EN 13964:2004

(Main)Suspended ceilings - Requirements and test methods

Suspended ceilings - Requirements and test methods

The European Standard provides information for the various parties responsible for designing, manufacturing and specifying/selecting suspended ceilings used for interior applications in general building and civil engineering structures. It covers suspended ceilings sold as a complete kit (including, optionally, light fittings and other features), substructures sold as kits, individual components (products) of such substructures, and membrane components. It includes test methods and methods of assessment, as well as provisions for the evaluation of conformity of the products to the requirements of this standard.

In the absence of any other European Standard, this standard specifies dimensions, tolerances and, where relevant, performance requirements, for commonly available ceiling substructures and membrane components.

Unterdecken - Anforderungen und Prüfverfahren

Plafonds suspendus - Exigences et méthodes d'essai

La présente Norme européenne fournit des informations aux diverses parties chargées de la conception, de la fabrication et de la spécification/sélection des plafonds suspendus pour des applications intérieures dans les bâtiments et structures de génie civil. Elle couvre les plafonds suspendus vendus sous forme de kit complet (comprenant éventuellement des dispositifs d'éclairage et autres fonctionnalités), les ossatures vendues sous forme de kits, les éléments (produits) individuels de ces ossatures, et les éléments d'habillage. Elle contient les méthodes d'essai et d'évaluation ainsi que les dispositions relatives à l'évaluation de la conformité des produits aux exigences de la présente norme.

En l'absence de toute autre Norme européenne, la présente norme spécifie les dimensions, les tolérances et, le cas échéant, les exigences de performance, pour les ossatures de plafond et les éléments d'habillage couramment disponibles.

La présente norme ne couvre pas les produits suivants :

¾ plafonds installés dans des constructions mobiles, caravanes et autres formes de moyens de transport ;

¾ plafonds ayant des fonctions de chauffage ou de refroidissement ;

¾ plafonds soumis à des exigences en matière de pénétration de l'eau ;

¾ plafonds utilisés en extérieur auxquels s'appliquent des exigences autres que celles couvertes par le présent domaine d'application (tunnels, auvents, stations-service, arcades, installations sportives en plein air, parcs de stationnement, etc.) ;

¾ plafonds suspendus renforcés ou leur structure porteuse ;

¾ plafonds façonnés in situ sans membrane préfabriquée (par exemple, plafonds en plâtre).

La présente norme couvre les caractéristiques essentielles suivantes :

réaction au feu ;

résistance au feu (kits de plafonds suspendus uniquement) ;

rejet d'amiante (teneur) (kits de plafonds suspendus et éléments d'habillage uniquement) ;

rejet de formaldéhyde (kits de plafonds suspendus et éléments d'habillage uniquement) ;

caractéristiques d

Viseči stropi – Zahteve in preskusne metode

General Information

- Status

- Withdrawn

- Publication Date

- 09-Mar-2004

- Withdrawal Date

- 11-Mar-2014

- Technical Committee

- CEN/TC 277 - Suspended ceilings

- Drafting Committee

- CEN/TC 277 - Suspended ceilings

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 12-Mar-2014

- Completion Date

- 12-Mar-2014

Not Harmonized89/106/EEC - Construction productsOJ Ref: C 263, C 139, C 319, C 263, C 139, C 319, C 263, C OJ Date: 14-Dec-2005

Relations

- Effective Date

- 19-Mar-2014

- Effective Date

- 04-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 13964:2004 is a standard published by the European Committee for Standardization (CEN). Its full title is "Suspended ceilings - Requirements and test methods". This standard covers: The European Standard provides information for the various parties responsible for designing, manufacturing and specifying/selecting suspended ceilings used for interior applications in general building and civil engineering structures. It covers suspended ceilings sold as a complete kit (including, optionally, light fittings and other features), substructures sold as kits, individual components (products) of such substructures, and membrane components. It includes test methods and methods of assessment, as well as provisions for the evaluation of conformity of the products to the requirements of this standard. In the absence of any other European Standard, this standard specifies dimensions, tolerances and, where relevant, performance requirements, for commonly available ceiling substructures and membrane components.

The European Standard provides information for the various parties responsible for designing, manufacturing and specifying/selecting suspended ceilings used for interior applications in general building and civil engineering structures. It covers suspended ceilings sold as a complete kit (including, optionally, light fittings and other features), substructures sold as kits, individual components (products) of such substructures, and membrane components. It includes test methods and methods of assessment, as well as provisions for the evaluation of conformity of the products to the requirements of this standard. In the absence of any other European Standard, this standard specifies dimensions, tolerances and, where relevant, performance requirements, for commonly available ceiling substructures and membrane components.

EN 13964:2004 is classified under the following ICS (International Classification for Standards) categories: 91.060.30 - Ceilings. Floors. Stairs. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13964:2004 has the following relationships with other standards: It is inter standard links to EN 13964:2014, EN ISO 11925-2:2026, EN 1396:1996, EN ISO 12944-3:2017, EN 1993-1-9:2025, EN 717-1:2004, EN 10143:2006, EN 622-1:2003, EN ISO 6946:2017, EN 10346:2015, EN ISO 12460-3:2023, EN ISO 11925-2:2020, EN 1998-1-1:2024, EN 335:2013, EN ISO 717-1:2020. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13964:2004 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/121. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13964:2004 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Suspended ceilings - Requirements and test methodsPlafonds suspendus - Exigences et méthodes d'essaiUnterdecken - Anforderungen und Prüfverfahren91.060.30Stropi. Tla. StopniceCeilings. Floors. StairsICS:SIST EN 13964:2004enTa slovenski standard je istoveten z:EN 13964:200401-junij-2004SIST EN 13964:2004SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 13964March 2004ICS 91.060.30English versionSuspended ceilings - Requirements and test methodsPlafonds suspendus - Exigences et méthodes d'essaiUnterdecken - Anforderungen und PrüfverfahrenThis European Standard was approved by CEN on 3 November 2003.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Management Centre has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia,Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2004 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 13964:2004 E

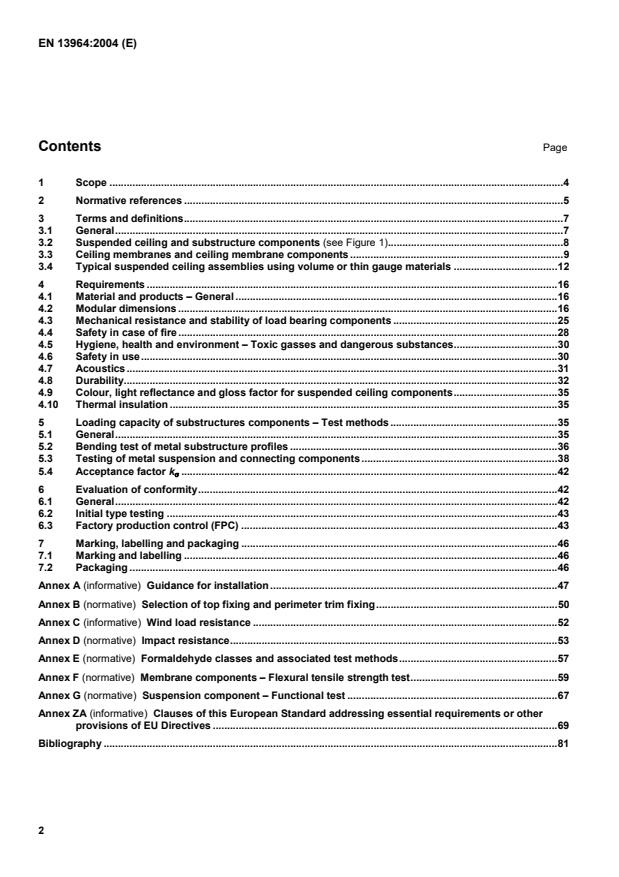

Guidance for installation.47Annex B (normative)

Selection of top fixing and perimeter trim fixing.50Annex C (informative)

Wind load resistance.52Annex D (normative)

Impact resistance.53Annex E (normative)

Formaldehyde classes and associated test methods.57Annex F (normative)

Membrane components – Flexural tensile strength test.59Annex G (normative)

Suspension component – Functional test.67Annex ZA (informative)

Clauses of this European Standard addressing essential requirements or otherprovisions of EU Directives.69Bibliography.81

Parallel to bottom flange+ 0,3-

0,3+ 0,3-

0,3+ 0,3-

0,3-+ 1,50-

1,50Bandraster+ 0,3- 0,3+ 0,3- 0,3-+ 0,3- 0,3+ 30- 30Furring channel+ 0,3- 0,3--+ 0,3- 0,3+ 30- 30Perimeter trims+ 0,5- 0,5--+ 0,3- 0,3+ 00- 30NOTE 1Measurements in mm are related to the manufactured sizeNOTE 2 nominal = 90°

Interlocking holes in section2

Splice in supporting componentDefinition:X : 1 Slot distanceY : Sum of slot distances

1,25 m including or excluding one spliceTolerance:X : + / - 0,25 mmY : + / - 0,30 mmCentre point substructureDefinition:M : Axis- axis distance between 2 main runnersX : Axis- axis distance between 2 cross teesTolerance:M : + / - 0,25 mm / mX : + / - 0,25 mm

03,0-mm-for width

04,0-mmb. Flatness :Key1

Tolerance b2

Tolerance al = length (mm)0 < l

1000 < l 20002000 < l

3000b = width (mm)ababab

0 < b

400400 <

b

500500 <

b

625625 <

b

1 250- 0,5+0,5- 0,5+0,5- 0,5+0,5- 0,5+0,5- 0,2+3,0- 0+4,0- 0+6,0- 0+10,0- 0,5+1,5- 0,5+1,5- 0,5+1,5- 0,5+1,5- 0,2+4,0- 0+5,0- 0+7,0- 0+13,0- 0,5+3,0- 0,5+3,5- 0,5+4,0--- 0,2+6,0- 0+7,0- 0+9,0--c.Angularity of the long edge in relation to short edgePanel width up to 625 mm

± 0,5 mmPanel width 625 mm to 1 250 mm

± 0,6 mmd.Depth of stops / supports ± 0,3 mm (measured on panel cut out edge)

Edge

Cut-out edgeDeviations from 90° angle on vertical upstand are dependent on the production process and the relative suspensionsystems. There are no fixed tolerances.Width 300mm

Load bearing structure

Linear component2

Top fixing

Perimeter trim3

Suspension

System height4

Supporting memberKey1

Load bearing structure

Linear component width2

Top fixing

Joint3

Suspension

Linear component module4

Supporting member

Join profile5

System height

Linear component

+ / - 0,5Component length (850 < 3 000) mm + / - 1,25

(3 000 Component width

+ / - 0,75Due to material and production propertiesadditional dimensional tolerances occur becauseof spring-back at the panel endsKeyA

Linear component lengthB

Linear component widthC

Linear component heightPlane and waves (dimensions in mm)PlaneKey1

Tolerance C2

Tolerance DKeyA

Linear component lengthB

Linear component widthLinear component width (in mm)0 < b 100 < b 200 < b 300 < b CCCC- 1,0- 1,25- 1,5- 1,75+ 1,5+ 2,0+ 2,5+ 2,7DDDD- 1,5- 2,5-3,5-4,0+ 1,5+ 2,0+2,5+2,7Concave = -Convex = +

Linear component spanLinear component width (in mm)0 < b 200 < b ABAB- 0,5+ 0,5- 0,8+ 0,8CamberThe deviation is maximum 1/1 500 ´ linear component length, measured in the middle of the length of the linear component(equals 0,67mm over 1,0m length).Deflection of the linearcomponentsThe maximum deflection between twosupporting members/ points of supportis 1/500 ´ supporting member distance,measured in the middle between thesupporting members/ points of support.Key1

Supporting member distance (linear component span)2

Supporting member3

Linear component4

Linear component deflection ( 1/500 ´ supporting member distance)Tolerance of the supporting member moduleThe tolerance of the supporting member module is ± 0,06 mm on a linear component module of 100 mm.

Supporting member length = X x Module – cutting toleranceB

Modular length supporting memberC

Supporting members' module1

Module tolerance2

Length tolerance3

Cutting toleranceDeflection of the supportingmembersThe maximum deflection of the supportingmembers between two suspension pointsis 1/500 x suspension distance, measuredin the middle between two suspensionpoints (Class 1, Table 6)Key1

Suspension distance (supporting member span)2

Supporting member deflection3

Linear component4

Supporting member5

Suspension4.3 Mechanical resistance and stability of load bearing components4.3.1 GeneralThis clause of the standard covers only the load bearing components of the suspended ceiling and ceiling lining. Itdoes not cover the mechanical characteristics of membrane components, for which see 4.6.2.The design of the suspended ceiling shall be made so that the admissible building tolerances (limits of buildingtolerances) and the movement and deflection of the adjoining building assemblies (elements) are considered.The stability of the suspended ceiling and / or the ceiling lining respectively shall not be reduced (disturbed) as aresult of the movement of adjoining building elements.In the case of partitions fixed to the suspended ceiling, the forces imposed by the partition shall be carried either bysuitable structural measures or transmitted by the suspended ceiling to the building structure.NOTEMost suspended ceilings are not designed to support the additional load imposed by a partition. In case partitionsare fixed to the suspended ceilings, only ceilings specifically designed for this purpose should be used.

1LB / 500 and not greater than 4,02LB / 3003No limitAThe maximum deflection is the accumulative value of the deflection of the substructure component and the deflection of themembrane componentBL is the span in mm between the suspension components or the suspension points4.3.2.2 Substructure materials4.3.2.2.1 Steel substructureWhere the substructure is formed in hot-galvanised strip or sheet of unalloyed steel, the minimum steel grade usedshall be DX 51D + Z according to EN 10142.If other steel types are used, they shall conform to either EN 10152 (ZE), EN 10169-1, EN 10214 (ZA) or EN 10215(AZ), as appropriate.The thickness tolerance shall be in accordance with EN 10143.For corrosion protection the minimum protection shall be in accordance with Table 8 related to the class ofexposure (see Table 7) to be encountered.4.3.2.2.2 Aluminium substructureWhere substructure members are made of aluminium alloy, the alloy shall be in accordance with EN 573-3 andhave 0,2 % yield strength of at least 160 N/mm2.For corrosion protection, the minimum protection shall be that given in Table 8.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...