EN 1114-1:2011

(Main)Plastics and rubber machines - Extruders and extrusion lines - Part 1: Safety requirements for extruders

Plastics and rubber machines - Extruders and extrusion lines - Part 1: Safety requirements for extruders

This European Standard specifies all significant hazards, hazardous situations and events relevant to all types of screw extruders for plastics and rubber, when they are used as intended and under conditions of misuse which are foreseeable by the manufacturer (see Clause 4).

This European Standard additionally covers the following feeding systems:

- hoppers;

- single roller feed;

- double roller feed;

- crammer feeder;

and the following ancillary equipment which form part of or are attached to the extruder:

- screen changers;

- melt/gear pumps;

- melt pipes and adaptors;

- static mixers;

- extruder head that give initial shape to the extruded material.

NOTE Metering devices are not covered by this standard.

This European Standard does not deal with hazards caused by the processing of materials and which may lead to a risk of fire or release of health hazardous materials.

An extruder conforming to this document is not regarded as a pressure vessel as defined in the Pressure Equipment Directive 97/23/EC.

Extruders usually do not produce explosive atmospheres. Where materials are processed, which may cause an explosive atmosphere, the Directive 94/9/EC on the Equipment intended for use in Potentially Explosive Atmospheres (ATEX) should be applied. Explosion hazards are not dealt with in this document.

This European Standard is not applicable to extruders which are manufactured before the date of its publication as EN.

Kunststoff- und Gummimaschinen - Extruder und Extrusionsanlagen - Teil 1: Sicherheitsanforderungen für Extruder

Diese Europäische Norm behandelt alle signifikanten Gefährdungen, Gefährdungssituationen und Gefährdungsereignisse, die auf alle Arten von Schneckenextrudern für Kunststoffe und Gummi zutreffen, wenn sie bestimmungsgemäß und unter Bedingungen, die vom Hersteller als Fehlanwendung vernünftigerweise vorhersehbar sind, verwendet werden (siehe Abschnitt 4). Diese Europäische Norm umfasst zusätzlich folgende Beschickungssysteme:

- Trichter;

- Einwalzen-Speiseeinrichtungen;

- Zweiwalzen-Speiseeinrichtungen;

- Stopfeinrichtungen; und folgende Zusatzeinrichtungen, die Teile des Extruders oder entlang des Extrudergehäuses angebracht sind:

- Siebwechsler;

- Schmelzepumpen/Zahnradpumpen;

- Schmelzeleitungen und -adapter;

⎯ statische Mischer;

⎯ Extrudierköpfe für die erste Ausformung des extrudierten Materials. ANMERKUNG Dosiereinrichtungen sind in dieser Norm nicht behandelt. Diese Europäische Norm behandelt nicht die Gefährdungen, die durch die verarbeiteten Materialien hervorgerufen werden und die zu einem Brandrisiko oder zu einem Risiko durch das Austreten gesundheitsgefährdender Materialien führen können. Ein Extruder, der mit diesem Dokument übereinstimmt, wird nicht als ein Druckbehälter nach der Druckgeräterichtlinie 97/23/EG angesehen. Extruder erzeugen üblicherweise keine explosionsfähigen Atmosphären. Wenn Materialien verarbeitet werden, die eine explosionsfähige Atmosphäre hervorrufen können, sollte die Richtlinie 94/7/EG für Geräte und Schutzsysteme zur bestimmungsgemäßen Verwendung in explosionsgefährdeten Bereichen angewendet werden. Gefährdungen durch Explosion sind in diesem Dokument nicht behandelt. Diese Europäische gilt nicht für Extruder, die vor Veröffentlichung dieser EN hergestellt wurden.

Machines pour les matières plastiques et le caoutchouc - Extrudeuses et lignes d'extrusion - Partie 1 : Prescriptions de sécurité pour les extrudeuses

La présente Norme européenne traite tous les phénomènes dangereux, situations et événements dangereux

significatifs concernant toutes les extrudeuses à vis pour les plastiques et le caoutchouc, lorsqu’elles sont

utilisées normalement et en cas de mauvaise utilisation prévisible par le constructeur (voir Article 4).

La présente Norme européenne couvre également les systèmes d’alimentation suivants :

- trémies ;

- alimentation à un galet bourreur ;

- alimentation à deux galets bourreurs ;

- alimentation par bourrage ;

ainsi que les équipements auxiliaires suivants, qui font partie de l’extrudeuse ou qui sont fixés sur celle-ci :

- changeurs de filtres ;

- pompes à engrenages ;

- conduites et raccords ;

- mélangeurs statiques ;

- têtes d’extrusion qui donnent la forme initale au matériau extrudé.

NOTE La présente norme ne couvre pas les dispositifs de dosage.

La présente Norme européenne ne traite pas des phénomènes dangereux dus au traitement des matériaux et

susceptibles d’entraîner un risque d’incendie ou la libération de substances dangereuses pour la santé.

Une extrudeuse conforme à la présente norme n’est pas considérée comme un récipient sous pression tel

que défini dans la Directive 97/23/CE relative aux équipements sous pression.

Généralement, les extrudeuses ne produisent pas d’atmosphères explosives. En cas de traitement de

matériaux susceptibles de créer une atmosphère explosive, il convient d’appliquer la Directive 94/9/CE

relative aux équipements destinés à être utilisés en atmosphères explosibles (ATEX). Le présent document

ne traite pas des phénomènes dangereux liés aux explosions.

La présente Norme européenne n’est pas applicable aux extrudeuses qui ont été fabriquées avant sa date de

publication comme EN.

Stroji za predelavo gume in plastike - Ekstruderji in oprema za iztiskavanje - 1. del: Varnostne zahteve za ekstruderje

Ta evropski standard obravnava vse velike nevarnosti, nevarne situacije in primere, ki se nanašajo na ekstruderje, kadar se uporabljajo, kot je predvideno, in pod pogoji napačne uporabe, ki jih predvidi proizvajalec (glej točko 4). Naslednje vrste ekstruderjev za plastike in gumo so zajete v tem standardu: ekstruderji z enim vijakom, ekstruderji z dvema vijakoma, ekstruderji z več vijaki, ekstruderji z vročim podajanjem, ekstruderji s hladnim podajanjem, vakuumski ekstruderji, ekstruderji z iglo. Ta standard dodatno zajema naslednje podajalne sisteme: vsipne lijake, podajalne sisteme z enim valjem, podajalne sisteme z dvema valjema, podajalne sisteme za vsipanje. Prav tako velja za naslednjo pomožno opremo, ki tvori del oziroma je priključena na ekstruder: izmenjalnike rešet, zobniške črpalke za taline, jaške za taline, opremo za razplinjevanje, naprave s strižnimi glavami, glavo ekstruderja. Ta standard velja samo za glave ekstruderjev, ki dajejo začetno obliko plastičnemu materialu. Ta standard ne velja za ekstruderje brez vijakov, npr.: ekstruderje z bati, ekstruderje z diski, ekstruderje z valji. Ta dokument ne velja za ekstruderje, ki so bili proizvedeni pred datumom objave dokumenta.

General Information

- Status

- Published

- Publication Date

- 18-Oct-2011

- Withdrawal Date

- 29-Apr-2012

- Technical Committee

- CEN/TC 145 - Rubber and plastics machines - Safety

- Drafting Committee

- CEN/TC 145/WG 3 - Extruders and extrusion lines - Safety

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 06-Sep-2016

- Completion Date

- 09-Feb-2026

- Directive

- 98/37/EC - Machinery

Relations

- Effective Date

- 08-Jun-2022

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview - EN 1114-1:2011 (CEN)

EN 1114-1:2011 is the CEN European standard that sets out safety requirements for screw extruders used in the plastics and rubber industries. It specifies the significant hazards, hazardous situations and events relevant to screw extruders when used as intended and under foreseeable misuse. The standard also covers common feeding systems (hoppers, single/double roller feeds, crammer feeders) and ancillary equipment attached to extruders such as screen changers, melt/gear pumps, melt pipes and adaptors, static mixers and extruder heads. Metering devices, explosion hazards (ATEX), fire originating from processed materials and pre‑existing machines are outside its scope.

Key topics and technical requirements

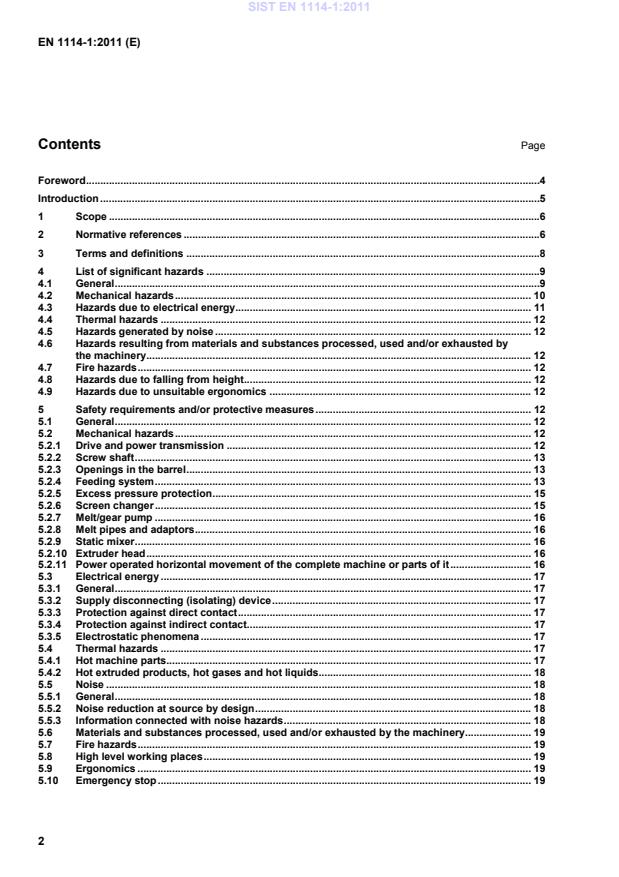

EN 1114-1:2011 organizes safety requirements around major hazard types and machine functions. Important topics include:

- Mechanical hazards: drive and power transmission, screw shaft, barrel openings, feeding systems, screen changers, melt pumps, static mixers, extruder heads, and moving parts protection.

- Electrical safety: requirements for electrical equipment, isolation/disconnect, protection against direct and indirect contact, and electrostatic phenomena.

- Thermal hazards: guarding for hot machine parts, hot extrudate, hot gases and liquids.

- Noise: noise assessment and the included Noise test code (Annex A) for measuring A‑weighted sound pressure and sound power levels.

- Materials-related hazards: guidance on hazards from processed materials (note: specific fire/toxic risks from materials processing are excluded).

- Ergonomics and working at height: design principles to reduce operator strain and fall risks.

- Protective measures and emergency systems: excess pressure protection, emergency stop, verification of conformity, machine marking and instruction manual requirements.

- Conformity and verification: procedures for checks, documentation and information for safe use.

Practical applications - who uses this standard

EN 1114-1 is used by:

- Extruder and extrusion-line manufacturers for safe design and CE‑compliance.

- Machine designers and OEMs integrating feeding systems and ancillary equipment.

- Safety engineers and maintenance teams implementing guards, interlocks, emergency stops and thermal/noise controls.

- Certification bodies and conformity assessors verifying compliance with EU Machinery Directive (see Annex ZA).

- Purchasing/procurement and plant engineers specifying safe extruders for production lines.

Related standards and notes

- Linked to EU Machinery Directive 2006/42/EC (see Annex ZA).

- Cross‑references to EN standards on guards, electrical equipment (EN 60204‑1), acoustics (EN ISO 11201, 3744, 3746), hydraulics (EN ISO 4413) and human factors (EN 614‑1).

- Does not cover ATEX (Directive 94/9/EC) or pressure vessels (Directive 97/23/EC).

Using EN 1114-1:2011 helps reduce mechanical, electrical, thermal and noise risks on screw extruders and supports safe design, operation and legal conformity of plastics and rubber extrusion equipment.

Get Certified

Connect with accredited certification bodies for this standard

Smithers Quality Assessments

US management systems and product certification.

DIN CERTCO

DIN Group product certification.

Sponsored listings

Frequently Asked Questions

EN 1114-1:2011 is a standard published by the European Committee for Standardization (CEN). Its full title is "Plastics and rubber machines - Extruders and extrusion lines - Part 1: Safety requirements for extruders". This standard covers: This European Standard specifies all significant hazards, hazardous situations and events relevant to all types of screw extruders for plastics and rubber, when they are used as intended and under conditions of misuse which are foreseeable by the manufacturer (see Clause 4). This European Standard additionally covers the following feeding systems: - hoppers; - single roller feed; - double roller feed; - crammer feeder; and the following ancillary equipment which form part of or are attached to the extruder: - screen changers; - melt/gear pumps; - melt pipes and adaptors; - static mixers; - extruder head that give initial shape to the extruded material. NOTE Metering devices are not covered by this standard. This European Standard does not deal with hazards caused by the processing of materials and which may lead to a risk of fire or release of health hazardous materials. An extruder conforming to this document is not regarded as a pressure vessel as defined in the Pressure Equipment Directive 97/23/EC. Extruders usually do not produce explosive atmospheres. Where materials are processed, which may cause an explosive atmosphere, the Directive 94/9/EC on the Equipment intended for use in Potentially Explosive Atmospheres (ATEX) should be applied. Explosion hazards are not dealt with in this document. This European Standard is not applicable to extruders which are manufactured before the date of its publication as EN.

This European Standard specifies all significant hazards, hazardous situations and events relevant to all types of screw extruders for plastics and rubber, when they are used as intended and under conditions of misuse which are foreseeable by the manufacturer (see Clause 4). This European Standard additionally covers the following feeding systems: - hoppers; - single roller feed; - double roller feed; - crammer feeder; and the following ancillary equipment which form part of or are attached to the extruder: - screen changers; - melt/gear pumps; - melt pipes and adaptors; - static mixers; - extruder head that give initial shape to the extruded material. NOTE Metering devices are not covered by this standard. This European Standard does not deal with hazards caused by the processing of materials and which may lead to a risk of fire or release of health hazardous materials. An extruder conforming to this document is not regarded as a pressure vessel as defined in the Pressure Equipment Directive 97/23/EC. Extruders usually do not produce explosive atmospheres. Where materials are processed, which may cause an explosive atmosphere, the Directive 94/9/EC on the Equipment intended for use in Potentially Explosive Atmospheres (ATEX) should be applied. Explosion hazards are not dealt with in this document. This European Standard is not applicable to extruders which are manufactured before the date of its publication as EN.

EN 1114-1:2011 is classified under the following ICS (International Classification for Standards) categories: 83.200 - Equipment for the rubber and plastics industries. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1114-1:2011 has the following relationships with other standards: It is inter standard links to EN 1114-1:1996, EN 60529:1991, EN 574:1996+A1:2008, EN ISO 14122-3:2001/A1:2010, EN 1037:1995+A1:2008, EN ISO 14122-1:2001, EN ISO 14122-3:2001, EN ISO 3744:2010, EN ISO 14122-2:2001/A1:2010, EN ISO 13732-1:2008, EN ISO 11202:2010, EN ISO 14122-2:2001, EN ISO 3747:2010, EN ISO 9614-2:1996, EN 614-1:2006+A1:2009. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1114-1:2011 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/079, M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1114-1:2011 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Stroji za predelavo gume in plastike - Ekstruderji in oprema za iztiskavanje - 1. del: Varnostne zahteve za ekstruderjeKunststoff- und Gummimaschinen - Extruder und Extrusionsanlagen - Teil 1: Sicherheitsanforderungen für ExtruderMachines pour les matières plastiques et le caoutchouc - Extrudeuses et lignes d'extrusion - Partie 1: Exigences de sécurité pour les extrudeusesPlastics and rubber machines - Extruders and extrusion lines - Part 1: Safety requirements for extruders83.200Oprema za gumarsko industrijo in industrijo polimernih materialovEquipment for the rubber and plastics industriesICS:Ta slovenski standard je istoveten z:EN 1114-1:2011SIST EN 1114-1:2011en,fr,de01-december-2011SIST EN 1114-1:2011SLOVENSKI

STANDARDSIST EN 1114-1:20001DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1114-1

October 2011 ICS 83.200 Supersedes EN 1114-1:1996English Version

Plastics and rubber machines - Extruders and extrusion lines - Part 1: Safety requirements for extruders

Machines pour les matières plastiques et le caoutchouc - Extrudeuses et lignes d'extrusion - Partie 1 : Prescriptions de sécurité pour les extrudeuses

Kunststoff- und Gummimaschinen - Extruder und Extrusionsanlagen - Teil 1: Sicherheitsanforderungen für Extruder This European Standard was approved by CEN on 17 September 2011.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2011 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1114-1:2011: ESIST EN 1114-1:2011

Noise test code . 24A.1 Introduction . 24A.2 Determination of the A-weighted emission sound pressure level at the workstation . 24A.3 Determination of the A-weighted sound power level . 24A.4 Mounting and operating conditions . 25A.5 Information to be recorded and reported . 25A.5.1 General . 25A.5.2 General data . 25A.5.3 Mounting and operating conditions . 25A.5.4 Standards . 26A.5.5 Noise data. 26A.6 Declaration and verification of noise emission values . 26Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC . 27Bibliography . 28 SIST EN 1114-1:2011

Crushing Shearing Cutting and severing Drawing-in or trapping Ejection of parts of machinery Splashing of material Corresponding requirements in Clause 5.2 Rotating parts of the drive and power transmission machinery

X

X

X

X

X

5.2.1 Rotation of screw(s)

X

X

X

X

5.2.2,

5.2.3,

5.2.4 Moving parts of the feeding system

X

X

X

X

5.2.4.2,

5.2.4.3,

5.2.4.4 Overpressure in the barrel

X

X 5.2.3.2,

5.2.5 Accessible moving parts of the screen changer

X

X

X

X

X

5.2.6 Accessible moving parts of the drive of the melt/gear pump

X

X

X

X

5.2.7 Overpressure in melt/gear pump

X

X 5.2.5, 5.2.7 Overpressure in melt pipes and adaptors

X

X 5.2.5,

5.2.8 Overpressure in static mixer

X

X 5.2.5, 5.2.9 Dangerous movement of the extruder head and/or its parts

X

X

X

X

5.2.10

Extruder itself when moved or moving

X

5.2.11

4.3 Hazards due to electrical energy Electrical shock or burns due for example to direct or indirect contact with live parts; electrical shock due to electrostatic phenomena. SIST EN 1114-1:2011

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...