IEC 61340-4-6:2015

(Main)Electrostatics - Part 4-6: Standard test methods for specific applications - Wrist straps

Electrostatics - Part 4-6: Standard test methods for specific applications - Wrist straps

IEC 61340-4-6:2015 provides electrical and mechanical test methods and performance limits for evaluation, acceptance and periodic verification testing of wrist straps. This standard is intended for testing wrist straps and wrist strap systems used for the grounding of personnel engaged in working with ESD sensitive assemblies and devices. It does not address constant monitoring systems. This edition includes the following significant technical changes with respect to the previous edition:

a) editorial comments made during the review of the first edition were reviewed and incorporated where appropriate;

b) several changes were made to update the Figures and improve the presentation of metric measurements (Imperial measurements have been removed);

c) the option of using an integrated checker for wrist strap system continuity testing has been added;

d) the evaluation and acceptance limit for wrist strap resistance has been changed so as to harmonize with IEC 61340-5-1.

Electrostatique - Partie 4-6: Méthodes d'essai normalisées pour des applications spécifiques - Bracelets de conduction dissipative

L'IEC 61340-4-6:2015 donne les méthodes d'essai électriques et mécaniques et les limites de performance pour les essais d'évaluation, d'acceptation et de vérification périodique des bracelets de conduction dissipative. Cette norme couvre les essais des bracelets de conduction dissipative et des systèmes de bracelets de conduction dissipative pour la mise à la terre du personnel amené à travailler avec des assemblages et dispositifs sensibles aux ESD. Elle ne couvre pas les systèmes de surveillance continue. Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

a) les commentaires éditoriaux émis au cours de la révision de la première édition ont été revus et intégrés le cas échéant;

b) plusieurs modifications ont été apportées pour la mise à jour des Figures et l'amélioration de la présentation des mesures métriques (les mesures britanniques ont été supprimées);

c) l'option consistant à utiliser un dispositif de contrôle intégré pour l'essai de continuité du système de bracelet de conduction dissipative a été ajoutée;

d) l'évaluation et la limite d'acceptation concernant la résistance du bracelet de conduction dissipative ont été modifiées pour harmonisation avec l'IEC 61340-5-1.

General Information

- Status

- Published

- Publication Date

- 19-May-2015

- Technical Committee

- TC 101 - Electrostatics

- Drafting Committee

- WG 5 - TC 101/WG 5

- Current Stage

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 61340-4-6:2015 is an international standard developed by the International Electrotechnical Commission (IEC) addressing electrostatic control through wrist straps. Specifically, this part of IEC 61340 focuses on standard test methods for wrist straps-essential personal grounding devices used to prevent electrostatic discharge (ESD) damage when handling sensitive electronic assemblies and devices.

The standard establishes electrical and mechanical test methods, performance limits, and procedures for the evaluation, acceptance, and periodic verification of wrist strap quality and functionality. It supports manufacturers, quality assurance professionals, and end users involved in ESD protection by defining rigorous testing methods for wrist strap systems. Notably, this edition introduces updated metric measurement presentations, eliminates imperial units, and allows integrated continuity testing options.

Key Topics

- Scope and Application: Covers wrist straps and wrist strap systems for grounding personnel during work with ESD-sensitive components. It excludes constant monitoring systems.

- Electrical Testing Methods: Includes wrist strap resistance and continuity tests to verify proper grounding functionality and electrical safety.

- Mechanical Testing Methods: Addresses band resistance, breakaway force, band size requirements, connection integrity, ground cord extendibility, and bending life to ensure durability and reliability.

- Performance Limits: Defines acceptance criteria harmonized with IEC 61340-5-1 for wrist strap resistance to ensure standardized safety levels.

- Test Procedures: Detailed step-by-step testing instructions including equipment setup, measurement methods, and reporting for consistent application across test environments.

- Integrated Checker Option: Allows use of integrated devices for wrist strap system continuity testing, simplifying compliance verification.

- Systematic Testing Levels: Clarifies different testing types such as evaluation, acceptance, and periodic verification, ensuring ongoing product quality.

Applications

- ESD Control Programs: Enables organizations to maintain and verify effective electrostatic discharge protection in manufacturing, assembly, repair, and testing of sensitive electronics.

- Quality Assurance: Assists manufacturers and suppliers of wrist straps to certify their products meet international electrical and mechanical standards.

- Periodic Maintenance: Supports facilities in scheduling regular wrist strap inspections to uphold worker safety and product integrity.

- Product Development: Guides design engineers in meeting standardized mechanical and electrical performance requirements for new wrist strap models.

- Training and Compliance: Provides clear testing protocols for technicians and auditors engaged in ESD compliance verification.

Related Standards

- IEC 61340-5-1: Protection of electronic devices from electrostatic phenomena – General requirements, harmonized for wrist strap resistance limits.

- IEC 61340 Series: A comprehensive collection of standards addressing various aspects of electrostatics and ESD control, including materials, equipment, and environments.

- ISO/IEC Directives, Part 2: Framework for drafting and maintaining IEC and ISO standards ensuring quality and international consensus.

Practical Value

Implementing testing protocols from IEC 61340-4-6:2015 ensures that wrist straps provide effective personnel grounding to mitigate electrostatic discharge risks. Compliance improves:

- Device Reliability: Protects sensitive electronics from latent failures caused by ESD.

- Worker Safety: Ensures grounding devices function correctly, reducing shock hazards.

- Cost Efficiency: Minimizes product failures, rework, and warranty claims.

- Global Market Access: Products meeting IEC standards have broader acceptance worldwide.

- Regulatory Compliance: Aligns with international ESD control requirements for electronics manufacturing.

By adhering to IEC 61340-4-6:2015, industries involved with ESD-sensitive assemblies can confidently verify and maintain wrist strap systems, fostering quality and safety in electrostatic-sensitive environments.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

TL 9000 QuEST Forum

Telecommunications quality management system.

UL Solutions

Global safety science company with testing, inspection and certification.

Sponsored listings

Frequently Asked Questions

IEC 61340-4-6:2015 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Electrostatics - Part 4-6: Standard test methods for specific applications - Wrist straps". This standard covers: IEC 61340-4-6:2015 provides electrical and mechanical test methods and performance limits for evaluation, acceptance and periodic verification testing of wrist straps. This standard is intended for testing wrist straps and wrist strap systems used for the grounding of personnel engaged in working with ESD sensitive assemblies and devices. It does not address constant monitoring systems. This edition includes the following significant technical changes with respect to the previous edition: a) editorial comments made during the review of the first edition were reviewed and incorporated where appropriate; b) several changes were made to update the Figures and improve the presentation of metric measurements (Imperial measurements have been removed); c) the option of using an integrated checker for wrist strap system continuity testing has been added; d) the evaluation and acceptance limit for wrist strap resistance has been changed so as to harmonize with IEC 61340-5-1.

IEC 61340-4-6:2015 provides electrical and mechanical test methods and performance limits for evaluation, acceptance and periodic verification testing of wrist straps. This standard is intended for testing wrist straps and wrist strap systems used for the grounding of personnel engaged in working with ESD sensitive assemblies and devices. It does not address constant monitoring systems. This edition includes the following significant technical changes with respect to the previous edition: a) editorial comments made during the review of the first edition were reviewed and incorporated where appropriate; b) several changes were made to update the Figures and improve the presentation of metric measurements (Imperial measurements have been removed); c) the option of using an integrated checker for wrist strap system continuity testing has been added; d) the evaluation and acceptance limit for wrist strap resistance has been changed so as to harmonize with IEC 61340-5-1.

IEC 61340-4-6:2015 is classified under the following ICS (International Classification for Standards) categories: 17.200.99 - Other standards related to thermodynamics; 29.020 - Electrical engineering in general; 33.160.40 - Video systems. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61340-4-6:2015 has the following relationships with other standards: It is inter standard links to IEC 61340-4-6:2010, IEC 61340-4-6:2025. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61340-4-6:2015 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61340-4-6 ®

Edition 2.0 2015-05

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Electrostatics –

Part 4-6: Standard test methods for specific applications – Wrist straps

Électrostatique –

Partie 4-6: Méthodes d’essai normalisées pour des applications spécifiques –

Bracelets de conduction dissipative

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing more than 30 000 terms and

Technical Specifications, Technical Reports and other definitions in English and French, with equivalent terms in 15

documents. Available for PC, Mac OS, Android Tablets and additional languages. Also known as the International

iPad. Electrotechnical Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a More than 60 000 electrotechnical terminology entries in

variety of criteria (reference number, text, technical English and French extracted from the Terms and Definitions

committee,…). It also gives information on projects, replaced clause of IEC publications issued since 2002. Some entries

and withdrawn publications. have been collected from earlier publications of IEC TC 37,

77, 86 and CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient plus de 30 000 termes et définitions en

Spécifications techniques, Rapports techniques et autres

anglais et en français, ainsi que les termes équivalents dans

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

15 langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

Plus de 60 000 entrées terminologiques électrotechniques, en

La recherche avancée permet de trouver des publications IEC

en utilisant différents critères (numéro de référence, texte, anglais et en français, extraites des articles Termes et

comité d’études,…). Elle donne aussi des informations sur les Définitions des publications IEC parues depuis 2002. Plus

projets et les publications remplacées ou retirées. certaines entrées antérieures extraites des publications des

CE 37, 77, 86 et CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 61340-4-6 ®

Edition 2.0 2015-05

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Electrostatics –

Part 4-6: Standard test methods for specific applications – Wrist straps

Électrostatique –

Partie 4-6: Méthodes d’essai normalisées pour des applications spécifiques –

Bracelets de conduction dissipative

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 17.220.99; 29.020 ISBN 978-2-8322-2675-9

– 2 – IEC 61340-4-6:2015 IEC 2015

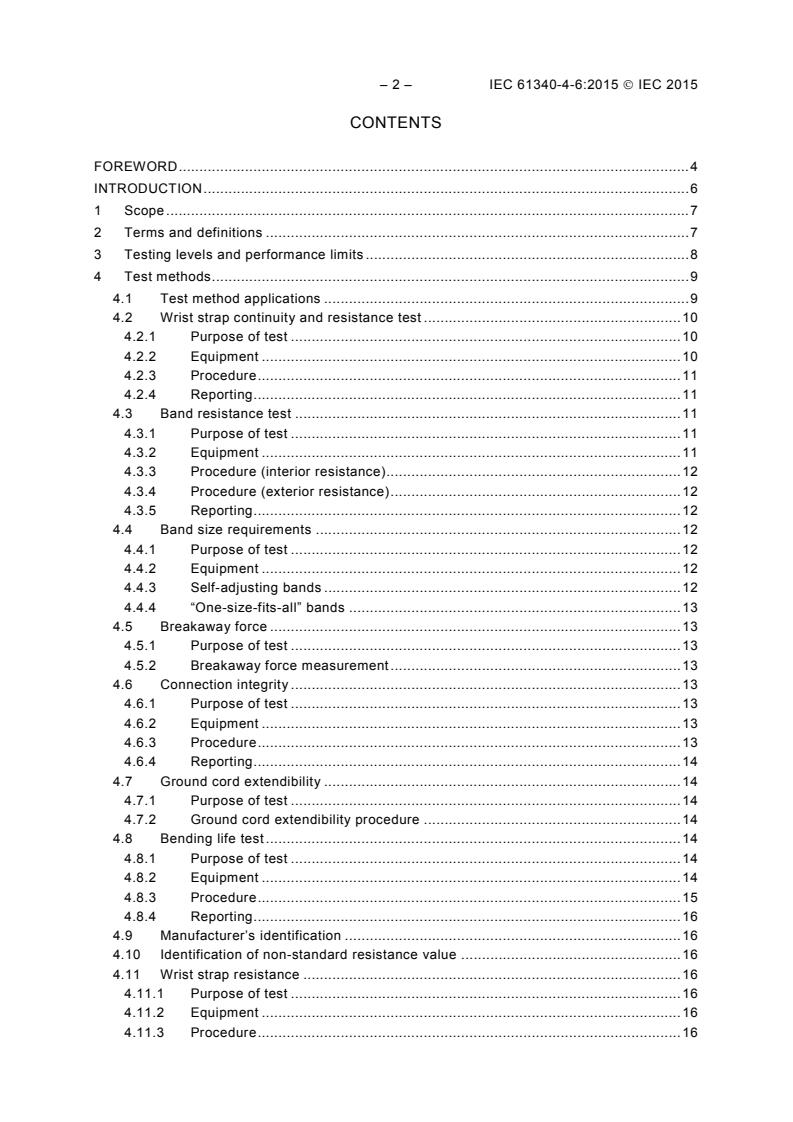

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Terms and definitions . 7

3 Testing levels and performance limits . 8

4 Test methods . 9

4.1 Test method applications . 9

4.2 Wrist strap continuity and resistance test . 10

4.2.1 Purpose of test . 10

4.2.2 Equipment . 10

4.2.3 Procedure . 11

4.2.4 Reporting . 11

4.3 Band resistance test . 11

4.3.1 Purpose of test . 11

4.3.2 Equipment . 11

4.3.3 Procedure (interior resistance) . 12

4.3.4 Procedure (exterior resistance) . 12

4.3.5 Reporting . 12

4.4 Band size requirements . 12

4.4.1 Purpose of test . 12

4.4.2 Equipment . 12

4.4.3 Self-adjusting bands . 12

4.4.4 “One-size-fits-all” bands . 13

4.5 Breakaway force . 13

4.5.1 Purpose of test . 13

4.5.2 Breakaway force measurement . 13

4.6 Connection integrity . 13

4.6.1 Purpose of test . 13

4.6.2 Equipment . 13

4.6.3 Procedure . 13

4.6.4 Reporting . 14

4.7 Ground cord extendibility . 14

4.7.1 Purpose of test . 14

4.7.2 Ground cord extendibility procedure . 14

4.8 Bending life test . 14

4.8.1 Purpose of test . 14

4.8.2 Equipment . 14

4.8.3 Procedure . 15

4.8.4 Reporting . 16

4.9 Manufacturer’s identification . 16

4.10 Identification of non-standard resistance value . 16

4.11 Wrist strap resistance . 16

4.11.1 Purpose of test . 16

4.11.2 Equipment . 16

4.11.3 Procedure . 16

4.11.4 Reporting . 16

4.12 Wrist strap system continuity test . 16

4.12.1 Purpose of test . 16

4.12.2 Equipment . 17

4.12.3 Procedure with ohmmeter . 18

4.12.4 Procedure with integrated checker . 18

4.12.5 Reporting . 18

Bibliography . 19

Figure 1 – Wrist strap resistance test apparatus . 11

Figure 2 – Mechanical ground cord flex tester (example) . 15

Figure 3 – Wrist strap system resistance test . 18

Table 1 – Evaluation testing . 9

Table 2 – Acceptance testing . 9

Table 3 – Periodic or verification testing . 9

– 4 – IEC 61340-4-6:2015 IEC 2015

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTROSTATICS –

Part 4-6: Standard test methods for specific

applications – Wrist straps

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61340-4-6 has been prepared by IEC technical committee 101:

Electrostatics.

This second edition cancels and replaces the first edition published in 2010. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) editorial comments made during the review of the first edition were reviewed and

incorporated where appropriate;

b) several changes were made to update the Figures and improve the presentation of metric

measurements (Imperial measurements have been removed);

c) the option of using an integrated checker for wrist strap system continuity testing has been

added;

d) the evaluation and acceptance limit for wrist strap resistance has been changed so as to

harmonize with IEC 61340-5-1.

The text of this standard is based on the following documents:

FDIS Report on voting

101/463/FDIS 101/476/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 61340 series, under the general title Electrostatics, can be found

on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC website under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – IEC 61340-4-6:2015 IEC 2015

INTRODUCTION

This part of IEC 61340 has been developed to establish test methods for evaluating the

electrical and mechanical attributes of wrist straps used in an electrostatic control program.

Wrist straps are intended to connect the user to electrical ground, thus preventing

electrostatic charge on a user’s body from attaining a level that may damage ESD susceptible

devices or assemblies.

Test methods and performance limits for evaluation, acceptance, and functional testing are

provided.

ELECTROSTATICS –

Part 4-6: Standard test methods for specific

applications – Wrist straps

1 Scope

This part of IEC 61340 provides electrical and mechanical test methods and performance

limits for evaluation, acceptance and periodic verification testing of wrist straps.

NOTE All dimensions are nominal except where indicated.

This standard is intended for testing wrist straps and wrist strap systems used for the

grounding of personnel engaged in working with ESD sensitive assemblies and devices.

It does not address constant monitoring systems.

2 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

2.1

wrist strap

assembled device consisting of a band and ground cord that is designed to provide electrical

connection from a person’s skin to ground

2.2

wrist strap system

wrist strap when properly worn by a person, where the electrical path includes the person, the

band and the ground cord

2.3

band

portion of the wrist strap worn on the wrist

Note 1 to entry: The band maintains electrical contact with a person’s skin.

2.4

ground cord

portion of the wrist strap that provides flexibility of movement while completing the electrical

circuit between the band and ground

2.5

evaluation testing

testing of a wrist strap to determine its electrical and mechanical performance abilities

Note 1 to entry: Data are in the form of values from laboratory testing.

2.6

acceptance testing

incoming tests to confirm proper marking and electrical functionality

Note 1 to entry: Data are in the form of visual inspection records and values or pass/fail notation.

– 8 – IEC 61340-4-6:2015 IEC 2015

2.7

periodic verification testing

end-use testing to confirm electrical functionality

Note 1 to entry: Data are in the form of pass/fail notation or resistance values.

2.8

current-limiting resistance

resistance value incorporated in series with the wrist strap’s electrical path to ground

Note 1 to entry: This resistance limits electrical current that could pass through the ground cord in the event of

inadvertent user contact with an electrical potential.

2.9

resistance range

user-specified upper and lower resistance values which define the user-acceptable resistance

values of a wrist strap or wrist strap system

2.10

strain relief

construction feature designed to protect the connections and cord from premature failure

2.11

breakaway force

force required to disconnect the ground cord from the band

3 Testing levels and performance limits

This standard specifies different types of testing for wrist straps. Tables 1, 2 and 3 detail the

three types of testing with the associated limits and subclause references to test methods.

The methods provide appropriate tests for the different levels of wrist strap examination.

Evaluation tests are laboratory tests for measuring the performance of a wrist strap or for the

comparison of wrist straps. Acceptance tests provide methods for incoming goods inspection.

Finally, the periodic verification or functional test is a simple check of electrical continuity.

This test shall be used on a regular, user defined basis, to ensure that the wrist strap is

electrically functional. Testing shall be carried out under ambient laboratory conditions. The

temperature and humidity at the time of testing shall be recorded and reported in the test

report. In the case of any dispute regarding test values, conditioning and testing shall be done

at (23 ± 2) °C and (12 ± 3) % RH.

NOTE Testing has shown that environmental conditions do not significantly affect test results.

Table 1 – Evaluation testing

Electrical Limit Test reference

Wrist strap continuity and resistance < 5 MΩ , or user defined value 4.2

Band resistance Interior: ≤ 100 kΩ or user defined value

4.3

Exterior:

> 10 MΩ

Mechanical Limit Test reference

Band size As defined in 4.4 4.4

Breakaway force > 4,4 N and < 22,6 N 4.5

Cord and connector integrity > 22,6 N and > 66 % of cord strength 4.6

Ground cord extendibility Extension to manufacturer’s specified length

4.7

with no loss of electrical continuity

Bending life 4.8

≥ 16 000 cycles

Marking Limit Test reference

Manufacturer’s identification Logo and/or name 4.9

Identification of non-standard resistance Prominent feature or value marked 4.10

value

Table 2 – Acceptance testing

Electrical Limit Test reference

Wrist strap resistance

< 5 MΩ, or user defined value 4.11

Marking Limit Test reference

Manufacturer’s identification Logo and/or name 4.9

Identification of non-standard Resistance Prominent feature or value marked 4.10

value

Table 3 – Periodic or verification testing

Electrical Limit Test reference

a

Wrist strap system continuity (as worn) 4.12

≤ 35 MΩ, or user defined value

a

A user defined lower limit of resistance may be required for safety or other considerations.

4 Test methods

4.1 Test method applications

Refer to Tables 1, 2 and 3 for test method applications.

WARNING: Test procedures described in this standard may expose personnel to potentially

hazardous electrical conditions. Appropriate electrical hazard reduction practices should be

exercised and proper earthing instructions for the equipment used should be followed when

performing tests.

– 10 – IEC 61340-4-6:2015 IEC 2015

4.2 Wrist strap continuity and resistance test

4.2.1 Purpose of test

This test measures the value of the current-limiting resistance and assures continuity between

the discrete parts of the wrist strap.

4.2.2 Equipment

The equipment shall consist of the following:

• a test fixture (see Figure 1) comprising an insulative stand and two (25,0 ± 0,5) mm

diameter stainless steel cylinders, with one cylinder fixed to the stand directly above

the second. The second cylinder with a mass of (0,11 ± 0,01) kg is mounted in a slot in

the stand that allows free vertical movement;

• an ohmmeter or other instrument(s) capable of reading from 50 kΩ to at least 100 MΩ

with a test voltage of 7 V to 100 V DC open circuit;

• six samples of wrist straps.

140 mm

100 mm

IEC

Figure 1a – Band test fixture construction

10 mm

120 mm

IEC

Figure 1b – Test method

Key

4 insulative stand

1 fixed metal cylinder test probe, (25,0 ± 0,5) mm diameter

5 ohmmeter

2 hole for banana plug

6 band

3 movable metal cylinder test weight, (25,0 ± 0,5) mm diameter

Figure 1 – Wrist strap resistance test apparatus

4.2.3 Procedure

Using the test fixture shown in Figure 1, place the band around the cylinders with the band

interior toward the cylinders and the ground cord connector on the right side and parallel to

the cylinders, evenly spaced between the cylinders. Allow the 0,11 kg cylinder to move freely

and stress the band.

Connect the ground cord to the band.

Connect the ohmmeter to the top cylinder and to the ground connector of the ground cord.

Measure and record the resistance value.

Repeat the procedure for a total of six wrist straps.

4.2.4 Reporting

Report the resistance for each wrist strap.

4.3 Band resistance test

4.3.1 Purpose of test

Resistance of the band interior and exterior is determined.

4.3.2 Equipment

See 4.2.2.

– 12 – IEC 61340-4-6:2015 IEC 2015

4.3.3 Procedure (interior resistance)

Using the test fixture shown in Figure 1, place the band around the cylinders with the band

interior toward the cylinders and the ground cord connector on the right side and parallel to

the cylinders, evenly spaced between the cylinders. Allow the 0,11 kg cylinder to move freely

and stress the band.

Connect the ohmmeter to the top cylinder and to the ground cord connector on the band.

Measure and record the resistance value.

Repeat the procedure for a total of six bands.

4.3.4 Procedure (exterior resistance)

Using the test fixture shown in Figure 1, place the band around the cylinders with the band

exterior toward the cylinders and the ground cord connector on the right side and parallel to

the cylinders, evenly spaced between the cylinders. Allow the 0,11 kg cylinder to move freely

and stress the band.

Connect the ohmmeter to the top cylinder and the ground cord connector on the band.

Measure and record the resistance value.

Repeat the procedure for a total of six bands.

4.3.5 Reporting

Report the interior resistance and exterior resistance of each band.

4.4 Band size requirements

4.4.1 Purpose of test

Band sizes are determined by the band’s ability to fit over a specifically sized cylinder. A

band’s ability to expand to fit over a hand, yet contract to fit correctly around a wrist is

determined by fitting the band over specifically sized large and small cylinders.

NOTE A band is fitted correctly when it is sufficiently tight to maintain electrical continuity during normal wearing

conditions, but not so tight as to cause discomfort or harm to the wearer.

4.4.2 Equipment

The equipment shall consist of the following:

• 1 cylinder having an outside diameter of (4,3 ± 0,1) cm;

• 1 cylinder having an outside diameter of (5,3 ± 0,1) cm;

• 1 cylinder having an outside diameter of (8,25 ± 0,1) cm;

• 1 cylinder having an outside diameter of (8,9 ± 0,1) cm.

4.4.3 Self-adjusting bands

“Large”-sized self-adjustable expanding metal or fabric bands shall make 360° contact with a

5,3 cm diameter cylinder, and be capable of fitting over an 8,9 cm diameter cylinder.

“Small”-sized self-adjustable expanding metal or fabric bands shall make 360° contact with a

4,3 cm diameter cylinder, and be capable of fitting over an 8,25 cm diameter cylinder.

4.4.4 “One-size-fits-all” bands

“One-size-fits-all” bands shall make 360° contact on a 4,3 cm diameter cylinder and be

capable of sufficient expansion to fit over an 8,9 cm cylinder.

4.5 Breakaway force

4.5.1 Purpose of test

For personnel safety considerations, the wrist strap ground cord shall disconnect from the

band while worn in the event of an emergency. However, the ground cord shall remain

connected during normal use. The breakaway force of the cord from the band is measured in

the following procedure.

4.5.2 Breakaway force measurement

With the ground cord connected to the band in a normal manner and the band held in a fixture

or by hand, a force of > 4,4 N and < 22,6 N applied to the ground cord, perpendicular to the

band back plate shall be required to separate the ground cord from the band.

Given the variation of the design of wrist straps, it is not possible to provide a detailed

description of the test procedure. Nevertheless, users of this standard shall adapt procedures

to suit the design of wrist straps that are in use, and shall describe these procedures as far as

possible in test reports. Variations in test procedures may be significant when evaluating

sample test results that are close to acceptance limits.

4.6 Connection integrity

4.6.1 Purpose of test

The strength of the wire used as a ground cord is measured to the breaking point. The

strengths of the mechanical connections between the wire and the terminals used for ground

connection and band connection are measured.

4.6.2 Equipment

The equipment shall consist of the following:

• tensile tester capable of 6,35 cm per minute travel;

• clamps (grippers) for tensile tester;

• chart recorder or data logging device.

Given the variation in the design of wrist straps, it is not possible to provide full details of the

use of tensile testers. Nevertheless, users of this standard shall adapt procedures to suit the

design of the wrist strap that is in use, and shall include the following information in test

reports: type of clamps, clamping force, specimen length between clamps, and rate of

extension. Variations in test procedures may be significant when evaluating sample test

results that are close to acceptance limits.

4.6.3 Procedure

4.6.3.1 General

Using the tensile tester and chart recorder or data logging device, test and record the tensile

strength (breaking point) of the ground cord, the ground connector to the ground cord, and the

band connector to the cord. Repeat the procedure for a total of six ground cords.

This is a test to failure so sufficient numbers of test samples should be on hand to complete

the evaluation.

– 14 – IEC 61340-4-6:2015 IEC 2015

4.6.3.2 Wire break strength

The ground cord under test is secured in the tensile tester by clamps gripping the wire

between a straight section of wire (not including the wire terminations). The tensile tester is

then activated and the wire pulled to the breaking point.

4.6.3.3 Ground cord termination strength

The ground cord under test is secured in the tensile tester so that the wire is clamped in one

gripper and one termination end of the ground cord is clamped in the other gripper. The

tensile tester is then activated and the ground cord stressed until the termination breaks or is

separated from the wire.

The same ground cord that is used in 4.6.3.2 may be used if sufficient wire length is available

for clamping in the tensile tester.

4.6.4 Reporting

Report the break strength of the wire and the break strength or pull off force of both

terminations. Calculate the percentage of the termination strength to wire strength by the

following formula:

Termination break or pull-off point/wire break strength × 100 = % Termination strength.

4.7 Ground cord extendibility

4.7.1 Purpose of test

Retractable-type ground cords (coiled cords) shall be capable of being extended to the

manufacturer’s specified working length (typically 1,5 m or 3,0 m) without pulling the band

away from the user’s wrist to the extent that electrical continuity, as measured in 4.11, is

interrupted.

4.7.2 Ground cord extendibility procedure

While wearing the wrist strap assembly and performing the wrist strap system continuity test

as described in 4.11, extend the distance between the wrist band and the integrated checker

or ohmmeter to the wrist strap manufacturer’s specified working length of the ground cord.

This test may require two people to prevent dropping the instruments used for measuring the

electrical continuity of the wrist strap system.

4.8 Bending life test

4.8.1 Purpose of test

Ground cord flex life is determined.

4.8.2 Equipment

The equipment shall consist of the following:

• mechanical ground cord flex tester: machine that drives a stressing mechanism

through an arc of 120°±5°at a rate of approximately 2 000 cycles per hour (see Figure

2 for an example of a flex tester);

NOTE 1 A flex tester designed to test more than one ground cord at a time is acceptable. Some testers

have been constructed that can test both ends of a ground cord or multiple ground cords at the same time.

NOTE 2 Ground cords are attached to the stressing mechanism by means of a mounting that simulates

the band connector (i.e. a snap) and the ground connector (i.e. a banana plug jack).

• a (0,45 ± 0,1) kg weight;

• an ohmmeter or other instrument(s) capable of reading from 50 kΩ to at least 100 MΩ

with a test voltage of 7 V to 100 V DC open circuit.

IEC

Key

1 ohmmeter, 7 V to 100 V DC open circuit 7 stressing mechanism

1a low input 8 mounting fixture

1b high input 9 banana plug termination (see NOTE 1)

2 female snap fastener termination (see NOTE 1) 10 mechanical counter (see NOTE 2)

3 wrist strap cord 11 mounting screw

4 motor control box 12 weight – (0,45 ± 0,1) kg rigidly attached to wrist

strap cord approximately 15 cm from cord

5 30 r/min motor

termination

6 rotating disc

NOTE 1 Figure shows test of banana plug termination; repeat with female snap fastener termination.

NOTE 2 One stress cycle is the equivalent of one revolution of the rotating disc.

Figure 2 – Mechanical ground cord flex tester (example)

4.8.3 Procedure

Attach one end of a ground cord to a stressing mechanism. Connect the opposite end to a

0,45 kg weight and allow the ground cord to hang freely. Connect the resistance monitoring

cable to the ground cord conductor at the weighted end.

– 16 – IEC 61340-4-6:2015 IEC 2015

Start the flex tester. Six cords shall be tested with the band connection attached to the

stressing mechanism and six cords shall be tested with the ground connection attached to the

stressing mechanism.

4.8.4 Reporting

Ground cord failure is defined as the total resistance of the circuit exceeding the user defined

value, or when there is visible evidence of mechanical failure in the cord jacket or strain relief.

Each ground cord shall have a minimum life of at least 8 000 cycles and the average of all

samples tested shall have a minimum life of 16 000 cycles.

4.9 Manufacturer’s identification

Wrist straps shall have the manufacturer’s name or logo embossed, moulded or otherwise

permanently marked in a prominent location.

4.10 Identification of non-standard resistance value

Wrist straps incorporating a resistance of non-standard value (other than 1,0 MΩ with a

relative tolerance of ± 20 %), shall be identified by having a prominent feature or the resistor

value, marked on the ground cord, or on the wrist strap component that contains the

resistance (generally the ground cord).

4.11 Wrist strap resistance

4.11.1 Purpose of test

Resistance of the wrist strap is determined.

4.11.2 Equipment

The equipment shall consist of the following:

• an ohmmeter or other instrument(s) capable of reading from 50 kΩ to at least 100 MΩ

with a test voltage of 7 V to 100 V DC open circuit.

4.11.3 Procedure

Connect the band to the ground cord. Attach the ground cord termination end to an ohmmeter

lead (typically using an alligator clip). Place the band on an insulating surface with the skin

contact area of the band facing up. For bands with a metal skin contact plate, touch the skin

contact area of the band with the other ohmmeter lead probe using hand pressure. For bands

that do not have a metal plate for skin contact, increase the ohmmeter probe contact area by

placing a metal disc (conductive coin or other 12 mm nominal diameter disc) on the band

interior and contact the disc with the other ohmmeter lead probe using hand pressure.

Measure the resistance of the wrist strap. Repeat the test for a total of six wrist straps.

4.11.4 Reporting

Report the resistance value of each wrist strap. Discrete current-limiting resistors should be

located near the connection between the ground cord and the band.

4.12 Wrist strap system continuity test

4.12.1 Purpose of test

This verifies the acceptability of the resistance path of the wrist strap system using an

integrated wrist strap checker or an ohmmeter. This test shall be performed with the wrist

strap on the intended user(s) wrist. This test includes the wrist strap user’s resistance as part

of the total system resistance.

4.12.2 Equipment

The equipment shall consist of the following:

• an ohmmeter or integrated checker capable of reading from 50 kΩ to at least 100 MΩ

with a test voltage of 7 V to 100 V DC open circuit, current limited to < 0,05 mA;

• a stainless steel cylinder (15,0 ± 0,1) cm in length and (2,5 ± 0,1) cm in diameter (only

required if using an ohmmeter, see Figure 3a).

1 2

IEC

Figure 3a – Test using ohmmeter

IEC

Figure 3b – Test using integrated checker

– 18 – IEC 61340-4-6:2015 IEC 2015

Key

1 band 5 ground cord

2 hand-held stainless steel electrode 6 integrated checker

3 ohmmeter 7 contact area

4 ohmmeter lead

Figure 3 – Wrist strap system resistance test

4.12.3 Procedure with ohmmeter

Place the band on the user’s wrist, attach the ground cord to the band, and attach the ground

cord to the common terminal (-) of the ohmmeter. Connect the stainless steel cylinder to the

positive terminal (+) of the ohmmeter. Grasp the cylinder with the hand closest to the band.

Measure and record the resistance of the wrist strap system (see Figure 3a).

4.12.4 Procedure with integrated checker

Place the band on the user’s wrist, attach the ground cord to the band and attach the other

end of the ground cord to the integrated checker. Touch the contact area on the integrated

checker with the fingers on the hand closest to the band and activate the integrated checker

following the manufacturer’s instructions. Record the resistance or the “pass” or “fail”

indication (see Figure 3b).

4.12.5 Reporting

It is necessary to determine the resistance level for the pass and fail indications of the

integrated checker to ensure that the requirements of the end user are met with regards to

personnel grounding through the wrist strap system. Then, a “pass” indication from the

integrated checker indicates that the resistance of the wrist strap system is acceptable for use.

A value of ≤ 35 MΩ or a reading falling within the user-specified resistance range indicates

that the wrist strap system is acceptable for use.

Bibliography

[1] IEC 61340-5-1, Electrostatics – Part 5-1: Protection of electronic devices from

electrostatic phenomena – General requirements

[2] IEC TR 61340-5-2, Electrostatics – Part 5-2: Protection of electronic devices from

electrostatic phenomena – User guide

[3] ANSI/ESD S1.1:2006, Wrist straps

_____________

– 20 – IEC 61340-4-6:2015 IEC 2015

SOMMAIRE

AVANT-PROPOS . 22

INTRODUCTION . 24

1 Domaine d’application . 25

2 Termes et définitions . 25

3 Niveaux d’essai et limites de performances . 26

4 Méthodes d’essai . 27

4.1 Applications des méthodes d’essai . 27

4.2 Essai de continuité et de résistance du bracelet de conduction dissipative. 28

4.2.1 Objectif de l’essai . 28

4.2.2 Equipement . 28

4.2.3 Mode opératoire . 29

4.2.4 Rapport . 29

4.3 Essai de résistance de la bande . 29

4.3.1 Objectif de l’essai . 29

4.3.2 Equipement . 29

4.3.3 Mode opératoire (résistance intérieure) . 30

4.3.4 Mode opératoire (résistance extérieure). 30

4.3.5 Rapport . 30

4.4 Exigences concernant la taille de la bande . 30

4.4.1 Objectif de l’essai . 30

4.4.2 Equipement . 30

4.4.3 Bandes auto-ajustables .

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...