IEC 60076-18:2012

(Main)Power transformers - Part 18: Measurement of frequency response

Power transformers - Part 18: Measurement of frequency response

IEC 60076-18:2012 covers the measurement technique and measuring equipment to be used when a frequency response measurement is required either on-site or in the factory either when the test object is new or at a later stage. This standard is applicable to power transformers, reactors, phase shifting transformers and similar equipment.

Transformateurs de puissance - Partie 18: Mesure de la réponse en fréquence

La CEI 60076-18:2012 couvre la technique de mesure et l'appareillage de mesure à utiliser lorsqu'une mesure de réponse en fréquence est requise, soit sur site, soit en usine, lorsque l'objet à soumettre à essai est neuf ou à un stade plus avancé. La présente norme est applicable aux transformateurs de puissance, bobines d'inductance, transformateurs déphaseurs et appareillages similaires.

General Information

- Status

- Published

- Publication Date

- 08-Jul-2012

- Technical Committee

- TC 14 - Power transformers

- Drafting Committee

- PT 60076-18 - TC 14/PT 60076-18

- Current Stage

- PPUB - Publication issued

- Start Date

- 09-Jul-2012

- Completion Date

- 15-Aug-2012

IEC 60076-18:2012 Overview

IEC 60076-18:2012 titled "Power transformers - Part 18: Measurement of frequency response" is an international standard developed by the International Electrotechnical Commission (IEC). It specifies the measurement techniques and appropriate equipment for conducting frequency response measurements on power transformers, reactors, phase-shifting transformers, and similar electrical equipment. Applicable for both factory and on-site testing, this standard ensures accurate assessment whether the equipment is new or undergoing later inspection.

Frequency response measurement (FRM) is a critical diagnostic method that assesses the mechanical integrity and electrical characteristics of transformer windings. By analyzing the transformer's frequency response, utilities and manufacturers can detect faults such as winding displacement, short circuits, or insulation degradation, which are vital for maintaining reliable power systems.

Key Topics in IEC 60076-18:2012

Scope and Application: Covers power transformers, reactors, phase shifting transformers, addressing both new units and in-service equipment.

Measurement Methodology: Details the procedures for establishing test conditions, connecting instruments, and performing measurements. It addresses factors like test object conditions, zero-check and repeatability tests, and selecting proper measurement configurations depending on winding type (star, delta, zig-zag).

Measurement Configuration Guidelines: Provides exhaustive guidance on suitable connection methods, including configurations for single and three-phase transformers, auto-transformers, reactors, and taps with neutral or delta connections.

Frequency Range & Points: Specifies the frequency spectrum and resolution points needed to accurately capture the frequency response.

Measuring Equipment Requirements: Defines instrument criteria such as dynamic range, amplitude and phase accuracy, frequency accuracy, measurement resolution bandwidth, operating temperature, and calibration protocols for reliable and standardized results.

Recording and Documentation: Recommends thorough record-keeping for each measurement, including test parameters and contextual information to enable traceability and comparative analysis.

Annexes for Practical Support: Includes informative annexes that elaborate on commonly used measurement configurations, factors influencing frequency response, application examples, and recommended data formats.

Practical Applications

Frequency response measurements as standardized by IEC 60076-18:2012 have several critical industrial applications:

Transformer Condition Assessment: Diagnose winding displacement, short circuits, and mechanical deformation to prevent catastrophic failures.

Factory Acceptance Testing: Verify new transformers meet design and manufacturing specifications before shipment.

On-site Diagnostics: Evaluate transformers after transportation or severe operational events to detect latent mechanical defects.

Maintenance and Asset Management: Monitor transformer health trends over time to plan preventive maintenance and optimize service life.

Research and Development: Assist in transformer design validation and fault analysis through precise frequency response characterization.

By following this standard, engineers can apply consistent, repeatable frequency response measurements that enhance the reliability and safety of electrical power infrastructure.

Related IEC Standards

IEC 60076-18 is part of the comprehensive IEC 60076 series covering power transformers. Other relevant standards within this series include:

IEC 60076-1: General requirements for power transformers.

IEC 60076-3: Insulation levels, dielectric tests, and external clearances.

IEC 60076-11: Dry-type transformers.

IEC 60076-14: Liquid-immersed transformers.

IEC 60076-15: Guide for seismic qualification of transformers.

These standards complement IEC 60076-18 by addressing mechanical design, testing procedures, and performance criteria, forming a robust framework for transformer safety, performance, and diagnostics.

Keywords: IEC 60076-18, frequency response measurement, power transformers testing, transformer diagnostics, transformer winding condition, electrical equipment testing, transformer maintenance, IEC standards power transformers, transformer frequency testing methods

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60076-18:2012 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Power transformers - Part 18: Measurement of frequency response". This standard covers: IEC 60076-18:2012 covers the measurement technique and measuring equipment to be used when a frequency response measurement is required either on-site or in the factory either when the test object is new or at a later stage. This standard is applicable to power transformers, reactors, phase shifting transformers and similar equipment.

IEC 60076-18:2012 covers the measurement technique and measuring equipment to be used when a frequency response measurement is required either on-site or in the factory either when the test object is new or at a later stage. This standard is applicable to power transformers, reactors, phase shifting transformers and similar equipment.

IEC 60076-18:2012 is classified under the following ICS (International Classification for Standards) categories: 29.060.20 - Cables; 29.180 - Transformers. Reactors. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60076-18:2012 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60076-18 ®

Edition 1.0 2012-07

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Power transformers –

Part 18: Measurement of frequency response

Transformateurs de puissance –

Partie 18: Mesure de la réponse en fréquence

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et les

microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Useful links:

IEC publications search - www.iec.ch/searchpub Electropedia - www.electropedia.org

The advanced search enables you to find IEC publications The world's leading online dictionary of electronic and

by a variety of criteria (reference number, text, technical electrical terms containing more than 30 000 terms and

committee,…). definitions in English and French, with equivalent terms in

It also gives information on projects, replaced and additional languages. Also known as the International

withdrawn publications. Electrotechnical Vocabulary (IEV) on-line.

IEC Just Published - webstore.iec.ch/justpublished Customer Service Centre - webstore.iec.ch/csc

Stay up to date on all new IEC publications. Just Published If you wish to give us your feedback on this publication

details all new publications released. Available on-line and or need further assistance, please contact the

also once a month by email. Customer Service Centre: csc@iec.ch.

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Liens utiles:

Recherche de publications CEI - www.iec.ch/searchpub Electropedia - www.electropedia.org

La recherche avancée vous permet de trouver des Le premier dictionnaire en ligne au monde de termes

publications CEI en utilisant différents critères (numéro de électroniques et électriques. Il contient plus de 30 000

référence, texte, comité d’études,…). termes et définitions en anglais et en français, ainsi que

Elle donne aussi des informations sur les projets et les les termes équivalents dans les langues additionnelles.

publications remplacées ou retirées. Egalement appelé Vocabulaire Electrotechnique

International (VEI) en ligne.

Just Published CEI - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications de la CEI.

Just Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur

Disponible en ligne et aussi une fois par mois par email. cette publication ou si vous avez des questions

contactez-nous: csc@iec.ch.

IEC 60076-18 ®

Edition 1.0 2012-07

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Power transformers –

Part 18: Measurement of frequency response

Transformateurs de puissance –

Partie 18: Mesure de la réponse en fréquence

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX X

ICS 29.180 ISBN 978-2-83220-222-7

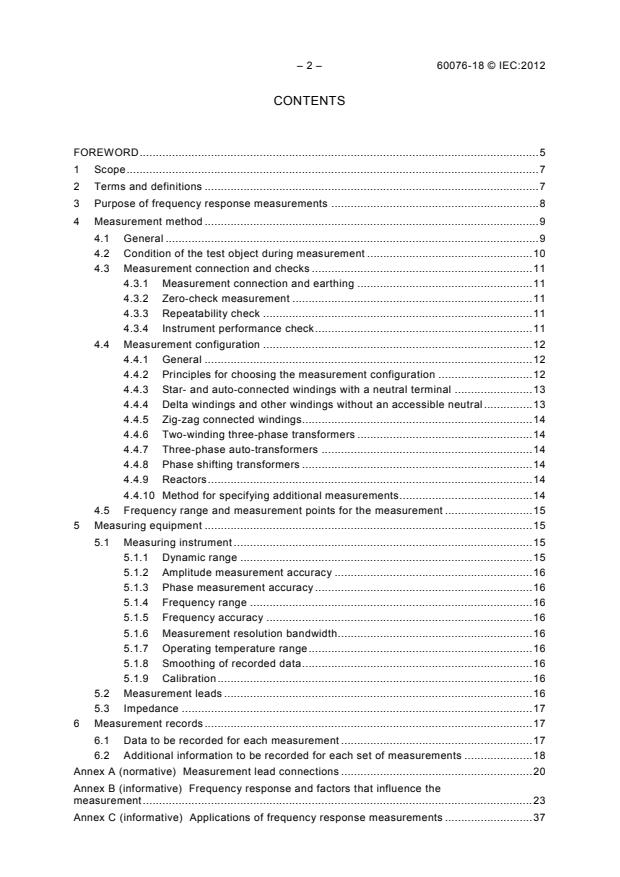

– 2 – 60076-18 © IEC:2012

CONTENTS

FOREWORD . 5

1 Scope . 7

2 Terms and definitions . 7

3 Purpose of frequency response measurements . 8

4 Measurement method . 9

4.1 General . 9

4.2 Condition of the test object during measurement . 10

4.3 Measurement connection and checks . 11

4.3.1 Measurement connection and earthing . 11

4.3.2 Zero-check measurement . 11

4.3.3 Repeatability check . 11

4.3.4 Instrument performance check . 11

4.4 Measurement configuration . 12

4.4.1 General . 12

4.4.2 Principles for choosing the measurement configuration . 12

4.4.3 Star- and auto-connected windings with a neutral terminal . 13

4.4.4 Delta windings and other windings without an accessible neutral . 13

4.4.5 Zig-zag connected windings. 14

4.4.6 Two-winding three-phase transformers . 14

4.4.7 Three-phase auto-transformers . 14

4.4.8 Phase shifting transformers . 14

4.4.9 Reactors . 14

4.4.10 Method for specifying additional measurements . 14

4.5 Frequency range and measurement points for the measurement . 15

5 Measuring equipment . 15

5.1 Measuring instrument . 15

5.1.1 Dynamic range . 15

5.1.2 Amplitude measurement accuracy . 16

5.1.3 Phase measurement accuracy . 16

5.1.4 Frequency range . 16

5.1.5 Frequency accuracy . 16

5.1.6 Measurement resolution bandwidth . 16

5.1.7 Operating temperature range . 16

5.1.8 Smoothing of recorded data . 16

5.1.9 Calibration . 16

5.2 Measurement leads . 16

5.3 Impedance . 17

6 Measurement records . 17

6.1 Data to be recorded for each measurement . 17

6.2 Additional information to be recorded for each set of measurements . 18

Annex A (normative) Measurement lead connections . 20

Annex B (informative) Frequency response and factors that influence the

measurement . 23

Annex C (informative) Applications of frequency response measurements . 37

60076-18 © IEC:2012 – 3 –

Annex D (informative) Examples of measurement configurations . 39

Annex E (informative) XML data format . 43

Bibliography . 44

Figure 1 – Example schematic of the frequency response measurement circuit. 10

Figure A.1 – Method 1 connection . 21

Figure A.2 – Method 3 connection . 22

Figure B.1 – Presentation of frequency response measurements . 23

Figure B.2 – Comparison with a baseline measurement . 24

Figure B.3 – Comparison of the frequency responses of twin transformers . 24

Figure B.4 – Comparison of the frequency responses from sister transformers . 25

Figure B.5 – Comparison of the frequency responses of three phases of a winding. 25

Figure B.6 – General relationships between frequency response and transformer

structure and measurement set-up for HV windings of large auto-transformer . 27

Figure B.7 – Effect of tertiary delta connection on the frequency response of a series

winding . 28

Figure B.8 – Effect of star neutral connection on the tertiary winding response . 29

Figure B.9 – Effect of star neutral termination on series winding response . 29

Figure B.10 – Measurement results showing the effect of differences between phases

in internal leads connecting the tap winding and OLTC . 30

Figure B.11 – Effect of measurement direction on frequency response . 30

Figure B.12 – Effect of different types of insulating fluid on frequency response . 31

Figure B.13 – Effect of oil filling on frequency response . 31

Figure B.14 – Effect of a DC injection test on the frequency response . 32

Figure B.15 – Effect of bushings on frequency response . 32

Figure B.16 – Effect of temperature on frequency response . 33

Figure B.17 – Examples of bad measurement practice . 34

Figure B.18 – Frequency response of a tap winding before and after partial axial

collapse and localised inter-turn short-circuit with a photograph of the damage . 34

Figure B.19 – Frequency response of an LV winding before and after axial collapse

due to clamping failure with a photograph of the damage [8] . 35

Figure B.20 – Frequency response of a tap winding with conductor tilting with a

photograph of the damage [1] . 36

Figure D.1 – Winding diagram of an auto-transformer with a line-end tap changer . 40

Figure D.2 – Connection diagram of an inductive inter-winding measurement on a

three-phase YNd1 transformer . 41

Figure D.3 – Connection diagram for a capacitive inter-winding measurement on a

three-phase YNd1 transformer . 42

Figure D.4 – Connection diagram for an end-to-end short-circuit measurement on a

three-phase YNd1 transformer . 42

Table 1 – Standard measurements for a star connected winding with taps . 13

Table 2 – Standard measurements for delta connected winding without tap . 14

Table 3 – Format for specifying additional measurements . 15

Table D.1 – Standard end-to-end measurements on a three-phase auto-transformer . 39

Table D.2 – Tap-changer connections . 40

– 4 – 60076-18 © IEC:2012

Table D.3 – Inductive inter-winding measurements on a three-phase YNd1 transformer . 41

Table D.4 – Capacitive inter-winding measurements on a three-phase YNd1

transformer . 41

Table D.5 – End-to-end short-circuit measurements on a three-phase YNd1

transformer . 42

60076-18 © IEC:2012 – 5 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

POWER TRANSFORMERS –

Part 18: Measurement of frequency response

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60076-18 has been prepared by IEC technical committee 14:

Power transformers.

The text of this standard is based on the following documents:

FDIS Report on voting

14/718/FDIS 14/728/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts of the IEC 60076 series can be found, under the general title Power

transformers, on the IEC website.

– 6 – 60076-18 © IEC:2012

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

60076-18 © IEC:2012 – 7 –

POWER TRANSFORMERS –

Part 18: Measurement of frequency response

1 Scope

This part of the IEC 60076 series covers the measurement technique and measuring

equipment to be used when a frequency response measurement is required either on-site or

in the factory either when the test object is new or at a later stage. Interpretation of the result

is not part of the normative text but some guidance is given in Annex B. This standard is

applicable to power transformers, reactors, phase shifting transformers and similar

equipment.

2 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

2.1

frequency response

amplitude ratio and phase difference between the voltages measured at two terminals of the

test object over a range of frequencies when one of the terminals is excited by a voltage

source

Note 1 to entry: The frequency response measurement result is a series of amplitude ratios and phase differences

at specific frequencies over a range of frequency.

Note 2 to entry: The measured voltage is the voltage developed across an impedance and so it is also related to

current.

2.2

frequency response analysis

FRA

technique used to detect damage by the use of frequency response measurements

Note 1 to entry: The terms SFRA and IFRA are commonly used and refer to the use of either a swept frequency

voltage source or an impulse voltage source. Provided the measuring equipment complies with the requirements of

Clause 5, this standard can be applied to both techniques.

2.3

source lead

lead connected to the voltage source of the measuring instrument used to supply an input

voltage to the test object

2.4

reference lead

V

in

lead connected to the reference channel of the measuring instrument used to measure the

input voltage to the test object

2.5

response lead

V

out

lead connected to the response channel of the measuring instrument used to measure the

output voltage of the test object

– 8 – 60076-18 © IEC:2012

2.6

end-to-end measurement

frequency response measurement made on a single coil (phase winding) with the source and

reference (V ) leads connected to one end and the response (V ) lead connected to the

in out

other end

2.7

сapacitive inter-winding measurement

frequency response measurement made on two adjacent coils (windings of the same phase)

with the source and reference (V ) leads connected to one end of a winding, the response

in

(V ) lead connected to one end of another winding and with the other winding ends floating

out

Note 1 to entry: This type of measurement is not applicable to windings which have common part or connection

between them.

2.8

inductive inter-winding measurement

frequency response measurement made on two adjacent coils (windings of the same phase)

with the source and reference (V ) leads connected to one end of the higher voltage winding,

in

the response (V ) lead connected to one end of the other winding and with the other ends of

out

both windings grounded

2.9

end-to-end short circuit measurement

frequency response measurement made on a single coil (phase winding) with the source and

reference (V ) leads connected to one end, the response (V ) lead connected to the other

in out

end, and another winding of the same phase short-circuited

2.10

baseline measurement

frequency response measurement made on a test object to provide a basis for comparison

with a future measurement on the same test object in the same configuration

3 Purpose of frequency response measurements

Frequency response measurements are made so that Frequency Response Analysis (FRA)

can be carried out. FRA can be used to detect changes to the active part of the test object

(windings, leads and core).

NOTE FRA is generally used to detect geometrical changes and electrical short-circuits in the windings, see

Annex B.

Some examples of conditions that FRA can be used to assess are:

• damage following a through fault or other high current event (including short-circuit

testing),

• damage following a tap-changer fault,

• damage during transportation, and

• damage following a seismic event.

Further information on the application of frequency response measurements is given in

Annex C.

The detection of damage using FRA is most effective when frequency response measurement

data is available from the transformer when it is in a known good condition (baseline

measurement), so it is preferable to carry out the measurement on all large transformers

either in the factory or when the transformer is commissioned at site or both. If a baseline

60076-18 © IEC:2012 – 9 –

measurement is not available for a particular transformer, reference results may be obtained

from either a similar transformer or another phase of the same transformer (see Annex B).

Frequency response measurements can also be used for power system modelling including

transient overvoltage studies.

4 Measurement method

4.1 General

To make a frequency response measurement, a low voltage signal is applied to one terminal

of the test object with respect to the tank. The voltage measured at this input terminal is used

as the reference signal and a second voltage signal (the response signal) is measured at a

second terminal with reference to the tank. The frequency response amplitude is the scalar

ratio between the response signal (V ) and the reference voltage (V ) (presented in dB) as

out in

a function of the frequency. The phase of the frequency response is the phase difference

between V and V (presented in degrees).

in out

The response voltage measurement is made across an impedance of 50 Ω. Any coaxial lead

connected between the test object terminal and the voltage measuring instrument shall have a

matched impedance. To make an accurate ratio measurement, the technical parameters of

the reference and response channels of the measuring instrument and any measurement

leads shall be identical.

NOTE 1 The characteristic impedance of the coaxial measuring leads is chosen to match the measuring channel

input impedance to minimise signal reflections and reduce the influence of the coaxial lead on the measurement to

the point where it has little or no practical effect on the measurement within the measurement frequency range.

With a matched impedance lead, the measuring impedance is effectively applied at the test object terminal.

NOTE 2 As V /V varies over a wide range, it is expressed in decibels (dB). The relative voltage response in dB

out in

is calculated as 20 × log (V /V ), where (V /V ) is the scalar ratio.

10 out in out in

An example of the general layout of the measurement method using coaxial measuring leads

is shown in Figure 1.

– 10 – 60076-18 © IEC:2012

B

A

C

D

50 Ω

50 Ω

V V

out

in

IEC 1370/12

A source lead

B reference lead

C response lead

D earth connection

Figure 1 – Example schematic of the frequency response measurement circuit

4.2 Condition of the test object during measurement

For factory and site measurements, the test object shall be fully assembled as for service

complete with all bushings, but coolers and related auxiliaries do not need to be assembled.

Liquid or gas filled transformers and reactors shall be filled with liquid or gas of the same type

(similar relative permittivity) as that which is to be used in service. All busbars or other system

or test connections shall be removed and there shall be no connections to the test object

other than those being used for the specific measurement being performed. If internal current

transformers are installed but not connected to a protection or measurement system, the

secondary terminals shall be shorted and earthed. The core and frame to tank connections

shall be complete and the tank shall be connected to earth.

If the transformer is not assembled in the factory in the service condition, for example if oil/air

bushings are used in the factory and oil/SF bushings are to be used in service then the FRA

baseline measurement can only be performed at site. Transport configuration measurements

may still be possible see below.

If special connections have been specified by the purchaser and are provided on the test

object to enable a frequency response measurement to be made when it is arranged for

transport, then additional measurements shall be made in the transport configuration (drained

if required for transport) before transport and when delivered to site or as specified by the

purchaser.

For site measurements, the test object shall be disconnected from the associated electrical

system at all winding terminals and made safe for testing. Line, neutral and any tertiary line

connections shall be disconnected but tank earth, auxiliary equipment and current transformer

service connections shall remain connected. In the case where two connections to one corner

of a delta winding are brought out, the transformer shall be measured with the delta closed

(see also 4.4.4). In instances where it is impossible to connect directly to the terminal, then

the connection details shall be recorded with the measurement data since the additional bus

bars connected to the terminals may impact on the measurement results.

60076-18 © IEC:2012 – 11 –

NOTE There may be a difference in the connection of current transformers (CTs) between measurements made

on-site and those made in the factory, the change in frequency response between a transformer with shorted and

earthed CTs and one with the CTs connected to a low impedance protection system is normally negligible.

If the transformer is directly connected to SF insulated busbars then it may be possible to

make the measurement by connecting to the disconnected earth connection of an earth

switch. In this case, the measurement shall be made both directly on the terminals before the

SF busbar is assembled and using the earth switch.

When carried out in the factory, the measurement shall be conducted at approximately

ambient temperature (for example not immediately following a temperature rise test). The

temperature of the test object dielectric (normally top liquid temperature) during the

measurement shall be recorded. For measurements made on-site the temperature is not

controlled, and although extreme temperatures may have a minor effect this is normally not

significant. The effect of temperature on frequency response measurements is illustrated in

B.4.8.

It is recommended that if possible measurements on-site are not made whilst the test object

temperature is changing rapidly for example immediately following oil treatment.

4.3 Measurement connection and checks

4.3.1 Measurement connection and earthing

The methods of connection of the leads and lead earths to the test object are given in

Annex A.

Poor connections can cause significant measurement errors, attention shall be paid to the

continuity of the main and earth connections. The continuity of the main and earth

connections shall be checked at the instrument end of the coaxial cable before the

measurement is made. In particular, connections to bolts or flanges shall be verified to ensure

that there is a good connection to the winding or the test object tank.

4.3.2 Zero-check measurement

If specified, a zero-check measurement shall be carried out as an additional measurement.

Before measurements commence, all the measuring leads shall be connected to one of the

highest voltage terminals and earthed using the normal method. A measurement is then made

which will indicate the frequency response of the measurement circuit alone. The zero check

measurement shall also be repeated on other voltage terminals if specified.

The zero-check measurement can provide useful information as to the highest frequency that

can be relied upon for interpretation of the measurement. The zero-check measurement is not

a calibration check and no attempt should be made to remove any deviations seen in the

zero-check measurement from the measurement results.

4.3.3 Repeatability check

On completion of the standard measurements the measurement leads and earth connections

shall be disconnected and then the first measurement shall be repeated and recorded.

This check is necessary to evaluate the repeatability and useable diagnostic frequency range

under the specific conditions of the measurement.

4.3.4 Instrument performance check

To verify the performance of the instrument, one of the following three checks shall be made

whenever the performance of the instrument is in doubt.

a) Connect the source, reference and response channels of the instrument together

using suitable low loss leads, check that the measured amplitude ratio is 0 dB

± 0,3 dB across the whole frequency range.

– 12 – 60076-18 © IEC:2012

Connect the source and reference channels together and leave the response terminal

open circuit, check that the measured amplitude ratio is less than -90 dB across the

whole frequency range.

b) The performance of the instrument may be checked by measuring the response of a

known test object (test box) and checking that the measured amplitude ratio matches

the expected response of the test object to within the requirements given in 5.1.2 over

the whole frequency range. The test object shall have a frequency response that

covers the attenuation range –10 dB to –80 dB.

c) The correct operation of the instrument may be checked using a performance check

procedure provided by the instrument manufacturer. This performance check

procedure shall verify that the instrument is operating within the parameters given in

5.1.2 at least over an attenuation range of –10 dB to –80 dB over the whole frequency

range.

4.4 Measurement configuration

4.4.1 General

For common transformer and reactor winding configurations, a standard set of measurements

is given which is sufficient in the majority of cases to provide a baseline measurement. These

measurements shall be made in all cases. Additional measurements may be specified if

required either to provide some additional information under particular circumstances or to

match previous measurements. Standard measurements on other types of transformers and

reactors shall follow the following principles.

4.4.2 Principles for choosing the measurement configuration

4.4.2.1 Type of measurement

The standard measurements shall be end-to-end measurements of each phase of each

winding, with the phases and windings separated as far as possible and with all other

terminals left floating. Additional measurements, where specified, can include capacitive inter-

winding, inductive inter-winding, and end-to-end short circuit measurements.

4.4.2.2 Tap-position

For transformers and reactors with an on-load tap-changer (OLTC), the standard

measurement on the tapped winding shall be

a) on the tap-position with the highest number of effective turns in circuit, and

b) on the tap-position with the tap winding out of circuit.

Other windings with a fixed number of turns shall be measured on the tap-position for the

highest number of effective turns in the tap winding. Additional measurements may be

specified at other tap-positions.

For auto-transformers with a line-end tap-changer, the standard measurements shall be:

• on the series winding with the minimum number of actual turns of the tap-winding in circuit

(the tapping for the highest LV voltage for a linear potentiometer type tapping

arrangement or the change-over position for a reversing type tapping arrangement, or the

tapping for the lowest LV voltage in a linear separate winding tapping arrangement),

• on the common winding with the maximum number of effective turns of the tap-winding in

circuit (the tapping for the highest LV voltage), and

• on the common winding with the minimum number of actual turns of the tap-winding in

circuit (the tapping for the lowest LV voltage for a linear potentiometer or separate winding

type tapping arrangement or the change-over position for a reversing type tapping

arrangement).

60076-18 © IEC:2012 – 13 –

NOTE 1 The choice of tap-position is intended to provide at least one measurement with and one without the tap

winding in circuit so that any damage can be more easily identified as being in the tap-winding or the main winding.

For neutral or change-over positions, the direction of movement of the tap-changer shall be in

the lowering voltage direction unless otherwise specified. The direction of movement (raise or

lower) shall be recorded.

NOTE 2 The position of the change-over selector in reversing and coarse-fine arrangements has a profound effect

on the measured frequency response.

For transformers with both an OLTC and a de-energised tap-changer (DETC), the DETC shall

be in the service position if specified or otherwise the nominal position for the measurements

at the OLTC positions described in 4.4.2.2.

For transformers fitted with a DETC, baseline measurements shall also be made on each

position of the DETC with the OLTC (if fitted) on the position for maximum effective turns.

It is not recommended that the position of a DETC on a transformer that has been in service

is changed in order to make a frequency response measurement, the measurement should be

made on the ‘as found’ DETC tap position. It is therefore necessary to make sufficient

baseline measurements to ensure that baseline data is available for any likely service (‘as

found’) position of the DETC.

4.4.3 Star- and auto-connected windings with a neutral terminal

For the standard measurement, the signal shall be applied to the line connection, or for series

windings the higher voltage terminal. An additional measurement may be specified with the

signal applied to the neutral terminal if this is required for compatibility with previous

measurements. A star connected winding with the neutral not brought out shall be treated as

a delta winding. The list of standard measurements for a star connected winding with taps is

given in Table 1.

Table 1 – Standard measurements for a star connected winding with taps

Measurement Source and reference lead (V ) Response lead (V ) Tap position

in out

number connected to connected to

1 Line terminal phase 1 Neutral Max effective turns

2 Line terminal phase 2 Neutral Max effective turns

3 Line terminal phase 3 Neutral Max effective turns

4 Line terminal phase 1 Neutral Tap winding out of circuit

5 Line terminal phase 2 Neutral Tap winding out of circuit

6 Line terminal phase 3 Neutral Tap winding out of circuit

4.4.4 Delta windings and other windings without an accessible neutral

If delta windings can be split into individual phases (six bushings brought out) then the

standard measurement shall be made with the windings split.

For large generator transformers where it is inconvenient to remove the phase to phase

connections in service it is recommended that the baseline measurement in the factory and

during commissioning is performed both with the delta open and closed.

Standard measurements shall be made on each phase in turn with the signal applied to the

terminal with the lowest number or letter nearest the start of the alphabet first and the

response measured on the next numbered or lettered terminal, and continuing in a cyclic

rotation (see Table 2).

For delta tertiary or stabilising windings, the delta shall be closed.

– 14 – 60076-18 © IEC:2012

For delta tertiary or stabilising windings that are earthed at one corner in service, the earth

shall be removed if possible without removing liquid or gas.

Table 2 – Standard measurements for delta connected winding without tap

Measurement number Source and reference lead (V ) connected to Response lead (V ) connected to

in out

1 A, U, R or 1 B, V, S or 2

2 B, V, S or 2 C, W, T or 3

3 C, W, T or 3 A, U, R or 1

4.4.5 Zig-zag connected windings

Zig-zag connected windings shall be measured as star windings with a neutral connection.

NOTE The correspondence between the frequency responses of different phases of a zig-zag connected winding

is not expected to be as close as would typically be expected for a star connected winding.

4.4.6 Two-winding three-phase transformers

The standard measurements shall be one measurement of each phase of each winding, a

total of six measurements for a transformer without taps and nine for a transformer with an

on-load tap-changer.

4.4.7 Three-phase auto-transformers

The standard measurements shall be one measurement of each phase of the series winding

and the common winding separately with an additional measurement of the common winding

for transformers with an on-load tap changer, a total of six measurements for a transformer

without taps and nine for a transformer with an on-load tap-changer. If the transformer has a

tertiary winding brought out to three line (phase) terminals an additional three measurements

are required on this winding.

4.4.8 Phase shifting transformers

The standard measurement shall be from input terminal to output terminal on each phase and

from the neutral of the shunt winding to the output terminal on each phase, each on neutral

tap and on each extreme tap, a total of 18 measurements. If the phase shifting transformer is

of the two core type that has external interconnections that can be removed on site then it

shall be treated as two separate transformers.

4.4.9 Reactors

Series reactors shall be measured from input terminal to output terminal on each phase, a

total of three measurements for a three-phase reactor. Shunt reactors shall be treated as a

star winding on a transformer, a total of three measurements for a three-phase reactor without

taps and six for a reactor with taps.

4.4.10 Method for specifying additional measurements

Additional measurements, if required, shall be specified by giving the connection to each test

object terminal (signal and reference, response, earthed, floating or connected together), the

tap-position and the previous tap-position for each additional measurement. The format

presented in Table 3 shall be used.

60076-18 © IEC:2012 – 15 –

Table 3 – Format for specifying additional measurements

Measurement Tap Previous Source and Response Terminals Terminals Comments

tap reference (V ) earthed connected

out

(V ) together

in

.

.

.

The terminal identification entered in the table shall be those permanently marked on the test

object and shall be shown on a diagram included in the specification.

Examples of particular measurement configurations using this format are given in Annex D.

4.5 Frequency range and measurement points for the measurement

The lowest frequency measurement shall be at or below 20 Hz.

The minimum highest frequency measurement for test objects with highest voltage > 72,5 kV

shall be 1 MHz.

The minimum highest frequency measurement for test objects with highest voltage of

≤ 72,5 kV shall be 2 MHz.

It is recommended that a highest measurement frequency of at least 2 MHz is used for

compatibility and simplicity for all test objects.

NOTE Reproducibility of the measurement is better at frequencies higher than 1 MHz with the shorter earth

connections possible with smaller bushings and higher frequency information is more important for the diagnosis of

physically smaller windings (see B.3).

Below 100 Hz, measurements shall be made at intervals not exceeding 10 Hz; above 100 Hz,

a minimum of 200 measurements approximately evenly spaced on either a linear or

logarithmic scale shall be made in each decade of frequency.

If the transfo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...