EN 13445-6:2009

(Main)Unfired pressure vessels - Part 6: Requirements for the design and fabrication of pressure vessels and pressure parts constructed from spheroidal graphite cast iron

Unfired pressure vessels - Part 6: Requirements for the design and fabrication of pressure vessels and pressure parts constructed from spheroidal graphite cast iron

This European Standard specifies requirements for the design, materials, manufacturing and testing of pressure

vessels and pressure vessel parts intended for use with a maximum allowable pressure, PS, equal or less than 100

bar and shell wall thicknesses not exceeding 60 mm, which are constructed of ferritic or austenitic spheroidal

graphite cast iron. The thickness limitation of the shell does not apply to thickness of flanges, reinforcements,

bosses etc.

The allowable grades do not include lamellar graphite cast iron grades for ferritic and austenitic grades, which are

explicitly excluded from this European Standard because of low elongation and brittle material behaviour, which

requires the use of different safety factors and a different approach.

NOTE 1 Austenitic spheroidal graphite cast iron grades are principally used for high and low temperature applications and for

their corrosion resistance properties.

NOTE 2 The allowable grades of spheroidal graphite cast iron are listed in Tables 3 and 4. Service conditions are given in

Clause 4.

Unbefeuerte Druckbehälter - Teil 6: Anforderungen an die Konstruktion und Herstellung von Druckbehältern und Druckbehälterteilen aus Gusseisen mit Kugelgraphit

Diese Europäische Norm legt Anforderungen an Konstruktion, Werkstoffe, Herstellung und Prüfung von

Druckbehältern und Druckbehälterteilen aus ferritischem oder austenitischem Gusseisen mit Kugelgraphit fest, die

für den Betrieb mit einem maximalen zulässigen Druck PS gleich oder kleiner als 100 bar und einer maximalen

Wanddicke von 60 mm vorgesehen sind. Die Grenzwerte für die Schalenwanddicke gelten nicht für die Dicke von

Flanschen, Verstärkungen, Nocken usw.

Zu den zulässigen Sorten gehören keine ferritischen und austenitischen Gusseisensorten mit Lamellengraphit, die

aufgrund ihrer nicht ausreichenden Dehnungs- und Sprödbrucheigenschaften von dieser Europäischen Norm

ausdrücklich ausgeschlossen sind, da für sie die Verwendung anderer Sicherheitsbeiwerte und ein anderer Ansatz

erforderlich sind.

ANMERKUNG 1 Austenitische Gusseisensorten mit Kugelgraphit werden hauptsächlich für Anwendungsfälle in hohen und

niedrigen Temperaturbereichen und aufgrund ihrer Korrosionsbeständigkeit eingesetzt.

ANMERKUNG 2 Die zulässigen Gusseisensorten mit Kugelgraphit sind in den Tabellen 3 und 4 aufgelistet. Die

Betriebsbedingungen sind in Abschnitt 4 angegeben.

Récipients sous pression non soumis à la flamme - Partie 6 : exigences pour la conception et la fabrication des récipients sous pression et des parties sous pression moulés en fonte à graphite sphéroïdal

La présente Norme européenne spécifie les prescriptions relatives à la conception, aux matériaux, à la fabrication

et aux essais des récipients sous pression et de leurs parties sous pression, destinés à être utilisés à une pression

maximale admissible, PS, inférieure ou égale à 100 bars et d’épaisseur de paroi de la coque ne dépassant pas

60 mm, fabriqués en fonte à graphite sphéroïdal ferritique ou austénitique. La limite d'épaisseur de la coque ne

s'applique pas à l'épaisseur des brides, renforcements, bossages, etc..

Les nuances admises n'incluent pas les nuances de fonte à graphite lamellaire qui sont explicitement exclues de la

présente Norme européenne du fait d'un faible allongement et d'un comportement de matériau fragile, nécessitant

l'application de coefficients de sécurité différents et d'une approche différente.

NOTE 1 Les nuances de fonte à graphite sphéroïdal austénitique sont utilisées principalement pour les applications à basse

température et à température élevée, ainsi que pour leurs propriétés de résistance à la corrosion.

NOTE 2 Les nuances admises de fonte à graphite sphéroïdal sont énumérées dans les Tableaux 3 et 4. Les conditions de

service sont données à l'Article 4.

Neogrevane tlačne posode - 6. del: Zahteve za konstruiranje in proizvodnjo tlačnih posod in tlačnih delov posode iz nodularne litine

General Information

- Status

- Withdrawn

- Publication Date

- 21-Jul-2009

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 54 - Unfired pressure vessels

- Drafting Committee

- CEN/TC 54/WG 55 - E - Inspection and testing

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 10-Sep-2014

- Completion Date

- 11-Feb-2026

- Directive

- 97/23/EC - Pressure equipment

Relations

- Effective Date

- 08-Jun-2022

- Effective Date

- 25-Jul-2009

- Effective Date

- 25-Jul-2009

- Effective Date

- 22-Dec-2008

- Effective Date

- 08-Jun-2022

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

EN 13445-6:2009 is a standard published by the European Committee for Standardization (CEN). Its full title is "Unfired pressure vessels - Part 6: Requirements for the design and fabrication of pressure vessels and pressure parts constructed from spheroidal graphite cast iron". This standard covers: This European Standard specifies requirements for the design, materials, manufacturing and testing of pressure vessels and pressure vessel parts intended for use with a maximum allowable pressure, PS, equal or less than 100 bar and shell wall thicknesses not exceeding 60 mm, which are constructed of ferritic or austenitic spheroidal graphite cast iron. The thickness limitation of the shell does not apply to thickness of flanges, reinforcements, bosses etc. The allowable grades do not include lamellar graphite cast iron grades for ferritic and austenitic grades, which are explicitly excluded from this European Standard because of low elongation and brittle material behaviour, which requires the use of different safety factors and a different approach. NOTE 1 Austenitic spheroidal graphite cast iron grades are principally used for high and low temperature applications and for their corrosion resistance properties. NOTE 2 The allowable grades of spheroidal graphite cast iron are listed in Tables 3 and 4. Service conditions are given in Clause 4.

This European Standard specifies requirements for the design, materials, manufacturing and testing of pressure vessels and pressure vessel parts intended for use with a maximum allowable pressure, PS, equal or less than 100 bar and shell wall thicknesses not exceeding 60 mm, which are constructed of ferritic or austenitic spheroidal graphite cast iron. The thickness limitation of the shell does not apply to thickness of flanges, reinforcements, bosses etc. The allowable grades do not include lamellar graphite cast iron grades for ferritic and austenitic grades, which are explicitly excluded from this European Standard because of low elongation and brittle material behaviour, which requires the use of different safety factors and a different approach. NOTE 1 Austenitic spheroidal graphite cast iron grades are principally used for high and low temperature applications and for their corrosion resistance properties. NOTE 2 The allowable grades of spheroidal graphite cast iron are listed in Tables 3 and 4. Service conditions are given in Clause 4.

EN 13445-6:2009 is classified under the following ICS (International Classification for Standards) categories: 23.020.30 - Pressure vessels, gas cylinders. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13445-6:2009 has the following relationships with other standards: It is inter standard links to EN 13445-6:2002/A2:2006, EN 13445-6:2002/A1:2004, EN 13445-6:2002, EN 13445-6:2002/A3:2008, EN 13445-6:2014, EN 837-3:1996, EN 13445-5:2009, EN 1559-1:1997, EN 13445-3:2009, EN 764-2:2002, EN 1369:1996, EN 837-1:1996, EN 1563:1997, EN 1559-3:1997, EN ISO 8062-1:2007. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13445-6:2009 is associated with the following European legislation: EU Directives/Regulations: 97/23/EC; Standardization Mandates: M/071. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13445-6:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Unbefeuerte Druckbehälter - Teil 6: Anforderungen an die Konstruktion und Herstellung von Druckbehältern und Druckbehälterteilen aus Gusseisen mit KugelgraphitRécipients sous pression non soumis à la flamme - Partie 6 : exigences pour la conception et la fabrication des récipients sous pression et des parties sous pression moulés en fonte à graphite sphéroïdalUnfired pressure vessels - Part 6: Requirements for the design and fabrication of pressure vessels and pressure parts constructed from spheroidal graphite cast iron23.020.30MHNOHQNHPressure vessels, gas cylindersICS:Ta slovenski standard je istoveten z:EN 13445-6:2009SIST EN 13445-6:2009en,fr,de01-november-2009SIST EN 13445-6:2009SLOVENSKI

STANDARDSIST EN 13445-6:2002/A2:2007SIST EN 13445-6:2002/A3:2009SIST EN 13445-6:2002SIST EN 13445-6:2002/A1:20041DGRPHãþD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 13445-6July 2009ICS 23.020.30Supersedes EN 13445-6:2002

English VersionUnfired pressure vessels - Part 6: Requirements for the designand fabrication of pressure vessels and pressure partsconstructed from spheroidal graphite cast ironRécipients sous pression non soumis à la flamme - Partie 6: exigences pour la conception et la fabrication desrécipients sous pression et des parties sous pressionmoulés en fonte à graphite sphéroïdalUnbefeuerte Druckbehälter - Teil 6: Anforderungen an dieKonstruktion und Herstellung von Druckbehältern undDruckbehälterteilen aus Gusseisen mit KugelgraphitThis European Standard was approved by CEN on 30 June 2009.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre:

Avenue Marnix 17,

B-1000 Brussels© 2009 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 13445-6:2009: ESIST EN 13445-6:2009

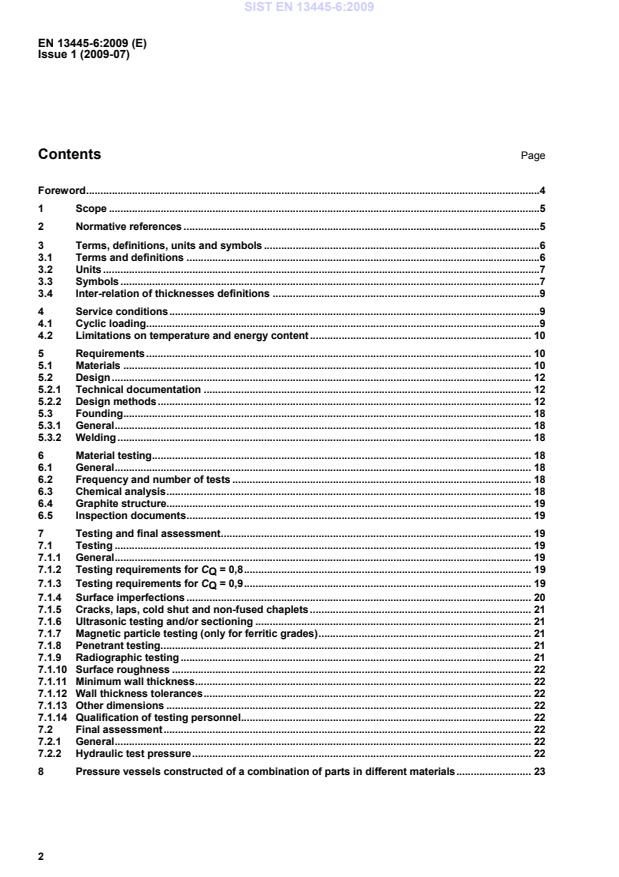

Issue 1 (2009-07) 2 Contents Page Foreword.4 1 Scope.5 2 Normative references.5 3 Terms, definitions, units and symbols.6 3.1 Terms and definitions.6 3.2 Units.7 3.3 Symbols.7 3.4 Inter-relation of thicknesses definitions.9 4 Service conditions.9 4.1 Cyclic loading.9 4.2 Limitations on temperature and energy content.10 5 Requirements.10 5.1 Materials.10 5.2 Design.12 5.2.1 Technical documentation.12 5.2.2 Design methods.12 5.3 Founding.18 5.3.1 General.18 5.3.2 Welding.18 6 Material testing.18 6.1 General.18 6.2 Frequency and number of tests.18 6.3 Chemical analysis.18 6.4 Graphite structure.19 6.5 Inspection documents.19 7 Testing and final assessment.19 7.1 Testing.19 7.1.1 General.19 7.1.2 Testing requirements for CQ = 0,8.19 7.1.3 Testing requirements for CQ = 0,9.19 7.1.4 Surface imperfections.20 7.1.5 Cracks, laps, cold shut and non-fused chaplets.21 7.1.6 Ultrasonic testing and/or sectioning.21 7.1.7 Magnetic particle testing (only for ferritic grades).21 7.1.8 Penetrant testing.21 7.1.9 Radiographic testing.21 7.1.10 Surface roughness.22 7.1.11 Minimum wall thickness.22 7.1.12 Wall thickness tolerances.22 7.1.13 Other dimensions.22 7.1.14 Qualification of testing personnel.22 7.2 Final assessment.22 7.2.1 General.22 7.2.2 Hydraulic test pressure.22 8 Pressure vessels constructed of a combination of parts in different materials.23 SIST EN 13445-6:2009

Issue 1 (2009-07) 3 9 Marking and documentation.23 9.1 Marking of castings.23 9.2 Name plate for the complete pressure vessel.23 9.3 Documentation.23 Annex A (normative)

Technical data for the design calculations.24 Annex B (informative)

Ductility.26 Annex C (informative)

Determination of the minimum local wall thickness and minimum required burst test pressure.27 Annex D (normative)

Assessment of fatigue life.28 Annex E (normative)

Design by analysis for castings.41 Annex F (informative)

Recommandations for in-service validation and inspection.43 Annex G (normative)

Specific design requirements.45 Annex H (normative)

Experimental cyclic pressure testing procedure.47 Annex Y (informative)

Differences between EN 13445-6:2002 and EN 13445-6:2009.51 Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of the EU Pressure Equipment Directive 97/23/EC.52 Bibliography.53

Issue 1 (2009-07) 4 Foreword This document (EN 13445-6:2009) has been prepared by Technical Committee CEN/TC 54 “Unfired pressure vessels”, the secretariat of which is held by BSI. This European Standard shall be given the status of a national standard, either by publication of an identical text or by endorsement, at the latest by December 2009, and conflicting national standards shall be withdrawn at the latest by December 2009. Attention is drawn to the possibility that some of the elements of this document may be the subject of patent rights. CEN [and/or CENELEC] shall not be held responsible for identifying any or all such patent rights. This document has been prepared under a mandate given to CEN by the European Commission and the European Free Trade Association, and supports essential requirements of EU Directive(s). For relationship with EU Directive(s), see informative annex ZA, which is an integral part of this document. In this standard the Annexes A, D, E, G and H are normative and the Annexes B, C and F are informative. This European Standard consists of the following Parts: ⎯ Part 1: General ⎯ Part 2: Materials ⎯ Part 3: Design ⎯ Part 4: Fabrication ⎯ Part 5: Testing and Inspection ⎯ Part 6: Requirements for the design and fabrication of pressure vessels and pressure parts constructed from spheroidal graphite cast iron

⎯ CR 13445-7, Unfired pressure vessels — Part 7: Guidance on the use of conformity assessment procedures ⎯ Part 8: Requirements for the design and fabrication of pressure vessels and pressure parts constructed from spheroidal graphite cast iron. ⎯ CEN/TR 13445-9, Unfired pressure vessels — Part 9: Conformance of EN 13445 series to ISO 16528 This document supersedes EN 13445-6:2002. This new edition incorporates the Amendments which have been approved previously by CEN members and the corrected pages up to Issue 36 without any further technical change. Annex Y to EN 13445-1:2009 and Annex Y to this Part provides details of significant technical changes between this European Standard and the previous edition. Amendments to this new edition may be issued from time to time and then used immediately as alternatives to rules contained herein. It is intended to deliver a new Issue of EN 13445:2009 each year, consolidating these Amendments and including other identified corrections. According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and the United Kingdom. SIST EN 13445-6:2009

Issue 1 (2009-07) 5 1 Scope This European Standard specifies requirements for the design, materials, manufacturing and testing of pressure vessels and pressure vessel parts intended for use with a maximum allowable pressure, PS, equal or less than 100 bar and shell wall thicknesses not exceeding 60 mm, which are constructed of ferritic or austenitic spheroidal graphite cast iron. The thickness limitation of the shell does not apply to thickness of flanges, reinforcements, bosses etc. The allowable grades do not include lamellar graphite cast iron grades for ferritic and austenitic grades, which are explicitly excluded from this European Standard because of low elongation and brittle material behaviour, which requires the use of different safety factors and a different approach. NOTE 1 Austenitic spheroidal graphite cast iron grades are principally used for high and low temperature applications and for their corrosion resistance properties. NOTE 2 The allowable grades of spheroidal graphite cast iron are listed in Tables 3 and 4. Service conditions are given in Clause 4. 2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 764-2:2002, Pressure equipment — Part 2: Quantities, symbols and units. EN 764-5:2002, Pressure equipment — Part 5: Compliance and inspection documentation of materials. EN 837-1:1996, Pressure gauges — Part 1: Bourdon tube pressure gauges — Dimensions, metrology, requirements and testing. EN 837-3:1996, Pressure gauges — Part 3: Diaphragm and capsule pressure gauges — Dimensions, metrology, requirements and testing. EN 1369:1996, Founding — Magnetic particle inspection. EN 1370:1996, Founding — Surface roughness inspection by visual tactile comparators. EN 1371-1:1997, Founding — Liquid penetrant inspection — Part 1: Sand, gravity die and low pressure die castings. EN 1559-1:1997, Founding — Technical conditions of delivery — Part 1: General. EN 1559-3:1997, Founding — Technical conditions of delivery — Part 3: Additional requirements for iron castings. EN 1563:1997, EN 1563:1997/A1:2002, EN 1563:1997/A2:2005, Founding — Spheroidal graphite cast irons. EN 12680-3:2003, Founding — Ultrasonic examination — Part 3: Spheroidal graphite cast iron castings. EN 12681:2003, Founding — Radiographic examination. EN 13445-1:2009, Unfired pressure vessels — Part 1: General. EN 13445-3:2009, Unfired pressure vessels — Part 3: Design. EN 13445-5:2009, Unfired pressure vessels — Part 5: Inspection and testing. SIST EN 13445-6:2009

Issue 1 (2009-07) 6 EN 13835:2002, EN 13835/A1:2006, Founding — Austenitic cast irons. EN ISO 945:1994, Cast iron — Designation of microstructure of graphite (ISO 945:1975). EN ISO 8062-1:2007, Geometrical product specifications (GPS) — Dimensional and geometrical tolerances for moulded parts — Part 1: Vocabulary (ISO 8062-1:2007). EN ISO 8062-3:2007, Geometrical product specifications (GPS) — Dimensional and geometrical tolerances for moulded parts — Part 3: General dimensional and geometrical tolerances and machining allowances for castings (ISO 8062-3:2007). 3 Terms, definitions, units and symbols 3.1 Terms and definitions For the purposes of this European Standard, the following terms and definitions apply. 3.1.1 critical zone highly stressed area where a fracture is expected to occur in a burst test or where surface fatigue cracks are expected to be initiated due to fluctuating pressure loads NOTE 1 Critical zones may occur, for example, by any of the following: ⎯ sudden change in cross section; ⎯ sharp edges; ⎯ sharp radii; ⎯ peak stresses; ⎯ bending stresses; ⎯ stresses due to other than membrane stress; ⎯ changes in curvature. NOTE 2

A critical zone is analysed by any appropriate method, e.g. holographic, interferometric, strain gauge methods, burst test, fatigue testing, FEM analysis etc. NOTE 3

Additionally, thermal gradients and thermal stresses due to different operating wall temperatures need to be considered in defining critical zones. 3.1.2 purchaser individual or organisation that buys pressure equipment, including assemblies or

parts, for its own use or on behalf of the user and/or operator

3.1.3 manufacturer individual or organisation responsible for the design, fabrication, testing, inspection, installation of pressure equipment and assemblies where relevant NOTE 1 The manufacturer may subcontract one or more of the above mentioned tasks under its responsibility. NOTE 2 In EU member states the manufacturer is responsible for compliance with the Pressure Equipment Directive 97/23/EC. For those manufacturers outside of the EU their authorized representative inside the EU assumes this responsibility. SIST EN 13445-6:2009

Issue 1 (2009-07) 7 3.1.4 casting manufacturer subcontractor that produces the castings used in the manufacture of pressure equipment 3.1.5 testing factor

A reduction factor applied to the nominal design stress to take account of possible manufacturing deficiencies 3.1.6 temperature factor A reduction factor applied to the 0,2 % proof strength to take account of temperature influence 3.1.7 wall thickness factor a reduction factor applied to the nominal design stress to take account of reduced mechanical properties 3.1.8 ferritic spheroidal graphite cast iron cast material, iron and carbon based (carbon being present mainly in the form of spheroidal graphite particles) with a predominantly ferritic matrix 3.1.9 austenitic spheroidal graphite cast iron cast material with an austenitic matrix which is iron and carbon based and alloyed with nickel and manganese, copper and/or chromium in order to stabilize the austenitic structure at room temperature 3.2 Units For the purposes of this European Standard, the units given in EN 764-2:2002 apply. 3.3 Symbols Symbols used in this European Standard are listed in Table 3.3-1. SIST EN 13445-6:2009

Issue 1 (2009-07) 8 Table 3.3-1 — Symbols Symbol Quantity Unit c Corrosion allowance mm e Required thickness mm ea Analysis thickness

mm eact Actual thickness mm emin Minimum thickness as specified on drawing mm E Modulus of elasticity MPa f Nominal design stress

MPa F Fatigue factor related to 99,8 % survival _ Pb,act Actual burst test pressure MPaa

Pb Minimum required bursting pressure MPa a

Pd Design pressure MPa a

PS, Ps Maximum allowable pressure MPa a

PT, Pt Test pressure MPa a

RM Material strength parameter MPa

Rp0,2 0,2 %-proof strength

MPa

Rm Tensile strength

MPa Rm(3) Average tensile strength of 3 test bars taken from the same lot or heat MPa TSmin , TSmax Minimum / maximum allowable temperature °C T Calculation temperature °C V Volume

L Ce=Wall thickness factor _ CT=Temperature factor _ CQ=Testing factor _ n=Factor depending on shape of shell _ fe=Thickness correction factor _ fm=Mean stress correction factor _ fs=Surface finish correction factor _ S=Safety factor _ γR=Partial safety factor _ δ Casting tolerance mm 0=Extra thickness due to casting process mm ν=Poisson’s ratio _ a MPa for calculation purpose only, otherwise the unit be bar (1 MPa = 10 bar)

Issue 1 (2009-07) 9 3.4 Inter-relation of thicknesses definitions

Key e is the required thickness ea is the analysis thickness emin is the minimum thickness including corrosion allowance as indicated on drawings eact

is the actual

thickness c is the corrosion allowance ε is the extra thickness due to casting process δ is the casting tolerance Figure 3.4-1 — Inter-relation of thicknesses definitions 4 Service conditions 4.1 Cyclic loading Spheroidal graphite cast iron pressure vessels and vessel parts can be used for cyclic operation if the stress factor is limited to 3. If the calculated number of cycles is close to a limit number of cycles mentioned in Table 4.1-1 below to determine the need for fatigue analysis, a worst-case model shall be implemented for this determination. If it is expected that under service conditions the maximum number of full pressure cycles will exceed the limit number according to Table 4.1-1, or exceeds more than the equivalent number of cycles with smaller amplitude, then a fatigue analysis shall be performed according to Annex D. SIST EN 13445-6:2009

Issue 1 (2009-07) 10 Table 4.1-1 — Number of full pressure cycles for cyclic loading consideration Testing factor Maximum number of full pressure cycles without mandatory fatigue analysis according to Annex D CQ = 0,9 1 000 40 000 if 2,5 < stress factor ≤ 3 CQ = 0,8 200 000 If stress factor ≤ 2,5

NOTE 1 A testing factor of 0,9 implies the application of higher nominal design stresses and consequently results in a lower maximum number of full pressure cycles without mandatory fatigue analysis. NOTE 2 A stress factor (ratio of peak stress to fatigue stress) of more than 3, determined by any of the design methods given in 5.2 can be the result of inappropriate design. By enlarging radii or other small changes, an acceptable design may be generated. For pressure cycles at a pressure difference ûPi less than the full pressure, the number of equivalent full cycles is given by Equation (4.1-1): 6,8i1iin⎟⎟⎠⎞⎜⎜⎝⎛⋅=∑==maxieqnPûPN (4.1-1) where N is the total number of envisaged types of pressure cycles with different amplitude; ni is the number of cycles of amplitude ûP; ûPi is the pressure cycle amplitude; Pmax is the maximum permissible pressure, as defined in 3.15 of EN 13445-3:2009. 4.2 Limitations on temperature and energy content The minimum and maximum allowable temperatures TSmin and TSmax shall be in accordance with the limits given in Tables 5.1-1 and 5.1-2. The product PS · V for a single casting shall not exceed 100 000 bar⋅L. 5 Requirements 5.1 Materials All cast iron grades subject to internal or external pressure shall comply with EN 1563 for ferritic spheroidal graphite cast iron and EN 13835 for austenitic spheroidal graphite cast iron. The ferritic material grades given in Table 5.1-1 shall be used for applications where the minimum allowable temperature is higher or equal to – 10 ⎪C. The material grades listed in Table 5.1-2 are intended for low temperature or high temperature design conditions. SIST EN 13445-6:2009

Issue 1 (2009-07) 11 Table 5.1-1 — Allowable material grades for usual design temperatures (-10 °C up to 300 °C) Material designation b Material standard Symbol Number Design temperature limits °C EN-GJS-350-22 EN-JS1010 -10 ≤ TS ≤ 300 EN-GJS-350-22-RT EN-JS1014 -10 ≤ TS ≤ 300 EN-GJS-350-22 U a EN-JS1032 -10 ≤ TS ≤ 300 EN-GJS-350-22U-RT a EN-JS1029 -10 ≤ TS ≤ 300 EN-GJS-400-18 EN-JS1020 -10 ≤ TS ≤ 300 EN-GJS-400-18-RT EN-JS1024 -10 ≤ TS ≤ 300 EN-GJS-400-18U a EN-JS1062 -10 ≤ TS ≤ 300 EN 1563 EN-GJS-400-18U-RT a EN-JS1059 -10 ≤ TS ≤ 300 a

Mechanical properties verified on test pieces from cast-on samples. These grades should be chosen in preference to the material grades with the separately cast samples when the unit mass of the casting is equal to or greater than 2 000 kg or when the relevant wall thickness varies between 30 mm and 200 mm. The material grades listed in Table 5.1-1 and Table 5.1-2 may be produced in the as-cast or heat treated condition (see EN 1563:1997, Clause 6). b

When materials specified in these tables are not available, other suitable materials may be used when the technical documentation defining the characteristics of the materials has been accepted in accordance with the requirements for European approval for materials (EAM) or particular material appraisal (PMA).

Table 5.1-2 — Allowable material grades for low or high temperature design conditions Material designation b Material standard Symbol Number Design temperature limits °C EN-GJS-350-22-LT EN-JS1015 -40 ≤ TS ≤ 300 EN-GJS-350-22U-LT a EN-JS1019 -40 ≤ TS ≤ 300 EN-GJS-400-18-LT EN-JS1025 -20 ≤ TS ≤ 300 EN 1563 EN-GJS-400-18U-LT a EN-JS1049 -20 ≤ TS ≤ 300 EN-GJSA-XNiMn23-4 EN-JS3021 -196 ≤ TS ≤ 300 EN-GJSA-XNi22 EN-JS3041 -40 ≤ TS ≤ 540 EN 13835 EN-GJSA-XNiMn13-7 EN-JS3071 -40 ≤ TS ≤ 300 a

Mechanical properties verified on test pieces from cast-on samples. These grades should be chosen in preference to the material grades with the separately cast samples when the unit mass of the casting is equal to or greater than 2 000 kg or when the relevant wall thickness varies between 30 mm and 200 mm. The material grades listed in Table 5.1-1 and Table 5.1-2 may be produced in the as-cast or heat treated condition (see EN 1563:1997, Clause 6 and EN 13835:2002, Clause 6). b

When materials specified in these tables are not available, other suitable materials may be used when the technical documentation defining the characteristics of the materials has been accepted in accordance with the requirements for European approval for materials (EAM) or particular material appraisal (PMA). SIST EN 13445-6:2009

Issue 1 (2009-07) 12 Material grades EN-GJS-350-22-LT or EN-GJS-350-22U-LT can be used at design temperatures down to – 60 °C. When used between (-40 ± 2) °C and (-60 ± 2) °C, impact testing at the minimum design temperature shall be: ⎯ mean value from 3 tests 12 J for acte ≤ 60 mm; ⎯ 10 J for 60 mm ≤ acte ≤ 200 mm; ⎯ individual value 9 J for acte ≤ 60 mm and 7 J for 60 mm ≤ acte ≤ 200 mm. The applicable requirements for the delivery conditions given in EN 1559-1:1997 and EN 1559-3:1997 shall also apply. NOTE The use of materials working in the creep domain is not applicable to this standard since stress ranges are limited to elastic behaviour. 5.2 Design 5.2.1 Technical documentation The manufacturer shall document those items listed in Clause 5 of EN 13445-5:2009 prior to fabrication. 5.2.2 Design methods 5.2.2.1.1 Principle The loadings to be accounted for shall be in accordance with EN 13445-3:2009, Clause 5. The service conditions of Clause 4 shall be accounted for. Design methods shall be in accordance with this European Standard and, when applicable, with the relevant clauses of EN 13445-3:2009. If the geometry of the component or the loading case do not allow calculation by the formulas given in

EN 13445-3:2009 and Annex G, design by analysis (DBA) (see Annex E) or design by experiment (DBE) shall be applied. Depending on the complexity of the component, the loading conditions and the level of NDT testing, the designer may choose one of the following available design methods mentioned below. Guidance is given on the correlation between safety factor, testing factor and the method to assess dynamic loading (see Table 5.2-1). 5.2.2.1.2

Static loading In order to design the part for static loading, the following options can be considered by the designer. 5.2.2.1.3 Design by formula (DBF) Equations for the calculation of the various components of the pressure part are given in EN 13445-3:2009 and Annex G. Annex G gives additional equations for non-standard shaped parts often used in casting design. SIST EN 13445-6:2009

Issue 1 (2009-07) 13 5.2.2.1.4 Design by analysis (DBA) The following applies: 1) decide whether the direct route (limit load – EN 13445-3:2009, Annex B) or the stress categorisation method (EN 13445-3:2009, Annex C) will be followed. Decide whether linear or non-linear approach will be used; 2) base modelling and interpretation of calculation results shall be based on analysis thicknesses (ea) and material characteristics at operation temperature; 3) for interpretation of calculation results, follow the evaluation procedures and assessment criteria in order to evaluate the fitness for purpose of the real structure. These design checks and related procedures are typical for the failure mode to be dealt with. For the different failure modes see EN 13445-3:2009. 5.2.2.1.5 Design by experiment (DBE) Where design by equations according to EN 13445-3:2009 is not considered appropriate due to complex shape of the component, then a hydraulic burst test to determine the analysis thickness ea and the minimum thickness emin shall be performed according to the procedure in 5.2.2.1.6. This test is also a part of the technical documentation. This design method may be used without additional calculations if Pd · V < 6000 bar⋅L. If Pd · V > 6000 bar⋅L

for the complete vessel, this method can be used in addition to DBA or DBF. The minimum required thickness at a specific location is given by: neTQpactbmactaCCCRPRPSSee12,0,)3(⎟⎟⎠⎞⎜⎜⎝⎛⋅⋅⋅⋅⋅⋅⋅= (5-1) cee+≥amin (5-2) where eact. is the minimum measured wall thickness at the specific location; Rp0,2 is in accordance with Annex A; Pb,act is the actual obtained value of burst pressure or the highest pressure during the test; n = 1

for curved surfaces (cylinders, spheres) or cones with angles α ≤ 60°, stayed surfaces and stressed parts if bending stress is less than 2/3 of the total stress;

n = 2

for all other surfaces. 5.2.2.1.6 Determination of the hydraulic burst pressure and maximum allowable pressure for static loading A random sample from the production of the vessel or vessel part shall be taken for the burst test or to determine the maximum allowable working conditions. The procedure shall be as follows: SIST EN 13445-6:2009

Issue 1 (2009-07) 14 1) verify that the part or vessel to be tested is cast according to the specified drawing and any revision thereof. The material used shall be the same type and grade as for the production part; 2) verify that the part or vessel is machined to the same dimensions as the production part; 3) verify that the material properties meet the requirements of 5.1. For each casting used for the burst test, 3 test pieces for tensile testing, and, if applicable, for impact testing, shall be separately cast and tested. The results and the calculated average tensile strength shall be certified in accordance with 6.5; 4) the wall thicknesses of the entire casting shall be measured (at least one measurement per

100 mm x 100 mm). The results shall be marked on the casting at the location of the measurement or on the drawing; 5) verify that a calibrated pressure gauge is used; maximum tolerance shall conform to at least class 1 or better according to EN 837-1 and EN 837-3. The scale of the pressure gauge shall be approximately 4/3 of the anticipated burst pressure; 6) the pressure shall be increased in a controlled manner until the minimum required burst pressure is obtained: nceefRPSP⎟⎟⎠⎞⎜⎜⎝⎛−⋅≥minact)3(mb (5-3) The pressure shall be increased further in a controlled manner until rupture occurs. Record burst pressure Pb,act, test date, material specification, details of material, part number, and wall thickness eact measured at burst location. A relation with the actual burst pressure Pb,act , which can be higher than Pb on account of a better stress distribution, and the maximum allowable pressure PS, can be deducted according the converted Equation 5-3, replacing Pb by Pb,act neceRfPPS⎟⎟⎠⎞⎜⎜⎝⎛−⋅≤actmin)3(mact,b (5-4) 7) if a part fails to meet any of those requirements, a second identical production part may undergo the same test procedure. If this second part meets the test requirements, this part may be accepted after investigation of the cause of failure of the first part. If the second part does not meet the test requirements, the design of the part shall be deemed not to conform to the specification; 8) during the burst test, it is acceptable for leaks and lack of pressure tightness to occur between flanged, gasketted or bolted parts as long as the pressure Pb can be reached during the test. It is acceptable for gasket(s) to break during the burst test; their characteristics may be modified without unduly changing flange load properties as long as their design meets the design rules of EN 13445-3:2009 for the anticipated maximum allowable pressure Ps; 9) only for the test, bolts of higher mechanical strength than required by the design specification may be accepted; SIST EN 13445-6:2009

Issue 1 (2009-07) 15 10) when flanged connections are designed according to the requirements of EN 13445-3:2009 with respect to minimum required thickness, minimum required bolt area and shape, it is acceptable, in order to reach burst test pressure, to install extra bolts in addition to the number specified for production; 11) the rupture under test pressure or any hydraulic test shall not be performed by means of a construction on a hydraulic press that can counteract the free shell bending under pressure. 5.2.2.1.7 Dynamic loading If the number of full pressure cycles or equivalent full pressure cycles according to Equation (4.1-1) exceeds the number of full pressure cycles for static loading considered in Table 4.1-1, a fatigue assessment of the complete design is required. In order to design the part for dynamic loading, the following options can be considered by the designer. 5.2.2.1.8 Simplified fatigue assessment (SFA) A simplified fatigue assessment will return a value of maximum allowable number of equivalent pressure fluctuations under service conditions. The assessment shall be performed according to Annex D. A maximum stress factor of 3 is pre-supposed, unless for construction details as limited in Table D.1A where equal or lower values than 3 may be used. NOTE This Table D.1A may also be used for other metallic castings than spheroidal graphite cast iron (e.g. cast steel, cast aluminium and so on). 5.2.2.1.9 Detailed fatigue assessment (DFA)

A detailed fatigue assessment returns a value of maximum allowable number of equivalent pressure fluctuations using detailed stress analysis in service conditions. The assessment shall be performed according to Annex D. 5.2.2.1.10 Experimental fatigue assessment (EFA) This method, as described in Annex H, shall be used if a theoretical stress analysis is inadequate or for which the design analysis shows abnormal low fatigue life values indicating a too conservative approach by theory. An evaluation of a part by experimental fatigue design is not required when a similar part underwent already such a fatigue assessment and the data are available and transposable into the new design. Cyclic loading shall be in accordance with EN 13445-3:2009, subclause 5.3. This method does not take into account excessive wall thickness of the material, linings and all material, which does not contribute to strength. NOTE For vessels for which Pd · V ≥ 6000 bar⋅L this experimental method may be used in addition to detailed fatigue design. SIST EN 13445-6:2009

Issue 1 (2009-07) 16 Table 5.2-1 — Determination of safety factor, testing factor and design method Non destructive testing Safety factor S Testing factor CQ Design method Static loading Design assessment dynamic loading SFA DFA Not required 3,0 0,8 EFA (SFA) a DFA Required 2,0 0,9 DBF DBA DBE EFA NOTE: DBF = design by formula

DBA = design by analysis

DBE = design by experiment

SFA = simplified fatigue analysis

DFA = detailed fatigue analysis

EFA = experimental fatigue analysis a not recommended

5.2.2.2 Design conditions The design stress for ferritic and for austenitic grades shall be calculated as follows: SCCCRfeQT0,2p⋅⋅⋅= (5.2-1) where 0,2 % proof strength at calculation temperature: 0,2pT/T0,2pRCR⋅= (5.2-2) The temperature reduction factor CT is: for ferritic grades CT = 1 for T ≤ 20 °C (5.2-3) CT = 1 – 0,001 (T – 20) for 20 °C < T ≤ 200 °C (5.2-4) CT= 0,82 for 200 °C < T ≤ 300 °C (5.2-5) and for austenitic grades CT = 1 for T ≤ 20 °C (5.2-6) CT = 1 – 0,000 5 (T – 20) for 20 °C < T ≤ 540 °C (5.2-7) Wall thickness reduction factor: 1=eC for mm60min≤e

(5.2-8) SIST EN 13445-6:2009

Issue 1 (2009-07) 17 8,0=eC for mm20060min≤

Issue 1 (2009-07) 18 5.3 Founding 5.3.1 General The castings shall be free from surface and internal defects that might impair their usability. No excessive residual stress shall be permitted to be built up in the casting that can impair the fracture behaviour or the fatigue life of the casting. This can be achieved by allowing the casting sufficiently long cooling periods in the mould followed by cooling in still air. The casting manufacturer shall document this cooling procedure (required cooling time) in a process or work instruction. If this procedure to avoid excessive residual stresses cannot be complied with, a stress relieving heat treatment shall be carried out, based on agreement between the parties concerned.

5.3.2 Welding No production, repair or cosmetic welding shall be carried out on cast iron parts both in ferritic or austenitic grades, which are manufactured according to this European Standard. 6 Material testing 6.1 General All material tests as required by EN 1563 or EN 13835 shall be performed. 6.2 Frequency and number of tests For each batch the amount of testing shall be, on each ladle treated for spheroidization or each heat treatment batch: ⎯ chemical analysis; ⎯ one tensile test; ⎯ one hardness test; ⎯ impact testing, when required by material specification (consisting of 3 test pieces). If the spheroidizing treatment is carried out in the mould, the same amount of testing for each 2 500 kg cast weight of identical parts produced during the same day shall be carried out. For series production of RT grades according to Table 5.1-1, the amount of impact testing can be reduced to one test per day on the ladle with the highest silicon content. The separately cast or cast–on test pieces shall be chosen according to EN 1563 or EN 13835. The test sample size shall represent the wall thickness of the part (see EN 1563 or EN 13835 for size determination). NOTE Cast-on test pieces are representative of the castings to which they are attached and their size depends on the relevant wall thickness of the casting. 6.3 Chemical analysis The methods used to determine the chemical composition of the material shall be in accordance with recognised standards. For ferritic spheroidal graphite cast iron the following elements shall be analysed: C, Si, Mn, P, S and Mg. SIST EN 13445-6:2009

Issue 1 (2009-07) 19 For austenitic spheroidal graphite cast iron the following elements shall be analysed: C, Si, Mn, P, S, Mg, Cu and Ni. 6.4 Graphite structure Graphite morphology of the material shall comply with form VI and V in accordance with EN ISO 945. The verification of nodularity shall preferably be carried out either by microscopic examination or by an ultrasonic method. Visual or computerised and/or automated methods are allowed. When the ultrasonic method is used, the ultrasonic velocity shall be a minimum of 5 460 m/s using a calibrated measuring device. If the velocity is less than 5 460 m/s, the nodularity may still be verified and approved using the microscopic method on the worst test specimen. If the spheroidization is found acceptable, the material is approved. When ultrasonic examination is used, the verification shall be carried out on the last cast metal of each ladle. 6.5 Inspection documents Inspection documents shall be in accordance with EN 764-5:2002, 4.3.3. 7 Testing and final assessment 7.1 Testing 7.1.1 General All material tests of cast vessels and vessel parts, manufactured according to this part, shall be in accordance with Table 7.1-1 and Table 7.1-2. Table 7.1-1 — Summary of testing requirements

Testing factor CQ Magnetic particle inspection Ultra sonic testing/ radiographic testing Sectioning Visual inspection Wall thickness measure-ment 0,8 - + + + + Initial sample 0,9 + + + + + 0,8 - + (10 %) - + + 0-serie: pre-production 0,9 + + + (1 part) + + 0,8 - - - + + Serial production 0,9 + - - + + NOTE

+ = required, - = not required 7.1.2 Testing requirements for CQ = 0,8 Testing shall be carried out in accordance with the requirements and adopting the acceptance criteria given in Table 7

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...