EN 13617-1:2012

(Main)Petrol filling stations - Part 1: Safety requirements for construction and performance of metering pumps, dispensers and remote pumping units

Petrol filling stations - Part 1: Safety requirements for construction and performance of metering pumps, dispensers and remote pumping units

This European Standard applies to metering pumps, dispensers and remote pumping units to be installed at petrol filling stations, designed to dispense liquid fuels into the tanks of motor vehicles, boats and light aircraft and into portable containers at flow rates up to 200 l min-1, and intended for use and storage at ambient temperatures between 20 °C and +40 °C. Measures in addition to those required by this European Standard may be required for use and storage at temperature outside this range. The need for and nature of additional requirements should be determined by the manufacturer, if necessary after consulting the client.

This European Standard deals with all significant hazards, hazardous situations and events relevant to metering pumps, dispensers and remote pumping units, when they are used as intended and under the conditions foreseeable by the manufacturer (see Clause 4).

This European Standard gives health and safety related requirements for the selection, construction and performance of the equipment.

This European Standard does not deal with noise and with hazards related to transportation and installation.

This European Standard does not include any requirements for metering performance.

Vapour recovery efficiency rates are not considered within this European Standard.

Fuels other than the ones of Explosion Group IIA are excluded from this European Standard.

This European Standard is not applicable to metering pumps, dispensers and remote pumping units which are manufactured before the date of publication of this document by CEN.

This European Standard does not apply to equipment for use with liquefied petroleum gas (LPG) or liquefied natural gas (LNG) or compressed natural gas (CNG).

Tankstellen - Teil 1: Sicherheitstechnische Anforderungen an Bau- und Arbeitsweise von Zapfsäulen, druckversorgten Zapfsäulen und Fernpumpen

Diese Europäische Norm gilt für Zapfsäulen, druckversorgte Zapfsäulen und Fernpumpen, die an Tankstellen installiert werden für die Abgabe von flüssigen Kraftstoffen in Tanks von Kraftfahrzeugen, Booten und Leicht-flugzeugen sowie in tragbare Behälter bei Durchflussraten bis zu 200 l ⋅ min−1 und die für den Gebrauch und die Lagerung bei Umgebungstemperaturen zwischen –20 °C und +40 °C vorgesehen sind. Zusätzlich zu den nach dieser Europäischen Norm erforderlichen Maßnahmen können weitere Maßnahmen für den Gebrauch und die Lagerung bei Umgebungstemperaturen außerhalb dieses Bereichs erforderlich sein. Notwendigkeit und Art der zusätzlichen Anforderungen sollten vom Hersteller, gegebenenfalls nach Beratung mit dem Kunden, bestimmt werden. Diese Europäische Norm behandelt alle signifikanten Gefährdungen, Gefährdungssituationen und -ereignisse in Zusammenhang mit Zapfsäulen, druckversorgten Zapfsäulen und Fernpumpen bei bestimmungsgemäßer Verwendung entsprechend den vom Hersteller vorhersehbaren Bedingungen (siehe Abschnitt 4). Diese Europäische Norm enthält gesundheits- und sicherheitstechnische Anforderungen an die Auswahl sowie die Bau- und Arbeitsweise der Einrichtungen. Diese Europäische Norm behandelt weder Lärm noch Gefährdungen in Zusammenhang mit Transport und Installation. Diese Europäische Norm enthält keine Anforderungen für Messausführungen. Effizienzraten für Gasrückführung werden in dieser Europäischen Norm nicht behandelt. Diese Europäische Norm gilt nicht für Kraftstoffe, die nicht zur Explosionsgruppe IIA gehören. Diese Europäische Norm gilt nicht für Zapfsäulen, druckversorgte Zapfsäulen und Fernpumpen, die vor der Veröffentlichung dieser Norm durch CEN hergestellt wurden. Diese Europäische Norm gilt nicht für Ausrüstung für Anwendungen mit Flüssiggas (LPG, en: liquefied petroleum gas) oder Flüssigerdgas (LNG, en: liquefied natural gas) oder komprimiertem Erdgas (CNG, en: compressed natural gas).

Stations-service - Partie 1: Exigences relatives à la construction et aux performances de sécurité des distributeurs à pompe immergée, distributeurs de carburants et unités de pompage à distance

La présente Norme européenne s’applique aux distributeurs à pompe immergée, distributeurs de carburants et unités de pompage à distance destinés à être installés sur les stations-service et utilisés pour distribuer des carburants liquides dans des réservoirs de véhicules à moteur, bateaux, avions légers, réservoirs portables à des débits jusqu’à 200 l∙min-1 et pouvant être utilisés et stockés à des températures ambiantes comprises entre -20 °C et 40 °C. Des mesures complétant celles requises par la présente norme Européenne peuvent être exigées pour l’utilisation et le stockage à une température en dehors de cette plage. Il convient que la nécessité d’établir des exigences supplémentaires et la nature de ces dernières soient déterminées par le fabricant, si nécessaire après consultation du client.

La présente Norme européenne traite tous les phénomènes dangereux, situations et évènements dangereux liés aux distributeurs avec pompe immergée, aux distributeurs de carburant et aux unités de pompage à distance utilisés selon les conditions pouvant être prévues par le fabricant (voir l’Article 4).

La présente Norme européenne indique des exigences liées à l’hygiène et à la sécurité pour le choix, la construction et les performances de l’équipement.

La présente Norme européenne ne traite pas du bruit et des phénomènes dangereux liés au transport et à l’installation.

La présente Norme européenne ne comporte aucune exigence relative aux performances métrologiques.

Les taux d’efficacité de récupération des vapeurs ne sont pas pris en compte dans la présente Norme européenne.

Les carburants autres que ceux du Groupe d’Explosion IIA sont exclus de la présente Norme européenne.

La présente Norme européenne n’est pas applicable aux distributeurs de carburants et unité de pompage à distance fabriqués avant la date de publication du présent document par le CEN.

La présente Norme européenne ne s’applique pas aux équipements mettant en oeuvre du gaz de pétrole liquéfié (GPL) ou du gaz naturel liquéfié (GNL) ou du gaz naturel compressé (GNC).

Bencinski servisi - 1. del: Varnostne zahteve za izdelavo in lastnosti tlačnih in sesalnih naprav za točenje goriva in naprav za točenje goriva z daljinskim vodenjem

Ta evropski standard se uporablja za tlačne in sesalne naprave za točenje goriva ter naprave za točenje goriva z daljinskim vodenjem, ki bodo postavljene na bencinskih servisih in se uporabljajo za točenje tekočih goriv v rezervoarje motornih vozil, čolnov in lahkih letal ter v premične rezervoarje s pretokom do 200 lmin-1 ter so namenjene uporabi in shranjevanju pri temperaturah okolja od -20 °C do +40 °C. Za uporabo in shranjevanje pri temperaturi zunaj teh omejitev se lahko zahtevajo dodatni ukrepi poleg ukrepov iz tega standarda. Potrebo po dodatnih zahtevah in njihovo naravo mora določiti proizvajalec, po potrebi po posvetovanju s naročnikom. Ta evropski standard opisuje večja tveganja, nevarne situacije in dogodke v zvezi s tlačnimi in sesalnimi napravami za točenje goriva ter napravami za točenje goriva z daljinskim vodenjem, kadar se uporabljajo v skladu z njihovim namenom in pod pogoji, ki jih določa proizvajalec (glejte točko 4). Ta evropski standard določa zahteve v zvezi z zdravjem in varnostjo za izbiro, izdelavo ter lastnosti opreme. Ta evropski standard ne obravnava hrupa in nevarnosti v zvezi s prevozom in namestitvijo. Ta evropski standard ne vključuje zahtev za lastnosti merjenja. Stopnje učinkovitosti rekuperacije hlapov niso zajete v tem evropskem standardu. V tem evropskem standardu niso obravnavana goriva, ki ne spadajo v eksplozijsko skupino IIA. Ta evropski standard se ne uporablja za tlačne in sesalne naprave za točenje goriva ter naprave za točenje goriva z daljinskim vodenjem, ki so bile izdelane, preden je CEN izdal ta dokument. Ta evropski standard se ne uporablja za opremo, namenjeno uporabi z utekočinjenim naftnim plinom (LPG) ali utekočinjenim zemeljskim plinom (LNG) ali stisnjenim zemeljskim plinom (CNG).

General Information

- Status

- Withdrawn

- Publication Date

- 29-May-2012

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 393 - Equipment for storage tanks and for service stations

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 15-Sep-2021

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 21-Nov-2009

- Effective Date

- 08-Jun-2022

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Refers

EN 60079-7:2007 - Explosive atmospheres - Part 7: Equipment protection by increased safety "e" - Effective Date

- 09-Feb-2026

- Refers

EN 60079-1:2007 - Explosive atmospheres - Part 1: Equipment protection by flameproof enclosures "d" - Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

ABS Quality Evaluations Inc.

American Bureau of Shipping quality certification.

Element Materials Technology

Materials testing and product certification.

ABS Group Brazil

ABS Group certification services in Brazil.

Sponsored listings

Frequently Asked Questions

EN 13617-1:2012 is a standard published by the European Committee for Standardization (CEN). Its full title is "Petrol filling stations - Part 1: Safety requirements for construction and performance of metering pumps, dispensers and remote pumping units". This standard covers: This European Standard applies to metering pumps, dispensers and remote pumping units to be installed at petrol filling stations, designed to dispense liquid fuels into the tanks of motor vehicles, boats and light aircraft and into portable containers at flow rates up to 200 l min-1, and intended for use and storage at ambient temperatures between 20 °C and +40 °C. Measures in addition to those required by this European Standard may be required for use and storage at temperature outside this range. The need for and nature of additional requirements should be determined by the manufacturer, if necessary after consulting the client. This European Standard deals with all significant hazards, hazardous situations and events relevant to metering pumps, dispensers and remote pumping units, when they are used as intended and under the conditions foreseeable by the manufacturer (see Clause 4). This European Standard gives health and safety related requirements for the selection, construction and performance of the equipment. This European Standard does not deal with noise and with hazards related to transportation and installation. This European Standard does not include any requirements for metering performance. Vapour recovery efficiency rates are not considered within this European Standard. Fuels other than the ones of Explosion Group IIA are excluded from this European Standard. This European Standard is not applicable to metering pumps, dispensers and remote pumping units which are manufactured before the date of publication of this document by CEN. This European Standard does not apply to equipment for use with liquefied petroleum gas (LPG) or liquefied natural gas (LNG) or compressed natural gas (CNG).

This European Standard applies to metering pumps, dispensers and remote pumping units to be installed at petrol filling stations, designed to dispense liquid fuels into the tanks of motor vehicles, boats and light aircraft and into portable containers at flow rates up to 200 l min-1, and intended for use and storage at ambient temperatures between 20 °C and +40 °C. Measures in addition to those required by this European Standard may be required for use and storage at temperature outside this range. The need for and nature of additional requirements should be determined by the manufacturer, if necessary after consulting the client. This European Standard deals with all significant hazards, hazardous situations and events relevant to metering pumps, dispensers and remote pumping units, when they are used as intended and under the conditions foreseeable by the manufacturer (see Clause 4). This European Standard gives health and safety related requirements for the selection, construction and performance of the equipment. This European Standard does not deal with noise and with hazards related to transportation and installation. This European Standard does not include any requirements for metering performance. Vapour recovery efficiency rates are not considered within this European Standard. Fuels other than the ones of Explosion Group IIA are excluded from this European Standard. This European Standard is not applicable to metering pumps, dispensers and remote pumping units which are manufactured before the date of publication of this document by CEN. This European Standard does not apply to equipment for use with liquefied petroleum gas (LPG) or liquefied natural gas (LNG) or compressed natural gas (CNG).

EN 13617-1:2012 is classified under the following ICS (International Classification for Standards) categories: 01.040.75 - Petroleum and related technologies (Vocabularies); 75.200 - Petroleum products and natural gas handling equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13617-1:2012 has the following relationships with other standards: It is inter standard links to EN 13617-1:2004+A1:2009, EN 13617-1:2021, EN 60529:1991, EN IEC 60079-0:2018, EN IEC 60079-10-1:2021, EN 60730-2-10:2007, EN IEC 60079-14:2024, EN IEC 60947-3:2021, EN 50525-2-51:2011, EN IEC 62368-1:2024, EN 60079-7:2007, EN 60079-1:2007, EN 50525-2-21:2011, EN 14125:2025, EN ISO/IEC 80079-49:2024. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13617-1:2012 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 2014/34/EU, 94/9/EC; Standardization Mandates: M/079. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13617-1:2012 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.DOMLQVNLPYRGHQMHPTankstellen - Teil 1: Sicherheitstechnische Anforderungen an Bau- und Arbeitsweise von Zapfsäulen, druckversorgten Zapfsäulen und FernpumpenStations-service - Partie 1 : Exigences relatives à la construction et aux performances de sécurité des distributeurs à pompe immergée, distributeurs de carburants et unités de pompage à distancePetrol filling stations - Part 1: Safety requirements for construction and performance of metering pumps, dispensers and remote pumping units75.200Petroleum products and natural gas handling equipmentICS:Ta slovenski standard je istoveten z:EN 13617-1:2012SIST EN 13617-1:2012en,fr,de01-september-2012SIST EN 13617-1:2012SLOVENSKI

STANDARDSIST EN 13617-1:2004+A1:20091DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13617-1

May 2012 ICS 75.200 Supersedes EN 13617-1:2004+A1:2009English Version

Petrol filling stations - Part 1: Safety requirements for construction and performance of metering pumps, dispensers and remote pumping units

Stations-service - Partie 1: Exigences relatives à la construction et aux performances de sécurité des distributeurs à pompe immergée, distributeurs de carburants et unités de pompage à distance

Tankstellen - Teil 1: Sicherheitstechnische Anforderungen an Bau- und Arbeitsweise von Zapfsäulen, druckversorgten Zapfsäulen und Fernpumpen This European Standard was approved by CEN on 13 April 2012.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2012 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 13617-1:2012: ESIST EN 13617-1:2012

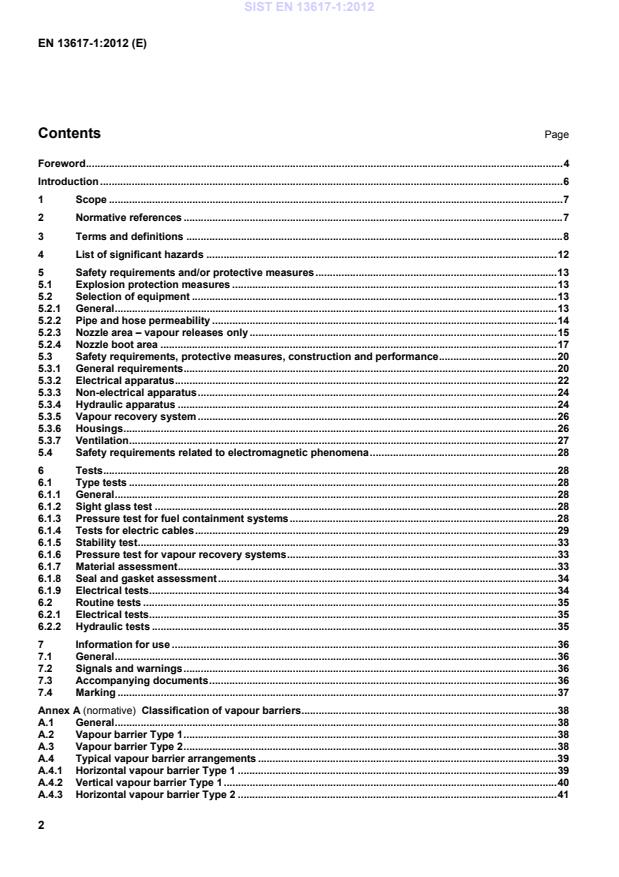

Classification of vapour barriers . 38A.1General . 38A.2Vapour barrier Type 1 . 38A.3Vapour barrier Type 2 . 38A.4Typical vapour barrier arrangements . 39A.4.1Horizontal vapour barrier Type 1 . 39A.4.2Vertical vapour barrier Type 1 . 40A.4.3Horizontal vapour barrier Type 2 . 41SIST EN 13617-1:2012

Information on explosion protected equipment . 45Annex C (informative)

Environmental aspects. 46Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 94/9/EC . 48Annex ZB (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC. 50Bibliography . 51 SIST EN 13617-1:2012

a new paragraph has been added in the scope: ‘Fuels other than the ones of Explosion Group IIA are excluded from this European Standard’; 7.2.1 has been added; the existing 7.2 has been made into 7.2.2; the informative Annex C concerning environmental aspects has been added. This document has been prepared under a mandate given to CEN by the European Commission and the European Free Trade Association, and supports essential requirements of EU Directive(s). For relationship with EU Directives, see informative Annexes ZA and ZB, which are integral parts of this document. This European Standard Petrol filling stations consists of four parts: Part 1: Safety requirements for construction and performance of metering pumps, dispensers and remote pumping units; Part 2: Safety requirements for construction and performance of safe breaks for use on metering pumps and dispensers; Part 3: Safety requirements for construction and performance of shear valves; Part 4: Safety requirements for construction and performance of swivels for use on metering pumps and dispensers. The key purpose for the review of the standards was to consider biofuels. In practice, only

EN 13617-1 was changed. According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech SIST EN 13617-1:2012

(IEC 60079-7:2006) EN 60079-10-1, Explosive atmospheres — Part 10-1: Classification of areas — Explosive gas atmospheres

(IEC 60079-10-1) EN 60079-14, Explosive atmospheres — Part 14: Electrical installations design, selection and erection

(IEC 60079-14) EN 60204-1:2006, Safety of machinery — Electrical equipment of machines — Part 1: General requirements (IEC 60204-1:2005, modified) EN 60529, Degrees of protection provided by enclosures (IP Code) (IEC 60529) EN 60730-2-10, Automatic electrical controls for household and similar use — Part 2-10: Particular requirements for motor-starting relays (IEC 60730-2-10) EN 60947-3, Low-voltage switchgear and controlgear — Part 3: Switches, disconnectors, switch-disconnectors and fuse-combination units (IEC 60947-3) EN 60950-1, Information technology equipment — Safety — Part 1: General requirements (IEC 60950-1) EN ISO 1182, Reaction to fire tests for products — Non-combustibility test (ISO 1182) EN ISO 1825, Rubber hoses and hose assemblies for aircraft ground fuelling and defuelling — Specification

(ISO 1825) EN ISO 12100:2010, Safety of machinery — General principles for design — Risk assessment and risk reduction (ISO 12100:2010) EN ISO 13849-1, Safety of machinery — Safety-related parts of control systems — Part 1: General principles for design (ISO 13849-1) EN ISO 16852, Flame arresters — Performance requirements, test methods and limits for use (ISO 16852) ISO 11925-3, Reaction to fire tests — Ignitability of building products subjected to direct impingement of flame — Part 3: Multi-source test HD 21.13 S1, Polyvinyl chloride insulated cables of rated voltages up to and including 450/750 V — Part 13: Oil resistant PVC sheathed cables with two or more conductors HD 22.4 S3, Cables of rated voltages up to and including 450/750 V and having cross-linked insulation — Part 4: Cords and flexible cables 3 Terms and definitions For the purposes of this document, the terms and definitions given in EN ISO 12100:2010 and the following apply. 3.1 air and/or vapour separator device used for continuously separating and removing air or gases contained in the liquid SIST EN 13617-1:2012

nozzle according to EN 13012 3.16 vapour recovery nozzle according to EN 13012 3.17 nozzle boot location, normally a partially enclosed housing, where the nozzle or vapour recovery nozzle is stored when not in use 3.18 nozzle sensor device detecting the nozzle position in the nozzle boot 3.19 vapour barrier sealing system to limit hazardous areas 3.20 shear valve

impact check valve normally open valve, activated by impact and heat, which closes to prevent flow from a pressure source and remains closed after activation 3.21 sight glass device to allow checking that all, or part, of the measuring system is completely filled with liquid 3.22 vapour recovery system system in and attached to the metering pump/dispenser to feed back the vapours displaced from the fuel tank and led back into the vapour return lines to the storage tank 3.23 vapour pump pump positioned in the vapour recovery system to supply vacuum for vapour suctioning 3.24 screen perforated cladding fabrication which may be provided to enhance the visual appearance of a pump or dispenser or to provide another related function 3.25 vapour pipe tubing of the vapour recovery system, excluding the vapour recovery delivery hose assembly and vapour recovery nozzle 3.26 retraction system system to assist the stowage of delivery hose assembly or vapour recovery delivery hose assembly 3.27 hose cassette separate assembly primarily for the storage of delivery hose assembly(s) or vapour recovery delivery hose assembly(s) SIST EN 13617-1:2012

It is the responsibility of the manufacturer, outside the scope of this standard, to identify such hazards and provide suitable protective measures. SIST EN 13617-1:2012

- Falling objects - High pressure

- Rotating elements

- Inadequate mechanical strength

- Stability

Moving parts and ejected

fuel Fluid in the hose, pipes etc.

Drive belts and/or shafts

Stability of the dispenser in normal use Vehicle movement

5.3.6 5.3.1.4,

5.3.1.5,

5.3.1.6,

5.3.3.2,

5.3.4,

5.3.5,

6.1.2, 6.1.3,

6.1.6 5.3.6.1,

5.3.6.2,

7.3

5.3.6.4,

6.1.7,

6.1.8

5.3.1.6,

6.1.5

5.3.4.7,

7.3 2 Electrical hazards - Electrostatic phenomena

- Live parts - Parts which have become live under fault conditions

Charging of belts, hoses and cladding

5.3.3,

5.3.4.1,

5.3.4.3

5.3.2,

6.1.4,

6.1.9 5.3.2,

6.1.4 3 Thermal hazards - Explosion

Ignition of possible explosive atmosphere by electrical or non-electrical parts or electrical change

5.1,

5.2,

5.3 7 Material/substance hazards - Explosive

- Fluid

- Gas

Sparks or high temperature from electrical and non-electrical parts in combination with explosive atmospheres Tightness of components, pipes, hoses Tightness of components, pipes, hoses

5.1,

5.2,

5.3

5.3.3,

5.3.4

5.3.3,

5.3.4 8 Ergonomic hazards - Design, location or identification of control devices - Human errors

Explosive atmosphere due to unexpected liquid flow Errors of fitting

5.3.1.1,

5.3.1.2,

5.3.1.3,

5.3.2,

5.3.4.2,

7.3 7.3

5 Safety requirements and/or protective measures 5.1 Explosion protection measures 5.1.1 Explosion protection measures should be taken in accordance with Annex B. 5.1.2 Equipment, components and protective systems used within hazardous areas, shall be suitable as a minimum requirement for Explosion Group IIA with temperature class T3 as defined in EN 60079-0 and

EN 13463-1. 5.2 Selection of equipment 5.2.1 General 5.2.1.1 Hazardous areas considered in this European Standard are only those created by an individual metering pump/dispenser in open air. NOTE 1 The following requirements for classification of zones are not intended to release the user of the equipment from his obligation to verify the correct classification as far as workplaces are concerned, and to implement additional health and safety arrangements if necessary. Required documents are identified in 7.3. SIST EN 13617-1:2012

Key Zone 2: category 3 equipment 1 nozzle 2 non hazardous area Figure 1 — Nozzle outside a housing at distance > 50 mm and ≤≤≤≤ 200 mm SIST EN 13617-1:2012

Key Zone 2: category 3 equipment 1 nozzle 2 non hazardous area Figure 2 — Nozzle outside a housing at distance > 50 mm and ≤≤≤≤ 200 mm 5.2.3.3 Nozzle outside the housing and positioned ≤ 50 mm from the dispenser wall. If the wall is IP67 within 200 mm horizontally and 50 mm vertically upwards and downwards to ground level from the nozzle spout then on the other side of the IP67 wall there is no hazardous area due to the nozzle, see Figure 3. SIST EN 13617-1:2012

Key Zone 2: category 3 equipment 1 nozzle 2 non hazardous area Figure 3 — Nozzle outside a housing at distance ≤≤≤≤ 50 mm 5.2.4 Nozzle boot area 5.2.4.1 The inside of the nozzle boot is zone 1, where category 2 equipment shall be used. 5.2.4.2 The nozzle boot shall prevent retaining of liquid and be drained to the outside. Drained liquid shall not create an additional hazard, see Figure 5. 5.2.4.3 When the nozzle boot consists of a pocket and the wall inside the pocket is continuous and: the wall below the nozzle boot is not less than IP67 downwards to the lower extremity of the wall containing the nozzle boot; the wall within 200 mm horizontally and 50 mm vertically upwards from the pocket is not less than IP54; then on the other side of the wall there is no hazardous area due to the nozzle, see Figures 4, 5 and 6. SIST EN 13617-1:2012

Key 1 nozzle boot Zone 1: category 2 equipment Zone 2: category 3 equipment Figure 4 — Nozzle boot area, front view SIST EN 13617-1:2012

Key 1 nozzle boot 2 non hazardous area Zone 1: category 2 equipment Zone 2: category 3 equipment Figure 5 — Nozzle boot area, side view SIST EN 13617-1:2012

Key 2 non hazardous area 3 continuous Zone 1: category 2 equipment Zone 2: category 3 equipment Figure 6 — Nozzle boot area, top view 5.2.4.4 Fuel from the nozzle boot can spread along any return surface of, or to, a non-hazardous area. Means shall be provided to ensure that any such fuel is prevented from: entering any non-hazardous area, or from becoming trapped on surfaces or glands below. 5.3 Safety requirements, protective measures, construction and performance 5.3.1 General requirements 5.3.1.1 General 5.3.1.1.1 Metering pumps, dispensers and remote pumping units shall comply with the safety requirements and/or protective measures of this clause. In addition, the machine shall be designed according to the principles of EN ISO 12100 for hazards relevant but not significant, which are not dealt with by this document (e.g. sharp edges). For hazards which are to be reduced by the application of a B-level standard such as EN 13463-1, EN 60730-2-10, EN 60529 and EN 60204-1 and where this standard does not identify specific requirements, the manufacturer should carry out a risk assessment to establish the requirements of the B-standard which are to be applied. This specific risk assessment is part of the general risk assessment of the machine. Where the means of reducing the risk is by the physical arrangement or positioning of the installed machine, the manufacturer shall include in the information for use a reference to the reduction means to be provided, and to any limiting value of the requirement, and, if appropriate, to the means of verification. Where the means of reducing the risk is by a safe system of working the machinery, such as for installation or maintenance, the manufacturer shall include in the information for use details of the safe system and of the elements of training required by the personnel. SIST EN 13617-1:2012

HD 22.4 S3, or be tested in accordance with 6.1.4 and shall meet the following requirements: a) when tested according to 6.1.4.2 there shall be no significant deterioration of the sheath or surface texture and no splits or cracks; and b) when tested according to 6.1.4.3 the sample shall show no evidence of splitting or cracking and no electrical breakdown shall occur; and c) when tested according to 6.1.4.4 the sample shall show no evidence of splitting or cracking; and d) when tested according to 6.1.4.5 no electrical breakdown shall occur and the measured values of insulation resistance shall be not less than 100 MΩ; and e) when tested according to 6.1.4.6 there shall be no ignition of the gas within the outer chamber. 5.3.2.5 Insulation and isolation a) In order to avoid danger from sources of electrical energy capable of causing shock, and also, in hazardous areas, from non-intrinsically safe energy sources capable of causing incentive sparks, all such sources of energy and conductive component

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...