EN 422:2009

(Main)Plastics and rubber machines - Blow moulding machines - Safety requirements

Plastics and rubber machines - Blow moulding machines - Safety requirements

This European Standard covers essential health and safety requirements for the design of blow moulding machines for the processing of plastics. The significant hazards inherent in blow moulding machines are listed in Clause 4.

This European Standard does not cover dip blow moulding machines.

This European Standard does not cover hazards due to the use of fluorine or other toxic fluids.

The safety requirements for the interaction between blow moulding machines and ancillary equipment are stipulated. The technical safety requirements for the design of this equipment are not covered.

This European Standard does not cover the requirements for the design of the exhaust system.

The European Standard does not cover noise hazards.

This European Standard is not applicable to blow moulding machines which are manufactured before the date of its publication as an EN. A transition period until 29 December 2009 is foreseen during which the manufacturer may choose to apply either this or the previous version of the standard.

Kunststoff- und Gummimaschinen - Blasformmaschinen - Sicherheitsanforderungen

Diese Europäische Norm behandelt die wesentlichen Gesundheits- und Sicherheitsanforderungen an die

Konstruktion von Blasformmaschinen für die Verarbeitung von Kunststoff. Die signifikanten Gefährdungen an

Blasformmaschinen sind in Abschnitt 4 angegeben.

Diese Europäische Norm behandelt nicht Tauchblasformmaschinen.

Diese Europäische Norm behandelt nicht Gefährdungen durch die Verwendung von Fluor oder anderen

toxischen Fluiden.

Die Sicherheitsanforderungen für das Zusammenwirken zwischen Blasformmaschinen und Zusatzeinrichtungen

werden festgelegt. Die Sicherheitsanforderungen für die Konstruktion dieser Zusatzeinrichtungen

werden nicht behandelt.

Diese Europäische Norm behandelt nicht die Anforderungen an die Gestaltung einer Absaugeinrichtung.

Diese Europäische Norm behandelt nicht die Gefährdungen durch Lärm.

Diese Europäische Norm gilt nicht für Blasformmaschinen, die vor dem Ausgabedatum der Norm hergestellt

wurden. Eine Übergangszeit bis zum 28. Dezember 2009 ist vorgesehen, in der der Hersteller wählen kann,

entweder diese oder die Vorgängerversion der Norm anzuwenden.

Machines pour les matières plastiques et le caoutchouc - Machines de moulage par soufflage - Prescriptions de sécurité

La présente Norme européenne spécifie les prescriptions essentielles de santé et de sécurité relatives à la

conception des machines de moulage par soufflage utilisées dans l’industrie des matières plastiques. Les

phénomènes dangereux significatifs associés aux machines de moulage par soufflage sont énumérés à

l'Article 4.

La présente Norme européenne ne couvre pas les machines de moulage par soufflage de préformes

obtenues par trempage.

La présente Norme européenne ne couvre pas les phénomènes dangereux résultant de l’utilisation de fluor ou

d’autres fluides toxiques.

Les prescriptions de sécurité relatives aux interactions entre les machines de moulage par soufflage et leurs

équipements auxiliaires sont spécifiées. Les prescriptions de sécurité relatives à la conception des

équipements auxiliaires ne sont pas spécifiées.

La présente Norme européenne ne donne pas de prescriptions sur la conception de systèmes d’aspiration.

La présente Norme européenne ne traite pas des phénomènes dangereux dus au bruit.

Ce document n'est pas applicable aux machines de moulage par soufflage fabriquées avant sa date de

publication comme EN. Il est prévu une période de transition allant jusqu’au 29 décembre 2009, pendant

laquelle le constructeur peut choisir d’appliquer soit la présente norme, soit sa version antérieure.

Stroji za predelavo gume in plastike - Pihalni stroji za oblikovanje - Varnostne zahteve

General Information

- Status

- Published

- Publication Date

- 09-Jun-2009

- Withdrawal Date

- 30-Dec-2009

- Technical Committee

- CEN/TC 145 - Rubber and plastics machines - Safety

- Drafting Committee

- CEN/TC 145/WG 5 - Blow moulding machines - Safety

- Current Stage

- 9092 - Decision on results of review/2YR ENQ - revise - Review Enquiry

- Start Date

- 17-Mar-2025

- Completion Date

- 11-Feb-2026

- Directive

- 98/37/EC - Machinery

Relations

- Effective Date

- 13-Jun-2009

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 422:2009 - published by CEN - is the European Type C standard that sets the essential health and safety requirements for the design of blow moulding machines used in the processing of plastics. It identifies significant hazards (Clause 4) and specifies technical safety measures for machine design and machine‑to‑ancillary equipment interaction. EN 422:2009 supersedes EN 422:1995 and applies to machines manufactured after its publication (manufacturers had a transition option until 29 Dec 2009).

Important exclusions:

- Does not cover dip blow moulding machines

- Does not cover hazards from fluorine or other toxic fluids

- Does not set requirements for exhaust system design or machine noise hazards

- Technical design of ancillary equipment itself is outside scope

Key topics and requirements

EN 422:2009 addresses practical safety requirements and verification methods, including:

- List of significant hazards inherent to blow moulding (Clause 4) - crushing, shearing, injection, thermal burns, fluid leaks, ejection of material, electrical and EMC issues

- General safety principles and basic design requirements following EN ISO 12100 (risk reduction by design)

- Safety distances and protective device positioning (relating to EN 999, EN ISO 13857)

- Emergency stop requirements and acknowledgement systems

- Fluid system safety (hydraulic/pneumatic) and risks from high‑pressure fluids (EN 982 / EN 983)

- Safeguards and guards for moving parts (EN 953), pressure sensitive devices and electro‑sensitive protective equipment (EN 1760‑2; EN 61496)

- Thermal and chemical hazards, including hot/cold surfaces and harmful emission controls (EN ISO 13732 series)

- Electrical safety and EMC requirements for machine electrical equipment (EN 60204‑1; EN 61000‑6‑2 / EN 61000‑6‑4)

- Verification, testing and documentation: procedures for verifying protective measures and required information for use, instruction handbook and marking obligations

Applications and who uses this standard

EN 422:2009 is primarily used by:

- Machine designers and manufacturers of blow moulding machines

- Safety engineers and risk assessors in plastics processing plants

- Compliance officers and notified bodies assessing conformity with the Machinery Directive (informative Annexes ZA/ZB)

- Integrators and buyers of blow moulding lines who need to ensure safe interaction with ancillary equipment

Practical uses:

- Designing safe blow moulding machinery and production lines

- Producing instruction handbooks, marking and safety documentation

- Preparing conformity evidence for CE marking and machine commissioning

Related standards

EN 422:2009 references and works alongside key standards such as:

- EN ISO 12100 (machine safety - design principles)

- EN 60204‑1 (electrical equipment)

- EN ISO 13849‑1 (safety‑related control systems)

- EN 953, EN 999, EN 1760‑2, EN 982 / EN 983, EN 61496, EN ISO 13732 series

Keywords: EN 422:2009, blow moulding machines safety, plastics and rubber machines, CEN standard, safety requirements, machine design, fluid systems, emergency stop.

Get Certified

Connect with accredited certification bodies for this standard

Smithers Quality Assessments

US management systems and product certification.

DIN CERTCO

DIN Group product certification.

Sponsored listings

Frequently Asked Questions

EN 422:2009 is a standard published by the European Committee for Standardization (CEN). Its full title is "Plastics and rubber machines - Blow moulding machines - Safety requirements". This standard covers: This European Standard covers essential health and safety requirements for the design of blow moulding machines for the processing of plastics. The significant hazards inherent in blow moulding machines are listed in Clause 4. This European Standard does not cover dip blow moulding machines. This European Standard does not cover hazards due to the use of fluorine or other toxic fluids. The safety requirements for the interaction between blow moulding machines and ancillary equipment are stipulated. The technical safety requirements for the design of this equipment are not covered. This European Standard does not cover the requirements for the design of the exhaust system. The European Standard does not cover noise hazards. This European Standard is not applicable to blow moulding machines which are manufactured before the date of its publication as an EN. A transition period until 29 December 2009 is foreseen during which the manufacturer may choose to apply either this or the previous version of the standard.

This European Standard covers essential health and safety requirements for the design of blow moulding machines for the processing of plastics. The significant hazards inherent in blow moulding machines are listed in Clause 4. This European Standard does not cover dip blow moulding machines. This European Standard does not cover hazards due to the use of fluorine or other toxic fluids. The safety requirements for the interaction between blow moulding machines and ancillary equipment are stipulated. The technical safety requirements for the design of this equipment are not covered. This European Standard does not cover the requirements for the design of the exhaust system. The European Standard does not cover noise hazards. This European Standard is not applicable to blow moulding machines which are manufactured before the date of its publication as an EN. A transition period until 29 December 2009 is foreseen during which the manufacturer may choose to apply either this or the previous version of the standard.

EN 422:2009 is classified under the following ICS (International Classification for Standards) categories: 83.200 - Equipment for the rubber and plastics industries. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 422:2009 has the following relationships with other standards: It is inter standard links to EN 422:1995, EN 61000-6-2:2001, EN 61496-3:2001, EN 61000-6-4:2001, EN 60529:1991, EN 61496-1:1997, EN ISO 13732-3:2008, EN ISO 14122-1:2001, EN 999:1998, EN ISO 12100-2:2003, EN 4613:2009, EN ISO 13857:2008, EN ISO 13849-1:2006, EN ISO 14122-4:2004, EN ISO 12100-1:2003. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 422:2009 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/079, M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 422:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Stroji za predelavo gume in plastike - Pihalni stroji za oblikovanje - Varnostne zahteveKunststoff- und Gummimaschinen - Blasformmaschinen - SicherheitsanforderungenMachines pour les matières plastiques et le caoutchouc - Machines de moulage par soufflage - Prescriptions de sécuritéPlastics and rubber machines - Blow moulding machines - Safety requirements83.200Oprema za gumarsko industrijo in industrijo polimernih materialovEquipment for the rubber and plastics industriesICS:Ta slovenski standard je istoveten z:EN 422:2009SIST EN 422:2009en,fr01-september-2009SIST EN 422:2009SLOVENSKI

STANDARDSIST EN 422:20001DGRPHãþD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 422June 2009ICS 83.200Supersedes EN 422:1995

English VersionPlastics and rubber machines - Blow moulding machines -Safety requirementsMachines pour les matières plastiques et le caoutchouc -Machines de moulage par soufflage - Prescriptions desécuritéKunststoff- und Gummimaschinen - Blasformmaschinen -SicherheitsanforderungenThis European Standard was approved by CEN on 13 May 2009.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre:

Avenue Marnix 17,

B-1000 Brussels© 2009 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 422:2009: ESIST EN 422:2009

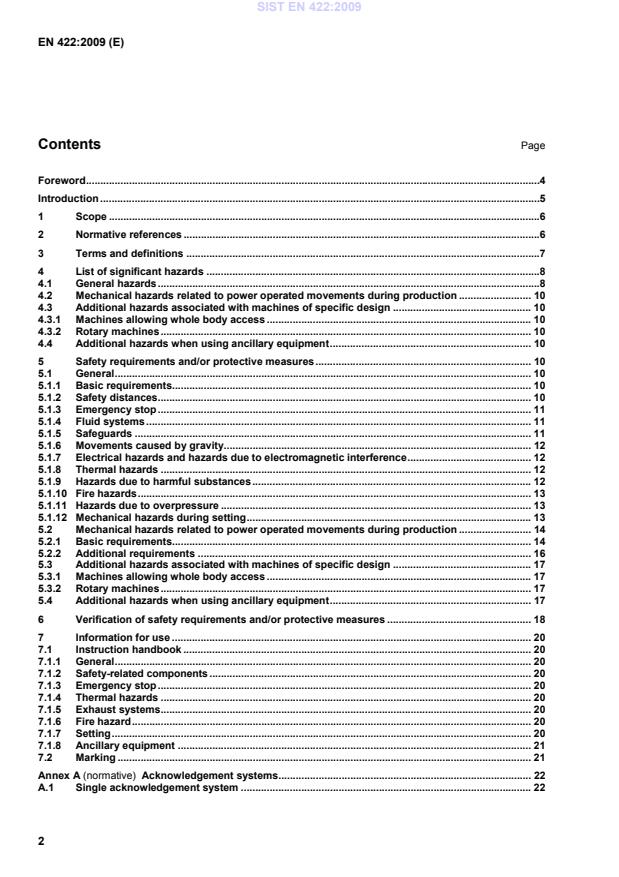

Acknowledgement systems . 22A.1 Single acknowledgement system . 22SIST EN 422:2009

Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC . 23Annex ZB (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC . 24 SIST EN 422:2009

Introduction This European Standard is a type C standard as defined in EN ISO 12100-1:2003. The machinery concerned and the extent to which hazards, hazardous situations and hazardous events are covered are indicated in the scope of this European Standard. When provisions of this type C standard are different from those which are stated in type A or B standards, the provisions of this type C standard take precedence over the provisions of the other standards for machines that have been designed and built according to the provisions of this type C standard. SIST EN 422:2009

1 Scope This European Standard covers essential health and safety requirements for the design of blow moulding machines for the processing of plastics. The significant hazards inherent in blow moulding machines are listed in Clause 4. This European Standard does not cover dip blow moulding machines. This European Standard does not cover hazards due to the use of fluorine or other toxic fluids. The safety requirements for the interaction between blow moulding machines and ancillary equipment are stipulated. The technical safety requirements for the design of this equipment are not covered. This European Standard does not cover the requirements for the design of the exhaust system. The European Standard does not cover noise hazards. This European Standard is not applicable to blow moulding machines which are manufactured before the date of its publication as an EN. A transition period until 29 December 2009 is foreseen during which the manufacturer may choose to apply either this or the previous version of the standard. 2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 953, Safety of machinery — Guards — General requirements for the design and construction of fixed and movable guards EN 982:1996, Safety of machinery — Safety requirements for fluid power systems and their components — Hydraulics EN 983:1996, Safety of machinery — Safety requirements for fluid power systems and their components — Pneumatics EN 999:1998, Safety of machinery — The positioning of protective equipment in respect of approach speeds of parts of the human body EN 1760-2:2001, Safety of machinery — Pressure sensitive protective devices — Part 2: General principles for the design and testing of pressure sensitive edges and pressure sensitive bars

EN 60204-1:2006, Safety of machinery — Electrical equipment of machines — Part 1: General requirements (IEC 60204-1:2005, modified) EN 60529:1991, Degrees of protection provided by enclosures (IP Code) (IEC 60529:1989) EN 61000-6-2:2001, Electromagnetic compatibility (EMC) — Part 6-2: Generic standards; Immunity for industrial environments (IEC 61000-6- 2:1999, modified) EN 61000-6-4:2001, Electromagnetic compatibility (EMC) — Part 6-4: Generic standards; Emission standard for industrial environments (IEC 61000-6-4:1997, modified) EN 61496-1:1997, Safety of machinery — Electro-sensitive protective equipment — Part 1: General requirements and tests (IEC 61496-1:1997) SIST EN 422:2009

(IEC 61496-3:2001) EN ISO 12100-1:2003, Safety of machinery — Basic concepts, general principles for design — Part 1: Basic terminology, methodology (ISO 12100-1:2003) EN ISO 12100-2:2003, Safety of machinery — Basic concepts, general principles for design — Part 2: Technical principles (ISO 12100-2:2003) EN ISO 13732-1:2008, Ergonomics of the thermal environment — Methods for the assessment of human responses to contact with surfaces — Part 1: Hot surfaces (ISO 13732-1:2006) EN ISO 13732-3:2008, Ergonomics of the thermal environment — Methods for the assessment of human responses to contact with surfaces — Part 3: Cold surfaces (ISO 13732-3:2005) EN ISO 13849-1:2006, Safety of machinery — Safety related parts of control systems — Part 1: General principles for design (ISO 13849-1:2006) EN ISO 13857:2008, Safety of machinery — Safety distances to prevent hazard zones being reached by upper and lower limbs (ISO 13857:2008) EN ISO 14122-1:2001, Safety of machinery — Permanent means of access to machinery — Part 1: Choice of a fixed means of access between two levels (ISO 14122-1:2001) EN ISO 14122-2:2001, Safety of machinery — Permanent means of access to machinery — Part 2: Working platforms and walkways (ISO 14122-2:2001) EN ISO 14122-3:2001, Safety of machinery — Permanent means of access to machinery — Part 3: Stairs, stepladders and guard-rails (ISO 14122-3:2001)

EN ISO 14122-4:2004, Safety of machinery — Permanent means of access to machinery — Part 4: Fixed ladders (ISO 14122-4:2004) ISO 7010 Graphical symbols — Safety colours and safety signs — Safety signs used in workplaces and public areas 3 Terms and definitions For the purposes of this document, the following terms and definitions apply. 3.1 blow moulding machine machine which expands a parison or preform to make a hollow article using fluid under pressure blown into a fixed or moving blow mould 3.2 area of movement of the moulds area in which the moulds move, close or open, also including the actuating equipment 3.3 feed area area of the extrusion head or of the injection nozzle or of the preform feeding device 3.4 cutting device apparatus which cuts the parison at the exit of the extrusion head SIST EN 422:2009

Crushing, shearing or impact due to movements of power operated guards, see 5.1.5.1 and 5.3.1. Crushing, shearing or impact due to movements of parts of the machine by gravity, see 5.1.6 and 5.1.12. Electric shock or burns due to direct or indirect contact with live conductive parts, see 5.1.7. Malfunction of the control circuits due to electromagnetic interference with the electrical equipment, see 5.1.7. Burns and/or scalds (see 5.1.8) due to very high or low temperatures of: SIST EN 422:2009

preforms or parisons. Contact with, or inhalation of, harmful substances (see 5.1.9) that may be released from: the blowing gas;

the cooling and conditioning fluids; or

the processed plastic and the blown part when the mould is not completely closed (before blowing) or when the mould opens (after blowing). Fire due to ignition of the plastic material when a hot cutting device is used, see 5.1.10.

Impact due to bursting of the blown parts when the moulds open (applicable only when moulded parts with volume greater than 20 litres are blown with pressure greater than 10 bar), see 5.1.11.

Crushing, shearing or impact during setting (see 5.1.12) due to movement of: the blowing mould and its parts; the blowing needles or mandrels; the stretch rods; the individual blowing stations (multistation machines); the rotary table; the injection unit; the insert loading system. SIST EN 422:2009

EN 983:1996. The flexible hoses for hydraulic fluids under a pressure of more than 50 bar and for pneumatic fluids of more than 10 bar

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...