EN 13445-5:2009

(Main)Unfired pressure vessels - Part 5: Inspection and testing

Unfired pressure vessels - Part 5: Inspection and testing

This Part of this European Standard specifies the inspection and testing of individual and serially produced

pressure vessels made of steels in accordance with EN 13445-2:2009 subject to predominantly non_cyclic

operation (i.e. vessels operating below 500 full equivalent pressure cycles).

Special provisions for cyclic operation are given in EN 13445-3:2009 and in Annex G of this Part.

Special provisions for vessels or vessel parts working in the creep range are given in Clause 5, Clause 6, Clause

10, Annex H and Annex I of this Part.

NOTE The responsibilities of parties involved in the conformity assessment procedures are given in Directive 97/23/EC.

Guidance on this can be found in CR 13445-7.

Unbefeuerte Druckbehälter - Teil 5: Inspektion und Prüfung

Dieser Teil 5 der EN 13445 legt die Inspektion und Prüfung von einzeln und in Serie gefertigten Druckbehältern aus

Stählen nach EN 13445-2:2009 unter vorwiegend nicht dynamischer Belastung fest (d. h. Behälter mit einer

äquivalenten Anzahl voller Druckzyklen im Betrieb unter 500).

Besondere Anforderungen für den Betrieb unter zyklischer Belastung sind in EN 13445-3:2009 und Anhang G des

vorliegenden Teils der Norm enthalten.

Besondere Anforderungen für Druckbehälter oder Druckbehälterteile, die im Zeitstandbereich betrieben werden,

sind in Abschnitt 5, Abschnitt 6, Abschnitt 10, Anhang H und Anhang I festgelegt.

ANMERKUNG Wird eine CE-Kennzeichnung gewünscht, können weitere Informationen über Tätigkeiten in Verbindung mit

den verschiedenen Stellen, die Prüfungen durchführen, CR 13445-7 entnommen werden.

Récipients sous pression non soumis à la flamme - Partie 5 : inspection et contrôles

La présente partie de la Norme européenne traite de l'inspection et des contrôles des récipients sous pression

construits à l'unité ou en série, à partir d'aciers conformes à l’EN 13445-2:2009 soumis à un fonctionnement à

prédominante non cyclique (c’est à dire des récipients soumis en exploitation à moins de 500 cycles pleins

équivalents en pression).

Des dispositions particulières relatives à l’exploitation cyclique sont données dans l’EN 13445-3:2009 et en annexe

G de la présente Partie.

Des dispositions particulières relatives aux récipients ou parties de récipients en service dans le domaine de fluage

sont données dans les Articles 5, 6, 10, l’Annexe F et l’Annexe I de la présente partie.

NOTE Les responsabilités des parties impliquées dans les procédures d’évaluation de la conformité sont données dans la

directive 97/23/CE. Un guide relatif à cet aspect peut être trouvé dans le CR 13445-7.

Neogrevane tlačne posode - 5. del: Kontrola in preskušanje

Ta del tega evropskega standarda določa pregled in preskušanje posamezno in serijsko izdelanih tlačnih posod, narejenih iz jekla, v skladu z EN 13445-2, ki večinoma obratujejo neciklično (tj. posode, ki obratujejo pod 500 polnimi ekvivalenti tlačnih ciklov). Posebne določbe za ciklično obratovanje so navedene v EN 13445-3 in dodatku G tega dela. Ta del ne navaja določb za pregled in preskušanje za posode, zasnovane z načrtovanjem z analizo – direktna pot (DBA) iz dodatka B EN 13445-3:2002. OPOMBA: Odgovornosti vključenih v postopke ocenjevanja skladnosti so navedene v Direktivi 97/23/ES. Navodilo v zvezi s tem je v CR 13445-7.

General Information

- Status

- Withdrawn

- Publication Date

- 21-Jul-2009

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 54 - Unfired pressure vessels

- Drafting Committee

- CEN/TC 54 - Unfired pressure vessels

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 10-Sep-2014

- Completion Date

- 11-Feb-2026

- Directive

- 97/23/EC - Pressure equipment

Relations

- Effective Date

- 08-Jun-2022

- Effective Date

- 25-Jul-2009

- Effective Date

- 25-Jul-2009

- Effective Date

- 25-Jul-2009

- Effective Date

- 25-Jul-2009

- Effective Date

- 25-Jul-2009

- Effective Date

- 22-Dec-2008

- Effective Date

- 08-Jun-2022

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

EN 13445-5:2009 is a standard published by the European Committee for Standardization (CEN). Its full title is "Unfired pressure vessels - Part 5: Inspection and testing". This standard covers: This Part of this European Standard specifies the inspection and testing of individual and serially produced pressure vessels made of steels in accordance with EN 13445-2:2009 subject to predominantly non_cyclic operation (i.e. vessels operating below 500 full equivalent pressure cycles). Special provisions for cyclic operation are given in EN 13445-3:2009 and in Annex G of this Part. Special provisions for vessels or vessel parts working in the creep range are given in Clause 5, Clause 6, Clause 10, Annex H and Annex I of this Part. NOTE The responsibilities of parties involved in the conformity assessment procedures are given in Directive 97/23/EC. Guidance on this can be found in CR 13445-7.

This Part of this European Standard specifies the inspection and testing of individual and serially produced pressure vessels made of steels in accordance with EN 13445-2:2009 subject to predominantly non_cyclic operation (i.e. vessels operating below 500 full equivalent pressure cycles). Special provisions for cyclic operation are given in EN 13445-3:2009 and in Annex G of this Part. Special provisions for vessels or vessel parts working in the creep range are given in Clause 5, Clause 6, Clause 10, Annex H and Annex I of this Part. NOTE The responsibilities of parties involved in the conformity assessment procedures are given in Directive 97/23/EC. Guidance on this can be found in CR 13445-7.

EN 13445-5:2009 is classified under the following ICS (International Classification for Standards) categories: 23.020.30 - Pressure vessels, gas cylinders. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13445-5:2009 has the following relationships with other standards: It is inter standard links to EN 13445-5:2002/A10:2008, EN 13445-5:2002/A1:2007, EN 13445-5:2002/A2:2005, EN 13445-5:2002, EN 13445-5:2002/A3:2006, EN 13445-5:2002/A4:2006, EN 13445-5:2002/A5:2006, EN 13445-5:2014, EN 287-1:2011, EN 895:1995, EN ISO 5817:2007, EN 583-4:2002, EN ISO 17635:2010, EN ISO 4063:2010, EN ISO 6520-1:2007. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13445-5:2009 is associated with the following European legislation: EU Directives/Regulations: 97/23/EC; Standardization Mandates: M/071. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13445-5:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Unbefeuerte Druckbehälter - Teil 5: Inspektion und PrüfungRécipients sous pression non soumis à la flamme - Partie 5 : inspection et contrôlesUnfired pressure vessels - Part 5: Inspection and testing23.020.30MHNOHQNHPressure vessels, gas cylindersICS:Ta slovenski standard je istoveten z:EN 13445-5:2009SIST EN 13445-5:2009en,fr,de01-november-2009SIST EN 13445-5:2009SLOVENSKI

STANDARDSIST EN 13445-5:2002/A3:2006SIST EN 13445-5:2002/A4:2007SIST EN 13445-5:2002/A5:2007SIST EN 13445-5:2002/A2:2005SIST EN 13445-5:2002SIST EN 13445-5:2002/A1:2009SIST EN 13445-5:2002/A10:20091DGRPHãþD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 13445-5July 2009ICS 23.020.30Supersedes EN 13445-5:2002

English VersionUnfired pressure vessels - Part 5: Inspection and testingRécipients sous pression non soumis à la flamme - Partie 5: inspection et contrôlesUnbefeuerte Druckbehälter - Teil 5: Inspektion und PrüfungThis European Standard was approved by CEN on 30 June 2009.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre:

Avenue Marnix 17,

B-1000 Brussels© 2009 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 13445-5:2009: ESIST EN 13445-5:2009

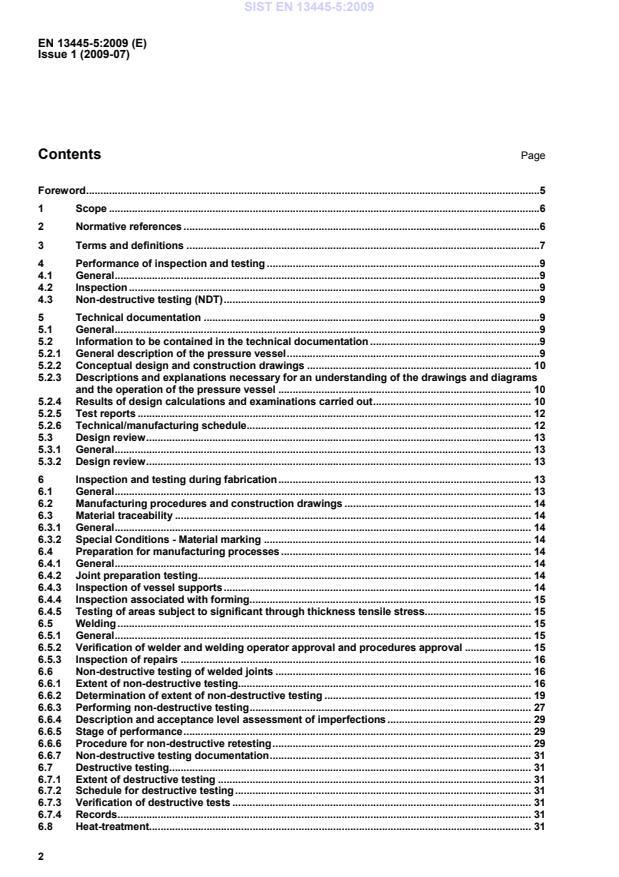

Issue 1 (2009-07) 2 Contents Page Foreword.5 1 Scope.6 2 Normative references.6 3 Terms and definitions.7 4 Performance of inspection and testing.9 4.1 General.9 4.2 Inspection.9 4.3 Non-destructive testing (NDT).9 5 Technical documentation.9 5.1 General.9 5.2 Information to be contained in the technical documentation.9 5.2.1 General description of the pressure vessel.9 5.2.2 Conceptual design and construction drawings.10 5.2.3 Descriptions and explanations necessary for an understanding of the drawings and diagrams and the operation of the pressure vessel.10 5.2.4 Results of design calculations and examinations carried out.10 5.2.5 Test reports.12 5.2.6 Technical/manufacturing schedule.12 5.3 Design review.13 5.3.1 General.13 5.3.2 Design review.13 6 Inspection and testing during fabrication.13 6.1 General.13 6.2 Manufacturing procedures and construction drawings.14 6.3 Material traceability.14 6.3.1 General.14 6.3.2 Special Conditions - Material marking.14 6.4 Preparation for manufacturing processes.14 6.4.1 General.14 6.4.2 Joint preparation testing.14 6.4.3 Inspection of vessel supports.14 6.4.4 Inspection associated with forming.15 6.4.5 Testing of areas subject to significant through thickness tensile stress.15 6.5 Welding.15 6.5.1 General.15 6.5.2 Verification of welder and welding operator approval and procedures approval.15 6.5.3 Inspection of repairs.16 6.6 Non-destructive testing of welded joints.16 6.6.1 Extent of non-destructive testing.16 6.6.2 Determination of extent of non-destructive testing.19 6.6.3 Performing non-destructive testing.27 6.6.4 Description and acceptance level assessment of imperfections.29 6.6.5 Stage of performance.29 6.6.6 Procedure for non-destructive retesting.29 6.6.7 Non-destructive testing documentation.31 6.7 Destructive testing.31 6.7.1 Extent of destructive testing.31 6.7.2 Schedule for destructive testing.31 6.7.3 Verification of destructive tests.31 6.7.4 Records.31 6.8 Heat-treatment.31 SIST EN 13445-5:2009

Issue 1 (2009-07) 3 7 Subcontracted elements.32 7.1 General.32 7.2 Subcontracted welding related activities.32 7.3 Subcontracted non-destructive testing activities.32 7.3.1 Use of contract NDT personnel at the premises of the vessel manufacturer.32 7.3.2 Subcontracting of NDT at a subcontractors premises.32 8 Miscellaneous tests.33 9 Calibration.33 9.1 General.33 9.2 Calibration procedure.33 9.2.1 General.33 9.2.2 Calibration.34 9.2.3 Frequency.34 9.3 Identification.34 9.4 Registration.34 10 Final assessment.35 10.1 General.35 10.2 Extent of final assessment.35 10.2.1 Visual and dimensional inspection.35 10.2.2 Review of documentation.36 10.2.3 Proof test.36 10.2.4 Post pressure test inspection.46 10.2.5 Inspection of safety accessories.46 11 Marking and declaration of compliance with the standard.46 11.1 General.46 11.2 Marking method.46 11.2.1 Direct stamping.47 11.2.2 Nameplate.47 11.3 Marking units.47 11.4 Marking contents.47 11.5 Declaration of compliance with the standard.48 12 Records.48 12.1 Type of records.48 12.2 Control and access of records.49 12.3 Retention of records.50 13 Shipping.50 Annex A (normative)

Inspection and testing of serially produced pressure vessels

Model acceptance51 Annex B (normative)

Detailed dimensional requirements for pressure vessels.57 Annex C (normative)

Access and inspection openings, closing mechanisms and special locking elements.59 Annex D (informative)

Leak Testing.71 Annex E (informative)

Acoustic emission.72 Annex F (normative)

Inspection and testing of pressure vessels or parts subject to creep.74 Annex G (normative)

Inspection and testing of pressure vessels subject to cyclic loads.77 Annex H (informative)

Declaration of compliance with this standard.79 SIST EN 13445-5:2009

Issue 1 (2009-07) 4 Annex I (informative)

Specific tests during construction to assist in-service inspection.81 Annex Y (informative)

Differences between EN 13445-5:2002 and EN 13445-5:2009.83 Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of the EU Pressure Equipment Directive 97/23/EC.84 Bibliography.85

Issue 1 (2009-07) 5 Foreword This document (EN 13445-5:2009) has been prepared by Technical Committee CEN/TC 54 “Unfired pressure vessels”, the secretariat of which is held by BSI. This European Standard shall be given the status of a national standard, either by publication of an identical text or by endorsement, at the latest by December 2009, and conflicting national standards shall be withdrawn at the latest by December 2009. Attention is drawn to the possibility that some of the elements of this document may be the subject of patent rights. CEN [and/or CENELEC] shall not be held responsible for identifying any or all such patent rights. This document has been prepared under a mandate given to CEN by the European Commission and the European Free Trade Association, and supports essential requirements of EU Directive(s). For relationship with EU Directive(s), see informative annex ZA, which is an integral part of this document. This European Standard consists of the following Parts: ⎯ Part 1: General. ⎯ Part 2: Materials. ⎯ Part 3: Design. ⎯ Part 4: Fabrication. ⎯ Part 5: Inspection and testing. ⎯ Part 6: Requirements for the design and fabrication of pressure vessels and pressure parts constructed from spheroidal graphite cast iron. ⎯ CR 13445-7, Unfired pressure vessels — Part 7: Guidance on the use of conformity assessment procedures.

⎯ Part 8: Additional requirements for pressure vessels of aluminium and aluminium alloys. ⎯ CEN/TR 13445-9, Unfired pressure vessels — Part 9: Conformance of EN 13445 series to ISO 16528 This document supersedes EN 13445-5:2009. This new edition incorporates the Amendments which have been approved previously by CEN members, and the corrected pages up to Issue 36 without any further technical change. Annex Y to EN 13445-1:2009 and Annex Y to this Part provides details of significant technical changes between this European Standard and the previous edition. Amendments to this new edition may be issued from time to time and then used immediately as alternatives to rules contained herein. It is intended to deliver a new Issue of EN 13445:2009 each year, consolidating these Amendments and including other identified corrections. According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and the United Kingdom.

Issue 1 (2009-07) 6 1 Scope This Part of this European Standard specifies the inspection and testing of individual and serially produced pressure vessels made of steels in accordance with EN 13445-2:2009 subject to predominantly non_cyclic operation (i.e. vessels operating below 500 full equivalent pressure cycles). Special provisions for cyclic operation are given in EN 13445-3:2009 and in Annex G of this Part. Special provisions for vessels or vessel parts working in the creep range are given in Clause 5, Clause 6, Clause 10, Annex H and Annex I of this Part. NOTE The responsibilities of parties involved in the conformity assessment procedures are given in Directive 97/23/EC. Guidance on this can be found in CR 13445-7. 2 Normative references This European Standard incorporates by dated or undated reference, provisions from other publications. These normative references are cited at the appropriate places in the text and the publications are listed hereafter. For dated references, subsequent amendments to or revisions of any of these publications apply to this European Standard only when incorporated in it by amendment or revision. For undated references the latest edition of the publication referred to applies (including amendments). EN 287-1:2004, EN 287-1:2004/A2:2005, Qualification test of welders — Fusion welding — Part 1: Steels. EN 473:2008, Non-destructive testing — Qualification and certification of NDT personnel — General principles. EN 571-1:1997, Non-destructive testing — Penetrant testing — Part 1: General principles. CEN/TS 764-6:2004, Pressure equipment — Part 6: Structure and content of operating instructions. EN 583-4:2002, EN 583-4:2002/A1:2003, Non-destructive testing — Ultrasonic examination — Part 4: Examination for discontinuities perpendicular to the surface. EN 895:1995, Destructive tests on welds in metallic materials — Transverse tensile test. EN 970:1997, Non-destructive examination of fusion welds — Visual examination. EN 1289:1998, EN 1289:1998/A1:2002, EN 1289:1998/A2:2003, Non-destructive testing of welds — Penetrant testing of welds — Acceptance levels. EN 1290:1998, EN 1290:1998/A1:2002, EN 1290:1998/A2:2003, Non-destructive testing of welds — Magnetic particle testing of welds. EN 1291:1998, EN 1291:1998/A1:2002, EN 1291:1998/A2:2003, Non-destructive testing of welds — Magnetic particle testing of welds — Acceptance levels. EN 1418:1997, Welding personnel — Approval testing of welding operators for fusion welding and resistance weld setters for fully mechanized and automatic welding of metallic materials. EN 1435:1997, EN 1435:1997/A1:2002, EN 1435:1997/A2:2003, Non-destructive testing of welds — Radiographic testing of welded joints. EN 1712:1997, EN 1712:1997/A1:2002, EN 1712:1997/A2:2003, Non-destructive testing of welds — Ultrasonic testing of welded joints — Acceptance levels. SIST EN 13445-5:2009

Issue 1 (2009-07) 7 EN 1713:1998, EN 1713:1998/A1:2002, EN 1713:1998/A2:2003, Non-destructive testing of welds — Ultrasonic testing — Characterization of indications in welds. EN 1714:1997, EN 1714:1997/A1:2002, EN 1714:1997/A2:2003, Non-destructive examination of welds — Ultrasonic examination of welded joints. EN 1779:1999, EN 1779:1999/A1:2003, Non-destructive testing — Leak testing — Criteria for method and technique selection. EN 12062:1997, EN 12062:1997/A1:2202, EN 12062:1997/A2:2003, Non-destructive testing of welds — General rules for metallic materials. EN 12517-1:2006, Non-destructive testing of welds — Radiographic testing of welded joints — Acceptance levels. EN 13445-1:2009, Unfired pressure vessels — Part 2: General. EN 13445-2:2009, Unfired pressure vessels — Part 2: Materials. EN 13445-3:2009, Unfired pressure vessels — Part 3: Design. EN 13445-4:2009, Unfired pressure vessels — Part 4: Fabrication. EN ISO 4063:2000, Welding and allied processes – Nomenclature of processes and reference numbers (ISO 4063:1998). EN ISO 5817:2007, Welding — Fusion-welded joints in steel, nickel, titanium and their alloys (beam welding excluded) – Quality levels for imperfections (ISO 5817:2003). EN ISO 6520-1:2007, Welding and allied processes — Classification of geometric imperfections in metallic materials — Part 1: Fusion welding (ISO 6520-1:2007). 3 Terms and definitions For the purposes of this European Standard the following terms and definitions apply. 3.1 design review procedure by which a manufacturer ascertains and attests that the design meets the requirements of this standard 3.2 design approval procedure by which a responsible authority ascertains and attests that the design meets the requirements of this standard 3.3 testing group grouping which determines the appropriate level of non-destructive testing (NDT) on a welded joint NOTE There are four testing groups. 3.4 inspection survey activity which assesses the compliance of the pressure vessel to the technical specification SIST EN 13445-5:2009

Issue 1 (2009-07) 8 NOTE It is a major activity, undertaken mainly by the manufacturer during design, manufacture and testing of equipment. It can be complemented by inspection by other parties. Inspection includes the assessment of testing activities. 3.5 testing procedure used to attest vessel compliance with the technical requirements of this standard by one or more tests 3.6 technical specification technical data included in the order or mandatory for pressure vessels and covering such things as regulations and user’s specific requirements 3.7 repair process of rectifying a condition in either base material or weld to ensure compliance with this standard NOTE The following definitions all relate to serially produced pressure vessels as described in Annex A. 3.8 serial production manufacture of identical vessels or parts which subsequently are joined to form a complete vessel and which are manufactured to a single model approval, using the same manufacturing procedure involving a continuous fabrication process 3.9 continuous fabrication process process where the welding of the main seams and branch welds is essentially continuous NOTE Stoppages or break-downs requiring resetting of the welding machine and/or NDT equipment constitute a break in continuity. Adjustments to the welding machine within the welding procedure limitations do not qualify as resetting the welding machine. 3.10 model acceptance procedure which ascertains and attests that a representative sample of the production (a prototype vessel/part) meets the requirements of this standard in respect of design, manufacturing and testing NOTE Model acceptance is conducted by the manufacturer or the responsible authority depending on the conformity assessment module chosen. 3.11 prototype vessel/part first or representative example of a series of pressure vessels/parts covered by a single model acceptance 3.12 batch of vessels part of a series where the welding of the main weld joints and branch welds has been essentially continuous NOTE A stoppage in vessel production greater than three consecutive days requires the designation of a new batch. 3.13 shift period of time per day during which the welding operator or operators remain the same SIST EN 13445-5:2009

Issue 1 (2009-07) 9 4 Performance of inspection and testing 4.1 General Each individual vessel shall be inspected during construction and upon completion. Inspections shall be made to ensure that in all respects the design, materials, manufacturing, and testing comply with the requirements of this standard. Documented evidence shall be prepared to verify implementation of this requirement. 4.2 Inspection Inspection shall be carried out by the manufacturer to verify that all requirements of this standard have been met. The level of non-destructive testing (NDT) shall be dependent on the testing group as described in 4.3. 4.3 Non-destructive testing (NDT) The type and amount of non-destructive testing of a pressure vessel shall be based upon the testing group or combination of testing groups when permitted in 6.6.1.1.2 (see Table 6.6.1-1: testing groups for steel pressure vessels and Table 6.6.2-1: extent of non-destructive testing).

5 Technical documentation 5.1 General The vessel manufacturer shall document those items listed in 5.2, which shall be reviewed in accordance with 5.3, prior to manufacture commencing. The manufacturer shall state which vessels are covered by the same design documentation. 5.2 Information to be contained in the technical documentation For the purposes of this standard the following types of documents shall be considered necessary as technical documentation. 5.2.1 General description of the pressure vessel a) Name of vessel manufacturer and subcontractors, if applicable; b) Location/s of vessel manufacturers and sub-contractors, if applicable; c) Document describing design data and special consideration which covers: 1) maximum and minimum allowable pressures, design pressures and test pressures in bar for each compartment (vacuum with minus sign); 2) capacity in litres for each compartment; 3) maximum and minimum design temperatures; 4) nature and location of marking of the pressure vessel, nameplate or stamp; 5) the fluid group. SIST EN 13445-5:2009

Issue 1 (2009-07) 10 6) if the vessel is designed for fatigue according to Clause 17 or Clause 18 of EN 13445-3:2009: ⎯ the cyclic loads considered; ⎯ the allowed numbers of cycles; ⎯ the relevant fatigue locations; 7) the design method used e.g. if the vessel is totally or in part designed by Design by Analysis – Direct Route of Annex B of EN 13445-3:2009 or designed according to 6.3 of EN 13445-3:2009. 8) If the vessel is working in the creep range, the following additional information: ⎯ the design life (e.g. 100000 h) and expected life for each load case ⎯ the parts of the vessel which are subjected to creep ⎯ the value of the weld creep strength reduction factor which has been used for each weld joint subjected to creep ⎯ whether lifetime monitoring, as defined in Clause 19 of EN 13445-3:2009, is or not being applied. 5.2.2 Conceptual design and construction drawings The manufacturer analysis of hazards identifying those which apply to the pressure vessel on account of pressure shall be documented and be of sufficient detail. Details of the conceptual design including the design methods adopted, performance criteria and construction drawings shall be provided. Guidance about the detailed dimensional information that shall be provided is given in Annex B. Process diagrams, sub-assemblies or other data relevant to conceptual design shall also be maintained. 5.2.3 Descriptions and explanations necessary for an understanding of the drawings and diagrams and the operation of the pressure vessel a) operating instructions; b) special checks to be carried out e.g. tests envisaged on closures, bellows, clamping bolts, etc. c) operational position if this is significant with regard to the safety evaluation. 5.2.4 Results of design calculations and examinations carried out 5.2.4.1 Design calculations shall be provided by the vessel manufacturer to the extent necessary to demonstrate compliance with this standard. Supporting detailed drawings shall be prepared with all dimension notations marked. The drawings shall clearly identify in the case of cyclic loaded vessels, the critical areas. The maximum permissible peaking for cyclically loaded vessels shall also be given in the drawing. At least on the pressure vessel general arrangement drawing, the testing group for each welded joint shall be clearly identified. SIST EN 13445-5:2009

Issue 1 (2009-07) 11 5.2.4.2 If calculations are made with the aid of a computer in order to comply with this standard, then at least the following data shall be presented: a) explanation of notations; b) input values; c) reference number of the standard including edition and reference number of the equation; d) results of intermediate equations; e) calculated minimum thickness without additions or the calculated stress and its comparison to the allowable stress; f) wastage (corrosion) allowance; g) thickness tolerance (negative thickness tolerance); h) the chosen thickness. 5.2.4.3 In the event that stress analysis is carried out with the finite element method or other design methods they shall be documented as follows: a) input data; b) plotter graphs (original and copy) form; 1) the element subdivision; 2) the stresses, e.g. as line or arrow figures or equal stress curves; stress curves of surfaces; 3) the displacements; c) boundary conditions; d) the stresses in the most critical areas; e) the dividing and classifying of the stresses into different stress categories; f) the comparison of stress intensities and the allowable stress values. 5.2.4.4 In specific cases the following information shall be necessary: a) type of post weld heat treatment and, where necessary, type and extent of associated material tests; b) construction sequence schedule if the structural testing is to be carried out in several partial steps; c) fluid(s) being contained and its (their) specific gravity, if this is required for the design of the vessel; d) pressure testing medium, if the initial or the periodic pressure tests are to be carried out with a medium other than water, the test minimum metal temperature for proof tests (both hydrostatic and pneumatic); e) position of the vessel in the pressure tests (e.g. horizontal or vertical), if this is significant with regard to the safety evaluation; f) maximum and minimum liquid levels, if these are required with regard to the safety evaluation;

Issue 1 (2009-07) 12 g) static supplementary forces, e.g. bearing forces, wind and snow loads. An extra calculation shall be presented if the supplementary forces essentially affect the design of the pressure vessel; h) cyclic and dynamic loading, including seismic loading, where applicable; i) additional requirements based on other regulations; j) purchaser’s requirements based on the vessel operating conditions in addition to the requirements of this standard; k) possible corrosion attack, especially in crevices, which shall be taken into account; l) joint coefficient. 5.2.5 Test reports These shall consist, as a minimum, of the following: a) welding procedure qualification records, certificate of qualification of welding personnel; b) material certificates; c) an example of the proposed list of the manufacturing records; d) values of measured peaking for vessels subject to cyclic loads. 5.2.6 Technical/manufacturing schedule This shall consist of the following information: a) the welding processes to be used for the pressure containing parts and welding of any temporary or other attachments to pressure containing parts. The following data are required for the structural testing: 1) weld location, shape and preparation and where necessary build up of the layers and treatment of welds; 2) welding process (in the case of multiple processes, identification of the process against the weld joint); 3) welding consumables (classification according to the relevant European Standards or trade names); 4) type and extent of production test, number of test plates, non-destructive tests; If some of the data listed before are not available for the design review, then these shall be completed before finishing the manufacture. b) special checks to be carried out e.g. the tests envisaged on closures, bellows, clamping, bolts; c) any pertinent details relative to vessel design and data required in specific cases; 1) additional wall thickness if this is required by the purchaser; 2) operational position if this is significant with regard to the safety evaluation; SIST EN 13445-5:2009

Issue 1 (2009-07) 13 3) location and size of inspection and access openings and also closing mechanisms and special locking elements in accordance with Annex C; 4) special equipment to enter the pressure vessel (e.g. spiral stairs, climbing irons); 5) linings, e.g. of masonry and inserts, if significant with regard to the safety evaluation; 6) marking of the welds that will be made on the construction site; 7) proposals on safety; 8) proposals on process requirements such as drainage etc. 5.3 Design review 5.3.1 General A design review and documented acceptance shall be conducted in all cases. In particular the review shall include design calculations in accordance with the requirements of this standard, taking into consideration the supporting information of the manufacturer analysis of hazards, and the technical/manufacturing schedule in respect of its intended services. Following the design the pressure vessel shall be manufactured in accordance with the approved manufacturing drawings. 5.3.2 Design review The design review shall consist of, but not be limited to, the following areas:

a) the suitability of material for intended use; b) welding processes and consumables; c) the access to perform the required levels of inspections and tests based on proposed vessel construction geometry; d) the suitability of openings and closures in meeting the requirements of this standard; e) the provision and adequacy of safety accessories against the requirements of this standard for individual pressure vessels or devices which are contained within the pressure system or assembly. Alternatively the parties responsible for satisfying the provision of safety accessories shall be identified; f) the adequacy of proposed pressure retaining boundary (thickness, vessel geometry, weld joint geometry etc.) for design conditions against those required by the design requirements of this standard; g) the adequacy of the stress analysis method in accordance with

5.2.4.3; h) manufacturing and test procedures. 6 Inspection and testing during fabrication 6.1 General The inspection and testing activities during fabrication, described in this clause, shall be the responsibility of the manufacturer and shall be fully implemented for all pressure vessels. SIST EN 13445-5:2009

Issue 1 (2009-07) 14 6.2 Manufacturing procedures and construction drawings The manufacturer shall ensure that all construction drawings and manufacturing procedures reviewed and approved at the design stage in clause 5, shall be available at the appropriate work area and shall be fully implemented in manufacturing. Inspection records shall document the use of the correct and appropriate procedures, and/or drawings including revision status at the time the inspection is performed. 6.3 Material traceability 6.3.1 General The vessel manufacturer shall have and maintain an identification system for materials used in fabrication so that all material subject to stress due to pressure and those welded thereto in the completed vessel can be traced to its origin. This includes the use of welding consumable. The identification system used shall satisfy the requirements of EN 13445-4:2009. Testing of material traceability, including transfer of markings, shall be performed throughout fabrication and records maintained to document the method used from those permitted in EN 13445-4:2009 (i.e. direct markings visible on the completed vessel, a direct coded marking on the vessel or tabulation/as built sketches). Final records shall include all material certification required by this standard.

6.3.2 Special Conditions - Material marking Where service conditions prohibit die-stamping for material identification (see EN 13445-4:2009) and when so specified by the purchase order, the manufacturer of the base materials shall mark the required data on the materials in a manner which will allow positive identification during inspection upon delivery. The markings shall be recorded so that each item of material will be positively identified in its position in the completed vessel (e.g. material/position list) and shall form part of the final records. 6.4 Preparation for manufacturing processes 6.4.1 General Preparation for manufacturing processes such as edge preparation, vessel supports for formed parts prior to welding and forming shall be controlled and inspected to ensure that such activities are not detrimental to the completed vessel. 6.4.2 Joint preparation testing The extent to which edges are dressed prior to testing shall be in accordance with EN 13445-4:2009. All joint preparations shall be subject to visual inspection prior to any welding. Defects such as laminations, cracks and slag inclusion shall be removed prior to welding. In case of an increased probability of occurrence of imperfections or when imperfections have been detected, a visual inspection shall be supplemented by additional non-destructive testing. All inspections shall be carried out by qualified personnel. The result of joint preparation testing shall be recorded in the NDT inspection schedule. 6.4.3 Inspection of vessel supports All tack welds associated with bars, jacks, clamps, or other appropriate means used to hold the edges of vessel parts and/or provide support in welding shall be inspected. SIST EN 13445-5:2009

Issue 1 (2009-07) 15 ⎯ Welds of permanent attachments to pressure parts shall be examined to the extent described in Table 6.6.2-1 (line 21). ⎯ Welds of temporary attachments shall be examined after removal for surface cracks to the extent described in Table 6.6.2-1 (line 22). ⎯ Any repairs necessary following removal of temporary attachments shall be tested as described in 6.5.3. 6.4.4 Inspection associated with forming Prior to any forming the material to be formed shall be subject to visual inspection and thickness measurement in accordance with the requirements of EN 13445-4:2009. The result of the inspection shall be recorded in the NDT inspection schedule. 6.4.5 Testing of areas subject to significant through thickness tensile stress In case of an increased probability of internal damage in areas subject to significant through thickness tensile stress caused by welding, these areas shall be examined for internal imperfections prior to welding. The result of the inspection shall be recorded in the NDT inspection schedule 6.5 Welding

6.5.1 General When permitted by EN 13445-3:2009, permanent backing strip and joggle joint shall be fitted and adjusted such that the quality of the weld achieved is the same as a conventional single-sided butt weld. The weld shall be subject to the same type of non-destructive testing and acceptance criteria as a single-sided butt weld. Welds in all testing groups shall be subject to in-process inspections, especially welds of testing groups 3 or 4 not required to be subject to NDT under Table 6.6.1.2-1 shall be specifically subject to visual inspection at the "fit-up" and "chip back of second side of sound metal" stages. All finished welding shall be subject to visual inspection. In addition, depending on the testing group, the finished welds shall be subject to NDT in accordance with Tables 6.6.1-1 and 6.6.2-1 for that type of weld. 6.5.2 Verification of welder and welding operator approval and procedures approval The vessel manufacturer shall verify that welding has been done only by welders and operators who have been approved under the requirements of EN 287-1:2004 and EN 1418:1997. Procedures shall be qualified in accordance with EN 13445-4:2009. Welder and welding operators identification shall be controlled in accordance with EN 13445-4:2009. Traceability of the welder and welding operator shall be monitored by inspection throughout construction of the pressure vessel and shall be verified at the final assessment, see 10.2.2. SIST EN 13445-5:2009

Issue 1 (2009-07) 16 6.5.3 Inspection of repairs

All welded repairs shall be subject to the same non-destructive testing requirements as those which detected the imperfection. This includes the same acceptance criteria. Such repairs shall be carried out using approved weld procedures and approved welders and welding operators. The extent of testing of repairs shall comply with Table 6.6.2-1 and cover 100 % of the area repaired. Non welded repairs by surface dressing are permissible providing that the area of repair is subject to NDT according to Table 6.6.2-1 and free from unacceptable imperfections, see 6.6.5 for retesting requirements. Weld metal deposited to restore base material shall be subject to non-destructive testing for the full surface area involved, using Magnetic Particle Testing (MT) or Penetrant Testing (PT). 6.6 Non-destructive testing of welded joints 6.6.1 Extent of non-destructive testing The required extent of non-destructive testing depends both on the testing group and the type of the welded joints. Guidance to determine the required extent of testing is given in the following clauses. For serially produced pressure vessels an alternative route is given in Annex A. This annex is not applicable to vessels or vessel parts designed according to Design by Analysis – Direct Route of Annex B of

EN 13445-3:2009 or designed according to 6.3 of EN 13445-3:2009. This annex is not applicable for vessels or vessel parts working

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...