EN 1493:1998+A1:2008

(Main)Vehicle lifts

Vehicle lifts

This standard applies to stationary, mobile and movable vehicle lifts, which are not intended to lift persons but which are designed to raise vehicles totally, for the purpose of examining and working on or under the vehicles whilst in a raised position. The vehicle lift may consist of one or more lifting units.

Power supply to the vehicle lift by internal combustion engines is not considered. The floor or ground supporting the vehicle lift in use is assumed to be horizontal.

Fahrzeug-Hebebühnen

Diese Norm gilt für stationäre, fahrbare und ortsveränderliche Fahrzeug-Hebebühnen, die bestimmungs-gemäß nicht für das Heben von Personen, sondern zum vollständigen Anheben von Fahrzeugen vorgesehen sind, um die angehobenen Fahrzeuge zu untersuchen und an oder unter ihnen zu arbeiten. Fahrzeug-Hebebühnen können aus einer oder mehreren Hubeinheiten bestehen.

Ein Antrieb der Fahrzeug-Hebebühne durch Verbrennungsmotoren wird nicht betrachtet. Es wird vorausgesetzt, dass der Boden, auf dem die Fahrzeug-Hebebühne benutzt wird, horizontal ist.

Elévateurs de véhicules

La présente norme s'applique aux élévateurs de véhicules fixes, mobiles et transférables, qui ne sont pas prévus pour le levage de personnes, mais qui sont conçus pour élever tout le véhicule afin de permettre les travaux de vérification, d'entretien et de réparation sur ou sous le véhicule lorsqu'il est en position levée.

L'élévateur de véhicule peut consister en une ou plusieurs unités de levage.

L'alimentation en énergie de l'élévateur de véhicule par des moteurs à combustion interne n'a pas été envisagée.

Le plancher ou le sol supportant l'élévateur de véhicule lors du fonctionnement est supposé être horizontal.

Dvigala za servisiranje vozil

General Information

- Status

- Withdrawn

- Publication Date

- 09-Dec-2008

- Withdrawal Date

- 03-Aug-2010

- Technical Committee

- CEN/TC 98 - Lifting platforms

- Drafting Committee

- CEN/TC 98/WG 3 - Vehicle lifting devices

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 04-Aug-2010

- Completion Date

- 04-Aug-2010

- Directive

- Harmonized Standard2006/42/EC - Directive 2006/42/EC of the European Parliament and of the Council of 17 May 2006 on machinery, and amending Directive 95/16/EC (recast)OJ Ref: C 214, C 214, C 214, C 214, C 214, C 214, C 214, C OJ Date: 08-Sep-2009

Not Harmonized98/37/EC - MachineryOJ Ref: C 74, C 74, C 74, C 74, C 74, C 74, C 74, C 74, C, OJ Date: 28-Mar-2009

- Ref Project

SIST EN 1493:1999+A1:2009 - Vehicle lifts

Relations

- Merged From

EN 1493:1998 - Vehicle lifts - Effective Date

- 22-Dec-2008

- Replaced By

EN 1493:2010 - Vehicle lifts - Effective Date

- 08-Jun-2022

Get Certified

Connect with accredited certification bodies for this standard

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

AIAG (Automotive Industry Action Group)

American automotive industry standards and training.

Sponsored listings

Frequently Asked Questions

EN 1493:1998+A1:2008 is a standard published by the European Committee for Standardization (CEN). Its full title is "Vehicle lifts". This standard covers: This standard applies to stationary, mobile and movable vehicle lifts, which are not intended to lift persons but which are designed to raise vehicles totally, for the purpose of examining and working on or under the vehicles whilst in a raised position. The vehicle lift may consist of one or more lifting units. Power supply to the vehicle lift by internal combustion engines is not considered. The floor or ground supporting the vehicle lift in use is assumed to be horizontal.

This standard applies to stationary, mobile and movable vehicle lifts, which are not intended to lift persons but which are designed to raise vehicles totally, for the purpose of examining and working on or under the vehicles whilst in a raised position. The vehicle lift may consist of one or more lifting units. Power supply to the vehicle lift by internal combustion engines is not considered. The floor or ground supporting the vehicle lift in use is assumed to be horizontal.

EN 1493:1998+A1:2008 is classified under the following ICS (International Classification for Standards) categories: 43.180 - Diagnostic, maintenance and test equipment; 53.020.99 - Other lifting equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1493:1998+A1:2008 has the following relationships with other standards: It is inter standard links to EN 1493:1998, EN 1493:2010. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1493:1998+A1:2008 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/079, M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1493:1998+A1:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Dvigala za servisiranje vozilFahrzeug-HebebühnenElévateurs de véhiculesVehicle lifts53.020.99Druga dvigalna opremaOther lifting equipment43.180Diagnostic, maintenance and test equipmentICS:Ta slovenski standard je istoveten z:EN 1493:1998+A1:2008SIST EN 1493:1999+A1:2009en,fr01-marec-2009SIST EN 1493:1999+A1:2009SLOVENSKI

STANDARD

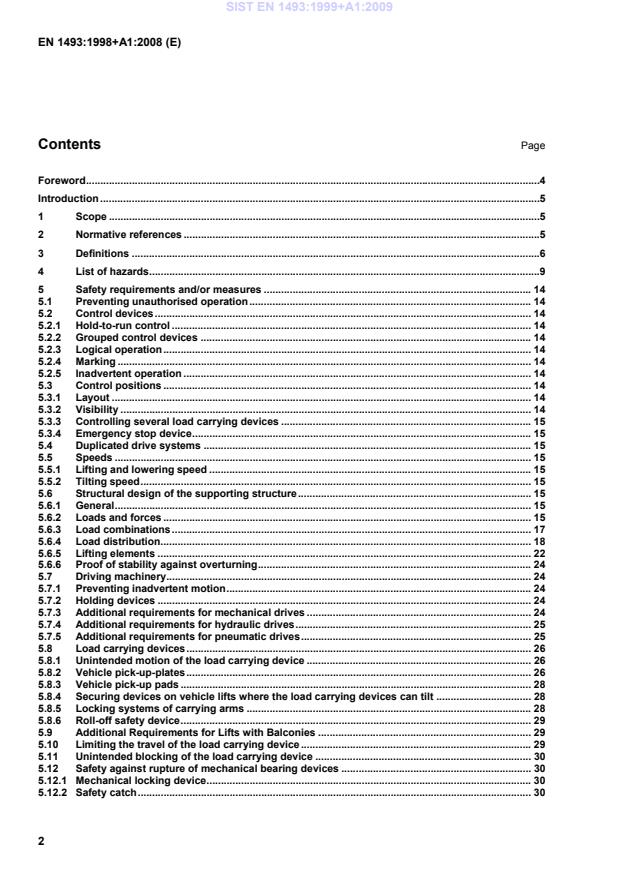

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1493:1998+A1

December 2008 ICS 43.180; 53.020.99 Supersedes EN 1493:1998English Version

Vehicle lifts

Elévateurs de véhicules

Fahrzeug-Hebebühnen This European Standard was approved by CEN on 10 July 1998 and includes Amendment 1 approved by CEN on 9 November 2008.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36

B-1050 Brussels © 2008 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1493:1998+A1:2008: ESIST EN 1493:1999+A1:2009

Structural calculations . 39Annex B (informative)

Examples of solutions . 44Annex C (normative)

Design of rope drives . 51Annex D (informative)

Example of information about wind . 52Annex ZA (informative)

!Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC" . 53Annex ZB (informative)

!Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC" . 54 SIST EN 1493:1999+A1:2009

Key 1 pick-up plate 2 load carrying device 3 pin Figure 1 — Pick-up plate 3.12 pick-up pad vehicle supporting pad which has direct contact with the vehicle but which does not have an assigned position, e.g. pads used on wheel free systems with platforms (see figure 2)

Key 1 pick-up pad 2 platform Figure 2 — Pick-up pad 3.13 lifting element Medium through which the force is transmitted from the power source to the load carrying device. Lifting elements include hydraulic and pneumatic cylinders, lead screw and nut systems as well as any flexible connections such as steel wire ropes and chains. SIST EN 1493:1999+A1:2009

HAZARDS CORRESPONDING REQUIREMENT1 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.9 1.10

1.11 1.12 Mechanical hazards Crushing hazards Shearing hazard Cutting or severing hazard Entanglement hazard Drawing-in or trapping hazard Impact hazard Stabbing or puncture hazard Friction or/abrasion hazard High pressure fluid injection hazard Ejection of parts (of machinery and processed material/workpieces) Loss of stability (of machinery and machine parts) Slip, trip and fall hazards in relationship with machinery (because of their mechanical nature) 5.6/5.8/5.16.1 5.2.1/5.5.1/5.5.2/5.16 5.2.1/5.5.1/5.5.2/5.16 5.7.3.3/5.17 5.3.3 5.3.4 5.4, 5.7.3.1/5.7.3.2/5.10/5.11/5.12/5.13 not applicable not applicable 5.7.4.1/5.7.4.3/5.18.3 not applicable

5.6.6 5.7.3.4/5.9 2 2.1 2.2 2.3

2.4 Electrical hazards Electrical contact (direct or indirect) Electrostatic phenomena Thermal radiation or other phenomena such as ejection of molten particles, and chemical effects from short-circuits, overloads, etc. External influences on electrical equipment

5.20.1,5.20.3 not applicable not applicable

5.20.1 3 3.1

3.2 Thermal hazards resulting in : Burns and scalds, by a possible contact of persons, by flames or explosions and also by the radiation of heat sources Health-damaging effects by hot or cold work environment

not applicable

not applicable

4.2 Hazards generated by noise hearing losses (deafness), other physiological disorders (e.g. loss of balance, loss of awareness, etc.) interferences with speech communication, acoustic signals, etc.

not significant

not applicable 5

Hazards generated by vibration (resulting in a variety of neurological and vascular disorders) not applicable 6 6.1 6.2 6.3 6.4 Hazards generated by radiation, especially by: electrical arcs lasers ionizing radiation sources machines making use of high frequency electromagnetic fields

not applicable not significant not applicable not applicable 7

7.1

7.2 7.3 Hazards generated by materials and substances processed, used or exhausted by machinery Hazards resulting from contact with or inhalation of harmful fluids, gases, mists, fumes and dust Fire or explosion hazard Biological and micro-biological (viral or bacterial) hazards

5.7.4 not applicable not applicable 8

8.1 8.2

8.3 8.4 8.5 8.6 Hazards generated by neglecting ergonomic principles in machine design (mismatch of machinery with human characteristics and abilities) caused for example by unhealthy postures or excessive efforts inadequate consideration of human hand-arm or foot-leg anatomy neglected use of personal protection equipment inadequate area lighting mental overload or underload, stress, etc. human error 5.3/5.15.3

5.15.5, 5.19 5.3.1

not applicable not applicable not applicable 5.1/5.2.1/5.2.2/5.2.3/5.2.4/5.2.5 9 Hazards combinations not applicable

10.1

10.2 10.3

10.4 10.5 Hazards caused by failure of energy supply, breaking down of machinery parts and other functional disorders

failure of energy supply (of energy and/or control circuits)

unexpected ejection of machine parts or fluids failure, malfunction of control system (unexpected start up, unexpected overrun) errors of fitting overturn, unexpected loss of machine stability

5.7.4.4/5.7.4.5/5.7.4.6/5.7.5.4/5.7.5.5 5.7.5.6/5.14

5.7.4.2/5.7.4.7/5.7.5.1/5.7.5.2/5.7.5.3 5.2.1/5.7.1

7.3.1 5.6.6 11

11.1 11.2 11.3 11.4 11.5 11.6 11.7 11.8 11.9

11.10 Hazards caused by (temporary) missing and/or incorrectly positioned safety-related measures/means. all kinds of guard all kinds of safety related (protection) devices starting and stopping devices safety signs and signals all kinds of information or warning devices energy supply disconnecting devices emergency devices feeding/removal means of workpieces essential equipment and accessories for safe adjusting and/or maintaining equipment evacuating gases, etc

5.9/5.16.3 5.6.5.1/5.16.3/5.17 5.7.2 5.2.4 7.2/7.3 5.20.1, 5.20.2, 5.20.3 5.3.5 not applicable 7.3

not applicable

HAZARDS DUE TO MOBILITY

12 Inadequate lighting of moving/working area 5.3.1/5.3.3 13 Hazards due to sudden movement, instability etc. during handling 5.15.1/5.15.2 14 14.1

14.2 14.3 Inadequate/inergonomic design of driving/operating position Hazards due to dangerous environments (contact with moving parts, exhaust gases etc.) inadequate visibility from driver's/operator's position inadequate seat/seating (seat index point) 5.3.1 not applicable

not applicable not applicable

15.7 Mechanical hazards. hazards to exposed persons due to uncontrolled movement hazards due to break-up and/or ejection of parts hazards due to rolling over (deflection limiting volume; DVL) hazards due to falling objects inadequate means of access hazards caused due to towing, coupling, connecting, transmission etc. hazards due to batteries, fire, emissions etc.

5.15.1 not applicable not applicable not applicable 5.9 not applicable

5.20.3, 5.20.4

HAZARDS DUE TO LIFTING OPERATION

16.1 16.2 16.3 16.4 16.5 lack of stability derailment of machinery loss of mechanical strength of machinery and lifting accessories hazards caused by uncontrolled movement hazards due to falling loads 5.6 5.15.4 5.6.5 5.7.1/5.7.2/5.3.5 5.8.3, 5.8.5.1, 5.12, 7.3.1 17 Inadequate view of trajectories of the moving parts 5.33 18 hazards caused by lighting 5.33 19 hazards due to loading/overloading 5.7.4.1/5.7.5.2

stabilizing weight effect [kN] and exposed surface [m2] axle wind force ratio in service out of service F1/Fw F2/Fw F3/Fw a) P ≤ 2,5 0,75 3 6 0,40 0,60 / b) 2,5 < P ≤ 3,5 1 4 8 0,40 0,60 / c) 3,5 < P ≤ 7,5 1,875 7,5 15 0,33 0,66 / d) 7,5 < P ≤ 20 2,25 9 18 0,33 0,66 / e) 20 < P ≤ 30 2,625 10,5 21 0,33 0,66 / f) 30 < P ≤ 40 3 12 24 0,45 0,55 / g) P ≤ 25 5,25 21 42 0,25 0,30 0,45 h) P ≤ 40 4,875 19,5 39 0,20 0,30 0,50 i) 40 < P ≤ 52 5,25 21 42 0,20 0,30 0,50 j) P ≤ 40 4,125 16,5 33 0,17 0,33 / k) 40 < P ≤ 52 4,875 19,5 39 0,17 0,33 / l) P ≤ 45 4,875 19,5 39 0,20 0,40 0,40

5.6.2.3 Exceptional loads a) Out-of-service wind If the vehicle lift is designed for outside use the influence of wind forces in the wheel base direction shall be included in the stress calculation (see also 5.6.3). The maximum pressure of out-of-service wind is 500 N/m2, which is related to a wind speed of 28 m/s. The wind forces acting on the normative vehicle (refer to table 4) shall be derived from table 2. It is assumed that in any case the operator lowers the raised vehicle in the nearest position to the ground level at the end of his working time. A corresponding requirement shall be written in the operation instructions if the vehicle lift is designed for outside use. For the overturning stability calculation a stabilizing weight effect of 1 kN for each m2 of exposed vehicle surface to the wind can be considered as stabilizing moment (refer to table 2). b) Action 1) Of the catching device or 2) Of the re-raising prevention device. c) Test load for

1) Dynamic test (see 6.1.4.1) 2) Static test (see 6.1.4.2) 5.6.3 Load combinations The loads defined in 5.6.2 shall be combined and classified as indicated in table 3. SIST EN 1493:1999+A1:2009

A1 A2 B1 B2 C1 C2 C3 Regular loads Structural loads – static Structural loads – dynamic Rated load Manual forces Effect of accessories Effect of inclination 5.6.2.1 a1 a2 b d e f

1 φ φ − φ φ

1 1 1 1 1 1

1 φ φ − φ φ

1 1 1 1 1 1

1 1 1 - 1 1

1 1 1 - 1 1

1 1 1 - 1 1 Occasional loads In-service wind 5.6.2.2

-

-

-

-

- Exceptional loads Out-of-service wind Action of the catching device Action of the re-raising prevention device 5.6.2.3 a b1 b2

- - -

- - -

- - -

- - -

1 - -

- 1 -

- - 1

Load combination A1: Normal operation (raising/lowering) without wind or special forces. Load combination A2: Normal operation (service/repair work) without wind or special forces. Load combination B1: Normal operation (raising/lowering) with wind force. Load combination B2: Normal operation (service/repair work) with wind force. Load combination C1: Vehicle lift out of service with wind force. Load combination C2: Action of the catching device. Load combination C3: Action of the re-raising prevention device.

φ: Multiplication factor according to 5.6.2.1.

5.6.4 Load distribution The following requirements shall be fulfilled if no special data are specified by the customer. The rated load shall be distributed on the four corners of a rectangle with the width equating to wheel track and the length to wheel base. 5.6.4.1 Wheel support vehicle lift for road vehicles The rated load shall be distributed according to normative vehicle dimensions as shown in table 4. When carrying out structural design in accordance with the data given in table 4 consideration shall be given in each case to normative vehicles both less than and equal to the rated load to ensure that the most adverse loading situations are considered. For structural design purposes vehicle positioning on load carrying devices shall be considered in both directions. The vehicle track symmetry axis and the wheel supports symmetry axis are coincidental. For all normative vehicles with more than 2 axles, the 2- or 3-axle combinations shall be considered as a single "virtual" axle. The minimum distance X between the nearest vehicle axle and the wheel support end depends on the type of normative vehicle (dimension, single-, double-, triple-axle) (refer to table 4). SIST EN 1493:1999+A1:2009

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...