The objective of this document is to ensure the soldering ability of the solder joint and of the lands of the printed boards. In addition, test methods are provided to ensure that the printed boards can resist the heat load to which they are exposed during soldering.

Méthodes d’essai pour les matériaux électriques, les cartes imprimées et autres structures d’interconnexion et ensembles - Partie 5-601: Méthodes d’essai générales pour les matériaux et les assemblages - Essai d’aptitude au brasage par refusion pour un joint brasé, et essai de résistance à la chaleur de refusion pour les cartes imprimées

L'IEC 61189-5-601:2021 spécifie la méthode d’essai d’aptitude au brasage par refusion pour les composants montés sur les cartes imprimées rigides organiques, la méthode d’essai de résistance à la chaleur de refusion pour les cartes imprimées rigides organiques, et la méthode d’essai d’aptitude au brasage par refusion pour les pastilles de cartes imprimées rigides organiques dans les applications utilisant des alliages de brasure, qui sont des alliages étain-plomb (Pb) eutectiques ou quasi eutectiques, ou des alliages sans plomb.

Les matériaux de ces cartes imprimées rigides organiques sont des feuilles stratifiées renforcées en tissu de verre de type E époxyde, spécifiées dans l'IEC 61249-2 (toutes les parties).

Le but du présent document est de garantir l’aptitude au brasage du joint brasé et des pastilles des cartes imprimées. De plus, des méthodes d’essai sont présentées afin d’assurer que les cartes imprimées peuvent résister à la charge de chaleur à laquelle elles sont exposées durant le brasage.

General Information

- Status

- Published

- Publication Date

- 02-Feb-2021

- Technical Committee

- TC 91 - Electronics assembly technology

- Drafting Committee

- WG 3 - TC 91/WG 3

- Current Stage

- PPUB - Publication issued

- Start Date

- 03-Feb-2021

- Completion Date

- 17-Feb-2021

Overview

IEC 61189-5-601:2021 is an international standard developed by the International Electrotechnical Commission (IEC) that specifies test methods related to reflow soldering ability and heat resistance for electrical materials, especially organic rigid printed boards and solder joints. It focuses on ensuring the reliability and quality of solder joints and printed boards subjected to reflow soldering processes using eutectic or near-eutectic tin-lead (Pb) or lead-free solder alloys.

This standard covers materials such as epoxide woven E-glass laminated sheets, following IEC 61249-2 series. It is essential for manufacturers and quality controllers in the electronics industry to verify that printed circuit boards (PCBs) and components can withstand thermal stresses during soldering without degradation or failure.

Key Topics

Reflow Soldering Ability Test

Evaluates the ability of solder joints and PCB lands to form reliable, defect-free connections during reflow soldering processes.Reflow Heat Resistance Test for Printed Boards

Measures the durability of organic rigid PCBs when exposed to reflow heat cycles to prevent issues such as warpage, delamination, or loss of mechanical properties.Solder Joint Quality Assessment

Includes initial quality checks, pre-conditioning, assembly processes like solder paste printing and device mounting, and final testing.Warpage Measurement

Determines the physical deformation (warping) of components and PCBs during reflow heating to ensure dimensional stability.Wetting and Dewetting Tests on PCB Lands

Examines solder wetting properties to spot potential issues such as non-wetting areas or dewetting, which can compromise electrical connections.Resistance to Dissolution

Assesses the PCB lands’ resilience against solder material dissolution, maintaining robust solder joint integrity over time.Pull Strength Testing

Measures mechanical strength of solder joints and land attachments using various methodologies to guarantee assembly robustness under mechanical stress.

Applications

IEC 61189-5-601:2021 provides practical test methods critical for:

Printed Circuit Board Manufacturers

To validate materials and board designs can endure soldering heat loads, preventing production failures.Electronics Assembly Facilities

To implement quality control tests during assembly processes ensuring reliable device mounting and solder joint formation.Solder Paste and Alloy Suppliers

To verify compatibility and performance of solder materials with organic rigid PCB substrates.Quality Assurance and Reliability Engineering

To establish baseline measurements and monitor solder joint integrity and board heat resistance throughout product life cycles.Research & Development

Enabling design improvements through thorough characterization of material responses to reflow soldering.

Related Standards

IEC 61249-2 Series

Defines material specifications for epoxide woven E-glass laminated sheets used in printed boards.IPC Standards (e.g., IPC-A-610)

Addresses acceptability criteria for electronic assemblies including solder joints.JEDEC Standards for Thermal Testing

Compliment soldering thermal assessments in semiconductor and PCB assembly industries.ISO 9001 / IATF 16949

Quality management systems standards integrating IEC test methods into production process controls.

This standard is vital for ensuring the quality, reliability, and performance of electrical interconnection structures undergoing reflow soldering. Adhering to IEC 61189-5-601:2021 helps minimize soldering defects, enhances thermal durability of PCBs, and supports high-quality electronics manufacturing. For up-to-date technical details and purchasing information, consult authorized IEC distributors.

IEC 61189-5-601:2021 - Test methods for electrical materials, printed boards and other interconnection structures and assemblies - Part 5-601: General test methods for materials and assemblies - Reflow soldering ability test for solder joint, and reflow heat resistance test for printed boards

Get Certified

Connect with accredited certification bodies for this standard

TL 9000 QuEST Forum

Telecommunications quality management system.

ANCE

Mexican certification and testing association.

Intertek Slovenia

Intertek testing, inspection, and certification services in Slovenia.

Sponsored listings

Frequently Asked Questions

IEC 61189-5-601:2021 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Test methods for electrical materials, printed boards and other interconnection structures and assemblies - Part 5-601: General test methods for materials and assemblies - Reflow soldering ability test for solder joint, and reflow heat resistance test for printed boards". This standard covers: IEC 61189-5-601:2021 specifies the reflow soldering ability test method for components mounted on organic rigid printed boards, the reflow heat resistance test method for organic rigid printed boards, and the reflow soldering ability test method for the lands of organic rigid printed boards in applications using solder alloys, which are eutectic or near-eutectic tin-lead (Pb), or lead-free alloys. The printed boards materials for this organic rigid printed boards are epoxide woven E-glass laminated sheets that are specified in IEC 61249-2 (all parts). The objective of this document is to ensure the soldering ability of the solder joint and of the lands of the printed boards. In addition, test methods are provided to ensure that the printed boards can resist the heat load to which they are exposed during soldering.

IEC 61189-5-601:2021 specifies the reflow soldering ability test method for components mounted on organic rigid printed boards, the reflow heat resistance test method for organic rigid printed boards, and the reflow soldering ability test method for the lands of organic rigid printed boards in applications using solder alloys, which are eutectic or near-eutectic tin-lead (Pb), or lead-free alloys. The printed boards materials for this organic rigid printed boards are epoxide woven E-glass laminated sheets that are specified in IEC 61249-2 (all parts). The objective of this document is to ensure the soldering ability of the solder joint and of the lands of the printed boards. In addition, test methods are provided to ensure that the printed boards can resist the heat load to which they are exposed during soldering.

IEC 61189-5-601:2021 is classified under the following ICS (International Classification for Standards) categories: 31.180 - Printed circuits and boards; 33.200 - Telecontrol. Telemetering. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61189-5-601:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61189-5-601 ®

Edition 1.0 2021-02

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Test methods for electrical materials, printed boards and other interconnection

structures and assemblies –

Part 5-601: General test methods for materials and assemblies – Reflow

soldering ability test for solder joint, and reflow heat resistance test for printed

boards

Méthodes d’essai pour les matériaux électriques, les cartes imprimées et autres

structures d’interconnexion et ensembles –

Partie 5-601: Méthodes d’essai générales pour les matériaux et

les assemblages – Essai d’aptitude au brasage par refusion pour un joint brasé,

et essai de résistance à la chaleur de refusion pour les cartes imprimées

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC online collection - oc.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always

committee, …). It also gives information on projects, replaced have access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 000 terminological entries in English

details all new publications released. Available online and

and French, with equivalent terms in 18 additional languages.

once a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - IEC online collection - oc.iec.ch

webstore.iec.ch/advsearchform Découvrez notre puissant moteur de recherche et consultez

La recherche avancée permet de trouver des publications IEC gratuitement tous les aperçus des publications. Avec un

en utilisant différents critères (numéro de référence, texte, abonnement, vous aurez toujours accès à un contenu à jour

comité d’études, …). Elle donne aussi des informations sur adapté à vos besoins.

les projets et les publications remplacées ou retirées.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

Le premier dictionnaire d'électrotechnologie en ligne au

Restez informé sur les nouvelles publications IEC. Just

monde, avec plus de 22 000 articles terminologiques en

Published détaille les nouvelles publications parues.

anglais et en français, ainsi que les termes équivalents dans

Disponible en ligne et une fois par mois par email.

16 langues additionnelles. Egalement appelé Vocabulaire

Electrotechnique International (IEV) en ligne.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 61189-5-601 ®

Edition 1.0 2021-02

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Test methods for electrical materials, printed boards and other interconnection

structures and assemblies –

Part 5-601: General test methods for materials and assemblies – Reflow

soldering ability test for solder joint, and reflow heat resistance test for printed

boards

Méthodes d’essai pour les matériaux électriques, les cartes imprimées et autres

structures d’interconnexion et ensembles –

Partie 5-601: Méthodes d’essai générales pour les matériaux et

les assemblages – Essai d’aptitude au brasage par refusion pour un joint brasé,

et essai de résistance à la chaleur de refusion pour les cartes imprimées

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 31.180 ISBN 978-2-8322-9293-8

– 2 – IEC 61189-5-601:2021 © IEC 2021

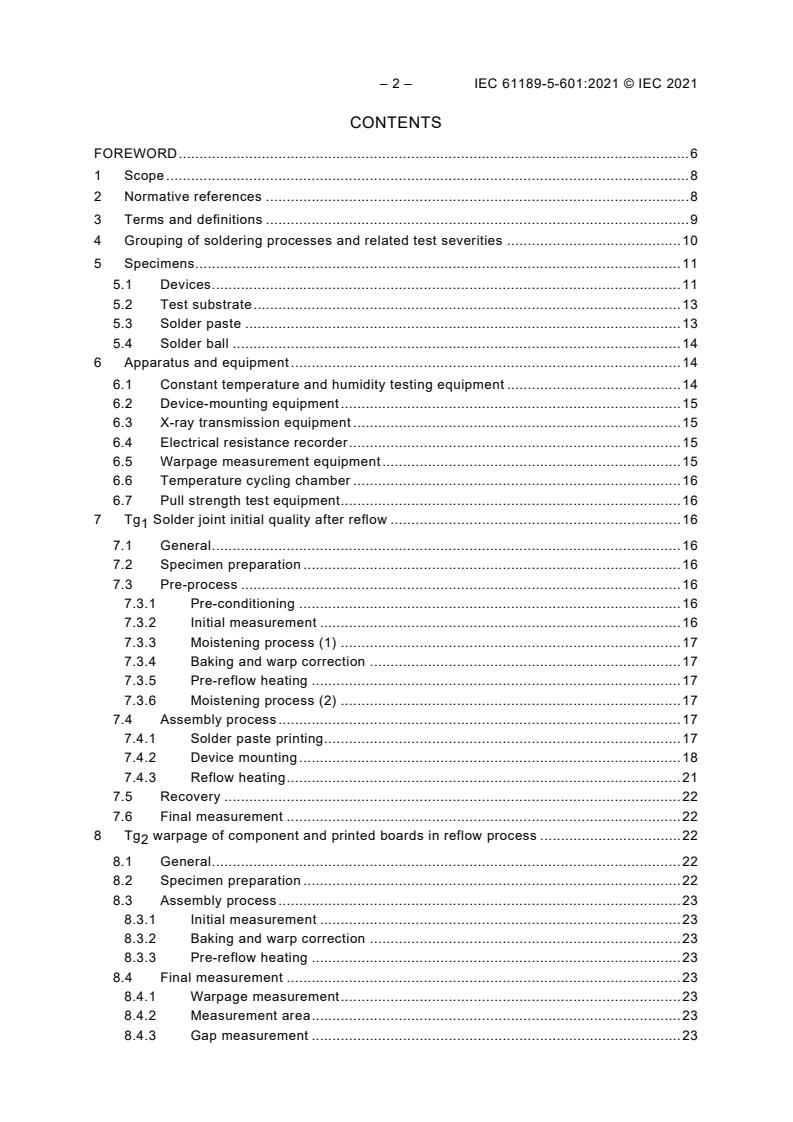

CONTENTS

FOREWORD . 6

1 Scope . 8

2 Normative references . 8

3 Terms and definitions . 9

4 Grouping of soldering processes and related test severities . 10

5 Specimens . 11

5.1 Devices . 11

5.2 Test substrate . 13

5.3 Solder paste . 13

5.4 Solder ball . 14

6 Apparatus and equipment . 14

6.1 Constant temperature and humidity testing equipment . 14

6.2 Device-mounting equipment . 15

6.3 X-ray transmission equipment . 15

6.4 Electrical resistance recorder . 15

6.5 Warpage measurement equipment . 15

6.6 Temperature cycling chamber . 16

6.7 Pull strength test equipment . 16

7 Tg Solder joint initial quality after reflow . 16

7.1 General . 16

7.2 Specimen preparation . 16

7.3 Pre-process . 16

7.3.1 Pre-conditioning . 16

7.3.2 Initial measurement . 16

7.3.3 Moistening process (1) . 17

7.3.4 Baking and warp correction . 17

7.3.5 Pre-reflow heating . 17

7.3.6 Moistening process (2) . 17

7.4 Assembly process . 17

7.4.1 Solder paste printing . 17

7.4.2 Device mounting . 18

7.4.3 Reflow heating . 21

7.5 Recovery . 22

7.6 Final measurement . 22

8 Tg warpage of component and printed boards in reflow process . 22

8.1 General . 22

8.2 Specimen preparation . 22

8.3 Assembly process . 23

8.3.1 Initial measurement . 23

8.3.2 Baking and warp correction . 23

8.3.3 Pre-reflow heating . 23

8.4 Final measurement . 23

8.4.1 Warpage measurement . 23

8.4.2 Measurement area . 23

8.4.3 Gap measurement . 23

9 Tg Resistance to soldering heat of printed boards . 25

9.1 General . 25

9.2 Specimen preparation . 26

9.3 Pre-process . 26

9.3.1 Pre-conditioning . 26

9.3.2 Initial measurement . 26

9.3.3 Moistening process (1) . 26

9.3.4 Baking and warp correction . 26

9.4 Reflow heating . 26

9.5 Final measurement . 27

10 Tg Wetting and dewetting of a printed-board land . 27

10.1 General . 27

10.2 Specimen preparation . 27

10.3 Pre-process . 27

10.3.1 Pre-conditioning . 27

10.3.2 Initial measurement . 28

10.3.3 Moistening process (1) . 28

10.3.4 Pre-baking . 28

10.3.5 Pre-reflow heating . 28

10.3.6 Moistening process (2) . 28

10.4 Assembly process . 28

10.4.1 Solder paste printing . 28

10.4.2 Reflow heating . 28

10.5 Final measurement . 29

10.5.1 Measurement . 29

10.5.2 Flux removal . 30

11 Tg Resistance to dissolution of a printed-board land . 30

11.1 General . 30

11.2 Specimen preparation . 31

11.3 Pre-process . 31

11.3.1 Pre-conditioning . 31

11.3.2 Initial measurement . 31

11.4 Assembly process . 31

11.4.1 Solder paste printing . 31

11.4.2 Reflow heating . 31

11.5 Final measurement . 31

11.5.1 Observation . 31

11.5.2 Observation method . 32

11.5.3 Measurement . 32

11.5.4 Example of influence upon occurrence of dissolution . 33

12 Tg Pull strength of the test substrate land . 33

12.1 General . 33

12.2 Specimen preparation . 34

12.3 Pre-process . 34

12.3.1 Pre-conditioning . 34

12.3.2 Initial measurement . 34

12.3.3 Pre-baking . 34

12.3.4 Pre-reflow heating . 34

– 4 – IEC 61189-5-601:2021 © IEC 2021

12.4 Assembly process . 34

12.4.1 Solder paste printing . 34

12.4.2 Solder ball placement . 34

12.4.3 Reflow heating process . 35

12.5 Final measurement . 35

12.5.1 Pull strength measurement . 35

12.5.2 Pull strength measuring method A – Probe heat bond method . 35

12.5.3 Pull strength measuring method B – Ball pinch method . 35

12.5.4 Pull strength measuring method C – Pin pull down method . 36

12.5.5 Pull strength measuring method D – Lead pull method . 36

12.5.6 Final observation . 36

Annex A (informative) Test process items and meaning of processing contents and

condition . 38

A.1 General . 38

A.2 Meaning of processing contents and condition . 38

A.3 Test process items . 38

Bibliography . 40

Figure 1 – Example of a test circuit for the electrical continuity test of a solder joint . 12

Figure 2 – Example of area array type packages . 12

Figure 3 – Example of leaded type devices . 12

Figure 4 – Example of leadless termination type devices . 12

Figure 5 – Example of connector for card type devices . 13

Figure 6 – Example of shielding metal components . 13

Figure 7 – Recommended solder ball shape. 14

Figure 8 – Test procedure for Tg . 16

Figure 9 – Example of printed conditions of solder paste . 18

Figure 10 – Typical reflow soldering profile for Sn63Pb37 solder alloy . 18

Figure 11 – Typical reflow soldering profile for Sn96,5Ag3Cu,5 solder alloy . 19

Figure 12 – Reflow temperature profile for soldering ability . 20

Figure 13 – Temperature measurement of the package device using thermocouples . 21

Figure 14 – Temperature measurement of other specimen using thermocouples . 21

Figure 15 – Test procedure for Tg . 22

Figure 16 – Contact point . 24

Figure 17 – Maximum gap . 25

Figure 18 – Test procedure for Tg . 26

Figure 19 – Test procedure for Tg . 27

Figure 20 – State of solder wetting. 30

Figure 21 – Solder contact angle . 30

Figure 22 – Test procedure for Tg . 31

Figure 23 – Evaluation of resistance to dissolution of land . 32

Figure 24 – Cross-section observation . 33

Figure 25 – Test procedure for Tg . 34

Figure 26 – Measuring methods for pull strength . 35

Figure 27 – Breaking modes in pull strength test . 37

Table 1 – Test items defined in this standard . 8

Table 2 – Grouping of soldering processes and typical test severities – Overview . 11

Table 3 – Stencil design standard for devices . 15

Table 4 – Maximum reflow heating conditions . 20

Table 5 – Minimum reflow heating conditions . 21

Table 6 – Wetting level . 29

Table A.1 – Meaning of processing contents and condition . 38

Table A.2 – Test process items and clauses . 39

– 6 – IEC 61189-5-601:2021 © IEC 2021

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

TEST METHODS FOR ELECTRICAL MATERIALS, PRINTED BOARDS

AND OTHER INTERCONNECTION STRUCTURES AND ASSEMBLIES –

Part 5-601: General test methods for materials and assemblies –

Reflow soldering ability test for solder joint, and reflow heat

resistance test for printed boards

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

IEC 61189-5-601 has been prepared by IEC technical committee 91: Electronics assembly

technology. It is an International Standard.

The text of this International Standard is based on the following documents:

Draft Report on voting

91/1601/CDV 91/1674/RVC

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/standardsdev/publications.

A list of all parts in the IEC 61189 series, published under the general title Test methods for

electrical materials, printed boards and other interconnection structures and assemblies, can

be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 8 – IEC 61189-5-601:2021 © IEC 2021

TEST METHODS FOR ELECTRICAL MATERIALS, PRINTED BOARDS

AND OTHER INTERCONNECTION STRUCTURES AND ASSEMBLIES –

Part 5-601: General test methods for materials and assemblies –

Reflow soldering ability test for solder joint, and reflow heat

resistance test for printed boards

1 Scope

This part of IEC 61189 specifies the reflow soldering ability test method for components

mounted on organic rigid printed boards, the reflow heat resistance test method for organic rigid

printed boards, and the reflow soldering ability test method for the lands of organic rigid printed

boards in applications using solder alloys, which are eutectic or near-eutectic tin-lead (Pb), or

lead-free alloys.

The printed boards materials for this organic rigid printed boards are epoxide woven E-glass

laminated sheets that are specified in IEC 61249-2 (all parts).

The objective of this document is to ensure the soldering ability of the solder joint and of the

lands of the printed boards. In addition, test methods are provided to ensure that the printed

boards can resist the heat load to which they are exposed during soldering.

This document covers tests Tg , Tg , Tg , Tg , Tg , and Tg listed in Table 1:

1 2 3 4 5 6

Table 1 – Test items defined in this document

Number of

Test Method

test method

Tg

Solder joint initial quality after reflow

Tg

Warpage of component and printed boards in reflow process

Tg

Resistance to soldering heat of printed boards

Reflow

Tg

Wetting and dewetting of printed board land

Tg

Resistance to dissolution of printed board land

Tg

Pull strength of the test substrate land

NOTE The test methods do not apply to the solder bath method.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60068-2 (all parts), Environmental testing

IEC 60068-2-14, Environmental testing – Part 2-14: Tests – Test N: Change of temperature

IEC 60191-6-2, Mechanical standardization of semiconductor devices – Part 6-2: General rules

for the preparation of outline drawings of surface mounted semiconductor devices packages –

Design guide for 1,50 mm, 1,27 mm and 1,00 mm pitch ball and column terminal packages

IEC 60191-6-5, Mechanical standardization of semiconductor devices – Part 6-5: General rules

for the preparation of outline drawings of surface mounted semiconductor device packages –

Design guide for fine-pitch ball grid array (FBGA)

IEC 60191-6-19, Mechanical standardization of semiconductor devices – Part 6-19:

Measurement methods of the package warpage at elevated temperature and the maximum

permissible warpage

IEC 60194-1 , Printed boards design, manufacture and assembly – Vocabulary – Part 1:

Common usage in printed board and electronic assembly technologies

IEC 60194-2, Printed boards design, manufacture and assembly – Vocabulary – Part 2:

Common usage in electronic technologies as well as printed board and electronic assembly

technologies

IEC 61190-1-3, Attachment materials for electronic assembly – Part 1-3: Requirements for

electronic grade solder alloys and fluxed and non-fluxed solid solder for electronic soldering

applications

IEC 62137-3, Electronics assembly technology – Part 3: Selection guidance of environmental

and endurance test methods for solder joints

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60191-6-2,

IEC 60191-6-5, IEC 60194-1 and IEC 60194-2, as well as the following, apply.

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

solderability

ability of the lead or termination of a component or electrode of a component or printed board

to be wetted by solder at the temperature of the lead, termination or electrode, which is assumed

to be the lowest temperature in the soldering process, within the applicable temperature range

of the solder alloy

Note 1 to entry: The term "solderability" is often used in combination with the term "test", indicating a specific

method to evaluate the wettability or ability to be soldered of a surface under worst case conditions (soldering

temperature and contact time with solder). It is not to be confused with the concepts "soldering ability" (see 3.3).

3.2

wettability

intrinsic property of the termination material to form an alloy with the solder

___________

Under preparation. Stage at the time of publication: IEC/FDIS 60194-1:2020.

– 10 – IEC 61189-5-601:2021 © IEC 2021

Note 1 to entry: Wettability depends on the base metal used to produce the termination or, in the case of a plated

termination, the condition and material used to plate the base metal.

3.3

soldering ability

ability of a specific combination of components to facilitate the formation of a proper solder joint

Note 1 to entry: See 3.2, wettability.

3.4

resistance to soldering heat

ability of the component to withstand the highest temperature in terms of temperature gradient,

peak temperature and duration of the soldering process, within the applicable temperature

range of the solder alloy

3.5

reflow soldering

joining of surfaces that have been tinned and/or have solder between them, placing them

together, heating them until the solder flows, and allowing the surface and the solder to cool in

the joined position

3.6

wetting

formation of an adherent coating of solder on a surface indicated by a small contact angle

3.7

dewetting

retraction of molten solder on a solid area that it has initially wetted

Note 1 to entry: In some cases, an extremely thin film of solder may remain. As the solder retracts, the contact

angle increases.

3.8

non-wetting

inability to form an adherent coating of solder on a surface indicated by a contact angle greater

than 90°

3.9

dissolution of printed-board land

process of dissolving metal, usually by introduction of chemicals

4 Grouping of soldering processes and related test severities

The melting temperatures of lead-free solder alloys selected for industrial processes are

significantly different from those for Sn-Pb solder alloy. Moreover, the melting temperatures of

lead-free solder alloys are different from each other but can be clustered in groups.

The groups of soldering processes indicated in Table 2 are given as a guideline to select the

severities for the wetting and resistance tests at a specified soldering heat.

Table 2 – Grouping of soldering processes and typical test severities – Overview

a

Process temperature group 1 2

Typical solder alloy group Sn-Pb Sn-Ag-Cu

Typical

process Reflow peak temperature 210 °C to 240 °C 235 °C to 250 °C

temperature

Test

Test property Reflow peak temperature/Duration

method

b

Solder joint initial Maximum profile

Reflow

235 °C / 20 s or more 245 °C / 30 s or more

quality "Soldering temperature

ability"

Minimum profile

215 °C / 10 s or less 235 °C / 10 s or less

temperature

Warpage 235 °C / 20 s or more 245 °C / 30 s or more

Resistance to soldering heat 235 °C / 20 s or more 245 °C / 30 s or more

Wetting and dewetting 215 °C / 10 s or less 235 °C / 10 s or less

Resistance to dissolution 235 °C / 20 s or more 245 °C / 30 s or more

Pull strength 235 °C / 20 s or more 245 °C / 30 s or more

Typical process temperatures for reflow soldering are the land temperatures in device area on printed boards.

The Sn-Ag-Cu alloy listed in this table represents compositions that are currently preferred for lead-free soldering

processes. However, other solder alloys when matching with the specified group should not be excluded.

a

Refer to each appropriate subclauses for the detailed test conditions.

b

Measured at the solder joint or land of printed boards.

5 Specimens

5.1 Devices

Device specimens for this test are specified in IEC 62137-3.

When the evaluation needs to be conducted, the device used for this test is a dummy device

within which the terminations are connected as shown in Figure 1.

When the evaluation for leadless termination type devices needs to be conducted on the

resistance device, the device resistance for the test is a low-resistance device [as shown in

Figure 1 b)]. The resistance of the low-resistance device should be 50 mΩ or less.

– 12 – IEC 61189-5-601:2021 © IEC 2021

a) Example of area array type packages

b) Example of leadless termination type devices

Figure 1 – Example of a test circuit for the electrical continuity test of a solder joint

The following Figure 2, Figure 3, Figure 4, Figure 5 and Figure 6 show the typical appearance

of each package type.

Figure 2 – Example of area array type packages

Figure 3 – Example of leaded type devices

Figure 4 – Example of leadless termination type devices

Figure 5 – Example of connector for card type devices

Figure 6 – Example of shielding metal components

5.2 Test substrate

The test substrate material shall be single or double-sided mounting with single-layer, double-

layer or multilayer printed boards for material structure used with product. Unless otherwise

specified in the product specification, the test substrate shall be as follows.

a) Test substrate material

Test substrate material shall be a single-sided printed board for general use, for example,

copper-clad epoxide woven fiberglass reinforced laminated sheets as specified in

IEC 61249-2-7 or IEC 61249-2-8. The thickness shall be (1,6 ± 0,2) mm including copper

foil. The copper foil thickness shall be (35 ± 10) µm.

b) Test substrate dimensions

The test substrate dimensions depend on the mounted package size and shape. However,

the test substrate dimensions shall be able to be fixed on the pull strength test equipment.

c) Land shape and land dimensions

Land shape and land dimensions should be the same specification as used for product

design. Land shape and land dimensions should be as specified in IEC 61188-5-8.

Moreover, the test substrate and the test package shall be designed in such a way that their

land pattern forms a daisy chain circuit after mounting for the electrical continuity

measurement.

d) Surface finish of land pattern

If specified in the product specification, the surface finish treatment (for land pattern of the

printed board) shall be the same as specified in the product specification.

EXAMPLE: organic solderability preservative (OSP) or electroless nickel immersion gold (ENIG) plating layer.

5.3 Solder paste

Solder paste is made of flux, finely divided particles of solder, and additives to promote wetting

and to control viscosity, tackiness, slumping, drying rate, etc. Unless otherwise specified in the

product specification, one of the solder alloys listed below (as specified in IEC 61190-1-3) shall

be used. The product specification shall specify details of the solder paste.

The major composition of the solder alloys are as follows:

a) 63 % mass fraction of Sn (tin) and 37 % mass fraction of Pb (lead);

b) from 3,0 % to 4,0 % mass fraction of Ag (silver), from 0,5 % to 1,0 % mass fraction of Cu

(copper) and the remainder of Sn (tin).

EXAMPLE: Sn-Ag-Cu ternary alloy such as Sn96,5Ag3Cu,5 alloy is used.

– 14 – IEC 61189-5-601:2021 © IEC 2021

Solder paste shall be properly stored in accordance with the product's specification.

5.4 Solder ball

The diameter and height of the solder ball used should be the following size a) and b) and the

shape should be as shown in Figure 7. The composition should be equivalent to the one

indicated in IEC 61190-1-3.

a)

D

≤1,5

d

b)

D

1,1≤ ≤ 2,2

H

a) Solder ball

b) Solder mask defined (SMD) c) Non solder mask defined (NSMD)

type land type land

Key

d Land opening diameter

D1 Solder ball diameter

D2 Solder ball diameter after solder ball assembling

H Solder ball height after solder ball assembling

Figure 7 – Recommended solder ball shape

6 Apparatus and equipment

6.1 Constant temperature and humidity testing equipment

The pre-conditioning oven shall be able to maintain the evaluation conditions specified in the

specimen’s product specification. The general requirements for the pre-conditioning oven are

specified in IEC 60068-2 (all parts).

The humidifier shall be able to maintain the evaluation temperature and humidity as specified

in the specimen’s product specification. The material of the oven should not react at high

temperature. The water used for the test should be purified or de-ionized water, with a resistivity

of 5 000 MΩm (0,5 MΩcm) or higher (conductivity of 2 µS/cm or less). The equipment should

perform the test in accordance with IEC 60068-2-78.

6.2 Device-mounting equipment

a) Stencil for screen printing

The stencil shall be suitable for permitting the application of solder paste for the device

types and sizes to be mounted.

Unless otherwise specified in the product specification, the stencil used should conform to

the design standard shown in Table 3.

Table 3 – Stencil design standard for devices

Terminal type Stencil thickness Aperture diameter

For device 80 µm to 150 µm Match with the land size specified for device

There are three processing methods for the stencil: the etching method, the additive method,

and the laser processing method. It is recommended to use the stencil made by the additive

method or by the laser processing method, whose solder paste printing characteristic is

superior as it allows for finer pitches to be created.

b) Solder paste applying equipment

1) Screen printing equipment

The screen-printing equipment shall be capable of solder printing as described in 7.4.1.

2) Other equipment

If a dispenser, inkjet printing equipment or solder transfer apparatus are used to apply solder

paste, they shall be able to apply the amount defined by the product specification.

c) Device-mounting equipment

The device-mounting equipment shall be capable of mounting the devices described in 7.4.2.

d) Reflow soldering equipment

The reflow soldering equipment shall be able to realize the reflow soldering temperature

profile specified in Clause 4. Examples of temperature profiles

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...