EN 1493:2010

(Main)Vehicle lifts

Vehicle lifts

This European Standard applies to stationary, mobile and movable vehicle lifts, which are not intended to lift persons but which are designed to raise vehicles totally, for the purpose of examining and working on or under the vehicles whilst in a raised position. The vehicle lift may consist of one or more lifting-units.

Power supply to the vehicle lift by internal combustion engines is not considered.

The floor or ground supporting the vehicle lift in use is assumed to be horizontal.

This document is not applicable to vehicle lifts which are manufactured ½ year after the date of its publication as EN.

Fahrzeug-Hebebühnen

Diese Europäische Norm gilt für stationäre, fahrbare und ortsveränderliche Fahrzeug-Hebebühnen, die

bestimmungsgemäß nicht für das Heben von Personen, sondern zum vollständigen Anheben von Fahrzeugen

vorgesehen sind, um die angehobenen Fahrzeuge zu untersuchen und an oder unter ihnen zu arbeiten.

Fahrzeug-Hebebühnen können aus einer oder mehreren Hubeinheiten bestehen.

Ein Antrieb der Fahrzeug-Hebebühne durch Verbrennungsmotoren wird nicht betrachtet.

Es wird vorausgesetzt, dass der Boden, auf dem die Fahrzeug-Hebebühne benutzt wird, horizontal ist.

Dieses Dokument ist anwendbar für Fahrzeug-Hebebühnen, die ½ Jahr nach der Veröffentlichung als

EN hergestellt wurden.

Élévateurs de véhicules

La présente norme européenne s'applique aux élévateurs de véhicules fixes, mobiles et déplaçables, qui ne sont

pas prévus pour le levage de personnes, mais qui sont conçus pour élever tout le véhicule afin de permettre les

travaux de vérification, d'entretien et de réparation sur ou sous le véhicule lorsqu'il est en position levée.

L'élévateur de véhicule peut consister en une ou plusieurs unités de levage.

L'alimentation en énergie de l'élévateur de véhicule par des moteurs à combustion interne n'a pas été envisagée.

Le plancher ou le sol supportant l'élévateur de véhicule lors du fonctionnement est supposé être horizontal.

Ce document est applicable aux élévateurs de véhicule qui sont fabriqués 6 mois après la date de publication en

norme EN.

Dvigala za servisiranje vozil

Ta evropski standard velja za nepremična, prenosna in premična dvigala za servisiranje vozil, ki niso namenjena dvigovanju oseb, pač pa so zasnovana za popoln dvig vozila za pregled in delo na vozilu ali pod njim, medtem ko je to dvignjeno. Dvigalo za servisiranje vozil je lahko sestavljeno iz ene ali več dvižnih enot. Pogon dvigala za servisiranje vozil s stroji z notranjim izgorevanjem ni obravnavan. Predpostavlja se, da so tla ali podlaga, ki podpira dvigalo za servisiranje vozil, vodoravna. Ta dokument velja za dvigala za servisiranje vozil, ki so bila izdelana pol leta po datumu, ko je bil objavljen kot EN.

General Information

- Status

- Withdrawn

- Publication Date

- 03-Aug-2010

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 98 - Lifting platforms

- Drafting Committee

- CEN/TC 98/WG 3 - Vehicle lifting devices

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 09-Nov-2022

- Completion Date

- 11-Feb-2026

- Directive

- 98/37/EC - Machinery

- Ref Project

SIST EN 1493:2010 - Vehicle lifts

Relations

- Effective Date

- 08-Jun-2022

- Replaced By

EN 1493:2022 - Vehicle lifts - Effective Date

- 16-Nov-2022

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN ISO 13850:2008 - Safety of machinery - Emergency stop - Principles for design (ISO 13850:2006) - Effective Date

- 28-Jan-2026

- Revised

EN 1493:1998 - Vehicle lifts - Effective Date

- 22-Dec-2008

Get Certified

Connect with accredited certification bodies for this standard

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

AIAG (Automotive Industry Action Group)

American automotive industry standards and training.

Sponsored listings

Frequently Asked Questions

EN 1493:2010 is a standard published by the European Committee for Standardization (CEN). Its full title is "Vehicle lifts". This standard covers: This European Standard applies to stationary, mobile and movable vehicle lifts, which are not intended to lift persons but which are designed to raise vehicles totally, for the purpose of examining and working on or under the vehicles whilst in a raised position. The vehicle lift may consist of one or more lifting-units. Power supply to the vehicle lift by internal combustion engines is not considered. The floor or ground supporting the vehicle lift in use is assumed to be horizontal. This document is not applicable to vehicle lifts which are manufactured ½ year after the date of its publication as EN.

This European Standard applies to stationary, mobile and movable vehicle lifts, which are not intended to lift persons but which are designed to raise vehicles totally, for the purpose of examining and working on or under the vehicles whilst in a raised position. The vehicle lift may consist of one or more lifting-units. Power supply to the vehicle lift by internal combustion engines is not considered. The floor or ground supporting the vehicle lift in use is assumed to be horizontal. This document is not applicable to vehicle lifts which are manufactured ½ year after the date of its publication as EN.

EN 1493:2010 is classified under the following ICS (International Classification for Standards) categories: 43.180 - Diagnostic, maintenance and test equipment; 53.020.99 - Other lifting equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1493:2010 has the following relationships with other standards: It is inter standard links to EN 1493:1998+A1:2008, EN 1493:2022, EN 60204-32:2008, EN 60947-5-1:2004, EN 60529:1991, EN ISO 13849-1:2008, EN 982:1996+A1:2008, EN ISO 12100-1:2003, EN 2286:1989, EN 14504:2016, EN 983:1996+A1:2008, EN ISO 13849-2:2008, EN ISO 12100-2:2003, EN ISO 13850:2008, EN 1493:1998. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1493:2010 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/396, M/BC/CEN/91/1. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1493:2010 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Dvigala za servisiranje vozilFahrzeug-HebebühnenÉlévateurs de véhiculesVehicle lifts53.020.99Druga dvigalna opremaOther lifting equipment43.180Diagnostic, maintenance and test equipmentICS:Ta slovenski standard je istoveten z:EN 1493:2010SIST EN 1493:2010en,fr,de01-oktober-2010SIST EN 1493:2010SLOVENSKI

STANDARDSIST EN 1493:1999+A1:2009SIST EN 1493:19991DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1493

August 2010 ICS 43.180; 53.020.99 Supersedes EN 1493:1998+A1:2008English Version

Vehicle lifts

Elévateurs de véhicules

Fahrzeug-Hebebühnen This European Standard was approved by CEN on 26 June 2010.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2010 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1493:2010: ESIST EN 1493:2010

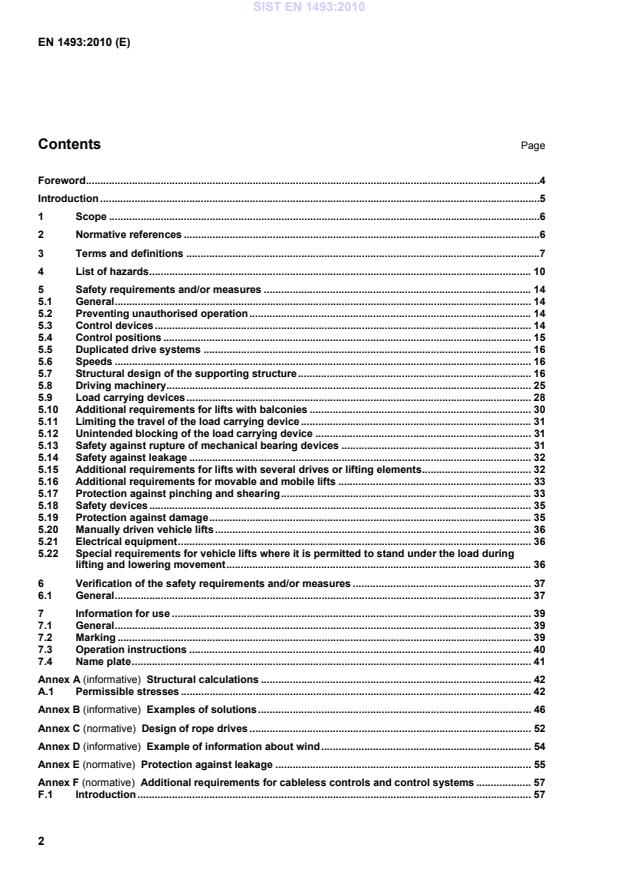

Structural calculations . 42A.1Permissible stresses . 42Annex B (informative)

Examples of solutions . 46Annex C (normative)

Design of rope drives . 52Annex D (informative)

Example of information about wind . 54Annex E (normative)

Protection against leakage . 55Annex F (normative)

Additional requirements for cableless controls and control systems . 57F.1Introduction . 57SIST EN 1493:2010

Noise . 60Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC . 61Bibliography . 62 SIST EN 1493:2010

The requirement concerning loading control is not deemed pertinent to this standard insofar as: experience and the state of the art suggests that failing to observe this requirement has not historically given rise to unsafe situations; such devices which would give protection against overall and local overloading are not currently available in forms which cover all eventualities; the weight and weight distribution is freely available for the type of vehicles to be lifted and as such it is the responsibility of the user to prevent an unsafe situation arising; vehicle lifts are generally designed to suit the maximum weight of vehicle to which it would reasonably be subjected, hence the normal duty of a lift is substantially lower than the maximum.

NOTE 1 The guidance of the load carrying device is given by the supporting structure. NOTE 2 A vehicle lift may have the ability to tilt the load carrying device about a horizontal axis parallel to or perpendicular to the main axis of the lifted vehicle. NOTE 3 The following types of vehicle lift are examples of those covered by this definition: single and multi-column lifts, single and multi-cylinder lifts, mobile column lifts, scissor and parallelogram lifts, short stroke lifts, which support vehicle wheels, chassis or other designated lifting points (see Annex B (informative)). NOTE 4 Short stroke lifts are floor mounted vehicle lifts with a maximum vertical travel of not more than 500 mm, which are not designed for working under the raised load. 3.2 manually driven vehicle lift vehicle lift where the load carrying device is driven by manual effort 3.3 power-driven vehicle lift vehicle lift where the load carrying device is not driven by manual effort 3.4 fixed vehicle lift vehicle lift fixed permanently to its location 3.5 movable vehicle lift vehicle lift which can fulfil its function without being fixed to the floor and may be designed to be transportable 3.6 mobile vehicle lift movable vehicle lift equipped with wheels, rollers, etc. such that it can be moved from one place to another with or without load 3.6.1 manually mobile vehicle lift mobile vehicle lift which is moved by manual effort alone 3.6.2 vehicle lift with powered mobility mobile vehicle lift which is not moved by manual effort 3.7 initial position lower limit position of the carrying device SIST EN 1493:2010

NOTE Carrying arms are usually used on two column lifts. 3.11 pick-up plate part of the load carrying device, e.g. on two column lifts with carrying arms, which has direct contact to the vehicle and which has an assigned position on the load carrying device

NOTE See Figure 1. 3.12 pick-up pad vehicle supporting pad which has direct contact with the vehicle but which does not have an assigned position, e.g. pads used on wheel free systems with platforms

NOTE See Figure 2.

Key

1 pick-up plate

2 load carrying device

3 pin Figure 1 — Pick-up plate SIST EN 1493:2010

Key

1 pick-up pad

2 platform Figure 2 — Pick-up pad 3.13 lifting element medium through which the force is transmitted from the power source to the load carrying device

NOTE Lifting elements include hydraulic and pneumatic cylinders, lead screw and nut systems as well as any flexible connections such as steel wire ropes and chains. 3.14 catching device device which holds the load carrying device in case of failure of the lifting element 3.15 re-raising prevention device device which prevents re-raising of load carrying device from the initial position in the event of failure of the lifting element 3.16 unauthorised use use by a person who has not received permission to operate the lift and instruction on its safe operation 3.17 braking 3.17.1 automatic brake braking device which is normally held on and which is released only by application of power NOTE Operation is also instigated automatically by releasing the lift controls and by interruption of the power supply. 3.17.2 self braking system system which, due to its inherent resistance to movement, stops the movement of the load carrying device when the drive power is interrupted 3.18 safety switch switch in which the opening contacts are directly connected to the control mechanism without springs or flexible elements

NOTE The whole of the specified opening of the contacts should be achieved by operation of the control mechanism through its intended travel using the force stated by the manufacturer of the switch (see K.2.1 of EN 60947-5-1:2004). SIST EN 1493:2010

road vehicle used for calculations in 5.7 3.20 wheel track distance between the centre lines of the wheels on one axle or between centre lines of wheel pairs on twin wheel axles 3.21 wheel base distance between the centres of wheels of front and rear axle or from the centre of the wheels on the front axle to a point mid way between axle pairs on twin axle vehicles 3.22 multiple lifting units combination of independent couples of mobile column lifts or two or more vehicle lifts 3.23 wheel free system lifting unit which is used in conjunction with a pit or vehicle lift with platform lifting the whole vehicle and allows the wheels to be removed 4 List of hazards Table 1 contains a list of hazards which are applicable in the situations described and could involve risks to persons if not reduced or eliminated. The corresponding requirements are designed to limit the risk or reduce these hazards in each situation. "Not applicable" in Table 1 means that this hazard does not exist on vehicle lifts. "Not significant" in Table 1 means that this hazard can exist on vehicle lifts, but it causes no risk to persons. SIST EN 1493:2010

(e.g. loss of balance, loss of awareness, etc.) see Annex G

(contact with moving parts, exhaust gases, etc.) not applicable 14.2 Inadequate visibility from driver's/operator's position not applicable 14.3 Inadequate seat/seating (seat index point) not applicable 14.4 Inadequate/inergonomic design/positioning of controls 5.4.1 14.5 Starting/moving of self-propelled machinery 5.16.1, 5.16.2 14.6 Road traffic of self-propelled machinery not applicable 14.7 Movement of pedestrian controlled machinery 5.16.3 15 Mechanical hazards 15.1 Hazards to exposed persons due to uncontrolled movement 5.16.1 15.2 Hazards due to break-up and/or ejection of parts not applicable 15.3 Hazards due to rolling over (deflection limiting volume; DVL) not applicable 15.4 Hazards due to falling objects not applicable 15.5 Inadequate means of access 5.10 15.6 Hazards caused due to towing, coupling, connecting, transmission etc. not applicable 15.7 Hazards due to batteries, fire, emissions, etc. 5.21.3, 5.21.4 HAZARDS DUE TO LIFTING OPERATION 16.1 Lack of stability 5.7 16.2 Derailment of machinery 5.16.4 SIST EN 1493:2010

5 Safety requirements and/or measures 5.1 General Machinery shall comply with the safety requirements and/or protective measures of this clause. In addition, the machine shall be designed according to the principles of EN ISO 12100 (all parts) for relevant but not significant hazards, which are not dealt with by this document. 5.2 Preventing unauthorised operation Vehicle lifts shall be equipped with an accessible and fixed device that prevents unauthorized use after taking the lift out of operation (refer to Annex B (informative)). 5.3 Control devices 5.3.1 Hold-to-run control Control devices shall be of the hold-to-run type and shall fulfil the conditions of performance level c of EN ISO 13849-1:2008. The stop-function shall comply with category 0 of 9.2.2 of EN 60204-1:2006. 5.3.2 Grouped control devices If the control devices for more than one vehicle lift are grouped together in one position each control device shall be clearly marked to show which vehicle lift it controls. 5.3.3 Logical operation The control devices shall be designed so that the movement of the control and its location are consistent with its effect (refer to Annex B (informative)). 5.3.4 Marking The direction of the movement of the lifting element shall be permanently marked (refer to Annex B (informative)). The marks shall be suitable symbols or text and can be located on the control devices themselves or directly adjacent to them. 5.3.5 Inadvertent operation Control devices shall be protected from unintentional operation (refer to Annex B (informative)). SIST EN 1493:2010

NOTE This needs negotiation between user and manufacturer respectively supplier of the vehicle lift. In addition if the vehicle lift is mobile the operator shall be able to observe the space especially in moving direction of the vehicle lift. 5.4.3 Controlling several load carrying devices If the load carrying devices of a vehicle lift are intended to be moved independently, a selection control shall be provided that enables: a) the independent movement of each load carrying device; and b) movements of all load carrying devices together. Other combinations of movements of the load carrying devices may also be incorporated and selected by the selection control. The non-selected load carrying devices shall be prevented from operating. 5.4.4 Emergency stop device At a column lift for rail-bound vehicles, each column shall be equipped with an emergency stopping device which fulfils the requirements of EN ISO 13850:2008 and stops the movements of all columns. The emergency stop device shall comply with performance level d of EN ISO 13849-1:2008. The main switch can act as an emergency stop (refer to 5.3.3 and 10.7.4 of EN 60204-1:2006). SIST EN 1493:2010

5.6.2 Tilting speed The speed of tilting, measured at the part of the load carrying device which is furthest away from the turning centre, shall not exceed 0,1 m/s. 5.7 Structural design of the supporting structure 5.7.1 General The design of vehicle lifts in relation to materials, construction and equipment shall be such that a satisfactory level of safety is achieved under all operating conditions including the failure situations described in this standard. This shall be demonstrated by calculation. Use of the permissible stress method is allowable. The stress, resulting from the most unfavourable load distribution, shall be calculated for each load bearing part. For permissible stresses refer to Annex A (informative). The values of Annex A are given under the condition of 22 000 load cycles at rated load. If this value is exceeded, fatigue calculation shall be performed for structure and mechanism. In case of exceptional situation the yield stress divided by a safety factor of 1,1 is acceptable. Wheel support vehicle lifts for road vehicles shall be designed in such a way that during normal operation the maximum inclination of the platform in its longitudinal axes is limited to 1°.

5.7.2 Loads and forces 5.7.2.1 Regular loads a) Structural loads The masses of components of the vehicle lift produce the structural loads. 1) Loads due to components which are not moving are considered to be static structural loads. 2) Loads due to moving components are considered to be dynamic structural loads. b) Rated load SIST EN 1493:2010

5.7.2.3 Exceptional loads a) Out-of-service wind If the vehicle lift is designed for outside use the influence of wind forces in the wheel base direction shall be included in the stress calculation (see also 5.7.3). The maximum pressure of out-of-service wind is 500 N/m2, which is related to a wind speed of 28 m/s. The wind forces acting on the normative vehicle (refer to Table 4) shall be derived from Table 2. It is assumed that in any case the operator lowers the raised vehicle in the nearest position to the ground level at the end of his working time. A corresponding requirement shall be written in the operation instructions if the vehicle lift is designed for outside use. For the overturning stability calculation a stabilising weight effect of 1 kN for each square metre of exposed vehicle surface to the wind can be considered as stabilising moment (refer to Table 2). b) Action 1) of the catching device; or 2) of the re-raising prevention device. c) Test load for: 1) dynamic test (see 6.1.5.2); 2) static test (see 6.1.5.3). SIST EN 1493:2010

Structural loads – static a1 1 1 1 1 1 1 1 Structural loads – dynamic a2 φ 1 φ 1 1 1 1 Rated load b φ 1 φ 1 1 1 1 Manual forces d - 1 - 1 - - - Effect of accessories e φ 1 φ 1 1 1 1 Effect of inclination f φ 1 φ 1 1 1 1 Occasional loads - In-service wind 5.7.2.2 - - 1 1 - - - Exceptional loads 5.7.2.3

Out-of-service wind a - - - - 1 - - Action of the catching device b1 - - - - - 1 - Action of the re-raising prevention device b2 - - - - - - 1

Load combination A1:

Normal operation (raising/lowering) without wind or special forces Load combination A2:

Normal operation (service/repair work) without wind or special forces Load combination B1:

Normal operation (raising/lowering) with wind force Load combination B2:

Normal operation (service/repair work) with wind force Load combination C1:

Vehicle lift out of service with wind force Load combination C2:

Action of the catching device Load combination C3:

Action of the re-raising prevention device φ: Multiplication factor according to 5.7.2.1. 5.7.4 Load distribution 5.7.4.1 General The following requirements shall be fulfilled if no special data are specified by the customer. The rated load shall be distributed on the four corners of a rectangle with the width equating to wheel track and the length to wheel base. 5.7.4.2 Wheel support vehicle lift for road vehicles The rated load shall be distributed according to normative vehicle dimensions as shown in Table 4. SIST EN 1493:2010

WT

m

Wheel base

m Axle load ratios Min. distance

m WB1 WB2 WB3 AL1/P AL2/P AL3/PX1 X2 a P ≤ 2,5 Passenger cars 2

1,5 2,5 - - 0,40 0,60 - 0,3 0,3 b 2,5 < P ≤ 3,5 Commercial light truck 2

1,6 3 - - 0,40 0,60 - 0,3 0,3 c 3,5 < P ≤ 7,5 Commercial medium trucks 2 1,7 3 - - 0,33 0,66 - 0,3 0,3 d 7,5 < P ≤ 20 Lorries 2/3

1,8 3,5 - - 0,33 0,66 - 0,5 0,5 e 20 < P ≤ 30 Lorries 3

1,9 4 - - 0,33 0,66 - 0,5 1 f 30 < P ≤ 40 Lorries 4

1,9 4,5 - - 0,45 0,55 - 1 1 g P ≤ 25 Articulated busses 3

1,8 5,5 6,5 - 0,25 0,30 0,45 0,5 0,5 h P ≤ 40 Articulated lorries 4

1,9 3,5 7 - 0,20 0,30 0,50 0,5 1

m Wheel base

m Axle load ratios Min. distance

m WB1 WB2 WB3 AL1/P AL2/P AL3/PX1 X2 i 40 < P ≤ 52 Articulated lorries ≥ 5

1,9 3,5 7 - 0,20 0,30 0,50 0,5 1,6 j P ≤ 40 Lorries with trailer 4

1,9 3,5 3 3,5 0,17 0,33 - 0,5 0,5 k 40 < P ≤ 52 Lorries with trailer ≥ 5

1,9 4, 3 4 0,17 0,33 - 0,5 1 l P ≤ 45 Lorries with trailer ≥ 5

1,9 4 5 - 0,20 0,40 0,40 0,5 1 SIST EN 1493:2010

For rated loads ≤ 3,5 t the load ratios between the front and rear load carrying points shall be (in both

directions): 2 : 3 and 3 : 2 (maximum load one pick-up point 3/10 of P)

On platform lifts the rated load shall be distributed on the four corners of a rectangle with the dimensions

of: 100 cm (width) × 140 cm (length); and 170 cm (width) × 140 cm (length)

at the maximum length of the platform and at the worst condition (with the maximum load at the corner of

the platform or platform extension).

On vehicle lifts with carrying arms the rated load shall be distributed on the four corners of a rectangle

with the dimensions of 100 cm (width) with the maximum load at the maximum length of the longest arm

and the short arm in the position which gives the worst condition. b) Rated load > 3,5 t

For rated loads > 3,5 t the load ratios between the front and rear load carrying points shall be (in both

directions): 1 : 3 and 3 : 1 (maximum load one pick-up point 3/8 P)

On platform lifts the rated load shall be distributed on the four corners of a rectangular with the

dimensions of: 100 cm (width) × 180 cm (length); and 170 cm (width) × 180 cm (length)

at the maximum length of the platform and at the worst condition (with the maximum load at the corner of

the platform or platform extension).

On vehicle lifts with carrying arms the rated load shall be distributed on the four corners of a rectangle

with the dimensions of 100 cm (width) with the maximum load at the maximum length of the longest arm

and the short arm in the position which gives the worst condition. 5.7.4.4 Special vehicle lifts (lifts for forklift trucks, dumpers, rail-bound vehicles, etc.) Where the prescriptions of 5.7.4.2 and 5.7.4.3 cannot be applied: a) the load distribution shall be in accordance with the axle loadings of the vehicles which are to be lifted. If the lift is intended for use with different models of vehicle, the distribution shall suit the most unfavourable model; SIST EN 1493:2010

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...